Schwartzberg, Henry. "Batch Coffee Roasting; Roasting Energy Use

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

University of Florida Thesis Or Dissertation Formatting

COFFEE ROASTING: COLOR AND AROMA-ACTIVE SULFUR COMPOUNDS By ALBERTO MONTEIRO CORDEIRO DE AZEREDO A DISSERTATION PRESENTED TO THE GRADUATE SCHOOL OF THE UNIVERSITY OF FLORIDA IN PARTIAL FULFILLMENT OF THE REQUIREMENTS FOR THE DEGREE OF DOCTOR OF PHILOSOPHY UNIVERSITY OF FLORIDA 2011 1 © 2011 Alberto Monteiro Cordeiro de Azeredo 2 To God, for giving me the most caring wife, the most precious daughter, and the most supportive parents and family, who helped me in achieving this honorable milestone 3 ACKNOWLEDGMENTS I would like to give my deepest thanks to my advisors Dr. Balaban and Dr. Marshall for giving me this opportunity to pursue my PhD degree, and for their support, advice and friendship throughout this experience. Thanks to Dr. Rouseff for his invaluable help, assistance and time for my research, thanks for letting me be part of his lab. I also want to thank my other committee members, Dr. Sims and Dr. Welt, for all their expertise and help. I acknowledge all the assistance provided to me from the University of Florida, the Institute of Food and Agricultural Sciences, and the department of Food Science and Human Nutrition. I would also like to give my special thanks to Dr. Susan Percival for her continuous encouragement to pursue a PhD. I would like to thank Mr. Washington Rodrigues and Mr. Edgard Bressani from Ipanema Coffees, located in southern Minas Gerais, Brazil, for kindly providing green coffee beans for this research. I would like to thank my lab mates Milena and Maria for all their help and suggestions, and would like to extend my special thanks to Dr. -

Brochure (PDF)

COFFEE ROASTERS & TEA BLENDERS INTRODUCTION Tudor Tea & Coffee Ltd was established in 1984 as a Tea Company. Introducing the facility to roast its ‘own’ coffee just 6 years later, it now boasts a ‘State of the Art’ Coffee Roasting plant. Being one of the few companies today employing its ‘own’ team of fully trained engineers, it is able to produce a product and offer a service to the people in the UK Food Service Market that other companies strive to emulate! Tudor Tea & Coffee Ltd achieved awards from the Tea Council for barista training can be carried out. Tudor Coffee, on behalf of INDEX the consistent high quality Tea that is produced and maintained. the client, can create their own coffee blend, and roast and Coffee Roasting Page 3 Tudor import, blend and produce Leaf Tea and Tea bags of personalise the product and can be tasted from our Sample Single Origin Coffee Page 4 various sizes for the UK Food Service Market. A complete range Roaster (by prior arrangement). Coffee Bean Pricing Page 5 of superior products such as the Masterpiece range of pure Tudor Tea & Coffee Ltd has over many years established an Tudor Tea Page 6 specialist string and tagged teabags to offer a comprehensive enviable reputation within the Food Service Industry, with all Tudor Tea Catering Range Page 7 and highly successful product range, guaranteed by our own of its engineers being fully employed by the company and we experienced tea tasters. Rainforest Alliance Product Range Page 8 ensure all are fully trained by the manufacturers directly. -

