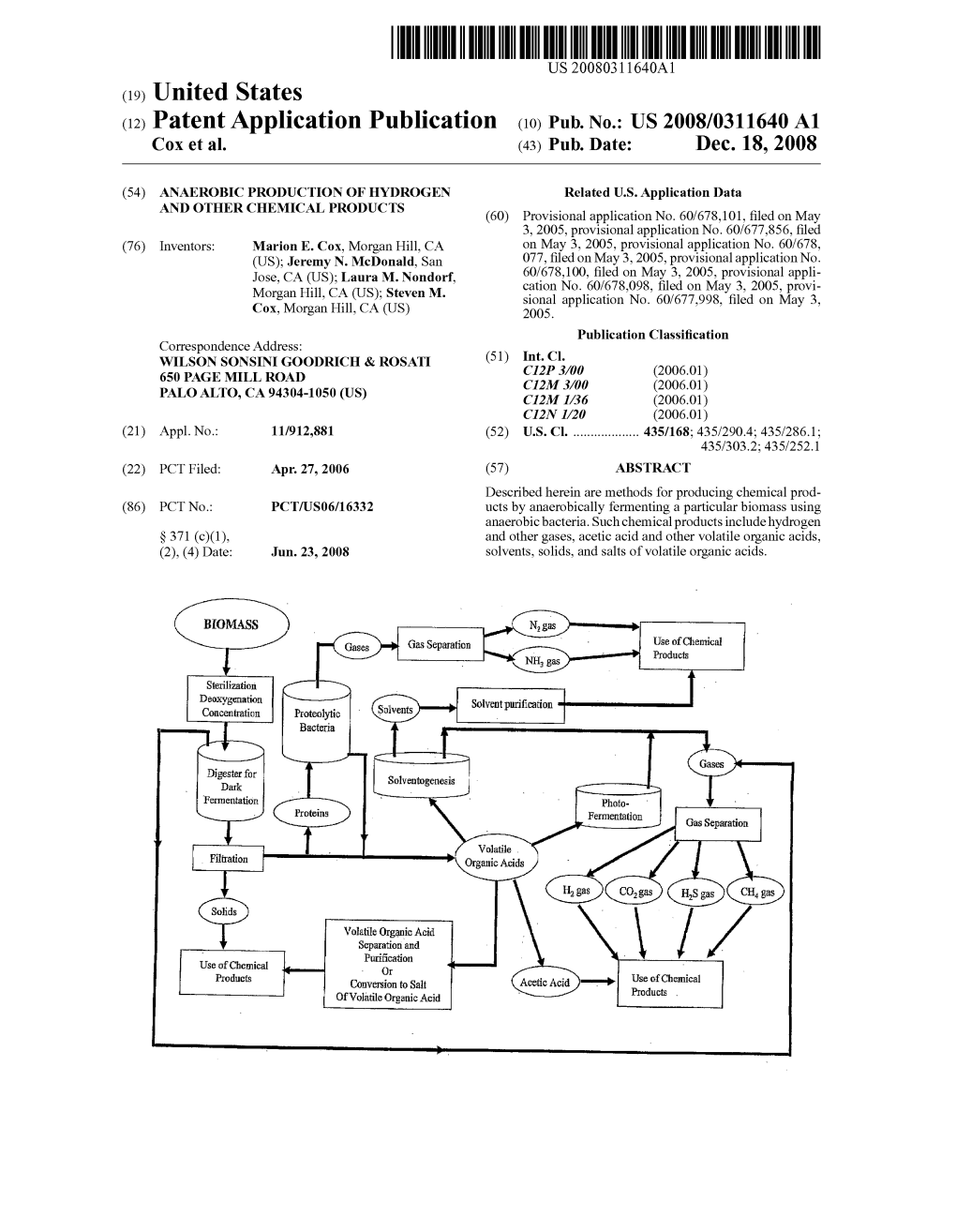

(12) Patent Application Publication (10) Pub. No.: US 2008/0311640 A1 Cox Et Al

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Int J Syst Evol Microbiol 67 1

