And Moisture-Sensitive Compounds

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Laboratory Glassware N Edition No

Laboratory Glassware n Edition No. 2 n Index Introduction 3 Ground joint glassware 13 Volumetric glassware 53 General laboratory glassware 65 Alphabetical index 76 Índice alfabético 77 Index Reference index 78 [email protected] Scharlau has been in the scientific glassware business for over 15 years Until now Scharlab S.L. had limited its sales to the Spanish market. However, now, coinciding with the inauguration of the new workshop next to our warehouse in Sentmenat, we are ready to export our scientific glassware to other countries. Standard and made to order Products for which there is regular demand are produced in larger Scharlau glassware quantities and then stocked for almost immediate supply. Other products are either manufactured directly from glass tubing or are constructed from a number of semi-finished products. Quality Even today, scientific glassblowing remains a highly skilled hand craft and the quality of glassware depends on the skill of each blower. Careful selection of the raw glass ensures that our final products are free from imperfections such as air lines, scratches and stones. You will be able to judge for yourself the workmanship of our glassware products. Safety All our glassware is annealed and made stress free to avoid breakage. Fax: +34 93 715 67 25 Scharlab The Lab Sourcing Group 3 www.scharlab.com Glassware Scharlau glassware is made from borosilicate glass that meets the specifications of the following standards: BS ISO 3585, DIN 12217 Type 3.3 Borosilicate glass ASTM E-438 Type 1 Class A Borosilicate glass US Pharmacopoeia Type 1 Borosilicate glass European Pharmacopoeia Type 1 Glass The typical chemical composition of our borosilicate glass is as follows: O Si 2 81% B2O3 13% Na2O 4% Al2O3 2% Glass is an inorganic substance that on cooling becomes rigid without crystallising and therefore it has no melting point as such. -

Site-Directed Spin Labeling of Large Riboswitches Using Click Chemistry

Site-Directed Spin Labeling of Large Riboswitches Using Click Chemistry Dissertation zur Erlangung des Doktorgrades (Dr. rer. nat.) der Mathematisch-Naturwissenschaftlichen Fakultät der Rheinischen Friedrich-Wilhelms-Universität Bonn vorgelegt von Mark Kerzhner aus Winnyzja, Ukraine Bonn 2018 Angefertigt mit Genehmigung der Mathematisch-Naturwissenschaftlichen Fakultät der Rheinischen Friedrich-Wilhelms-Universität Bonn 1. Gutachter: Prof. Dr. Michael Famulok 2. Gutachter: Prof. Dr. Olav Schiemann Tag der Promotion: 25.10.2018 Erscheinungsjahr: 2019 Parts of this thesis have been published in: Kerzhner, M.; Abdullin, D.; Więcek, J.; Matsuoka, H.; Hagelueken, G.; Famulok, M.; Schiemann, O., Post-synthetic Spin-Labeling of RNA through Click Chemistry for PELDOR Measurments, Chem. Eur.J. 2016, 22, 12113 –12121. Kerzhner, M.; Matsuoka, H.; Wuebben, C.; Famulok, M.; Schiemann, O., High- Yield Spin Labeling of Long RNAs for Electron Paramagnetic Resonance Spectroscopy, Biochemistry, 2018, 57, 2923–2931. Danksagung An erster Stelle möchte ich Herrn Prof. Dr. Michael Famulok danken, dass er mir die Chance ermöglicht hat, an diesem anspruchsvollen aber hochinteressanten Projekt zu arbeiten. Außerdem bin ich ihm sehr dankbar, dass er mir über die Jahre sein Vertrauen geschenkt hat. Großer Dank gilt außerdem dem Kooperationspartner Herrn Prof. Dr. Olav Schiemann, ohne dessen Unterstützung die Umsetzung dieses Projektes nicht möglich gewesen wäre. Er und seine Arbeitsgruppe haben entscheidende Beiträge zu den erzielten Ergebnissen dieser Arbeit geleistet. Allen Mitgliedern meiner Prüfungskommission danke ich für die Begutachtung dieser Dissertation. Ich danke meinen Kooperationspartnern aus der Arbeitsgruppe von Herrn Prof. Dr. Olav Schiemann. Bei Dr. Dinar Abdullin, Dr. Hideto Matsuoka und Dr. Andreas Meyer bedanke ich mich herzlich für die zahlreichen PELDOR-Messungen sowie Hilfe bei verschiedenen Fragestellungen. -

