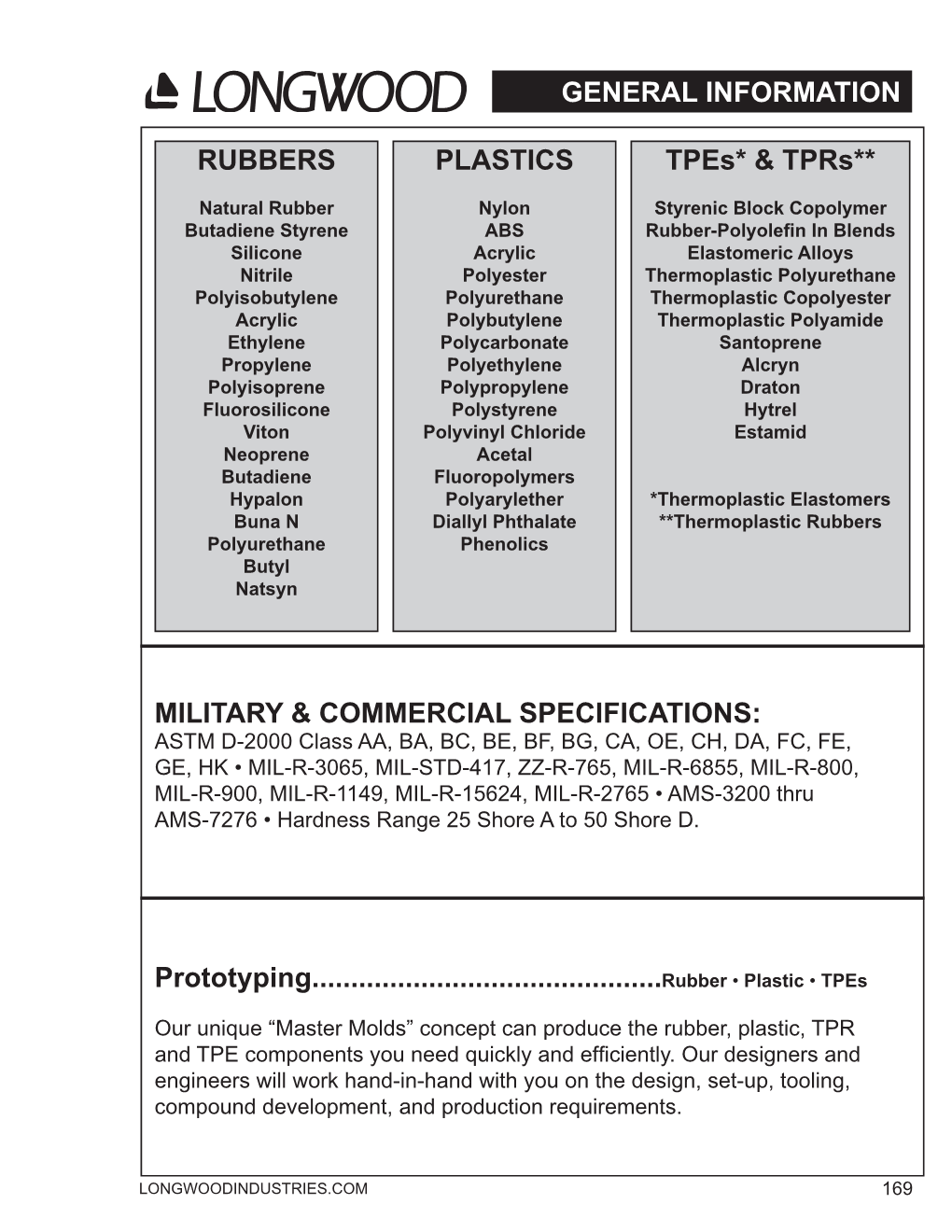

General Information Rubbers Plastics

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Bioinspired Surfaces Adapted from Lotus Leaves for Superliquiphobic Properties DISSERTATION Presented in Partial Fulfillment Of

