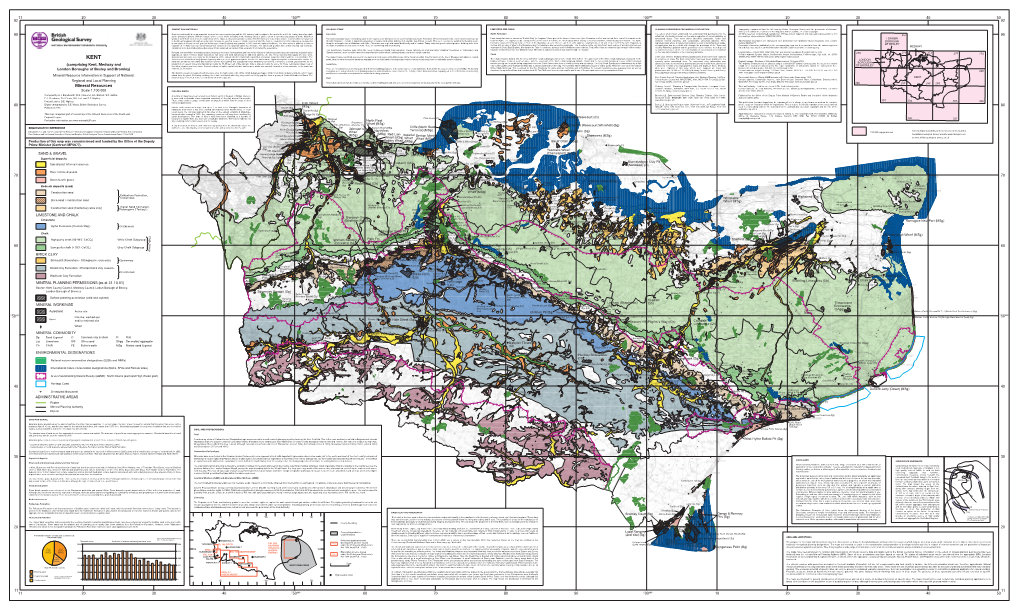

Mineral Resources Map for Kent

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Bus and Rail Guide

FREQUENCY GUIDE FREQUENCY (MINUTES) Chatham Town Centre Gillingham Town Centre Monday – Friday Saturday Sunday Operator where to board your bus where to board your bus Service Route Daytime Evening Daytime Evening Daytime Evening 1 M Chatham - Chatham Maritime - Dockside Outlet Centre - Universities at Medway Campus 20 minutes - 20 minutes - hourly - AR Destination Service Number Bus Stop (- Gillingham ASDA) - Liberty Quays - The Strand (- Riverside Country Park (Suns)) Fort Amherst d t . i a e Hempstead Valley 116 E J T o e t Coouncil Offices r . R t e Trinity Road S d R e 2 S M Chatham - Chatham Maritime - Dockside Outlet Centre 20 minutes 20 minutes 20 minutes 20 minutes 20 minutes 20 minutes AR m Medway r u ll t Liberty Quays 176 177 (Eves/Sun) D H D o PUBLIC x rt Y i S ha Park o O K M A CAR F n t 6*-11* Grain - Lower Stoke - Allhallows - High Halstow - Hoo - Hundred of Hoo Academy school - - - - - AR 16 e C C e PPARKARK d ro Lower Halstow 326 327 E J e s W W r s Chathamtham Library K i r T Bus and rail guide A t A E S 15 D T S R C tr E E e t 100 M St Mary’s Island - Chatham Maritime - Chatham Rail Station (see also 1/2 and 151) hourly - hourly - - - AR and Community Hub E e t O 19 R E Lower Rainham 131* A J T F r R e A R F e T e E . r D M T n S t Crown St. -

Monitoring and Predicting Railway Subsidence Using Insar and Time Series Prediction Techniques

