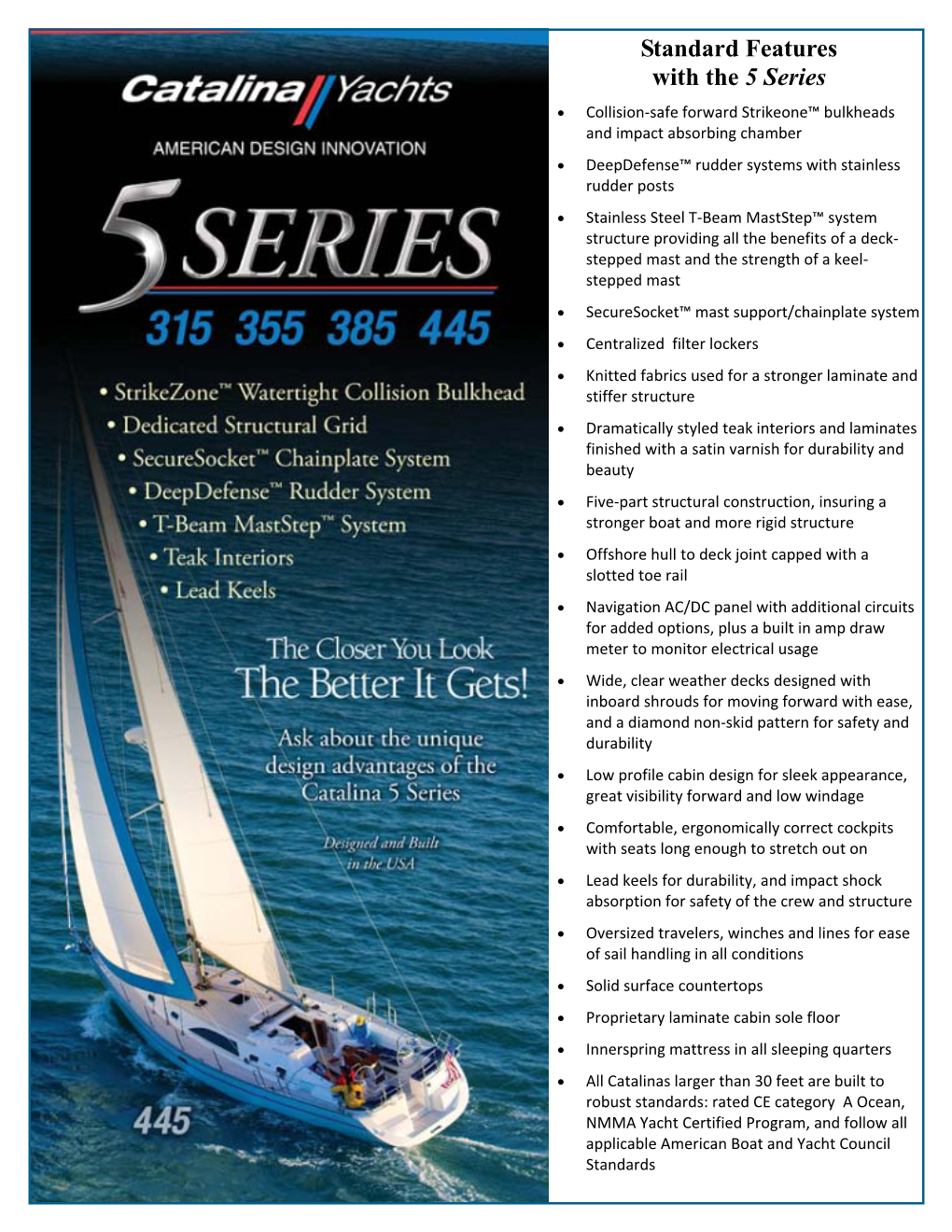

Standard Features with the 5 Series

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Touring Rudder Sit-On Top Kit Kit to Fit Rudder Enabled Sit-On Tops with a 10Mm Rudder Fixing Point