Bioinspired Surfaces Adapted from Lotus Leaves for Superliquiphobic Properties DISSERTATION Presented in Partial Fulfillment of the Requirements for the Degree Doctor of Philosophy in the Graduate School of The Ohio State University By Samuel Graeme Martin, M.S. Graduate Program in Mechanical Engineering The Ohio State University 2017 Dissertation Committee: Professor Noriko Katsube, Advisor Professor Anthony Luscher Professor Shaurya Prakash Copyrighted by Samuel Graeme Martin 2017 Abstract Nature can be turned to for inspiration into novel engineering designs that help address scientific difficulties. Through evolution, nature has created efficient and multipurpose objects using commonly occurring materials. These objects have many applications that can aid humanity and can be of commercial interest. One technical difficulty that nature can help solve includes liquid repellency. Inspiration for extreme liquid repellency, also known as superliquiphobicity, can be found on lotus leaves (Nelumbo nucifera) due to their extreme water repellency. The motivation for studying the surface of lotus leaves is that their unique surface features can be adapted for commercial applications to save time, money, and lives. Nature has a limited material toolbox, but by incorporating synthetic materials and better manufacturing processes, the surface properties can be enhanced. Mimicking these biological structures and using them for design inspirations is the field of biomimetics. In this thesis, an introduction chapter on biomimetics and liquid repellency is first presented. These principles are referred to throughout the thesis for creating superliquiphobic surfaces. Next, a chapter on experimental procedure and sample characterization is presented. Afterwards, three chapters are presented containing original research on surfaces inspired by lotus leaves for liquid repellency. -

Mechanical Properties of Rubber

8434_Harris_33_b.qxd 09/20/2001 12:30 PM Page 33.1 CHAPTER 33 MECHANICAL PROPERTIES OF RUBBER Ronald J. Schaefer INTRODUCTION Rubber is a unique material that is both elastic and viscous. Rubber parts can there- fore function as shock and vibration isolators and/or as dampers.Although the term rubber is used rather loosely, it usually refers to the compounded and vulcanized material. In the raw state it is referred to as an elastomer. Vulcanization forms chem- ical bonds between adjacent elastomer chains and subsequently imparts dimen- sional stability, strength, and resilience. An unvulcanized rubber lacks structural integrity and will “flow” over a period of time. Rubber has a low modulus of elasticity and is capable of sustaining a deformation of as much as 1000 percent. After such deformation, it quickly and forcibly retracts to its original dimensions. It is resilient and yet exhibits internal damping. Rubber can be processed into a variety of shapes and can be adhered to metal inserts or mounting plates. It can be compounded to have widely varying properties.The load- deflection curve can be altered by changing its shape. Rubber will not corrode and normally requires no lubrication. This chapter provides a summary of rubber compounding and describes the static and dynamic properties of rubber which are of importance in shock and vibration isolation applications. It also discusses how these properties are influenced by envi- ronmental conditions. RUBBER COMPOUNDING Typical rubber compound formulations consist of 10 or more ingredients that are added to improve physical properties, affect vulcanization, prevent long-term dete- rioration, and improve processability.These ingredients are given in amounts based on a total of 100 parts of the rubber (parts per hundred of rubber). -

Ozone Resistance of Neoprene Rubber Sheet by Neoprene Rubber Sheet - [email protected], Date: Dec.10.06