Author version : International Journal of Systematic and Evolutionary Microbiology, vol.67(6); 2017; 1949-1956 Imhoffiella gen. nov.. a marine phototrophic member of family Chromatiaceae including the description of Imhoffiella purpurea sp. nov. and the reclassification of Thiorhodococcus bheemlicus Anil Kumar et al. 2007 as Imhoffiella bheemlica comb. nov. Nupur1, Mohit Kumar Saini1, Pradeep Kumar Singh1, Suresh Korpole1, Naga Radha Srinivas Tanuku2, Shinichi Takaichi3 and Anil Kumar Pinnaka1* 1Microbial Type Culture Collection and Gene Bank, CSIR-Institute of Microbial Technology, Sector 39A, Chandigarh – 160 036, INDIA 2CSIR-National Institute of Oceanography, Regional Centre, 176, Lawsons Bay Colony, Visakhapatnam-530017, INDIA 3Nippon Medical School, Department of Biology, Kyonan-cho, Musashino 180-0023, Japan Address for correspondence* Dr. P. Anil Kumar Microbial Type Culture Collection and Gene Bank, Institute of Microbial Technology (CSIR), Sector 39A, Chandigarh – 160 036, INDIA Email: [email protected] Telephone: 00-91-172-6665170 Running title Imhoffiella purpurea sp. nov. Subject category New taxa (Gammaproteobacteria) The GenBank/EMBL/DDBJ accession number for the 16S rRNA gene sequence of strain AK35T is HF562219. A coccoid-shaped phototrophic purple sulfur bacterium was isolated from a coastal surface water sample collected from Visakhapatnam, India. Strain AK35T was Gram-negative, motile, purple colored, containing bacteriochlorophyll a and the carotenoid rhodopinal as major photosynthetic pigments. Strain AK35T was able to grow photoheterotrophically and could utilize a number of organic substrates. It was unable to grow photoautotrophically. Strain AK35T was able to utilize sulfide and thiosulfate as electron donors. The main fatty acids present were identified as C16:0, C18:1 T 7c and C16:1 7c and/or iso-C15:0 2OH (Summed feature 3) were identified. -

Coupled Reductive and Oxidative Sulfur Cycling in the Phototrophic Plate of a Meromictic Lake T

Geobiology (2014), 12, 451–468 DOI: 10.1111/gbi.12092 Coupled reductive and oxidative sulfur cycling in the phototrophic plate of a meromictic lake T. L. HAMILTON,1 R. J. BOVEE,2 V. THIEL,3 S. R. SATTIN,2 W. MOHR,2 I. SCHAPERDOTH,1 K. VOGL,3 W. P. GILHOOLY III,4 T. W. LYONS,5 L. P. TOMSHO,3 S. C. SCHUSTER,3,6 J. OVERMANN,7 D. A. BRYANT,3,6,8 A. PEARSON2 AND J. L. MACALADY1 1Department of Geosciences, Penn State Astrobiology Research Center (PSARC), The Pennsylvania State University, University Park, PA, USA 2Department of Earth and Planetary Sciences, Harvard University, Cambridge, MA, USA 3Department of Biochemistry and Molecular Biology, The Pennsylvania State University, University Park, PA, USA 4Department of Earth Sciences, Indiana University-Purdue University Indianapolis, Indianapolis, IN, USA 5Department of Earth Sciences, University of California, Riverside, CA, USA 6Singapore Center for Environmental Life Sciences Engineering, Nanyang Technological University, Nanyang, Singapore 7Leibniz-Institut DSMZ-Deutsche Sammlung von Mikroorganismen und Zellkulturen, Braunschweig, Germany 8Department of Chemistry and Biochemistry, Montana State University, Bozeman, MT, USA ABSTRACT Mahoney Lake represents an extreme meromictic model system and is a valuable site for examining the organisms and processes that sustain photic zone euxinia (PZE). A single population of purple sulfur bacte- ria (PSB) living in a dense phototrophic plate in the chemocline is responsible for most of the primary pro- duction in Mahoney Lake. Here, we present metagenomic data from this phototrophic plate – including the genome of the major PSB, as obtained from both a highly enriched culture and from the metagenomic data – as well as evidence for multiple other taxa that contribute to the oxidative sulfur cycle and to sulfate reduction. -