Monitoring and Predicting Railway Subsidence Using InSAR and Time Series Prediction Techniques ZIYI YANG A thesis submitted to The University of Birmingham for the degree of DOCTOR OF PHILOSOPHY School of Civil Engineering College of Engineering and Physical Sciences The University of Birmingham, UK March 2015 University of Birmingham Research Archive e-theses repository This unpublished thesis/dissertation is copyright of the author and/or third parties. The intellectual property rights of the author or third parties in respect of this work are as defined by The Copyright Designs and Patents Act 1988 or as modified by any successor legislation. Any use made of information contained in this thesis/dissertation must be in accordance with that legislation and must be properly acknowledged. Further distribution or reproduction in any format is prohibited without the permission of the copyright holder. Abstract Abstract Improvements in railway capabilities have resulted in heavier axle loads and higher speed operations. Both of these factors increase the dynamic loads on the track. As a result, railway subsidence has become a threat to good railway performance and safe railway operation. Poor infrastructure performance requires more maintenance work, and therefore the life cycle costs of the railway will increase. In order to ensure good performance and reduce life cycle costs, railway subsidence should be monitored and predicted. The author of this thesis provides an approach for railway performance assessment through the monitoring of railway subsidence and prediction of railway subsidence based on a time series of Synthetic Aperture Radar (SAR) images. The railway is a long and relatively narrow infrastructure, which subsides continuously over a long time period. -

TIMETABLE 142 & 185.Cdr

TIMETABLE OF ALL BUSES AT DAVIS ESTATE BUS 185 Mondays to Fridays - not Bank, National or Public Holdays Nu-Venture service number 185 185 185 185 185 185 185 185 185 185 CHATHAM WATERFRONT BUS STN STOP A7 - - 1018 1108 1158 a 1248 e 1350 1550 1705 1815 Chatham Station - - 1021 1111 1201 a 1251 e 1353 1553 1708 1818 Grosvenor Avenue - - 1024 1114 1204 a 1254 e 1356 1556 1711 1821 Wilson Avenue/Wallace Road - - 1027 1117 1207 a 1257 e 1359 1559 p - - Huntsmans Corner - - - - - - - 1559 z 1714 1824 Blue Bell Hill Village 0747 - - - - - - - - - Bridgewood Roundabout northbound 0751 - - - - - - - - - Davis Estate Vale Road 0758 0915 1030 1120 1210 a 1300 e R R R R Davis Estate opp Holland Rd Shops 0802 0920 1035 1125 1215 a 1305 e R R R R Davis Estate Shirley Ave Shops, Post Office 0806 0926 1041 1131 1221 a 1311 e R R R R Bridgewood Roundabout southbound - - - - - - - R R - Blue Bell Hill Village - - - - - - - R R - Wilson Avenue/Wallace Road - 0930 1045 1135 1225 a 1315 e - - - - Huntsmans Corner 0810 - - - - - - - - - Grosvenor Avenue 0813 0933 1048 1138 1228 a 1318 e - - - - CHATHAM WATERFRONT BUS STATION 0820 0939 1054 1144 1234 a 1324 e - - - - Saturdays - also work-days between Christmas and New Year Nu-Venture service number 185 185 185 185 185 185 CHATHAM WATERFRONT BUS STN STOP A7 - 0956 1156 1356 1550 1730 Chatham Station - 0959 1159 1359 1553 1733 Grosvenor Avenue - 1002 1202 1402 1556 1736 Huntsmans Corner - 1005 1205 1405 1559 1739 Blue Bell Hill Village 0752 - - - - - Bridgewood Roundabout northbound 0756 - - - - - Davis Estate Vale Road 0803 1008 1208 1408 R R Davis Estate opp Holland Rd Shops 0807 1013 1213 1413 R R Davis Estate Shirley Ave Shops, Post Office 0811 1019 1219 1419 R R Bridgewood Roundabout southbound - - - - R R Blue Bell Hill Village - - - - R R Huntsmans Corner 0815 1023 1223 1423 - - Grosvenor Avenue 0818 1026 1226 1426 - - CHATHAM WATERFRONT BUS STATION 0825 1032 1232 1432 - - NO SERVICE ON SUNDAYS, BANK, NATIONAL OR PUBLIC HOLIDAYS, OR ON 1 JANUARY, 25/26 DECEMBER. -

