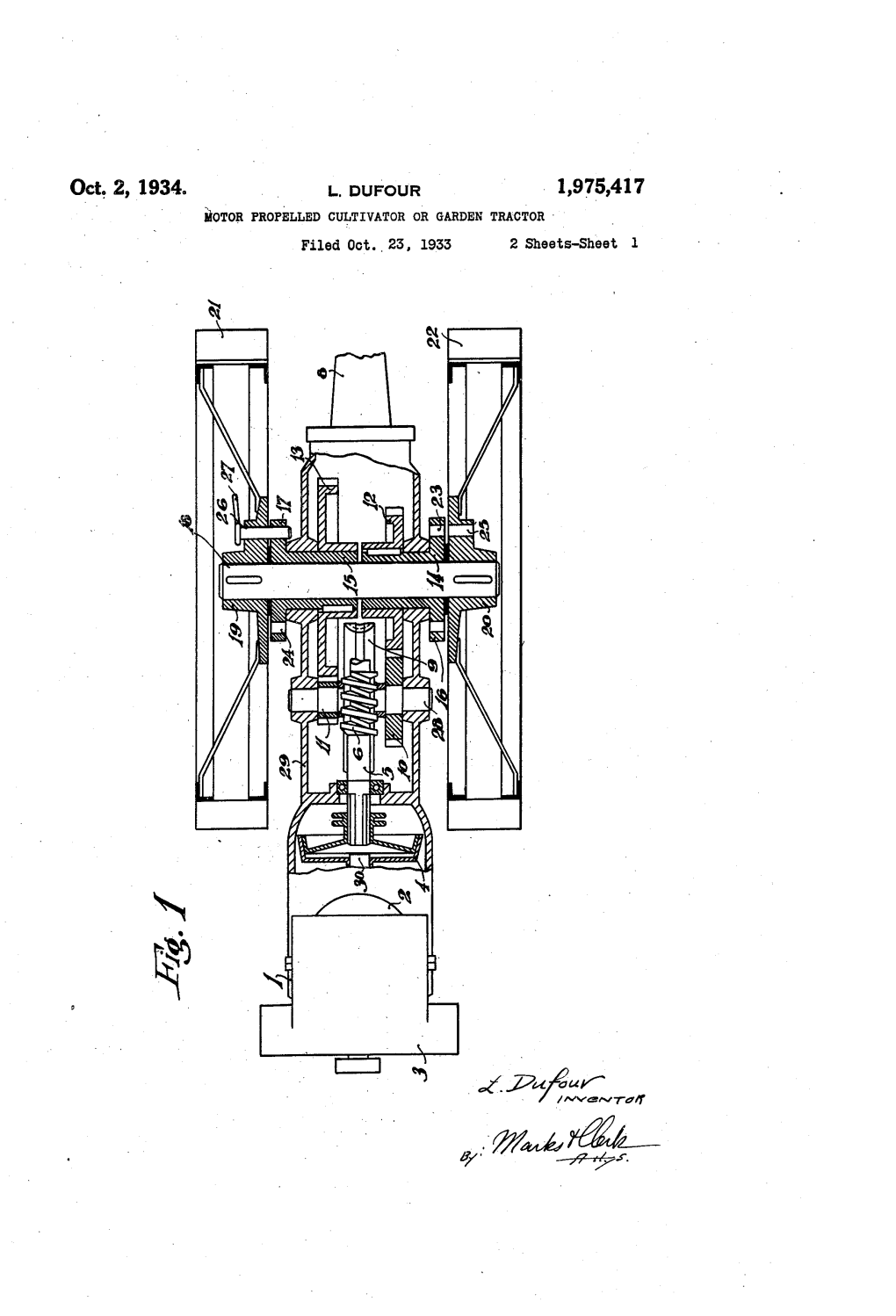

L DUFQUR ' - 1,975,417 ' Iotor Prop-ELLED Cuptivator 0R GARDEN TRACTOR - Filed Oct