This Article Was Published in an Elsevier Journal. the Attached Copy

This article was published in an Elsevier journal. The attached copy is furnished to the author for non-commercial research and education use, including for instruction at the author’s institution, sharing with colleagues and providing to institution administration. Other uses, including reproduction and distribution, or selling or licensing copies, or posting to personal, institutional or third party websites are prohibited. In most cases authors are permitted to post their version of the article (e.g. in Word or Tex form) to their personal website or institutional repository. Authors requiring further information regarding Elsevier’s archiving and manuscript policies are encouraged to visit: http://www.elsevier.com/copyright Author's personal copy Available online at www.sciencedirect.com Geochimica et Cosmochimica Acta 72 (2008) 1396–1414 www.elsevier.com/locate/gca Okenane, a biomarker for purple sulfur bacteria (Chromatiaceae), and other new carotenoid derivatives from the 1640 Ma Barney Creek Formation Jochen J. Brocks a,*, Philippe Schaeffer b a Research School of Earth Sciences and Centre for Macroevolution and Macroecology, The Australian National University, Canberra, ACT 0200, Australia b Laboratoire de Ge´ochimie Bio-organique, CNRS UMR 7177, Ecole Europe´enne de Chimie, Polyme`res et Mate´riaux, 25 rue Becquerel, 67200 Strasbourg, France Received 20 June 2007; accepted in revised form 12 December 2007; available online 23 December 2007 Abstract Carbonates of the 1640 million years (Ma) old Barney Creek Formation (BCF), McArthur Basin, Australia, contain more than 22 different C40 carotenoid derivatives including lycopane, c-carotane, b-carotane, chlorobactane, isorenieratane, b-iso- renieratane, renieratane, b-renierapurpurane, renierapurpurane and the monoaromatic carotenoid okenane. -

(12) United States Patent (10) Patent No.: US 8,501,463 B2 Cox Et Al

USOO85O1463B2 (12) United States Patent (10) Patent No.: US 8,501,463 B2 Cox et al. (45) Date of Patent: Aug. 6, 2013 (54) ANAEROBC PRODUCTION OF HYDROGEN (56) References Cited AND OTHER CHEMICAL PRODUCTS U.S. PATENT DOCUMENTS (75) Inventors: Marion E. Cox, Morgan Hill, CA (US); 5,350,685 A 9/1994 Taguchi et al. Laura M. Nondorf, Morgan Hill, CA 5,464,539 A 11/1995 Ueno et al. 6,090,266 A 7/2000 Roychowdhury (US); Steven M. Cox, Morgan Hill, CA 6,251,643 B1 6/2001 Hansen et al. (US) 6,299,774 B1 * 10/2001 Ainsworth et al. ........... 210,603 6,342,378 B1 1/2002 Zhang et al. (73) Assignee: Anaerobe Systems, Morgan Hill, CA 6,569,332 B2 * 5/2003 Ainsworth et al. ........... 210,603 2004/0050778 A1 3/2004 Noike et al. (US) 2004/O115782 A1 6/2004 Paterek (*) Notice: Subject to any disclaimer, the term of this FOREIGN PATENT DOCUMENTS patent is extended or adjusted under 35 WO WO-2006-119052 A2 11/2006 U.S.C. 154(b) by 1347 days. OTHER PUBLICATIONS (21) Appl. No.: 11/912,881 Liu et al., 2004. Effects of Culture and Medium Conditions on Hydro gen Production from Starch Using Anaerobic Bacteria. Journal of (22) PCT Fled: Apr. 27, 2006 Bioscience and Bioengineering, vol. 98, No. 4, pp. 251-256.* Zhang et al., Distributed Computer Control of Penicillin Fermenta (86) PCT NO.: PCT/US2OO6/O16332 tion Industrial Production. Proceedings of the IEEE International Conference on Industrial Technology, 1996, pp. 52-56.* S371 (c)(1), New Brunswick, an eppenforf Company, pp. -