touring rudder sit-on top kit Kit to fit rudder enabled sit-on tops with a 10mm rudder fixing point. Note: It is easier to fit the Touring Rudder System if you have a screw hatch fitted to the rear stowage area of the kayak. If your kayak does not have this screw hatch and you wish to fit one, please contact a Perception dealer for advice. These instructions explain how to fit the rudder kit to a kayak with or without a rear screw hatch in place. Please make sure you follow the correct steps for your version of sit-on top kayak. This kit should contain the following: 1x rudder assembly with up-haul rope & split ring 4x deck fittings 4x length of rudder hose 5x self tapping screws 2x Dyneema control line - with cord end assembly 2x oval toggle 1x pair of Tip-Toes control footrests with foam washers 1x length of 4mm shock cord 6x footrest screws, washers and nuts - pre-fitted 1x rudder park - inc. hook, shock cord & fixing block You will also require some tools to fit this kit: Drill with 3mm, 5mm and 6mm drill bits Marker pen Short phillips screwdriver Wire cutters Small adjustable spanner or pair of pliers Lighter Tape measure Small amount of sticky tape Please read these instructions carefully before fitting! Step 1 - Control line entry points The rudder will need to have two control lines attached, each one running through hose sections inside the kayak from the rudder to the Tip-Toes footrests. This kit has four hose sections (two pairs) as two sections are needed per control line. -

Know About Boating Before You Go Floating

Know About Boating Before You Go Floating KEY TERMS All-around white light: Navigation light that Gunwale: Upper edge of a boat’s side. is visible in all directions around the boat from Hull: The main body of a boat. 2 miles away. Port: The left side of a boat. Bow: The front part of a boat. Propeller: A device with two or more blades Buoy: An object that floats on the water in that turn quickly and cause a boat to move. a bay, river, lake or other body of water and Sidelights: Red (port side) and green provides information to boats. (starboard side) navigation lights on a boat, Capsize: To turn a craft upside down in visible from 1 mile away. the water. Skipper: The person who commands a boat. Cleat: A wooden or metal fitting on the deck Starboard: The right side of a boat. of a boat. It has two projecting horns around which a rope or line may be tied. Stern: The back part of a boat. OBJECTIVES After completing this lesson, students will be able to: zz Name the main parts of a boat. zz Explain some boating terms. zz Describe some important safety equipment that should be on a boat. zz Demonstrate putting on a life jacket. zz Explain how to board a boat. zz Understand how to balance a boat. zz Explain what to do if a boat capsizes (turns over). MATERIALS, EQUIPMENT AND SUPPLIES zz Poster: Know About Boating Before You Go Floating zz Several Type II and/or Type III life jackets (in the various sizes that would fit the students) zz Mat or tape to create outline of boat zz Chairs (6) zz Watch or clock with a second hand zz Crayons, markers -

Cargo Hold Bilge Wells

AMVP INSPECTION MANUAL BILGE STRUM BOX OR EQUIVALENT MISSING ITEM: CARGO HOLD BILGE WELLS FINDING: BILGE STRUM BOX OR EQUIVALENT MISSING Strum box Bilge well without strum box Strainer plate on top of bilge Strum box equivalent or strainer well (also strum box fitted) WHY IS THIS A PROBLEM? TECHNICAL DATA: BILGE STRUM BOX OR EQUIVALENT • The bilge suction line is normally fitted with a perforated strum box around the suction which prevents cargo debris from entering the bilge line • This is not to be confused with a strainer plate on top of the bilge well (see photos) • Some bilges are provided with a two-compartment system: one bilge well with a perforated cover (strainer) and one with a full cover. Between the two compartments there is an opening to allow water to overflow, which can also be fitted with a perforated plate to prevent debris from entering the bilge line ISSUE WHEN NO PROTECTION IS FITTED • When no protection is provided for the bilge suction, any debris can enter the suction line and cause clogging (impair suction) or get stuck in the non-return system on the bilge line (cause backflow) IMCS BVBA – SHIP INSPECTION DEPARTMENT – [email protected] - WWW.IMCS-GROUP.COM PAGE 1/2 AMVP INSPECTION MANUAL BILGE STRUM BOX OR EQUIVALENT MISSING WHAT KIND OF FEEDBACK IS EXPECTED? CORRECTIVE ACTION • If spare parts are installed: order note or photograph of installation PREVENTIVE MEASURES • Explanation of your protection in place. This can be physical or procedural IMCS BVBA – SHIP INSPECTION DEPARTMENT – [email protected] - WWW.IMCS-GROUP.COM PAGE 2/2 . -