Ozone resistance of neoprene rubber sheet By Neoprene Rubber Sheet - www.dongrubber.com, [email protected], Date: Dec.10.06 Neoprene rubber sheet is a polymer of good ozone resistance. According to the ozone resistance, elastomers can be divided into three categories: ① The elastomer itself has ozone resistance, which has no double bond or less double bonds saturated elastomer. Such as EPDM rubber, chlorosulfonated polyethylene, chlorinated polyethylene rubber and silicone rubber, etc. ② The elastomer which itself has good ozone resistance, and with the help of a formula can be obtained better ozone resistance, such as butyl rubber, neoprene rubber and so on. ③ The elastomer itself has poor ozone resistance, must cooperate with ozone resistance antiager, such as natural rubber, styrene butadiene rubber, butadiene rubber and butyl rubber, etc. Diene elastomer basically belongs to the third class, and why butyl rubber and neoprene rubber are listed in good ozone resistance of the second class? This is due to the low unsaturation of butyl rubber, similar to the low unsaturation elastomer with good ozone resistance. About neoprene rubber we can make the following instructions: olefins compounds after the double bond parts subjected to ozone, ozone compound generated, the ozonide is unstable, easy to crack, so as to cut the carbon-carbon main chain, namely the so-called "ozone cracking". This reaction can be interpreted as a double bond part with characteristics of nucleophilic carbon atoms react with oxygen atoms with characteristics of electrophilic in the ozone, and formed the ozonide. The nucleophilic properties of carbon atoms depend on the substituent of the molecule is easy to attract electrons or easy to emit electrons. -

Degradable Plastics Are Vulnerable to Cracks

Journal Pre-proofs Degradable plastics are vulnerable to cracks Xuxu Yang, Jason Steck, Jiawei Yang, Yecheng Wang, Zhigang Suo PII: S2095-8099(21)00148-X DOI: https://doi.org/10.1016/j.eng.2021.02.009 Reference: ENG 661 To appear in: Engineering Received Date: 30 August 2020 Revised Date: 13 January 2021 Accepted Date: 8 February 2021 Please cite this article as: X. Yang, J. Steck, J. Yang, Y. Wang, Z. Suo, Degradable plastics are vulnerable to cracks, Engineering (2021), doi: https://doi.org/10.1016/j.eng.2021.02.009 This is a PDF file of an article that has undergone enhancements after acceptance, such as the addition of a cover page and metadata, and formatting for readability, but it is not yet the definitive version of record. This version will undergo additional copyediting, typesetting and review before it is published in its final form, but we are providing this version to give early visibility of the article. Please note that, during the production process, errors may be discovered which could affect the content, and all legal disclaimers that apply to the journal pertain. The Authors Engineering 7 (2021) Research Green Chemical Engineering: Soft Materials—Letter Degradable Plastics Are Vulnerable to Cracks Xuxu Yang a,b, Jason Steck a, Jiawei Yang a, Yecheng Wang a, Zhigang Suo a,* a John A. Paulson School of Engineering and Applied Sciences, Kavli Institute for Bionano Science and Technology, Harvard University, Cambridge, MA 02138, USA b State Key Laboratory of Fluid Power and Mechatronic System, Key Laboratory of Soft Machines and Smart Devices of Zhejiang Province, Department of Engineering Mechanics and Center for X-Mechanics, Zhejiang University, Hangzhou 310027, China * Corresponding author. -

Troubleshooting

8 Troubleshooting Common Reasons for O-Ring Failure Compression Set O-rings typically fail in their applications because of Failure Pattern: Common to both static and dynamic the combined adverse effects of several environmental seals, compression set failure produces flat surfaces factors. on both sides of the O-ring’s cross section. The most common causes of O-ring failure have Problem Sources: Selection of elastomer with poor been found to be: compression set properties... Low heat resistance • Improper gland design: allowing for too much or of material... Excessive swelling of O-ring material in too little compression, not enough room for seal system fluid... Too much squeeze to achieve seal... expansion, and tolerance stack-up. Incomplete curing (vulcanization) of O-ring material during production. • Incorrect O-ring size. Suggested Solutions: Employ a low set elastomer... • Incompatibility of O-ring elastomer and Specify an O-ring material that resists both operating environmental elements. and friction generated heat... Re-check O-ring material • Improper O-ring installation. compatibility with system chemicals... Reduce O-ring squeeze if possible... Inspect incoming O-rings for • Inadequate O-ring lubrication. correct physical properties. The combination of stresses on the O-ring can be complex and difficult to evaluate. Therefore, it is very important that both the O-ring compound and size be tested in the real environment of its service. The following examples are a classification of the types of O-ring failure that can occur. Illustration 8.1 83 www.applerubber.com 1.800.828.7745 (US & Canada Only) • +1.716.684.6560 (International) Extrusion & Nibbling Abrasion Extrusion & Nibbling Failure Pattern: Typical of high Failure Pattern: Occurring primarily in dynamic seals pressure systems, this pattern can be identified by the involving reciprocating, oscillating, or rotary motion, many small bites (nibbles) taken from the O-ring on the this failure pattern can be identified by a flattened low pressure (downstream) side. -