Bergey's Manual Of

BERGEY’S MANUALா OF Systematic Bacteriology Second Edition Volume Two The Proteobacteria Part B The Gammaproteobacteria BERGEY’S MANUALா OF Systematic Bacteriology Second Edition Volume Two The Proteobacteria Part B The Gammaproteobacteria Don J. Brenner Noel R. Krieg James T. Staley EDITORS, VOLUME TWO George M. Garrity EDITOR-IN-CHIEF EDITORIAL BOARD James T. Staley, Chairman, David R. Boone, Vice Chairman, Don J. Brenner, Paul De Vos, George M. Garrity, Michael Goodfellow, Noel R. Krieg, Fred A. Rainey, Karl-Heinz Schleifer WITH CONTRIBUTIONS FROM 339 COLLEAGUES George M. Garrity, Sc.D. Bergey’s Manual Trust Department of Microbiology and Molecular Genetics Michigan State University East Lansing, MI 48824-4320 USA Library of Congress Cataloging-in-Publication Data TO COME This volume is dedicated to our colleagues, David R. Boone, Don J. Brenner, Richard W. Castenholz, and Noel R. Krieg, who retired from the Board of Trustees of Bergey’s Manual Trust as this edition was in preparation. We deeply appreciate their efforts as editors and authors; they have devoted their time and many years in helping the Trust meet its objectives. EDITORIAL BOARD AND TRUSTEES OF BERGEY’S MANUAL TRUST James T. Staley, Chairman David R. Boone, Vice Chairman George M. Garrity Paul De Vos Michael Goodfellow Fred A. Rainey Karl-Heinz Schleifer Don J. Brenner, Emeritus Richard W. Castenholz, Emeritus John G. Holt, Emeritus Noel R. Krieg, Emeritus John Liston, Emeritus James W. Moulder, Emeritus R.G.E. Murray, Emeritus Charles F. Niven, Jr., Emeritus Norbert Pfennig, Emeritus Peter H.A. Sneath, Emeritus Joseph G. Tully, Emeritus Stanley T. -

Contents Topic 1. Introduction to Microbiology. the Subject and Tasks

Contents Topic 1. Introduction to microbiology. The subject and tasks of microbiology. A short historical essay………………………………………………………………5 Topic 2. Systematics and nomenclature of microorganisms……………………. 10 Topic 3. General characteristics of prokaryotic cells. Gram’s method ………...45 Topic 4. Principles of health protection and safety rules in the microbiological laboratory. Design, equipment, and working regimen of a microbiological laboratory………………………………………………………………………….162 Topic 5. Physiology of bacteria, fungi, viruses, mycoplasmas, rickettsia……...185 TOPIC 1. INTRODUCTION TO MICROBIOLOGY. THE SUBJECT AND TASKS OF MICROBIOLOGY. A SHORT HISTORICAL ESSAY. Contents 1. Subject, tasks and achievements of modern microbiology. 2. The role of microorganisms in human life. 3. Differentiation of microbiology in the industry. 4. Communication of microbiology with other sciences. 5. Periods in the development of microbiology. 6. The contribution of domestic scientists in the development of microbiology. 7. The value of microbiology in the system of training veterinarians. 8. Methods of studying microorganisms. Microbiology is a science, which study most shallow living creatures - microorganisms. Before inventing of microscope humanity was in dark about their existence. But during the centuries people could make use of processes vital activity of microbes for its needs. They could prepare a koumiss, alcohol, wine, vinegar, bread, and other products. During many centuries the nature of fermentations remained incomprehensible. Microbiology learns morphology, physiology, genetics and microorganisms systematization, their ecology and the other life forms. Specific Classes of Microorganisms Algae Protozoa Fungi (yeasts and molds) Bacteria Rickettsiae Viruses Prions The Microorganisms are extraordinarily widely spread in nature. They literally ubiquitous forward us from birth to our death. Daily, hourly we eat up thousands and thousands of microbes together with air, water, food. -