Glossary of Terms

Glossary of Terms Below are new words for our Glossary of Terms based on AB Barlow’s activities the last couple of weeks. To see all the terms from AB Barlow’s past activities, please scroll down. Battle of Cape St. Vincent – one of the first battles of the Anglo-Spanish War (1796-1808). The battle was a decisive English victory and saw four Spanish ships of the line captured by the British; two by Horatio Nelson Battle of Flamborough Head – a battle fought during the American War of Independence during which Captain John Paul Jones captured the British frigate Serapis even as his own ship, Bonhomme Richard, sank out from under him Boarding – the act of sending sailors or soldiers from one’s own ship to an enemy ship for the purpose of capturing the other vessel. In modern context, boarding can also occur for more peaceful purposes such as a safety or customs inspection Brig – a ship with two masts, both carrying square sails. Also, a jail located on board a ship Cutting Out – the act of attacking a ship from small boats filled with sailors or marines. Often used as a surprise tactic Fighting Top – a platform part way up a ship’s mast used as a firing position by sharpshooters during a naval engagement First-Rate – the largest warships in the now-obsolete Royal Navy ranking system. Generally, first-rates mounted around 100 carriage guns Frigate – a small, fast warship; usually built for maneuverability and speed over firepower Gangway – traditionally, a narrow passage connecting a ship’s quarterdeck and forecastle. -

3-Section Rowboat

3-SECTION ROWBOAT \WHEN the three sections are taken apart and nested, this 12-ft. rowboat occupies a space only 6V2 ft. long, and by virtue of its thin plywood construction is so light that one man can easily stow it on top of his car, using a suitable cradle to hold it. The boat is designed along standard lines, and construction differs only in the use of %-in. plywood for sides and bottom. In fact, it is built up as a single-unit row- boat, and then sawed between the two dou ble bulkheads to form the three sections. It is highly advisable to use waterproof plywood, if it is available. If not, the ordi nary grade can be satisfactorily water %-in. pine having grain at right angles. proofed by giving it three or four coats of The stem is fastened to a knee and keelson paint or shellac, taking care to work it by means of galvanized carriage bolts, with well into the exposed edges. If the wood heads countersunk. Next make the frames is not thoroughly waterproofed, moisture Nos. 1, 2 and 3, and the bulkheads. Note will loosen the thin layers of wood and that there is a frame on each bulkhead. All ruin the boat. In fact, all parts, whether frames are notched for chines, keelson and directly exposed to the water or not, inwale, and frames Nos. 2 and 3 for the should be given two coats of paint or seat rail. The bulkheads should not be shellac before assembling lliem, and at notched. -

Marine Investigation Report M96N0063

MARINE OCCURRENCE REPORT SWAMPING AND SINKING FISHING VESSEL "NANCY PAULA" OFF NOTION ISLAND LIGHTHOUSE, TRINITY BAY, NEWFOUNDLAND 01 JULY 1996 REPORT NUMBER M96N0063 The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. MARINE OCCURRENCE REPORT Swamping and Sinking Fishing Vessel "NANCY PAULA" Off Notion Island Lighthouse, Trinity Bay, Newfoundland 01 July 1996 REPORT NUMBER M96N0063 Summary While the "NANCY PAULA" was en route to Gooseberry Cove to land her catch of approximately 11 tonnes of capelin, she was swamped by two heavy seas. The fishing vessel lost all reserve buoyancy and sank so quickly that the crew had no time to don life jackets or call for assistance before abandoning the vessel. Ce rapport est également disponible en français. M96N0063.IP RESPONSE TO PDI DRAFT 05 SEPTEMBER 1997 2 OTHER FACTUAL INFORMATION Particulars of the Vessel Name "NANCY PAULA" Port of Registry St. John's, Nfld. Flag Canada Official Number 329075 Type Fishing vessel Gross Tonnage 25 Length 14.6 m Propulsion Cummins diesel engine, 228 kW Built 1967, Fortune Bay, Nfld. Owner/Operator Mr. G. White, Newville, Nfld. The "NANCY PAULA" was a vessel of Cape Island design with a beam of approximately 4 m amidships. The afterdeck, some 7.6 m in length, was surrounded by an 83 cm-high bulwark fitted with freeing ports. She had a valid Safety Inspection Certificate (SIC 29), with an expiry date of 09 April 1999. The vessel departed Catalina on 01 July 1996 at 0500, which coincided with the start of the local permissible time for capelin fishing. -