Barista Training Classes

Sept - Oct 2018 (click for larger image) Latte Art Barista Training Classes Increasingly in cafes around the world, Latte Art has In Depth - Hands On become more than a frilly add-on; it has become the Coffee Roaster | Coffee Roasting signature of a properly constructed, delicious handcrafted Tues Sept 11, 7 pm Latte Art coffee. A coffee that looks as good as it tastes, a coffee Thurs Sept 13, Noon Barista Level 1 that keeps the customer coming back, a coffee that deserves a premium price, a coffee that fills the tip jar, a Tues Sept 18, 7 pm Barista Level 1 coffee that cannot be created by the large chains. The Thurs Sept 20, Noon Latte Art benefits do not end there: the pursuit of the perfect pour Tues Sept 25, 7 pm Latte Art engages baristas in their craft, creating positive energy Wed Sept 26, Noon Preventative Maintenance customers notice and enjoy. Thurs Aug 27, Noon Cupping Average class length 2 hours, first class free for folks Tues Oct 2, 7 pm Pour Over Brewing in the trade or those looking to get started, $40 per Thurs Oct, 4 Noon Nitro Cold Brew - Cold Press class or $120 per 6 month unlimited pass otherwise. Tuesday Oct 9, 7 pm Barista Level 1 Please, call or email us to reserve your seat or Thursday Oct 9, Noon Barista Level 1 schedule a private class. [email protected] Barista Level 1- intro to green coffee, intro to roasting, espresso extraction in depth, micro-foam in depth, make a complete drink. -

The Coffee Bean: a Value Chain and Sustainability Initiatives Analysis Melissa Murphy, University of Connecticut, Stamford CT USA Timothy J

The Coffee Bean: A Value Chain and Sustainability Initiatives Analysis Melissa Murphy, University of Connecticut, Stamford CT USA Timothy J. Dowding, University of Connecticut, Stamford CT USA ABSTRACT This paper examines Starbucks’ corporate strategy of sustainable efforts in Ethiopia, particularly in the sustainable sourcing Arabica coffee. The paper discusses the value chain of coffee, issues surrounding the coffee supply chain and the need for sustainable coffee production. In addition it also discusses Starbucks’ position and influence on the coffee trade, and the measures that Starbucks is taking to ensure sustainability efforts throughout the coffee supply chain. COFFEE VALUE CHAIN & P3G ANALYSIS Coffee is produced in more than fifty developing countries in Latin America, Africa, and Asia and it is an important source of income for 20-25 million families worldwide [1]. The initial production of coffee beans including farming, collecting, and processing is labor intensive and as a result is performed in more labor abundant developing countries. The roasting and branding of coffee is more capital intensive and therefore is situated in northern industrialized countries. The top five coffee consumers are United States of America, Brazil, Germany, Japan, and France [1]. The structure of the value chain is very similar regardless of producing or consuming country. The coffee value chain is made up of the four main phases: Cultivation, Processing, Roasting, and Consumption. Each phase in the process has environmental, social, economic -

Kinetics of Volatile Generation During Coffee Roasting and Analysis Using Selected Ion Flow Tube-Mass Spectrometry

Kinetics of volatile generation during coffee roasting and analysis using Selected Ion Flow Tube-Mass Spectrometry THESIS Presented in Partial Fulfillment of the Requirements for the Degree Master of Science in the Graduate School of The Ohio State University By Sangeetha Krishnaswamy Graduate Program in Food Science and Technology The Ohio State University 2017 Master's Examination Committee: Dennis R. Heldman, Advisor Sudhir Sastry Christopher Simons Copyrighted by Sangeetha Krishnaswamy 2017 Abstract Roasting is a critical step comprising of a series of complex reactions that are responsible for flavor generation in coffee. This study presents a real-time analytical technique that predicts the mechanism of volatile generations during different roasting conditions which could be ultimately used for online process control to deliver a more consistent target roast profile. The objectives of this research were to 1) To monitor the volatile compound generation during coffee roasting in real-time using online SIFT-MS 2) To investigate the influence of the time-temperature process during coffee roasting on the kinetics of volatiles generated and develop predictive models to determine kinetic parameters of volatile compounds and 3) predict temperature distribution histories within the coffee bean at different roasting conditions. Colombian Arabica coffee beans were roasted in a horizontal drum roaster at 210, 220 and 230 °C for 10, 15 and 20 minutes respectively. The concentrations of 7 volatile organic compounds (VOC’s), with impact on coffee flavor, were measured in the gas stream at the exit from the roaster using online Selected Ion Flow Mass Spectrometry (SIFT-MS) and were compared to the amounts retained in the final coffee extract. -

