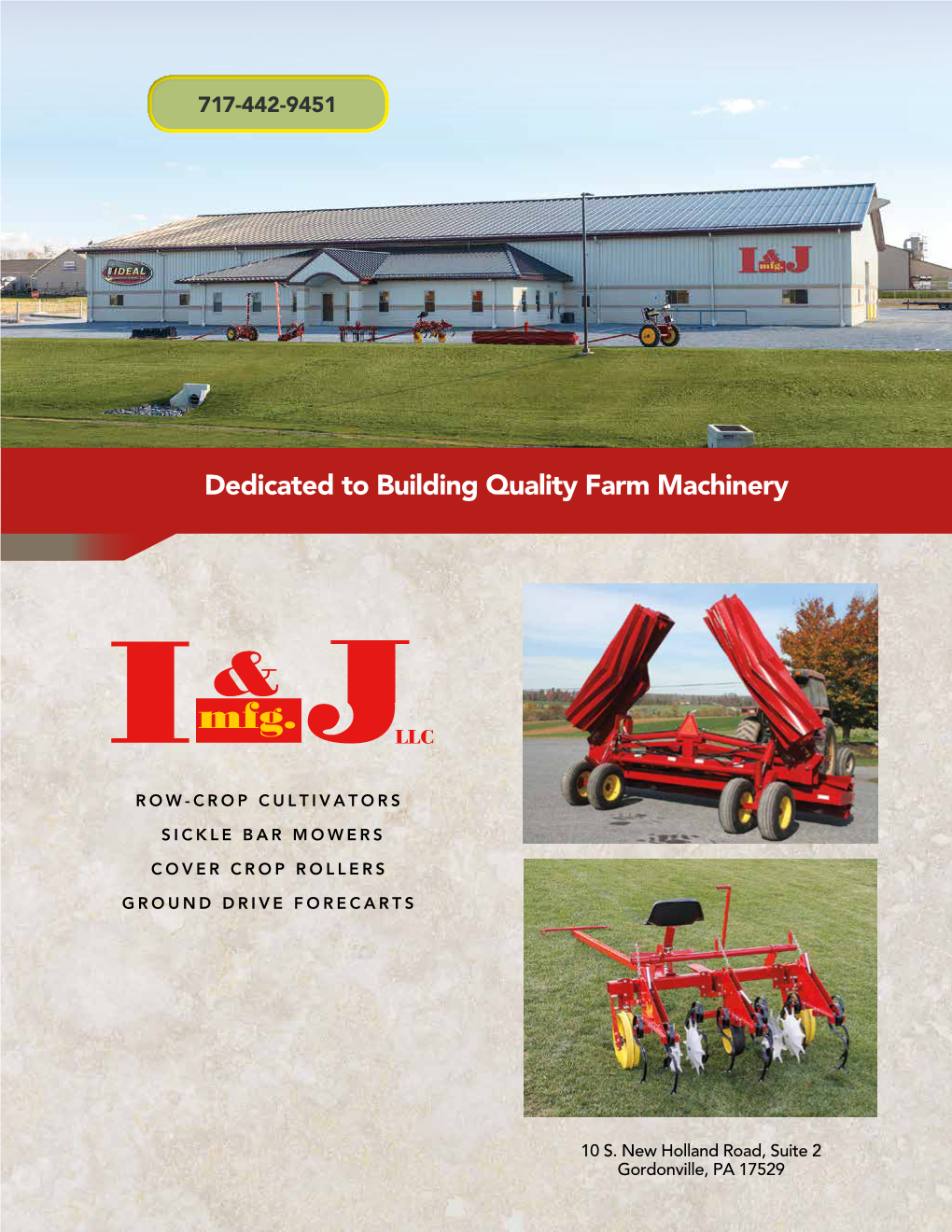

Dedicated to Building Quality Farm Machinery

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Cobrahead an Historic American Farming Implement Gets a Modern Facelift from a Wisconsin Tool Inventor