Entry Level Wind System Nederlands Espagñol Italiano Entry Level Wind System

English Français Deutsch Nederlands Espagñol Italiano Entry Level Wind System Entry Level Wind System Important Suitability: the Entry Level Wind System is only recommended for use on cruising boats up to 10.5m (35ft). For larger boats and for racing please consider the mn100 Micronet Range. If installing to a boat of aluminium, steel or Carbon Fibre construction, please consult www.tacktick.com for installation advice. Aid to navigation: like any other electronic instruments your Micronet system is designed to serve only as an aid to navigation and it remains the skippers responsibility to maintain a permanent watch and be aware of developing situations. Dismantling the product: any attempt to take a Micronet product apart will invalidate the warranty. Safety and disposal: do not dispose of any instrument in domestic waste. Refer to regulations in force in your country. If in doubt return the instrument to Tacktick Ltd. for correct disposal. EMC conformance: All Tacktick equipment is designed to the best industry standards for use in the recreational marine environment. The design and manufacture of Tacktick equipment conforms to the appropriate Electromagnetic Compatibility (EMC) standards. Correct installation is required to ensure that performance is not compromised. www.tacktick.com Key Features Key Features and Benefits English Completely wireless Wind Transmitter. The Wind Transmitter is solar powered and requires no external power supply. It communicates wirelessly with any Tacktick Micronet display. Ultra low power requirement. The innovative Micronet technology means the Entry Level Wind System draws just 1mA from the boats battery. Simple installation. The only cable required is a connection from the display to the boat’s electrical supply. -

Glossary of Terms for Cruising and Cruise

GLOSSARY OF TERMS FOR CRUISING AND CRUISE PLANNING USPS Marine Environment Committee TERM / WORD = DEFINITION / EXPLANATION AIS = Automatic Indentification System (transponders / receivers) ‐ An automatic tracking system used by vessels for exchanging identifying information. Anchor = A heavy metal device fastened to a chain or line to hold a vessel in position, partly because of its weight but chiefly because the design shape digs into the bottom. Parts consist of: Flute, Shank, Crown, Ring, etc. (see Appendix C) Anchor set and hold = How easily an anchor will properly orient itself to penetrate the bottom and how much effort it will take to break the anchor free. Bare Boat = A type of chartering in which the person chartering a boat assumes responsibility and provides their own crew. Barometer = An instrument for measuring atmospheric pressure. Beam = The width of a boat from gunwale to gunwale at the widest point. Biocide = A chemical substance or microorganism which can deter, render harmless, or exert a controlling effect on any harmful organism. Biocides can be added to other materials (such as diesel fuel) to protect them against biological infestation and growth. Boat Survey = An inspection of a boat by a marine surveyor for insurance purposes or prior to the purchase of the boat. 1 Boom Vang = A system of fittings to hold the boom down under some sailing conditions. Bosun Chair = A chair used to hoist a crew member to the top of a mast or rigging, usually for making repairs. Broker Firm = A company which will help you find a suitable boat to charter. Bulwarks = The extension of the ship’s side above the main deck or walkway fore and aft to protect it against heavy weather. -

True Wind Angle

User’s Guide by TrueWind David Burch About TrueWind...................................................................2 How to use TrueWind...........................................................3 Definitions Wind direction............................................................4 Apparent wind............................................................4 Apparent wind angle..................................................4 Apparent wind speed.................................................. 5 True wind angle.......................................................... 5 True wind speed ......................................................... 5 Speed .......................................................................... 6 Heading ...................................................................... 6 Discussion Telltales ...................................................................... 7 Electronic wind instruments....................................... 7 True wind versus apparent wind ................................ 8 Tips, tricks, and special cases .................................... 8 How to find true wind Reading the water....................................................... 9 Formulas and diagrams .............................................. 10 Graphical method ....................................................... 12 2 Starpath TrueWind INDEX About Starpath TrueWind Starpath TrueWind is a Windows program designed to compute very conveniently true wind from apparent wind for use in maneuvering and weather analysis. -