Evolution of Coffee Roasting

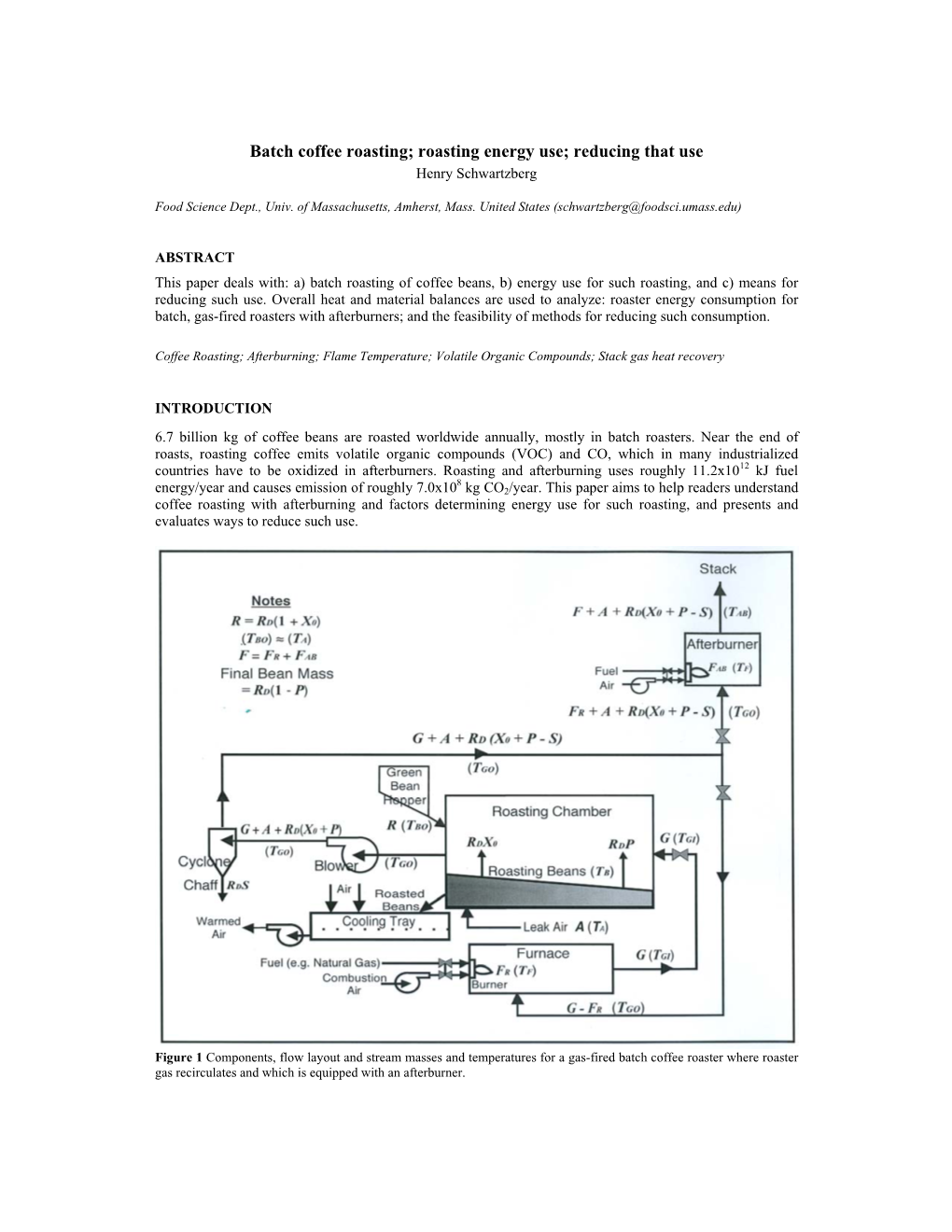

Introduction: In order of presentation, this paper describes: batch coffee roasting in general; batch roasting systems used in the 1950's; conventional methods for controlling coffee roasting; new batch roasting systems introduced in the past 35 years; the development of fast-roasted, high- yield coffee; fluidized-bed roasters; continuous roasters; pollution control for roasting; new knowledge about roasting chemistry; and new roasting control methods.. Batch Roasters with Gas Recirculation Fig.1 schematically depicts a typical industrial-scale, batch, coffee roasting system used in the 1940's. The same basic system is used today. It consists of: 1):a hopper containing a preweighed charge of green coffee beans; 2) a roasting chamber through which hot gas passes and into which, at the start of a roast, the green bean charge is dumped and where bean roasting and mixing occur; 3) a spray lance through which a metered volume of water is sprayed on the beans so as to quickly cool them to slightly more than 100oC and rapidly terminate the roast; 4) a normally-closed port that is opened to discharge beans after the end of a roast; 5) a damper that interrupts gas flow through the roasting chamber during bean quenching and unloading and that regulates pressure in the roasting chamber during roasting; 5) a furnace which heats roaster gas by admixing hot combustion products generated by burning a fuel gas or, less frequently, fuel oil; 6) a small blower that delivers air to the burner in the furnace; 7) effectively coupled valves that control the -

Effect of Green and Degree of Roasted Arabic Coffee on Hyperlipidemia and Antioxidant Status in Diabetic Rats

Advance Journal of Food Science and Technology 5(5): 619-626, 2013 ISSN: 2042-4868; e-ISSN: 2042-4876 © Maxwell Scientific Organization, 2013 Submitted: January 03, 2013 Accepted: January 31, 2013 Published: May 05, 2013 Effect of Green and Degree of Roasted Arabic Coffee on Hyperlipidemia and Antioxidant Status in Diabetic Rats 1Gaafar M. Ahmed and 2Heba E. El-Ghamery and 3Mahmuod F. Samy 1Food Technology Research Institute, Agricultural Research Center, Giza, Egypt 2Faculty of Education, King Khalid University, Saudi Arabia 3Department of Biotechnology, Faculty of Science, Taif University, Taif, Kingdom of Saudi Arabia Abstract: This study aims to examine the effects of green and different roasted degree of Arabic coffee on alloxan induced diabetes in rats. Animals were allocated into five groups of six rats each: a normal control group, diabetic group, diabetic rats fed with