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

This Clock Is a Rather Curious the Movement Is That of a a Combination

MINERAL GLASS CRYSTALS 36 pc. Assortment Clear Styrene Storage Box Contains 1 Each of Most Popular Sizes From 19.0 to 32.0 $45.00 72 pc. Assortment Clear Styrene Storage Box Contains 1 Each of Most Popular Refills Available Sizes From 14.0 to 35.0 On All Sizes $90.00 :. JJl(r1tvfolet Gfa:ss A~hesive Jn ., 'N-e~ilie . Pofot Tobe · Perfect for MinenifGlass Crystals - dire$ -iA. secondbn ~un or ultraviolet µgh{'DS~~~ cfa#ty as gl;lss. Stock Up At These Low Prices - Good Through November 10th FE 5120 Use For Ronda 3572 Y480 $6.50 V237 $6.50 Y481 $6.95 V238 $6.95 Y482 $6.95 V243 $6.95 51/2 x 63/4 $9.95 FREE - List of Quartz Movements With Interchangeability, Hand Sizes, Measurements, etc. CALL TOLL FREE 1-800-328-0205 IN MN 1-800-392-0334 24-HOUR FAX ORDERING 612-452-4298 FREE Information Available *Quartz Movements * Crystals & Fittings * * Resale Merchandise * Findings * Serving The Trade Since 1923 * Stones* Tools & Supplies* VOLUME13,NUMBER11 NOVEMBER 1989 "Ask Huck" HOROLOGICAL Series Begins 25 Official Publication of the American Watchmakers Institute ROBERT F. BISHOP 2 PRESIDENT'S MESSAGE HENRY B. FRIED QUESTIONS & ANSWERS Railroad 6 Emile Perre t Movement JOE CROOKS BENCH TIPS 10 The Hamilton Electric Sangamo Clock Grade MARVIN E. WHITNEY MILITARY TIME 12 Deck Watch, Waltham Model 1622-S-12 Timepieces WES DOOR SHOP TALK 14 Making Watch Crystals JOHN R. PLEWES 18 REPAIRING CLOCK HANDS 42 CHARLES CLEVES OLD WATCHES 20 Reality Sets In ROBERT D. PORTER WATCHES INSIDE & OUT 24 A Snap, Crackle, & Pop Solution J.M. -

The Evolution of Tower Clock Movements and Their Design Over the Past 1000 Years

The Evolution Of Tower Clock Movements And Their Design Over The Past 1000 Years Mark Frank Copyright 2013 The Evolution Of Tower Clock Movements And Their Design Over The Past 1000 Years TABLE OF CONTENTS Introduction and General Overview Pre-History ............................................................................................... 1. 10th through 11th Centuries ........................................................................ 2. 12th through 15th Centuries ........................................................................ 4. 16th through 17th Centuries ........................................................................ 5. The catastrophic accident of Big Ben ........................................................ 6. 18th through 19th Centuries ........................................................................ 7. 20th Century .............................................................................................. 9. Tower Clock Frame Styles ................................................................................... 11. Doorframe and Field Gate ......................................................................... 11. Birdcage, End-To-End .............................................................................. 12. Birdcage, Side-By-Side ............................................................................. 12. Strap, Posted ............................................................................................ 13. Chair Frame ............................................................................................. -

High-Speed Ground Transportation Noise and Vibration Impact Assessment

High-Speed Ground Transportation U.S. Department of Noise and Vibration Impact Assessment Transportation Federal Railroad Administration Office of Railroad Policy and Development Washington, DC 20590 Final Report DOT/FRA/ORD-12/15 September 2012 NOTICE This document is disseminated under the sponsorship of the Department of Transportation in the interest of information exchange. The United States Government assumes no liability for its contents or use thereof. Any opinions, findings and conclusions, or recommendations expressed in this material do not necessarily reflect the views or policies of the United States Government, nor does mention of trade names, commercial products, or organizations imply endorsement by the United States Government. The United States Government assumes no liability for the content or use of the material contained in this document. NOTICE The United States Government does not endorse products or manufacturers. Trade or manufacturers’ names appear herein solely because they are considered essential to the objective of this report. REPORT DOCUMENTATION PAGE Form Approved OMB No. 0704-0188 Public reporting burden for this collection of information is estimated to average 1 hour per response, including the time for reviewing instructions, searching existing data sources, gathering and maintaining the data needed, and completing and reviewing the collection of information. Send comments regarding this burden estimate or any other aspect of this collection of information, including suggestions for reducing this burden, to Washington Headquarters Services, Directorate for Information Operations and Reports, 1215 Jefferson Davis Highway, Suite 1204, Arlington, VA 22202-4302, and to the Office of Management and Budget, Paperwork Reduction Project (0704-0188), Washington, DC 20503. -