The Warren Farm Chamber: a Reconsideration

http://kentarchaeology.org.uk/research/archaeologia-cantiana/ Kent Archaeological Society is a registered charity number 223382 © 2017 Kent Archaeological Society THE WARREN FARM CHAMBER: A RECONSIDERATION PAUL ASHBEE At least seven ruined but recognisable stone-chambered long barrows, Kit's Coty House being the best known, still remain in the Medway valley where that river cuts through the chalk of the North Downs. They had exceptionally high rectangular chambers, proportional facades, and stone kerbs. In plan they recall the southern English earthen long barrows, originally of timber, such as Fussell's Lodge in Wiltshire (Ashbee 1966). They are distinct from other groups and are likely to have been versions of the stone-built long barrows of Holland and Northern Germany (Ashbee 1999). The Medway's megalithic long barrows (Fig. 1), like others of their kind, were surrogate long houses (Ashbee 1999, 270) and also repositories for human remains rather than mere tombs. There may have been centuries of recourse to them, before they were finally sealed with occupation debris (Piggott 1962, 26; Woodward 1993). Their construction with sarsen stones, some of almost Stonehenge calibre, required considerable labour, while they cannot but have fulfilled a central role for the Neolithic communities of the terrain that was to become Kent. Early in 1822 the great stones of a long barrow chamber's remnant part were encountered, just within the 300ft contour, and close by Warren Farm, on Blue Bell Hill (NGR TQ 753 606). An obstruction to ploughing had led to digging which disclosed large sarsen stones just below the surface. George Fowle, of Cobtree Manor, the landowner, ordered their removal, but when three uprights emerged he determined that they should be uncovered. -

The South East and the Midwest of England Tour of Castles And

Welcome to The South East and the Midwest of England Tour of Castles and Mansions Explore and Feel the History A 14 day packaged Tour starting August 30, 2019 Leave your luggage at a Hotel location and enjoy up to 11 separate guided day tour trips staying at only 3 hotels returning to your accommodation each evening No daily unpacking and packing Total one price package to include: Domestic and International flights – Transportation to and from the Airport Hotel accommodation Bed and Breakfast Entrance Fees and Day time lunches as indicated From $2,573.00 Per Person Sharing plus Flight Costs $846.00 Supplement for Single Person Call Barry Devo 330 284 4709 (Est) Or email [email protected] Prepco Island Vacations and Tours LLC 3687 Dauphin Drive NE., Canton, OH 44721 ITINERARY OVERVIEW for A Tour of English Castles and Mansions DAY DATE DAY 1 Aug 30 Friday Depart US location 2 Aug 31 Saturday Arrive London Heathrow Airport. Lunch will be provided but dependent on flight arrival time. Meet and travel 10 Miles West to Windsor Hotel Bed and Breakfast for 2 nights 3 Sept 1 Sunday Day at Windsor Castle. Entrance Fee and Lunch included 4 Sept 2 Monday Check out Windsor Hotel travel 30 Miles to Tower of London. Entrance Fee and Lunch included followed by onward Travel 62 Miles to Canterbury Hotel Bed and Breakfast for 5 nights 5 Sept 3 Tuesday Travel 30 Miles to Leeds Castle. Entrance Fee and Lunch included 6 Sept 4 Wednesday Travel 65 Miles to Hever Castle. Entrance Fee and lunch included 7 Sept 5 Thursday Travel 37 Miles to Scotney Castle. -

My Ancestors Who Lived in Leeds Castle (And Some of Them Even Owned It!)