green Arabic coffee, diabetic rats fed with light roasted coffee and diabetic rats fed with dark roasted coffee group. The results showed increasing roasting degrees led to a decrease in moisture, radical- scavenging activity and total phenols. The diabetic rats presented a significant increase in blood glucose, plasma lipid profile compared to the control group. In addition, plasma malonaldialdehyde levels significantly increased compared to normal control group. Antioxidant enzymes activities such as superoxide dismutase and reduced Glutathione (GSH) levels significantly decreased in the plasma of diabetic rats compared to normal controls. The results showed that the experimental rats supplemented by green and roasted Arabic coffee significant increased feed efficiency ratio than diabetic control group. At the end of the study period, the experimental rats were showed significant improvement in blood glucose. -

Roasting the First Time

ARTICLE REPRINT RULING THE ROAST Roast Right The First Time How To Prevent Inconsistencies, Deficiencies and Errors This article was originally by Willem J. Boot published in the July/August 2005 issue of Roast ONE OF MY PREVIOUS ARTICLES roasting defects to occur when any of these described various examples of roasting defects factors is not adequately managed. and how to deal with them in your coffee roasting business. In the past year, I have Roasting defects fall into three main received a lot of feedback from roasters in and categories: outside the United States who, after reading my • Roasting inconsistencies, the most articles, confessed that they had noticed many common type and the easiest to opportunities for change in their own roasting prevent. practice. Over the last year, I’ve also noticed • Roasting deficiencies caused by that many roasters find it easy to take small ignorance of process or market errors and defects for granted. Most likely, this requirements attitude stems from the fact that in the majority • Roasting errors that actually damage the of specialty businesses, roasting is done very bean, like tipping, scorching, baking or frequently; as a result, the roaster might easily bean cracks. fall into the habit of thinking that the consumer won’t notice a slight variation in the roast degree or roast profile. Thus, it seemed like a Roasting Inconsistencies good time to look at some additional common examples of roasting defects and explore simple Roasting inconsistencies are the most strategies to help prevent them. common form of defect, and I see them In the art and practice of coffee roasting, more often than you might imagine. -