KOM DIGITAL NOTES.Pdf

DIGITAL NOTES Kinematics of Machinery R18A0307 B.Tech –II – I DEPARTMENT OF MECHANICAL ENGINEERING MALLA REDDY COLLEGE OF ENGINEERING & TECHNOLOGY (An Autonomous Institution – UGC, Govt.of India) Recognizes under 2(f) and 12(B) of UGC ACT 1956 (Affiliated to JNTUH, Hyderabad, Approved by AICTE –Accredited by NBA & NAAC-“A” Grade-ISO 9001:2015 Certified) MALLA REDDY COLLEGE OF ENGINEERING & TECHNOLOGY Department Of Mechanical Engineering,MRCET. COURSE OBJECTIVES: Understand the fundamentals of the theory of kinematics and dynamics of machines. Understand techniques for studying motion of machines and their components. Use computer software packages in modern design of machines. UNIT – I Mechanisms : Elements or Links , Classification, Rigid Link, flexible and fluid link, Types of kinematic pairs , sliding, turning, rolling, screw and spherical pairs lower and higher pairs, closed and open pairs, constrained motion, completely, partially or successfully constrained and incompletely constrained . Machines : Mechanism and machines, classification of machines, kinematic chain , inversion of mechanism, inversion of mechanism , inversions of quadric cycle, chain , single and double slider crank chains. UNIT – II Straight Line Motion Mechanisms: Exact and approximate copiers and generated types Peaucellier, Hart and Scott Russul Grasshopper Watt T. Chebicheff and Robert Mechanisms and straight line motion, Pantograph. Steering Mechanisms: Conditions for correct steering Davis Steering gear, Ackermans steering gear velocity ratio. Hooke’s Joint: Single and double Hookes joint Universial coupling application problems. UNIT – III Kinematics: Velocity and acceleration - Motion of link in machine - Determination of Velocity and acceleration diagrams - Graphical method - Application of relative velocity method four bar chain. Analysis of Mechanisms: Analysis of slider crank chain for displacement, velocity and acceleration of slider - Acceleration diagram for a given mechanism, Kleins construction, Coriolis acceleration, determination of Coriolis component of acceleration. -

Kinematics of Machinery

KINEMATICS OF MACHINERY Subject code: ME302ES Regulations: R16-JNTUH Class: II Year B. Tech MECH I Sem Department of Mechanical Engineering BHARAT INSTITUTE OF ENGINEERING AND TECHNOLOGY Ibrahimpatnam - 501 510, Hyderabad 1 | P a g e KINEMATICS OF MACHINERY (ME302ES) COURSE PLANNER I. COURSE OBJECTIVE AND RELEVANCE: 1. To understand the basic components and layout of linkages in the assembly of a system/machine. 2. To understand the principles involved in the displacement, velocity and acceleration at any point in a link of a mechanism. 3. To understand the motion resulting from a specified set of linkages. 4. To understand and to design few linkage mechanisms and cam mechanisms for specified output motions. 5. To understand the basic concepts of toothed gearing and kinematics of gear trains. II. PRE REQUISITES: Knowledge of engineering mechanics is required. III. COURSE PURPOSE This course introduces students to involve in kinematics study how a physical system might develop or alter over time and study the causes of those changes. In particular, kinematics is mostly related to Newton's second law of motion. However, all three laws of motion are taken into consideration, because these are interrelated in any given observation or experiment. Kinematics of machine deals with the relative motion of machine parts. Kinematic schemes of a machine can be investigated without considering the forces. IV. COURSE OUTCOME: S.NO Description Bloom’s Taxonomy Level 1 Classify different types of links and mechanisms used for different Knowledge, Understand, purposes in different machines. (Level1, Level2,) 2 Solve the forces, velocities and accelerations in different Understand, Apply mechanisms and machines components ( Level2,Level 3) 3 List, Predict and Design different type of links applied to get the Understand, Apply required motion of different types of the parts of machines ( Level2,Level 3) 2 | P a g e V. -