Chapter 75 My Ancestors Who Lived in Leeds Castle (and Some of Them Even Owned It!) [originally written 4 January 2021] On 20 December 2020, Russ Leisenheimer posted a photo of a sunset over Leeds Castle to his Facebook page.1 Russ was one of my high school classmates in Euclid, Ohio, and he still lives in the Cleveland area. Here is the photo: I have been using the “World Family Tree” on Geni.com to investigate my European ancestors who lived during the Middle Ages, and seeing the photo of Leeds Castle got me to wondering if any of my ancestors lived there. OK, I realized that this was going to be a long shot, but due to the coronavirus pandemic, I have lots of free time to look into such seemingly trifling things. I immediately went to Wikipedia.org to learn about Leeds Castle, and that prompted the following reply to Russ on Facebook: Wikipedia states that “Leeds Castle is a castle in Kent, England, 5 miles (8 km) southeast of Maidstone. A castle has existed on the site since 1119, the first being a simple stone stronghold constructed by Robert de Crevecoeur which served as a military post in the time of Norman intrusions into England. In the 13th century, it came into the hands of King Edward I, for whom it became a favourite residence; in the 16th century, Henry VIII used it as a dwelling for his first wife, Catherine of Aragon.” According to the World Family Tree on Geni.com, Robert de Crevecoeur was my 25th great uncle. -

Malherbe Monthly

Malherbe Monthly Number 37 August 2007 Incorporating Liverton Street & Platts Heath Useful contact names and telephone Nos. BOUGHTON MALHERBE/GRAFTY GREEN County Councillor Lord Sandy Bruce-Lockhart 890651 Borough Councillors Jenny Gibson 890200 Richard Thick 891224 Church Wardens Kenneth Alexander 858348 Joan Davidson 850210 Parish Council Clerk Pat Anderson 858350 Village Hall Doreen Walters 850387 bookings KM Correspondent Sylvia Close 858919 Gardening Club Sue Burch 850381 Church Choir Doreen Hulm 850287 Sunday School Mair Chantler 859672 Yoga Liz Watts 737321 Neighbourhood Keith Anderson 858350 Watch Sue Burch 850381 Incumbent To be announced Benefice Office Michelle Saunders (email: 850604 [email protected]) Mobile Library Wednesday afternoons St. Edmunds Centre Tricia Dibley 858891 Fresh Fish delivery Thursday afternoons at approx. 3.30 by Post Office Council Rubbish See article in magazine Freighter Malherbe Monthly Production Team Chris King Advertising: [email protected] 850711 Mike Hitchins Editor: [email protected] 858937 John Collins Treasurer 850213 The views expressed in “Malherbe Monthly” are not necessarily those of the Production Team; publication of articles/adverts does not constitute endorsement and we reserve the right to edit! Anything for the September edition should be left in Grafty Green Shop, or contact Mike on 01622 858937 ([email protected]) by 15th August Front cover: The Post bus leaves Grafty Post Office – but not for long!! Photograph courtesy of John Collins – 17th July 2007 News from St. Nicholas Church Cream Teas Cream teas are now being served at St. Nicholas. We have been lucky with the weather for the first two Sundays in July and hope our luck will hold for the rest of the Summer. -

FOI-7131-Response-Public-House

Maidstone Borough Council Freedom of Information Act Request Ref: FOI 7131 Date: 21 May 2018 Request and Response Can you supply me a list of all properties receiving public house rate relief in the form of a spreadsheet. Please include rateable value, property description, property address and account name in the case of limited companies. RV Property Ref Liable Name 1 Property Address 2 Property Address 3 Property Address 4 Postcode 2017 Property Description PUBLIC HOUSE AND 10363616008300 ALL RAPPED UP LTD WINDMILL INN 32 EYHORNE STREET HOLLINGBOURNE MAIDSTONE, KENT ME17 1TR £28,500 PREMISES PUBLIC HOUSE AND 10272764003400 ASPREY LICENSED PREMISES LTD KINGS ARMS THE STREET BOXLEY MAIDSTONE, KENT ME14 3DR £30,750 PREMISES PUBLIC HOUSE AND 10050525001801 BAR 6 LTD BAR 6 14 MIDDLE ROW MAIDSTONE KENT ME14 1TG £44,400 PREMISES PUBLIC HOUSE AND 10383833000100 BUSY GUYS LIMITED PLOUGH SUTTON ROAD LANGLEY MAIDSTONE, KENT ME17 3LX £17,250 PREMISES PUBLIC HOUSE AND 10080208007200 THE RATEPAYER THE STYLE & WINCH 72 UNION STREET MAIDSTONE KENT ME14 1ED £25,750 PREMISES DOMINION HOTELS AND INNS WEST STREET PUBLIC HOUSE AND 10343401000600 LTD ROEBUCK INN, HARRIETSHAM MAIDSTONE KENT ME17 1HX £21,250 PREMISES PUBLIC HOUSE AND 10313148001700 DONOHUE ENTERPRISE LIMITED COCK HORSE INN 39 THE STREET DETLING MAIDSTONE, KENT ME14 3JT £28,000 PREMISES PUBLIC HOUSE AND 10010561017600 GREENE KING PLC BULL INN PENENDEN HEATH MAIDSTONE KENT ME14 2DH £72,500 PREMISES PUBLIC HOUSE AND 10030013002400 GREENE KING PLC DRUIDS ARMS 24 EARL STREET MAIDSTONE KENT ME14 -