Heavy-Metal Contents and the Impact of Roasting on Polyphenols, Caffeine, and Acrylamide in Specialty Coffee Beans

foods Article Heavy-Metal Contents and the Impact of Roasting on Polyphenols, Caffeine, and Acrylamide in Specialty Coffee Beans Matúš Várady 1,*, Sylwester Slusarczyk´ 2 , Jana Boržíkova 3, Katarína Hanková 4, Michaela Vieriková 4, Slavomír Marcinˇcák 1 and Peter Popelka 1,* 1 Department of Food Hygiene, Technology and Safety, University of Veterinary Medicine and Pharmacy, Komenského 73, 041 81 Košice, Slovakia; [email protected] 2 Department of Pharmaceutical Biology and Botany, Wroclaw Medical University, Borowska 211, 50-556 Wroclaw, Poland; [email protected] 3 State Veterinary and Food Institute Dolný Kubin, Hlinkova 619, 043 65 Košice, Slovakia; [email protected] 4 State Veterinary and Food Institute Dolný Kubin, Jánošková 1611, 026 01 Dolný Kubín, Slovakia; [email protected] (K.H.); [email protected] (M.V.) * Correspondence: [email protected] (M.V.); [email protected] (P.P.); Tel.: +42-19-0280-7549 (M.V.); +42-19-0511-0774 (P.P.) Abstract: The aim of this study was to determine the effect of roasting on the contents of polyphenols (PPH), acrylamide (AA), and caffeine (CAF) and to analyze heavy metals in specialty coffee beans from Colombia (COL) and Nicaragua (NIC). Samples of NIC were naturally processed and COL was fermented anaerobically. Green beans from COL (COL-GR) and NIC (NIC-GR) were roasted ´ Citation: Várady, M.; Slusarczyk, S.; at two levels, light roasting (COL-LIGHT and NIC-LIGHT) and darker roasting (COL-DARK and Boržíkova, J.; Hanková, K.; Vieriková, NIC-DARK), at final temperatures of 210 ◦C (10 min) and 215 ◦C (12 min), respectively. -

Understanding the Formation of CO2 and Its Degassing Behaviours in Coffee

Understanding the Formation of CO2 and Its Degassing Behaviours in Coffee by Xiuju Wang A Thesis presented to The University of Guelph In partial fulfilment of requirements for the degree of Doctor of Philosophy in Food Science Guelph, Ontario, Canada © Xiuju Wang, May, 2014 ABSTRACT UNDERSTANDING THE FORMATION OF CO2 AND ITS DEGASSING BEHAVIOURS IN COFFEE Xiuju Wang Advisor: University of Guelph, 2014 Professor Loong-Tak Lim In the present study, the effect of roasting temperature-time conditions on residual CO2 content and its degassing behaviours in roasted coffee was investigated. The results show that the residual CO2 content in the roasted coffee beans was only dependent on the degree of roast and independent on the roasting temperature applied. However, CO2 degassing was shown significantly faster (p<0.05) in roasted coffee processed with high- temperature-short-time (HTST) than those roasted with low-temperature-long-time (LTLT) process. Moreover, the CO2 degassing rate increased with the degree of roast. CO2 degassing in ground coffee was significantly faster than in whole beans with the rate highly dependent on the grind size and roasting temperature, but less dependent on the degree of roast. CO2 degassing rate increased with the increasing of environmental temperature and relative humidity. Although CO2 degassing has been a challenging problem in the coffee industry for decades, there is still no clear understanding of precursors of CO2. In the present study, the hypothesis of “chlorogenic acid (CGA) is the principal precursor of CO2” was tested. Although strong negative linear correlation (R2>0.9) between total CGA and residual CO2 content during coffee roasting was detected, and vanishing of IR bands of the C=O group in caffeic acid and quinic acid moieties during heating of pure CGA at coffee roasting temperature was observed, the quantification analysis of CO2 generation from pure CGA heating indicated only ~ 8% yields at 230°C, which led us to conclude that CGA was one of the CO2 precursors but not the principal one. -