Dalton Transactions

Dalton Transactions View Article Online PAPER View Journal | View Issue The role of neutral Rh(PONOP)H, free NMe2H, boronium and ammonium salts in the dehydro- Cite this: Dalton Trans., 2019, 48, 14724 coupling of dimethylamine-borane using the 2 + cationic pincer [Rh(PONOP)(η -H2)] catalyst†‡ E. Anastasia K. Spearing-Ewyn,a Nicholas A. Beattie,b Annie L. Colebatch, a Antonio J. Martinez-Martinez, a Andrew Docker,a Timothy M. Boyd,a Gregg Baillie,b Rachel Reed,b Stuart A. Macgregor *b and Andrew S. Weller *a 1 F 3 The σ-amine-borane pincer complex [Rh(PONOP)(η -H3B·NMe3)][BAr 4][2, PONOP = κ -NC5H3-2,6- t 2 F (OP Bu2)2] is prepared by addition of H3B·NMe3 to the dihydrogen precursor [Rh(PONOP)(η -H2)][BAr 4], 1 F 1. In a similar way the related H3B·NMe2H complex [Rh(PONOP)(η -H3B·NMe2H)][BAr 4], 3, can be made in situ, but this undergoes dehydrocoupling to reform 1 and give the aminoborane dimer [H2BNMe2]2. Creative Commons Attribution 3.0 Unported Licence. NMR studies on this system reveal an intermediate neutral hydride forms, Rh(PONOP)H, 4, that has been prepared independently. 1 is a competent catalyst (2 mol%, ∼30 min) for the dehydrocoupling of H3B·Me2H. Kinetic, mechanistic and computational studies point to the role of NMe2H in both forming the neutral hydride, via deprotonation of a σ-amine-borane complex and formation of aminoborane, and Received 17th August 2019, closing the catalytic cycle by reprotonation of the hydride by the thus-formed dimethyl ammonium Accepted 3rd September 2019 + + [NMe2H2] . -

15.0 Hazardous Waste Disposal

LABORATORY SAFETY MANUAL Revised June 2018 Emergency Contact Information In case of emergency: 911 Security Services: (daytime) 705-474-7600 ext. 5555 (cell phone) 705-498-7244 Laboratory Safety Coordinator: 474-3450 ext. 4180 Emergency Procedures** Chemical Spill On Body • Rinse affected area immediately for 15 minutes using emergency shower, if required. • Care must be taken to avoid contamination with face and eye(s). In Eye(s) • Immediately flush eye(s) using emergency eyewash station for a minimum of 15 minutes. In Laboratory • Assess the scene. If the situation is beyond your capabilities, contact your supervisor. • If safe to do so, turn off any ignition sources if flammable material is present. • Use spill kits to assist in spill containment. • Dispose of waste material with other hazardous waste. Fire • If you hear the Fire Alarm ring continuously evacuate the building immediately. • If you hear the Fire Alarm ring intermittently be alert however evacuation is not necessary. • If Fire Alarm changes from intermittent to continuous evacuate immediately • If you detect a fire, do not attempt to extinguish it yourself unless you are capable and it is safe to do so. Report the injury/incident to your supervisor as soon as possible. ** This is to be used as a quick reference only. For more detailed information, please refer to section 8.0 Emergency Procedures. Laboratory Safety Manual – Nipissing University 2 Table of Contents Acknowledgements ................................................................................................... -

Gas Generator Bottle Introduction SCIENTIFIC This Gas Generator Setup Provides an Easy Way to Generate and Collect Gas