The Medway Megaliths and Neolithic Kent

http://kentarchaeology.org.uk/research/archaeologia-cantiana/ Kent Archaeological Society is a registered charity number 223382 © 2017 Kent Archaeological Society THE MEDWAY MEGALITHS AND NEOLITHIC KENT* ROBIN HOLGATE, B.Sc. INTRODUCTION The Medway megaliths constitute a geographically well-defined group of this Neolithic site-type1 and are the only megalithic group in eastern England. Previous accounts of these monuments2 have largely been devoted to their morphology and origins; a study in- corporating current trends in British megalithic studies is therefore long overdue. RECENT DEVELOPMENTS IN BRITISH MEGALITHIC STUDIES Until the late 1960s, megalithic chambered barrows and cairns were considered to have functioned purely as tombs: they were the burial vaults and funerary monuments for people living in the fourth and third millennia B.C. The first academic studies of these monuments therefore concentrated on the typological analysis of their plans. This method of analysis, though, has often produced incorrect in- terpretations: without excavation it is often impossible to reconstruct the sequence of development and original appearance for a large number of megaliths. In addition, plan-typology disregards other aspects related to them, for example constructional * I am indebted to Peter Drewett for reading and commenting on a first draft of this article; naturally I take responsibility for all the views expressed. 1 G.E. Daniel, The Prehistoric Chamber Tombs of England and Wales, Cambridge, 1950, 12. 2 Daniel, op. cit; J.H. Evans, 'Kentish Megalith Types', Arch. Cant, Ixiii (1950), 63-81; R.F. Jessup, South-East England, London, 1970. 221 THE MEDWAY MEGALITHS GRAVESEND. ROCHESTER CHATHAM r>v.-5rt AYLESFORD MAIDSTONE Fig. -

Item C1 TM/10/2029 – PROPOSED WESTERLY EXTENSION to HERMITAGE QUARRY, HERMITAGE LANE, AYLESFORD, KENT

SECTION C MINERALS AND WASTE DISPOSAL Background Documents - the deposited documents, views and representations received as referred to in the reports and included in the development proposals dossier for each case and also as might be additionally indicated. Item C1 TM/10/2029 – PROPOSED WESTERLY EXTENSION TO HERMITAGE QUARRY, HERMITAGE LANE, AYLESFORD, KENT A report by Head of Planning Applications Group to Planning Applications Committee on 10 May 2011. Planning application TM/10/2029 Proposed westerly extension to Hermitage Quarry, Hermitage Lane, Aylesford, Kent (MR. 717 556) Recommendation: Permission be granted subject to conditions. Local and adjoining Member(s): Mrs T Dean, Mrs P Stockell, Mr P Homewood, Mr D Daley, Mr M Robertson, Mrs V Dagger, Mrs S Hohler and Mr R Long, Classification: Unrestricted Background 1. The existing Hermitage Quarry lies within the strategic gap between Allington, to the east, the village of Aylesford, to the north and Barming Heath to the south. It forms part of 230ha of the Hermitage Farm Estate which comprises agricultural land and woodland as well as the quarry itself. The existing quarry has a purpose built access onto Hermitage Lane (B2246), leading to the A20 and M20 at junction 5. 2. Operational since 1990, the quarry is currently operating within an eastern extension area permitted under planning permission reference TM/05/2784. As part of the overall working plan, the consented phased working and restoration scheme requires the operator to work the site in an east to south direction, with final permitted reserves being worked in the permitted western extension (reference TM/02/2782) before infilling and restoration of the final phase which is currently occupied by the plant site area. -