Mechanisms Containing Wheel-Trains.-1Iechanisms Are of Common Occurrence in Which Wheel Train� Form Part of Chains Containing Also Sliding and Turning Pairs

CHAPTER VIII. ,vHEEL-TRAINS AND MECHANISMS CONTAINING THEM. CAMS. ' 68. Simple and Compound Wheel-trains.-The deter mination of the velocity ratio in such a ,vheel-train as that of Fig. 130 involves no difficulty, for it is plain that one or FIG, 1.30. more intermediate wheels (as b) will not affect the numerical value of the velocity ratio of the first and last wheels. The linear velocity of the pitch-line of every wheel is the same, and the angular velocity ratio of the first and last, there- fore, only depends on their �wn diameters, so that wad = ± rC, Wed ro the sign depending on the number of idle wheels. Inter mediate or idle wheels thus simply reverse the direction of motion. When all the wheels in the train have external contact, the angular velocity ratio of the first wheel to the last has a positive value (or, both wheels tum in the same 201 202 KINEMATICS OF MACHINES. sense) if the number of axes is odd, wl1ile an even number of axes gives the velocity ratio a negative value. l\Iore com plex wheel-trains, however, require further consideration. In Fig. 131 we have a compound spur-wheel mechanism of =- ,......_ �-f--i--=>t-�,,,...-------+---Ocdd --f:!r�=-- FIG. 131. four links, d being fixed, while b consists of two wheels rigidly connected and turning onthe same axis. r , r Let 0 b• Rb, re, be the radii of the pitch-circles, then from § 64 we have Also, Hence Suppose a to be the driving-wheel, while c is the driven one; ,ve see that the above result may be expressed by say ing that · revolutions of driving-wheel ve1 oci • ty ra t10 = revolutions of driven wheel _product of radii of followers - product of radii of drivers · Instead of radii we might evidently put numbers of teeth. -

Readingsample

History of Mechanism and Machine Science 21 The Mechanics of Mechanical Watches and Clocks Bearbeitet von Ruxu Du, Longhan Xie 1. Auflage 2012. Buch. xi, 179 S. Hardcover ISBN 978 3 642 29307 8 Format (B x L): 15,5 x 23,5 cm Gewicht: 456 g Weitere Fachgebiete > Technik > Technologien diverser Werkstoffe > Fertigungsverfahren der Präzisionsgeräte, Uhren Zu Inhaltsverzeichnis schnell und portofrei erhältlich bei Die Online-Fachbuchhandlung beck-shop.de ist spezialisiert auf Fachbücher, insbesondere Recht, Steuern und Wirtschaft. Im Sortiment finden Sie alle Medien (Bücher, Zeitschriften, CDs, eBooks, etc.) aller Verlage. Ergänzt wird das Programm durch Services wie Neuerscheinungsdienst oder Zusammenstellungen von Büchern zu Sonderpreisen. Der Shop führt mehr als 8 Millionen Produkte. Chapter 2 A Brief Review of the Mechanics of Watch and Clock According to literature, the first mechanical clock appeared in the middle of the fourteenth century. For more than 600 years, it had been worked on by many people, including Galileo, Hooke and Huygens. Needless to say, there have been many ingenious inventions that transcend time. Even with the dominance of the quartz watch today, the mechanical watch and clock still fascinates millions of people around the, world and its production continues to grow. It is estimated that the world annual production of the mechanical watch and clock is at least 10 billion USD per year and growing. Therefore, studying the mechanical watch and clock is not only of scientific value but also has an economic incentive. Never- theless, this book is not about the design and manufacturing of the mechanical watch and clock. Instead, it concerns only the mechanics of the mechanical watch and clock. -