Reaction of Moist Ozone with Natural Rubber: a Study by Attenuated Total Reflectance Spectroscopy

J.Rubb.Res., 1(3): 133-145 Reaction of Moist Ozone with Natural Rubber: A Study by Attenuated Total Reflectance Spectroscopy A.H. ENG ** **4t , S. KODAMA **, K. NAGATA ** AND H. KAWASAKI *** Surface treatment of prevulcanised latex film with ozone water leads to the formation of ester, aldehyde, and ketone groups as indicated by a FTIR-A TR study. In the presence of protems, the carbonyl oxide zwitterion intermediate reacts with the ammo groups of the protein to produce rubber-bonded protems on the surface. Reaction of moist ozone gas with dry rubber film produces more ozonides than with wet rubber gel and leads to the formation of visible cracks on the rubber surface. In the case of ozone-treated wet rubber gel, the tensile strength of the film remains high, indicating no significant ozone penetration. The reaction of ozone with natural rubber in the wet gel state may be used to chemically modify the surface of natural rubber products without sacrificing the excellent physical properties of the rubber Ozone attack on natural rubber was first cracks were found to develop simultaneously recognised as being important in the early 1950s on the rubber surface at the initial stage of the due to ozone cracking problems1. In the early reaction and then grow at a uniform rate. The stages of the reaction., ozone attack on natural net result is the formation of distinctive visible rubber double bonds occurs very rapidly at the cracks on the surfaces. In moist ozone, however, exposed surfaces. If stress is applied to the the crack's nuclei were reported to be rubber sample during ozonisation, degradation continuously created by localised attack between at regions of high strain, e.g. -

Determination of the Mechanical Properties of Rubber by FT-NIR

Hindawi Publishing Corporation Journal of Spectroscopy Volume 2016, Article ID 4024783, 7 pages http://dx.doi.org/10.1155/2016/4024783 Research Article Determination of the Mechanical Properties of Rubber by FT-NIR Rattapol Pornprasit,1 Philaiwan Pornprasit,2 Pruet Boonma,1 and Juggapong Natwichai1 1 Department of Computer Engineering, Faculty of Engineering, Chiang Mai University, Chiang Mai 50200, Thailand 2Rubber and Polymer Technology Program, Faculty of Engineering and Agro-Industry, Maejo University, Chiang Mai 50290, Thailand Correspondence should be addressed to Juggapong Natwichai; [email protected] Received 22 November 2015; Accepted 7 February 2016 Academic Editor: Vincenza Crupi Copyright © 2016 Rattapol Pornprasit et al. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. Mechanical tests, for example, tensile and hardness tests, are usually used to evaluate the properties of rubber materials. In this work, mechanical properties of selected rubber materials, that is, natural rubber (NR), styrene butadiene rubber (SBR), nitrile butadiene rubber (NBR), and ethylene propylene diene monomer (EPDM), were evaluated using a near infrared (NIR) spectroscopy technique. Here, NR/NBR and NR/EPDM blends were first prepared. All of the samples were then scanned using a FT-NIR spectrometer and fitted with an integration sphere working in a diffused reflectance mode. The spectra were correlated with hardness and tensile properties. Partial least square (PLS) calibration models were built from the spectra datasets with preprocessing techniques, that is, smoothing and second derivative. This indicated that reasonably accurate models, that is, with a coefficient of 2 determination [ ] of the validation greater than 0.9, could be achieved for the hardness and tensile properties of rubber materials. -