Industrial Units & Open Storage Land

Industrial Units & CORE COMMERCIAL Open Storage Land Former Funton Brickworks Sheerness Road, Lower Halstow SITTINGBOURNE Kent ME9 7EG 16 acres plus extensive buildings Produced and copyright by Core Commercial Former Funton Brickworks Sheerness Road, Lower Halstow SITTINGBOURNE CORE COMMERCIAL Kent ME9 7EG Lower Halstow 59,000 sqft on 8 acres PRODUCED & COPYRIGHT BY CORE COMMERCIAL Location RASPBERRY Sittingbourne is about 50 miles east of london, north of HILL LANE the M2 motorway. The property is about 4 miles north west of Sittingbourne in a rural position. LOWER A249 Description HALSTOW SHEERNESSROAD A former brickworks comprising a range of old industrial IWADE buildings and two cottages on a mostly concreted site of 7 acres plus a further 9 acres of land at the eastern end of the site that was used for brickearth storage. Accommodation BOBBING Western end site - 7 acres A2 A range of former brickwork buildings totalling some 59,000 sqft of buildings in a generally poor condition. SITTINGBOURNE There are large areas of concrete hardstanding previously NEWINGTON used for open brick storage. There are also two 3 A2 bedroomed residential cottages. A249 PRODUCED & COPYRIGHT BY CORE COMMERCIAL Eastern end site - 9 acres This area was previously used for the open storage of brickearth. Services: Substantial mains gas available, electricity and borehole water extraction. Terms To let on flexible terms or may sell freehold. Contact David Marriott or Neil Mason 01892 834483 www.CoreCommercial.co.uk N These particulars are provided in good faith but do not form part of a contract. No statements are to be relied upon as statements of fact and parties intending to rely upon the information for any purpose whatsoever must satisfy themselves by inspection or otherwise as to the correctness of each statement Not to scale Produced and copyright by Core Commercial Core Commercial Limited, Maidstone Road, Paddock Wood, Kent TN12 6DA Fax: 01892 833921 [email protected] www.CoreCommercial.co.uk 01892 834483. -

Brickearth Soils in the South-East New Forest Are Well Drained

BRIGKEARTH, AND ITS INFLUENCE ON THE CHARACTER OF SOILS, IN THE SOUTH-EAST NEW FOREST By G. C. FISHER I. INTRODUCTION BRICKEARTH is an indefinite geological term applied to loamy, superficial deposits of Quaternary age. Structureless deposits of brickearth are common in Southern and Eastern England and in most, particles in the size range iojxm to 200(j.m are dominant. The Geological Survey maps a number of patches of brickearth in the south western New Forest, most notably at Barton-on-Sea. Additional deposits of brickearth have been described from the New Forest (White 1915, Everard 1952, Lewin 1966a) and the author records several more in this paper for the south-east of the area. The first aim of the work here recorded was to determine the extent of brickearth deposits in the south-east corner of the New Forest. Everard (1952) provides a very general map of brickearth distribution around Southampton Water which shows a large deposit at Fawley not recorded by the Geological Survey. As well as adding to the map of Everard an attempt was made to locate shallow deposits of brickearth, not mappable by the geologist, but which may make an important contribution to soils. A further aim of the work was to try and determine the origin of the brickearth. Some brickearths have been described, especially from Kent (Pitcher et al 1954, Dines et al 1954), which have a particle size distribution which shows them to be true loesses, i.e. 50 per cent of the particles have diameters in the range 10 |un to 50 (im (Russell 1944, Pecsi 1968).