Development of the Constant Force Tool System with Abrasive Belt for Grinding and Polishing

International Conference on Manufacturing Science and Engineering (ICMSE 2015) Development of the constant force tool system with abrasive belt for grinding and polishing Xin Wang1, Yan Mu2 *, Huan Liu3, Xing-tian Qu4 and Xu Yang5 School of Mechanical Science and Engineering, Jilin University, Changchun, 130022, People’s Republic of China a b c [email protected], [email protected], [email protected] Keywords: Constant force polishing; Flexible polishing; Complex surfaces; Vibration; Simulation analysis. Abstract. A constant force tool system for the abrasive belt grinding and polishing was developed in the paper. With the addition of the constant force control during the finishing of curved surfaces, the accuracy and the surface roughness could be improved. The constant force tool system would be used on the hybrid machine tool, and was composed by the following function modules, the abrasive belt system, the detection and compensation unit of the grinding force, and the vibration isolation system. With the statics simulation, harmonic response analysis and modal analysis of the tool system were carried out. All results showed that the design was reasonable and effective. Introduction The finishing machining of complex surfaces was a technology with a great quantity of advanced theories and complicated machining processes which was widely applied in machining process. Particularly, abrasive belt polishing had the characteristics of high efficiency, low grinding heat, elastic grinding and high polishing quality, so it was widely regarded as a kind of high efficiency and low energy consumption mechanical manufacturing technology with flexible craft and wide adaptability [1,2]. Owning to the advantage of low cost, high stiffness and quick response, the traditional passive grinding and polishing tools was widely used. -

Kinematics of Machinery (R18a0307)

KINEMATICS OF MACHINERY (R18A0307) 2ND YEAR B. TECH I - SEM, MECHANICAL ENGINEERING DEPARTMENT OF MECHANICAL ENGINEERING UNIT – I (SYLLABUS) Mechanisms • Kinematic Links and Kinematic Pairs • Classification of Link and Pairs • Constrained Motion and Classification Machines • Mechanism and Machines • Inversion of Mechanism • Inversions of Quadric Cycle • Inversion of Single Slider Crank Chains • Inversion of Double Slider Crank Chains DEPARTMENT OF MECHANICAL ENGINEERING UNIT – II (SYLLABUS) Straight Line Motion Mechanisms • Exact Straight Line Mechanism • Approximate Straight Line Mechanism • Pantograph Steering Mechanisms • Davi’s Steering Gear Mechanism • Ackerman’s Steering Gear Mechanism • Correct Steering Conditions Hooke’s Joint • Single Hooke Joint • Double Hooke Joint • Ratio of Shaft Velocities DEPARTMENT OF MECHANICAL ENGINEERING UNIT – III (SYLLABUS) Kinematics • Motion of link in machine • Velocity and acceleration diagrams • Graphical method • Relative velocity method four bar chain Plane motion of body • Instantaneous centre of rotation • Three centers in line theorem • Graphical determination of instantaneous center DEPARTMENT OF MECHANICAL ENGINEERING UNIT – IV (SYLLABUS) Cams • Cams Terminology • Uniform velocity Simple harmonic motion • Uniform acceleration • Maximum velocity during outward and return strokes • Maximum acceleration during outward and return strokes Analysis of motion of followers • Roller follower circular cam with straight • concave and convex flanks DEPARTMENT OF MECHANICAL ENGINEERING UNIT – V (SYLLABUS) -

Cotton Spinning Calculations and Yarn Costs

C OTTO N SPI N NI N G CALC U LATI O N S AN D YA R N C O STS CO ON W A NG AN D D S IG N B TT E VI E ING . y H T TAY o n n W vin . L C an JO N LOR , late ecturer otto ea g d D i nin in the P n and h T ni a S es g g resto ot er ech c l chools . R i n r n W s d u d the di ti F . K Di e ev e er ec o of IL INSON , r ctor of the T x i and E n in in S B n Wi e t le g eer g chool , olto . th 402 D ia r m C wn 8 vo s . 6d net g a s. ro , 7 . L M N TH E E E E TS OF COTTON S PIN NING . W B H M and F W K . it e y JO N ORRIS . IL INSON h a Pr face i B . B . Wi i m S r A D C . E 1 6 D by O SON , , th 9 agra s and I i n C wn 8vo s 64. llustrat o s. ro , 7 . P N I O D P N N B RI C P LES F W ORSTE S IN I G . y W 1 1 8 l v H A D PR I E STMAN Wi I ti n . 8 c O R . -