As Seen in To Subscribe, visit: www.FloristsReview.com\Subscibe Made in the U.S.A CobraHead An historic American farming implement gets a modern facelift from a Wisconsin tool inventor. ’m pretty sure my Indiana granddad had one of those ancient, hard- Community is important to me, and I sure didn’t want to hop on a plane I working tools that looked like a steel claw at the end of a long, wooden to Beijing if I had a problem with my tools. By making them locally, even handle. Often called a five-tined garden cultivator, it was perfect for break- though it might be a little more expensive, I’m able to resolve any issues ing through compact soil to prepare for seed planting. According to Noel in person.” Valdes of CobraHead LLC, based in Cambridge, Wis., “Every American It took some hunting before Noel found Green Bay Drop Forge, a tool manufacturer of note made the cultivator, but rototillers put them out machine shop that also fabricates parts for the automotive and agricultural of business and so no one makes them anymore.” industries. The company president was a gardener and he agreed to Old-timers hung onto their timeworn cultivators, and so did Noel, manufacture the original CobraHead Weeder and Cultivator in 2002. A who has discovered through research that makers held patents for the Madison, Wisconsin-based molding shop makes the recycled plastic blue tool dating back to the pre-Civil War era. handle, its shape based on a hammer replacement handle sold at big box Several years ago, one of the five tines fell off of the handle of his vin- stores. -

Stable Farm, Munstone, Hereford, Hr1 3Ah

=Auctioneers= =Estate Agents= H.J. Pugh & Co. =Valuers= STABLE FARM, MUNSTONE, HEREFORD, HR1 3AH Dispersal sale of the renowned Colin Powell collection of FERGUSON TRACTORS, IMPLEMENTS, SPARES AND LITERATURE th SATURDAY 29 SEPTEMBER. 10.00AM BUYERS PREMIUM 5% + VAT. ONLINE BIDDING VIA EASYLIVE AUCTIONS Newmarket House, Market Street, Ledbury. Herefordshire. HR8 2AQ. Tel: 01531 631122. Fax: 01531 631818 Email: [email protected] CONDITIONS OF SALE 1. All prospective purchasers to register to bid and give in their name, address and telephone number, in default of which the lot or lots purchased may be immediately put up again and re-sold 2. The highest bidder to be the buyer. If any dispute arises regarding any bidding the Lot, at the sole discretion of the auctioneers, to be put up and sold again. 3. The bidding to be regulated by the auctioneer. 4. In the case of Lots upon which there is a reserve, the auctioneer shall have the right to bid on behalf of the Vendor. 5. No Lots to be transferable and all accounts to be settled at the close of the sale. 6. The lots to be taken away whether genuine and authentic or not, with all faults and errors of every description and to be at the risk of the purchaser immediately after the fall of the hammer but must be paid for in full before the property in the goods passes to the buyer. The auctioneer will not hold himself responsible for the incorrect description or authenticity of or any fault or defect in any lot and makes no warranty. -

Market Farm Tools and Systems

PREPARING A NEW GENERATION OF ILLINOIS FRUIT AND VEGETABLE FARMERS a USDA NIFA BEGINNING FARMER AND RANCHER DEVELOPMENT PROGRAM PROJECT GRANT # 2012-49400-19565 http://www.newillinoisfarmers.org GROWING A NEW GENERATION OF ILLINOIS FRUIT AND VEGETABLE FARMERS MARKET FARM TOOLS AND SYSTEMS Zachary Grant Bill Shoemaker Adapted from John Hendrickson April 2015 Objectives: • Capitalizing a Market Farm • Capitalization Priorities • The Front End of the Market Farm • The Middle of the Market Farm • The Back End of the Market Farm • Concluding Thoughts and Questions Estimated Equipment Needs for Various Sizes of Vegetable Farms. Power Source and Direct Production Postharvest Seed Starting Tillage Seeding Equipment Cultivation Harvesting Handling Delivery rototiller Field small hoop Earth- Wheel hoe, or Back-pack knives, Bulk tank, Pickup house, grow way hand hoes, 1-3 walking sprayer, hand canopy, with lights, seeder, digging acres tractor, irrigation, boxes, packing topper planting Cyclone forks, custom tools buckets, containers or van trays seeder spades work carts 35-40 hp 1000 sq. ft. tractor, Potato 1-row greenhouse, with Cultivat- digger, Roller track transplant cold frames, creeper Planet ing tractor bed lifter, conveyor, 4-6 er, Cargo field gear, Jr. plate (IH Super wagon, hand carts, acres irrigation, van tunnels, power seeder A or IH more walk-in more planting steering, 140) boxes, cooler tools trays high buckets clearance Market Gardening: A Start-up Guide https://attra.ncat.org/attra-pub/summaries/summary.php?pub=18 Estimated Equipment -