Α-Helical Segment 190 Α-Ketobutyrate 613 Α-Proteobacteria 780, 791 Α/Β

Index A acyltransferase 123 adduct formation 815, 822 α-helical segment 190 adenosine-5´-phosphosulfate (APS) 610, 613 α-ketobutyrate 613 adenosine-5´-phosphosulfate reductase 610, 611 α-Proteobacteria 780, 791 adenosyl-GDP-cobinamide 91 α/β heterodimer 137–139 adenosyl cobalamin 72, 73, 82, 91 α helix 511 adenosylcobinamide phosphate 91 α polypeptide 175, 188, 204 adenosylcobyric acid 90 αβ LH1 subunit 513 adenylylsulfate 610, 613 A-branch 301 adenylysulfate:phosphate adenylyltransferase (APAT) 610 A-side electron transfer 346 Adiantum capillus-veneris 814 aa3-type cytochrome c oxidase 407, 408, 541, 636, 788 AdoMet:diacylglycerol 3-amino-3-carboxypropyl transferase AAA+ 69, 748 128 AAA+ ATPases 749 ADP-inhibition 477 AAA proteins 69 ADP sulfurylase 610 AAA+ proteins 70 Aequoria victoria 845 AAnP. See aerobic anoxygenic phototrophs aerobic anoxygenic phototrophs 19, 31, 32–52, 599 AAP. See aerobic anoxygenic phototrophs carbon metabolism 40–41 ABC. See ATP-binding cassette (ABC) deep ocean absorbance spectra vertical distribution 50 in vivo 39 ecological roles 47–51 absorption maxima 431 environment 32 carotenoid 926 evolution 38–40 absorption transitions 200 marine 48–49 accA 122 morphology 35 accB 122 nutritional status 43 accC 122 phylogeny 33, 37 accD 122 taxonomy 37 acceptor pool 530 aerobic bacteria 112 acceptor quinone 379, 380–399 aerobic cobalamin biosynthetic pathway 84 reactions 382 aerobic conditions 58, 72, 112, 417 acceptor quinone complex 383 aerobic cyclization system 72 accessory phototrophy 50 aerobic pathway 84 Acetobacteraceae -

Fossil Carotenoids and Paleolimnology of Meromictic Mahoney Lake, British Columbia, Canada

Aquatic Sciences 55/1, 1993 1015-1621/93/010031-09 $1.50+0.20/0 © 1993 Birkh/iuser Verlag, Basel Fossil carotenoids and paleolimnology of meromictic Mahoney Lake, British Columbia, Canada J6rg Overmann 1,., Gerhard Sandmann 1, Ken J. Hall 2, Tom G. Northcote 3 1 Fakult/it ffir Biologie, Universitfit Konstanz, Postfach 5560, D-7750 Konstanz, Germany 2 Westwater Research Center, University of British Columbia, Vancouver, B.C., V 6T 1W 5, Canada 3 Department of Zoology, University of British Columbia, Vancouver, B.C., V6T 2A9, Canada Key words: Paleolimnology, fossil pigments, carotenoids, okenone, photosynthetic bacteria, meromixis. ABSTRACT Vertical distribution of fossil carotenoids in a sediment core from meromictic Mahoney Lake was studied. Besides okenone and demethylated okenone, lutein and zeaxanthin and fl-carotene isomers were identified. No carotenoids typical for purple nonsulfur or green sulfur bacteria were detected. The ratio of zeaxanthin to lutein (above 1:1 in all samples) indicates a dominance of cyanobacteria over green algae in the phytoplankton assemblages of the past. Okenone, which is found exclusively in Chromatiaceae, was the dominating carotenoid in all sediment zones. The oldest sediment layers containing okenone were deposited 11000 years ago. Between 9000 and 7000 and since 3000 years b.p., Chromatiaceae reached a considerable biomass in the lake. Vertical changes in okenone concentration were not related to changes of paleotemperatures. In contrast, okenone concentrations decreased during periods of volcanic ash input. During most of the lake history, however, mean okenone concentrations were positively correlated with sedimentation rates. This indicates that vertical changes of okenone concentration in the sediment reflect past changes of purple sulfur bacterial biomass in the lake. -