Global Cement: Conveying

GLOBAL CEMENT: CONVEYING Les Williams, Dunlop Conveyor Belting Invisible conveyor belt destroyers How ozone and ultraviolet light are dramatically shortening the working life of your cement plant’s conveyor belts... From protector to destroyer here are an awful lot of things that damage Tconveyor belts in cement plants. The constant Ozone (O3) occurs naturally in the upper atmos- abrasive action of material being loaded at speed onto phere, where it is formed continuously by the action the belt and then being accelerated across its surface of solar ultraviolet radiation on molecular oxygen at the discharge point; the hammering that the belt (O2). At high altitudes, O3 acts as a protective shield surface and its carcass takes as aggressive materials by absorbing harmful UV rays. Wind currents carry (often sharp and heavy) are dropped onto it; the rip- O3 to the atmosphere at the Earth’s surface. ping and tearing that occurs when rocks or foreign At low altitude, O3 becomes a pollutant. Ground objects become trapped; the softening and distortion level or ‘bad’ ozone is not emitted directly into the of the rubber caused by oils and resins; the hardening air, but is created by the photolysis of nitrogen di- and premature ageing of the rubber caused by heat. oxide (NO2) from vehicle exhausts and industrial The list goes on and on. discharges. The effects are known as ozonolysis. All of these factors are, of course, very well known The variability of weather, airflow patterns, sea- to operators of conveyors. The fact that conveyor belts sonal changes, vehicle and industrial emissions, can be engineered to significantly limit the amount of geographical and climatic conditions such as higher damage each of these factors can cause is also pretty altitudes and coastal areas mean that ozone concen- common knowledge. -

Ozone Detection by Crack-Induced Opacity in Rubber

Downloaded from http://polymerphysics.net OZONE DETECTION BY CRACK-INDUCED OPACITY IN RUBBER P. H. Mott Geo-Centers, Inc. Ft. Washington, MD 20744 C. M. Roland* Chemistry Division, Code 6126, Naval Research Laboratory, Washington, DC 20375-5342 ABSTRACT Initially transparent polybutadiene develops micron-sized surface cracks when stretched and exposed to ozone. The consequent reduction in the transparency of the rubber provides a facile method for quantifying the ambient ozone con- centration. The rate at which opacity develops is linearly dependent on the amount of ozone, and increases with increasing strain. This method of detecting atmospheric ozone has high sensitivity (1 ppb), a broad dynamic range, and is unaffected by the presence of other chemicals. The surface morphology of exposed material can be interpreted in terms of crack nucleation and growth. INTRODUCTION Ozone-induced stress cracking is normally considered a problem, diminishing the appearance and serviceability of rubber products. This cracking is the result of the rapid reaction of ozone with olefinic double bonds to form an ozonide ring.1 Scheme 1. Scission of the ring produces surface cracks when the elastomer is stretched. Previous studies of this phenomenon established the existence of three regimes2: (I) At sufficiently low stresses, no surface cracking occurs. (II) At intermediate stresses, a small number of cracks grow to substantial size, with concomitant reduction in the failure properties. (III) High stresses yield a plethora of cracks, but the mechanical properties are minimally affected. , This behavior can be explained using fracture mechanics.3 4 The tensile stress, σc, necessary to form an ozone crack is given by G E 1/2 σ = c c πa (1) where E is Young’s modulus, a is the crack depth, and Gc is the fracture energy (ca. -