Agriculture Paper 1

Agriculture second term Paper 1 1. Agriculture is the growing of crops and keeping of ....... A plastic papers B animals C keeping of bees D books 2. Agriculture is also called.......... A driver B farming C commercial farmer D peasant farmer 3. Crops are grown in the garden and in the ........... A bush B forest C field D axe 4. What do we get from agriculture? A promotion of laziness B promotion of soil erosion C food D support 5. .............is used for weeding. A Mattock B Pick C Secateurs D Hoe 6. What is the name of the tool used to dig hard surfaces? A mattock B pick C sickle D axe 7. ..........is a tool used for pruning by farmers. A mattock B machete C sickle D pick 8. Farmers use a ......... for pest and disease control. A syringe B water C sickle D axe 9. It is a____ tool. A. cutting tool B. moving C. watering D. digging. 10. What is the common farming practice used in rural areas? A subsistence farming B commercial faming C vegetable faming D axe 11 The tool is a_______. A. garden fork B. rake C. plough D. mattock 12. The following are soil components except....... A air B water C. Organic matter D metal 13. This is sand soil. One of its characteristic is that it is A gritty B very fertile C smooth D concrete-like 14. Organic matter is a soil component which comes from ...... A rubber B soil C dead organic matter D rocks 15. Mineral matter is a soil component which comes from finely broken A air B soil C organic matter D rocks 16. -

The European Bronze Age Sword……………………………………………….21

48-JLS-0069 The Virtual Armory Interactive Qualifying Project Proposal Submitted to the Faculty of the WORCESTER POLYTECHNIC INSTITUTE in partial fulfillment of the requirements for graduation by _____________________________ ____________________________ Patrick Feeney Jennifer Baulier _____________________________ Ian Fite February 18th 2013 Professor Jeffrey L. Forgeng. Major Advisor Keywords: Higgins Armory, Arms and Armor, QR Code 1 Abstract This project explored the potential of QR technology to provide interactive experiences at museums. The team developed content for selected objects at the Higgins Armory Museum. QR codes installed next to these artifacts allow visitors to access a variety of minigames and fact pages using their mobile devices. Facts for the object are selected randomly from a pool, making the experience different each time the code is scanned, and the pool adapts based on artifacts visited, personalizing the experience. 2 Contents Contents........................................................................................................................... 3 Figures..............................................................................................................................6 Introduction ……………………………………………......................................................... 9 Double Edged Swords In Europe………………………………………………………...21 The European Bronze Age Sword……………………………………………….21 Ancient edged weapons prior to the Bronze Age………………………..21 Uses of European Bronze Age swords, general trends, and common innovations -

Cutting Parts

GENUINE NEW HOLLAND CUTTING PARTS. Combines | Disc Mowers Draper Headers | Mowers Mower-Conditioners | Windrowers All-Makes | Kits WORK SMARTER WITH MY SHED™ AND MY SHED MOBILE APP 2.1. Google Play™ for Android™ Apple® Store for iPhone® WE KNOW WHAT YOUR MACHINE’S MADE OF. The Partstore has everything you need to keep your equipment up and running. Now you can easily store your machine models to access parts with My Shed and My Shed Mobile App, 2.1. My Shed offers: • Machine Management: Enter serial • Toolboxes: Oil/fluid selector and number, hours and notes battery finder • Parts Manuals: Access assembly • Machine Info: Product alerts diagrams and create part pick lists and videos • 24/7 Dealer Connection: Email part pick lists to a dealer SELECT US – YOUR LOCAL DEALER – ON PARTSTORE: WWW.PARTSTORE.AGRICULTURE.NEWHOLLAND.COM www.newholland.com/na ©2015 CNH Industrial America LLC. All rights reserved. New Holland is a trademark registered in the United States and many other countries, owned by or licensed to CNH Industrial N.V., its subsidiaries or affiliates. 2 TABLE OF CONTENTS CUTTING PARTS DISC MOWER KNIVES FOR TODAY’S 9–15 Blades, Kits DEMANDING DISK MOWER/ MOWER-CONDITIONERS SICKLE BAR MOWER APPLICATIONS 16–23 Knife Assemblies, Kits New Holland Original Equipment Cutting Parts are designed and manufactured for the finest agricultural harvesting equipment available today. Whether for the New Holland Mower, HAY MACHINES MY SHED Mower-Conditioner, Windrower or Combine Header, we’ve designed knife sections and knife assem blies to go the 24–27 Knife Assemblies, Kits MOBILE APP 2.1. -