Molecular Physiology of Anaerobic Phototrophic Purple and Green Sulfur Bacteria

International Journal of Molecular Sciences Review Molecular Physiology of Anaerobic Phototrophic Purple and Green Sulfur Bacteria Ivan Kushkevych 1,* , Jiˇrí Procházka 1,Márió Gajdács 2,3 , Simon K.-M. R. Rittmann 4 and Monika Vítˇezová 1,* 1 Department of Experimental Biology, Faculty of Science, Masaryk University, 62500 Brno, Czech Republic; [email protected] 2 Department of Pharmacodynamics and Biopharmacy, Faculty of Pharmacy, University of Szeged, Eötvös utca 6, 6720 Szeged, Hungary; [email protected] 3 Faculty of Medicine, Institute of Medical Microbiology, Semmelweis University, Nagyvárad tér 4, 1089 Budapest, Hungary 4 Archaea Physiology & Biotechnology Group, Department of Functional and Evolutionary Ecology, Universität Wien, 1090 Wien, Austria; [email protected] * Correspondence: [email protected] (I.K.); [email protected] (M.V.); Tel.: +420-549-495-315 (I.K.) Abstract: There are two main types of bacterial photosynthesis: oxygenic (cyanobacteria) and anoxygenic (sulfur and non-sulfur phototrophs). Molecular mechanisms of photosynthesis in the phototrophic microorganisms can differ and depend on their location and pigments in the cells. This paper describes bacteria capable of molecular oxidizing hydrogen sulfide, specifically the families Chromatiaceae and Chlorobiaceae, also known as purple and green sulfur bacteria in the process of anoxygenic photosynthesis. Further, it analyzes certain important physiological processes, especially those which are characteristic for these bacterial families. Primarily, the molecular metabolism of Citation: Kushkevych, I.; Procházka, sulfur, which oxidizes hydrogen sulfide to elementary molecular sulfur, as well as photosynthetic J.; Gajdács, M.; Rittmann, S.K.-M.R.; processes taking place inside of cells are presented. Particular attention is paid to the description Vítˇezová,M. -

Article What Caused the Pink Coloration of Water at the Bottom Of

Rikunomizu(Limnology in Tokai Region of Japan)87 : 1 - 9(2020) Article What caused the pink coloration of water at the bottom of Lake Shiraishi ? 1) 2) 3) Masaki KIHIRA , Suguru OKUNISHI , Tadashi INAGAKI , 1) 2) Susumu KATO and Hiroto MAEDA Abstract Pink water was collected from the bottom of Lake Shiraishi, a brackish lake located in Kihoku-cho, Mie Prefecture, in September 2009 and January 2010 for preliminary field investigation. The water quality and bacterial community structure were investigated again in August 2010 to clarify the cause of the pink water; microscopic observation to clarify the morphology and PCR-denaturing gradient gel electrophoresis (DGGE) to characterize bacterial community were performed. The water sampled from near the bottom of the lake at a depth of 8 m was colored pink and smelled of hydrogen sulfide. Microscopic examination revealed that the dominant cells were 5–7 µm in size, spherical or ovoid, pink to purple in color, with gas vesicles, and were not motile. The results of microscopy and phylogenetic analysis using PCR-DGGE suggested that the pink coloration was related to photosynthetic sulfur bacteria of either Halochromatium roseum or Lamprobacter modestohalophilus. Key words: Photosynthetic sulfur bacteria, PCR-DGGE, Lake Shiraishi (Received: 30 May 2020; Accepted: 18 July 2020) Microbial communities at layers where the dissolved Introduction oxygen gradient changes are interesting from the viewpoint Lake Shiraishi, located in Kihoku-cho, Mie, Japan, is of degradation of organic compounds in the redox system, a brackish lake covering an area of 472,000 m2 with a and analysis of these communities using 16S rRNA genes maximum depth of 9 m (Tsuchihashi et al., 1996). -