1. Introduction of Laboratory Center for Basic Experiment

1. Introduction of laboratory center for basic experiment Room area Room No. Laboratory Course (m2) 1. Measuring the volt-ampere characteristic of circuit element; 2. The validation of Kirchhoff's law; 3. Verification of superposition principle; Telecom Hall Basic Laboratory of 4. Verification of Thevenin law; 128 105,106,109,110 electronic technology 5.RC Frequency selection network characteristics test; 6. Series Resonant circuit experiment; 7. Mutual inductance circuit experiment 1. Verify the metallographic and Metallographic and test the hardness of metal; Telecom Hall 112 Heat Treatment 2. Preparation of metallographic 38 Laboratory specimens, mainly including grinding, polishing, inlay, cutting 1. Smooth hole, shaft diameter measurement; 2. Parallelism, verticality and Mechanical runout measurement; Machinery Hall 103 Measurement 3. Measurement of surface 77.44 Laboratory roughness parameters; 4. Measurement of length variation and mean length deviation of common normal line 1. Tensile test of metal materials; 2. Metal material compression experiment; 3. Torsion test of metal material; Laboratory of 4. Metal impact test; Machinery Hall 104 57.2 Engineering Mechanics 5. Fatigue test; 6. Bridge deformation experiment; 7. Elastic modulus and Poisson's ratio measurement experiment 507 Equipment, administrator, opening time and rules for each of the laboratory (listed above) Telecom Hall 105,106,109,110 Basic Laboratory of electronic technology 1. Equipment Description DC Voltage Source 36 DC voltage regulator Signal source 36 signal source Micro Computer 36 Microcomputer Circuit principle Experiment Box 36 Circuit principle experiment box Digital Electric model Electric Experiment Box 36 Number of electric model test box 2. Administrator Hou Zhaoqi,Wu zhigang,Zhang yongzhi 3. -

The Release of This Chapter in Supp. 18-3 Replaces Supp. Supp. 18-3 Questions About These Rules? Contact: 13 A.A.C. 13 Title 13

13 A.A.C. 13 Supp. 18-3 This Chapter contains rule Sections that were filed to be codified in the Arizona Administrative Code between the dates of July 1, 2018 through September 30, 2018 Title 13 TITLE 13. PUBLIC SAFETY CHAPTER 13. DEPARTMENT OF PUBLIC SAFETY - SCHOOL BUSES The table of contents on the first page contains quick links to the referenced page numbers in this Chapter. Refer to the notes at the end of a Section to learn about the history of a rule as it was published in the Arizona Administrative Register. Sections, Parts, Exhibits, Tables or Appendices codified in this supplement. The list provided contains quick links to the updated rules. R13-13-101. Definitions ............................................................ 2 R13-13-106. Minimum Standards for School Bus Chassis .....14 R13-13-102. Certification of School Bus Drivers ..................... 4 Questions about these rules? Contact: Name: Lance Larson, Sergeant Address: Arizona Department of Public Safety POB 6638, Mail Drop 1240 Phoenix, AZ 85009-6638 Telephone: (602) 712-5808 E-mail: [email protected] The release of this Chapter in Supp. 18-3 replaces Supp. 15-4, 35 pages Please note that the Chapter you are about to replace may have rules still in effect after the publication date of this supplement. Therefore, all superseded material should be retained in a separate binder and archived for future reference. i PREFACE Under Arizona law, the Department of State, Office of the Secretary of State (Office), accepts state agency rule filings and is the publisher of Arizona rules. The Office of the Secretary of State does not interpret or enforce rules in the Administrative Code.