June 29, 1947

FISH A7j::: K&DLIP% SERVICE For Release to SUXillBy PAPERSOF JUNX ;29, 1947 FISH A?XDWILDLIFE SERVICE VEXX,S DEPART FOR PHILIPPIXES Albert M, Day, Director of the Fish and Wildlife Service, announced today that two fishery research and e,qerimental fishing vessels, des$ned and equipped for the Philippine Fishery Rehabilitation Program, departed from San Francisco for Manila on June 26. Prom San Francisco, the vessels are to proceed to Los Angeles for a test run and, upon refueling, are to leave for Honolulu about June ;28. stops for fuel and supplies will be made enroute at Honolulu, Wake and Guam. It is expected that the vessels will arrive in Kanila about July 25. The Spencer P. Baird, under the commend of John P. Lowman, is the former U. S. Army LT-581 which has been converted into a combination oceanographic vessel and tuna clipper. It is 143 feet long, with a3 feet beam and a draft of 16 feet. Propulsion power consists of twin diesel electric installations geared into a single shaft and propeller which provides very flexible speeds of operation, ranging from 1s to 14 knots, The vessel is equipped with all of the latest electronic and special devices for navigation and oceanographic research. A complete biological and chemical laboratory is installed on the main deck, as well as special winches for handling hydrographic gear, and experimental trawls and other types of nets. A sharp-freeze compartment for experimentation with freezing fish at ‘sea is located in the after hold. On the after deck, bait tanks have been installed which are equipped with refrigeration and aeration &ich will make possible experimentation . -

Rethinking Inflatable the MOB Recovery

Even in moderate breezes, rescuers often speed past the person in the water, prompting many experts to suggest practicing recovery in a variety of conditions, and using the engine, if needed, to make up for any lost momentum. Rethinking the MOB Recovery Spate of accidents calls for re-assessment of long-held rescue practices. By Two years ago, we raised concerns able to quickly climb back aboard. Mo- over high stakes sailing adventure ments later, another “pay for adventure” an overboard recovery failures charters such as the Clipper Round crew, Simon Speirs, was also tossed Mhave become a frequent head- the World Yacht Race (see January overboard. line, and details about these tragedies 2017, (“Risk Management and Renting Speirs was clipped in, but a longer hold lessons worth learning. Adventure,” January 2017). tether caused him to be pressed against Recent, back-to-back incidents have Recently, the UK Marine Accident the hull and dragged through the heavy involved safety gear malfunctions, Investigation Branch released their seas at 9.3 knots, even though the skip- shortfalls in boat handling skills, and evaluation of the fatal MOB incident per had immediately tacked the boat All photos by by All photos lapses in sound decision making. They aboard CV30 “Great Britain.” It lends to put Speirs on the high side. The re- have also caused several aspects of res- support to the issues we’ve raised in a maining five crew on the foredeck, all cue orthodoxy to come into question. multiple reports, and are raising again of whom had been involved in the sail We’ve previously covered rescue here (see March 2018, “Safety Teth- dousing effort, were unable to hoist techniques such as the Quickstep, ers Under Scrutiny”). -

Open – Top Container Ships

OPEN – TOP CONTAINER SHIPS Prepared by: TECHNICAL SERVICES COMMITTEE Benefits and Exposures to Hull/Machinery and Cargo Underwriters The history of maritime commerce has been a continuum of endeavor and progress towards improving the operation, making it faster, more reliable, more economical – i.e. more efficient. Among the major accomplishments in the past were the times when oars gave way to sail, when sail was replaced by steam, and when breakbulk ships were surplanted by container ships. Today it is suggested that another sea change may be at hand, namely the advent of the open top container ship, also known as the hatchless container ship. It may well be that this is not merely a new type of ship but rather a major departure in cargo ship design. The sketch below illustrates the nature of the change. The essence of the change is that the hatch covers have been eliminated from the ship. The cargo space within the ship is open to the elements, harking back to the open vessels in which the Phoenicians traded on the Mediterranean thousands of years ago. The advantages claimed for this arrangement are: 1. The considerable weight of hatch covers has been eliminated, thus increasing the deadweight. Furthermore, since the hatch covers were located high in the ship, their removal (removal of their weight) significantly improves stability. 2. The elimination of the hatch covers also excludes the need to open and close same. This speeds up port turn-around time and has the potential for reducing cargo operation costs. 3. The fixed container guides do not terminate at the hatch coaming as in a conventional container ship.