Checklist (Pdf)

CONTENTS 5 CASES NET TRADE MARK COFFECOFFEEE& & CCUULLTTUURREE L������ L������ U��������� �� C���������, I����� C������ �� R������� L���������: R������ I������, D����� T����, ��� J��� S����� - 1 - An exhibit in the UC Irvine Langson Library Muriel Ansley Reynolds Exhibit Gallery November 2014 - April 2015 Featuring a talk by the Steven Topik UCI Professor of History and Martin Diedrich Founder & Master Roaster, Kéan Coffee THE UC IRVINE LIBRARIES • IRVINE, CALIFORNIA • 2014 Welcome to the UC Irvine Libraries’ Fall exhibit, From Bean to Brew: Coffee and Culture! From Bean To Brew highlights the adoption of coffee as a widely consumed beverage and spans areas covering coffee production, the marketing of coffee, and the modern economics of coffee. The exhibit also showcases coffee culture in Orange County. We are honored to have Steven Topik, UCI Professor of History, and Martin Diedrich, Founder and Master Roaster of Kéan Coffee, as opening night speakers at our event on November 12, 2014. Professor Topik specializes in world history through the study of commodities, especially coffee. He has authored, co-authored, and edited several books including “The Global Coffee Economy in Africa, Asia and Latin America, 1500-1989”, and is currently working on a world history of coffee since 1500. Mr. Diedrich founded Diedrich Coffee in Costa Mesa in 1984 and Kéan Coffee in 2005. He is considered one of the pioneers of the coffeehouse phenomenon and is an internationally recognized coffee expert. This exhibit will be on display through mid-April 2015 during regular library hours. I hope you enjoy learning about the evolution of coffee. I invite you to view additional thought provoking exhibits at the UCI Libraries in the future. -

Comparative Study of Mineral Elements and Caffeine in Imported

Available online www.jocpr.com Journal of Chemical and Pharmaceutical Research, 2016, 8(9):111-116 ISSN : 0975-7384 Research Article CODEN(USA) : JCPRC5 Comparative Study of Mineral Elements and Caffeine in Imported Coffee Varieties Affected by the Degree of Roasting by HPLC Analysis Sahar Aghanuri1, Maryam Salami2 and Parisa Ziarati1,3* 1Department of Food Sciences & Technology, Pharmaceutical Sciences Branch, Islamic Azad University, Tehran, Iran 2Departemnt of Food Science & Engineering, College of Agriculture and Natural Resources, Tehran University, Karaj, Iran 3Department of Medicinal Chemistry, Pharmacy Faculty, Pharmaceutical Sciences Branch, Islamic Azad University Tehran, Iran ___________________________________________________________________________________ ABSTRACT Factors influencing coffee consumption in the importing countries vary widely. The popularity and worldwide appeal of coffee, which stems from its unique flavor, make it currently one of the most desirable and frequently consumed beverages. Coffee beans found on the market are produced from two different species of Coffea genus: Coffea arabica and Coffea canephora syn. Coffea robusta. The objective of current study was to determine the content of caffeine in Green coffee beans of two varieties (Coffea Arabica Santus from Brazil and Coffea Canephora :Rubusta) from Vietnam as well as coffee beans roasted in three roasting degrees (light, medium and dark) . The coffee varieties analyzed in this study (Vietnam, Brazil) were obtained from importer coffee in Iran. Green beans of each coffee variety were ground with coffee mill and then roasted. Three different roasting degrees (coffee roasting at 250 oC for different roasting times - 8, 15 and 20 min called: light, medium and dark roasted coffee samples. Caffeine in coffee samples was extracted with water and magnesium oxide.