The Sickle's Edge

University of Wisconsin Milwaukee UWM Digital Commons Theses and Dissertations December 2015 The ickS le's Edge: an Experimental Use-wear Approach to Investigating Sickle Deposition in Bronze Age Europe Barbara Ellen McClendon University of Wisconsin-Milwaukee Follow this and additional works at: https://dc.uwm.edu/etd Part of the Archaeological Anthropology Commons Recommended Citation McClendon, Barbara Ellen, "The ickS le's Edge: an Experimental Use-wear Approach to Investigating Sickle Deposition in Bronze Age Europe" (2015). Theses and Dissertations. 1035. https://dc.uwm.edu/etd/1035 This Thesis is brought to you for free and open access by UWM Digital Commons. It has been accepted for inclusion in Theses and Dissertations by an authorized administrator of UWM Digital Commons. For more information, please contact [email protected]. THE SICKLE’S EDGE: AN EXPERIMENTAL USE-WEAR APPROACH TO INVESTIGATING SICKLE DEPOSITION IN BRONZE AGE EUROPE by Barbara Ellen McClendon A Thesis Submitted in Partial Fulfillment of the Requirements for the Degree of Master of Science in Anthropology at The University of Wisconsin-Milwaukee December 2015 ABSTRACT THE SICKLE’S EDGE: AN EXPERIMENTAL APPROACH TO INVESTIGATING SICKLE DEPOSITION IN BRONZE AGE EUROPE by Barbara Ellen McClendon The University of Wisconsin-Milwaukee, 2015 Under the Supervision of Dr. Bettina Arnold Prehistoric hoards—containing items such as precious metals, tools, ornaments, and weapons—have long fascinated archaeologists and the general public alike. The practice of intentional wealth deposition in hoards was particularly prolific during the European Bronze Age; however, the motivations behind this practice remain unclear. Comparisons of the contents of hoards through space and time can yield valuable data regarding the purpose and process of deposition, but one of the most common items found in Bronze Age hoards—bronze sickles—remains understudied. -

Operator's Manual SICKLE BAR MOWERS

PGF Operator’s Manual SICKLE BAR MOWERS SKM272, SKM284, SKM296 The operator’s manual is a technical service guide and must always accompany the machine. Manual 970-394B August 2015 SAFETY Take note! This safety alert symbol found throughout this manual is used to call your attention to instructions involving your personal safety and the safety of others. Failure to follow these instructions can result in injury or death. This symbol means: ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED! Signal Words Note the use of the signal words DANGER, WARNING and CAUTION with the safety messages. The appropriate signal words for each have been selected using the following guidelines: DANGER: Indicates an imminently hazardous situation that, if not avoided, will result in death or serious injury. WARNING: Indicates a potentially hazardous situation that, if not avoided, could result in death or serious injury, and includes hazards that are exposed when guards are removed. It may also be used to alert against unsafe practices. CAUTION: Indicates a potentially hazardous situation that, if not avoided, may result in minor or moderate injury. INDEX 1 - GENERAL INFORMATION 4 1.01 - General 4 1.02 - Warranty Information 4 1.03 - Model and Serial Number ID 5 2 - SAFETY PRECAUTIONS 6 2.01 - Preparation 6 2.02 - Starting and Stopping 6 2.03 - Messages and Signs 7 3 - OPERATION 10 3.01 - Operational Safety 10 3.02 - Setup 12 3.03 - Assembly Instructions 12 3.04 - Pre-Operational Check 14 3.05 - Attaching to the Tractor 14 3.06 - Start Up 16 3.07 - Working -

The Broadfork

The BroadFork Many gardeners and growers, especially those working on heavy soils, face the difficulty of deeply compacted soil and want to loosen and aerate it without bringing lower layers to the surface. On a field scale there are tractor-based solutions, but how to tackle the task in the smaller plot? The BroadFork is designed to be at least part of the solution! (The Glaser Bio cultivator (414) has the same objective.) Here are some of Eliot Coleman’s comments from his book The New Organic Grower:– “This two-handled deep tillage tool is known by different names, but broadfork comes as close to describing it as any other. Like most agricultural tools its genesis surely dates far back in agricultural history. It consists of a 2-foot wide spading fork with a 5-foot-long handle at either side of the fork. The teeth on the fork are spaced 4 inches apart and are about 12 inches long . The tines are designed with a parabolic shape and curve down from an attachment point at the back of the crossbar. This difference is the key. The parabolic curve . works with an easy, rolling motion. As the handles are pulled down, the tines curve under and lift the soil easily. “The broadfork is held with the handles tilted slightly forward of vertical. It is pressed into the soil as far as possible by stepping on the crossbar, then the two handles are pulled back towards the operator in an easy rocking motion. The broadfork is then lifted from the loosened soil, the operator steps backwards 6 inches, and the manoeuvre is repeated.. -