Phylogenetic Relationships Among the Chromatiaceae, Their

International Journal of Systematic Bacteriology (1998), 48, 11 29-1 143 Printed in Great Britain Phylogenetic relationships among the Chromatiaceae, their taxonomic reclassification and description of the new genera Allochromatium, Halochromatium, Isochromatium, Marichromatiurn , Thiococcus, Thiohalocapsa and Thermochromatium Johannes F. Imhoff, Jorg Wing and Ralf Petri Author for correspondence: Johannes F. Imhoff. Tel: +49 431 697 3850. Fax: +49 431 565876. e-mail : jimhoff(n ifm.uni-kiel.de lnstitut fur Meereskunde Sequences of the 16s rDNA from all available type strains of Chromatium an der Universitat Kiel, species have been determined and were compared to those of other Abteilung Marine Mikrobiologie, Chromatiaceae, a few selected Ectothiorhodospiraceae and Escherichia coli. Dusternbrooker Weg 20, The clear separation of Ectothiorhodospiraceae and Chromatiaceae is D-24105 Kiel, Germany confirmed. Most significantly the sequence comparison revealed a genetic divergence between Chromatium species originated from freshwater sources and those of truly marine and halophilic nature. Major phylogenetic branches of the Chromatiaceae contain (i)marine and halophilic species, (ii)freshwater Chromatium species together with Thiocystis species and (iii)species of the genera Thiocapsa and Amoebobacter as recently reclassified [Guyoneaud, R. & 6 other authors (1998). lnt J Syst Bacteriol48, 957-9641, namely Thiocapsa roseopersicina, Thiocapsa pendens (formerly Amoebobacter pendens), Thiocapsa rosea (formerly Amoebobacter roseus), Amoebobacter purpureus and Thiolamprovum pedioforme (formerly Amoebobacter pedioformis). The genetic relationships between the species and groups are not in congruence with the current classification of the Chromatiaceae and a reclassification is proposed on the basis of 16s rDNA sequence similarity supported by selected phenotypic properties. The proposed changes include the transfers of Chromatium minus and Chromatium violascens to Thiocystis minor comb. -

'El Tobar' (Cuenca, Spain)

AQUATIC MICROBIAL ECOLOGY Vol. 20: 299-303,1999 Published December 30 , Aquat Microb Ecol NOTE Vertical distribution of photosynthetic sulphur bacteria linked to saline gradients in Lake 'El Tobar' (Cuenca, Spain) ' Institute of Aquatic Ecology, University of Girona. Campus de Montilivi. 17071 Girona. Spain * Dept of Microbiology and Ecology. Faculty of Sciences. University of Valencia. Burjassot, 46100 Valencia. Spain ABSTRACT: The merornictic lake 'El Tobar' was sampled at 3 are subjected to an annual regime of mixing and strat- time points during the annual cycle, coinciding with the ther- ification that provides a high degree of variability in mal stratification period. The photosynthetic microbial com- the physical and chemical parameters, depending on munity was composed of mixoiimnetic oxygenic phototrophs. which were distributed throuqh the mixolimnion, phycoery- the season. However, in some meromictic lakes redox- trine-containing unicellular cyanobacteria and sulphu; photb- clines are placed at such a depth that light is the limit- trophic bacteria placed at the halocline. During the stratification ing factor for bacterial growth during most of the year. period anoxic conditions, formerly confined to the monimo- In Lake 'El Tobar' the vertical structure of both the limnion, moved 1 m upwards, reaching freshwater positions. Consequently, photosynthetic bacteria were re-arranged into water column and the bacterial community is strongly - A-..L,- 1- ----- L ..-- -,..--A :..-L -L -..- --A -- inf!ilenrc+ h.rr tho nrecenrp nf a cham calinitxr nrarliont u uu..t.,.r. ,,u.,,.c-y.LL.r Jnucrulr ,,.ucLu JUJL '."".C U1.U C..*- ' ---- 1- l i) bedded in the chemocline. In the freshwater layers we found A complete physical and chemical characterization of a population of the purple sulphur bacterium Chromatium the lake as well as a preliminary biological study can minus placed just above a population of the brown-colored be found in Vicente et al.