Ozone Cracking in Drafting Aprons

Ozone cracking in drafting aprons B. Sujai Manager –Application Technology Inarco Ltd Email: [email protected] INTRODUCTION Ozone Ozone (O3) is a triatomic molecule, consisting of three oxygen atoms. It is an allotrope of oxygen that is much less stable than the diatomic O2. Ground-level ozone is an air pollutant with harmful effects on the respiratory systems of animals. Ozone in the upper atmosphere filters potentially damaging ultraviolet light from reaching the Earth's surface. It is present in low concentrations throughout the Earth's atmosphere. It has many industrial and consumer applications. Ozone, the first allotrope of a chemical element to be recognized by science, was proposed as a distinct chemical compound by Christian Friedrich Schönbein in 1840, who named it after the Greek word for smell (ozein), from the peculiar odor in lightning storms. The formula for ozone, O3, was not determined until 1865 by J.L.Soret and confirmed by Schönbein in 1867.The odor from a lightning strike is from ions produced during the rapid chemical changes, not from the ozone itself. Ozone layer The highest levels of ozone in the atmosphere are in the stratosphere, in a region also known as the ozone layer between about 10 km and 50 km above the surface (or between 6.21 and 31.1 miles). Here it filters out photons with shorter wavelengths (less than 320 nm) of ultraviolet light, also called UV rays, (270 to 400 nm) from the Sun that would be harmful to most forms of life in large doses. These same wavelengths are also among those responsible for the production of vitamin D, which is essential for human health. -

Eriks.Info Sealing Elements Technical Handbook O-Rings

Sealing Elements Technical Handbook O-rings 20. Troubleshooting O-ring Failure The failure of an O-ring in service can usually be attributed to a combination of causes. It is important therefore, to maximize seal life and reliability by the use of good design practices, proper compound selection, pre-product testing, and continued education and training of personnel. The following brief summary of O-ring failure patterns is intended to give the engineer a brief overview of the more common types of failure and a listing of recommended cor- rective actions. Listed are the most common causes of seal failure. For a complete listing of O-ring failure modes obtain a copy of AIR1707 Patterns of O-ring Failure available from SAE INC. Picture of an extruded, Extrusion and Nibbling nibbled O-ring Failure Pattern: Typical of high pressure systems, this pattern can be identified by the many small bites (nibbles) taken from the O-ring on the downstream (low pressure) side. Problem Source: excessive clearances; excessive system pressures; O-ring material too soft; degradation of the O-ring by system fluid; irregular clearance gaps caused by eccentricity; improper machining; sharp edges; or the O-ring size is too large for the gland. Suggested solution: decrease gland clearances by machining; use back-up rings to prevent extrusion; employ harder O-rings; re-check elastomer compatibility; improve concentricity; break sharp edges; or install proper size O-ring. Spiral Failure Failure pattern: generally found on long stroke hydraulic piston seals with low pressure differential. The surface of the O-ring exhibits a series of deep, spiral, 45° angle cuts. -

Elastomer Types and Chemical Compatibility

Elastomer Types and Chemical Compatibility www.novotema.com Contents Elastomer types and properties 3 Elastomer chemical compatibility 8 Elastomer Seal Selection Criteria 30 Novotema is a world-class designer and manufacturer of technical components and elastomer sealing solutions for demanding applications. With over 300 elastomer (rubber) material grades to choose from, Novotema is sure to have a sealing material to suit any application. This guide details the generic chemical resistance of 15 different types of elastomer material, tested in ambient (room temperature) conditions. Elevated operating temperatures accelerate the speed at which chemical degradation of elastomer seals occurs. Seek advice from your seal provider, for clarification of material suitability for your application. 2 www.novotema.com Elastomer types and properties Elastomer types are often referred to under standard designations/acronyms listed in ASTM D1418 or ISO 1629. A brief description of each elastomer type and their typical characteristics follows: ACM (Polyacrylic or Polyacrylate) CR (Chloroprene) These rubbers are usually copolymers of ethyl acrylate and Chloroprene rubbers are essentially chlorinated a vinyl ether and are resistant to heat, hydrocarbon oils and polyisoprenes, which exhibit medium resistance to high in particular, oil additives, especially sulphurised types used molecular weight oils. Chloroprene rubbers contain chlorine for lubrication under extreme pressure conditions. in the polymer to reduce the reactivity to many oxidising agents, as well as to oil and flame. CR elastomers also ACM elastomers offer excellent heat resistance; they can have good resistance to ozone cracking, heat ageing and typically be used at temperatures of 150°C/302°F (up chemical attack. Some of the important applications of to 175°C/347°F for limited periods).