Farm Machinery Selection

Farm Machinery Ag Decision Maker Selection File A3-28 utting together an ideal machinery system long run; machinery that is too small may result in is not easy. Equipment that works best one lower crop yields or reduced quality. year may not work well the next because of P Ownership Costs changes in weather conditions or crop production practices. Improvements in design may make older Machinery ownership costs include charges for de- equipment obsolete. And the number of acres be- preciation, interest on investment, property taxes, ing farmed or the amount of labor available may insurance and machinery housing. These costs change. increase in direct proportion to machinery invest- ment and size. Because many of these variables are unpredictable, the goal of the good machinery manager should be Operating Costs to have a system that is flexible enough to adapt Operating costs include fuel, lubricants and repairs. to a broad range of weather and crop conditions Operating costs per acre change very little as ma- while minimizing long-run costs and production chinery size is increased or decreased. Using larger risks. To meet these goals several fundamental machinery consumes more fuel and lubricants per questions must be answered. hour, but this is essentially offset by the fact that more acres are covered per hour. Much the same is Machine Performance true of repair costs. Thus, operating costs are of mi- First, each piece of machinery must perform reli- nor importance when deciding what size machinery ably under a variety of field conditions or it is a is best suited to a certain farming operation. -

Producing a Past: Cyrus Mccormick's Reaper from Heritage to History

Loyola University Chicago Loyola eCommons Dissertations Theses and Dissertations 2014 Producing a Past: Cyrus Mccormick's Reaper from Heritage to History Daniel Peter Ott Loyola University Chicago Follow this and additional works at: https://ecommons.luc.edu/luc_diss Part of the United States History Commons Recommended Citation Ott, Daniel Peter, "Producing a Past: Cyrus Mccormick's Reaper from Heritage to History" (2014). Dissertations. 1486. https://ecommons.luc.edu/luc_diss/1486 This Dissertation is brought to you for free and open access by the Theses and Dissertations at Loyola eCommons. It has been accepted for inclusion in Dissertations by an authorized administrator of Loyola eCommons. For more information, please contact [email protected]. This work is licensed under a Creative Commons Attribution-Noncommercial-No Derivative Works 3.0 License. Copyright © 2014 Daniel Peter Ott LOYOLA UNIVERSITY CHICAGO PRODUCING A PAST: CYRUS MCCORMICK’S REAPER FROM HERITAGE TO HISTORY A DISSERTATION SUBMITTED TO THE FACULTY OF THE GRADUATE SCHOOL IN CANDIDACY FOR THE DEGREE OF DOCTOR OF PHILOSOPHY JOINT PROGRAM IN AMERICAN HISTORY / PUBLIC HISTORY BY DANIEL PETER OTT CHICAGO, ILLINOIS MAY 2015 Copyright by Daniel Ott, 2015 All rights reserved. ACKNOWLEDGMENTS This dissertation is the result of four years of work as a graduate student at Loyola University Chicago, but is the scholarly culmination of my love of history which began more than a decade before I moved to Chicago. At no point was I ever alone on this journey, always inspired and supported by a large cast of teachers, professors, colleagues, co-workers, friends and family. I am indebted to them all for making this dissertation possible, and for supporting my personal and scholarly growth. -

Multi-Tasking Hand Tools by Rita Pelczar

GREENc GARAGE® Multi-Tasking Hand Tools by Rita Pelczar hen I head to the garden, I Besides extracting weeds by their roots, it’s usually take just a couple of great for digging holes for transplants or Wtools with me, so they need bulbs; and it cuts through anything from to be able to perform a variety of tasks twine to the roots of perennials that you and they have to feel comfortable in my want to divide. The six-and-three-quarter- hands when I use them. here are a few inch, hardened stainless steel blade is ser- that fit the bill. rated and engraved with millimeter depth I’ve long been a fan of a handcraft- measurements to help ensure accurate ed tool from Lewiston, Idaho, with the odd name of Hoe-dag (available from hoss Tools (www.hosstools.com). It’s a well-balanced, short-handled hoe featur- Multi-Purpose Hori-Hori Knife planting. Its vinyl carrier has a loop that can be attached to a belt to keep it safely sheathed until ready for use. The 10-and-a-half-inch-long Handy Weeder Tool, also from Gardener’s edge, is small and light enough to carry on your belt. The five-inch-long, flat beveled blade is handy for weeding in tight places—between young vegetables or flowers, even in planters—easily cut- ting young weeds at their roots without 2-Tine Cultivator Hand Eye Hoe disturbing nearby plants. It also makes precise furrows for sowing seeds. Crafted in Germany, the 2-Tine Cultivator Hand Eye Hoe, available from Garden Tool Company (www.