Gas Generator Bottle Introduction SCIENTIFIC This gas generator setup provides an easy way to generate and collect gas. Specific instructions are provided for the generation of hydrogen gas using zinc and acid. Concepts • Generation of gases • Water displacement Materials Hydrochloric acid solution, HCl, 3 M Glass plates or Sulfuric acid solution, H2SO4, 3 M Glass tubing Mossy zinc, Zn, 6 g Pneumatic trough Water, tap Rubber tubing Bent glass tubing* Silicone grease packet* Gas collecting bottles or tubes, 3 or 4 Thistle tube* Gas generator bottle* Two-hole rubber stopper* *Materials included. Safety Precautions Hydrochloric acid solution is toxic by ingestion and inhalation and is severely corrosive to skin, eyes and other tissues, as is sulfuric acid solu- tion. Hydrogen gas is a highly flammable gas and a severe fire hazard. Exercise extreme caution when testing the gas and keep the gas generator away from flames. Wear chemical splash goggles, chemical-resistant gloves, and a chemical-resistant apron. This activity requires the use of hazardous components and/or has the potential for hazardous reactions. Please review current Material Safety Data Sheets for additional safety, handling, and disposal information. Procedure 1. Set up the apparatus as shown in the figure to the right. Lubricate the glass tubing and thistle tube with silicone grease before inserting into the stopper. Make sure Thistle tube the water level is above the platform. Prepare bottles for collecting gas by water Two-hole rubber stopper displacement. To do this, fill each gas collecting bottle (or tube) over the brim with tap water, and then cover each with a flat glass plate. -

Viruses at Glycocalyx Barriers SI Bioarxiv

Glycocalyx crowding with synthetic mucin mimetics strengthens interactions between soluble and virus-associated lectins and cell surface glycan receptors Authors: aDaniel J. Honigfort, b, † Meghan O. Altman, bPascal Gagneux, and Kamil Godula*,a Author Affiliation: aDepartment of Chemistry and Biochemistry, University of California San Diego, 9500 Gilman Drive, La Jolla, CA 92093-0358, USA bDepartment of Pathology, University of California San Diego, 9500 Gilman Drive, La Jolla, CA 92093-0687, USA Supporting Information 1 Table of contents: Instrumentation and reagents. ............................................................................................................ 4 Synthesis of propargyl glycosides. ........................................................... Error! Bookmark not defined. Scheme S1. Preparation of β-propargyl glycosides via the Schmidt glycosylation.Error! Bookmark not defined. Synthesis of glycopolymers GP-S/M/L ............................................................................................... 5 Scheme S2. Synthesis of Glycopolymers through iterative CuAAc click strategy. ................................ 5 General Procedure for the preparation of poly(epichlorohydrin) (P1). ............................................ 5 General Procedure for the end-functionalization of poly(epichlorohydrin) (P2). ............................ 6 General Procedure for the preparation of poly(Glycidyl Azide) (P3). .............................................. 6 General procedure for the preparation of Glycopolymers -

Application Note 160

APPLICATION NOTE 160 Degas Options for Sample Preparation Introduction A degas study was conducted to determine the effectiveness 1. Inert environment – shift from of flow versus vacuum degas. An amorphous silica- adsorbed phase to inert. alumina and a microporous zeolite were prepared by both techniques and then nitrogen isotherms were collected 2. Heat – increase the rate. for both materials. The resulting isotherms established equivalence between vacuum versus flow degas. Vacuum versus Flowing Degas Methods In the present study we accept that temperature may be controlled by various methods and that commercial temperature controllers provide repeatable performance. Rather than studying temperature control, this document will evaluate the topic of vacuum versus flowing degas. 1. Vacuum degas utilizes mass action as the only method for shifting the chemical equilibrium. An adsorbed molecule has a concentration on the surface, C and a negligible pressure, P=0 in the vapor phase. The pressure is maintained near zero since the sample is in a vacuum. Heating the sample increases the rate of transfer from the adsorbed molecules to the inert environment. 2. Flowing degas also utilizes mass action Theory by constant inert purge. The desorbed molecules are swept from the system Typical degas options include vacuum or flowing degas. The via the continuous inert gas flow and the basic concept of degas is quite simple. The sample material partial pressure of the desorbed molecules is placed in an inert environment. This inert environment in an inert stream approaches zero in a exploits chemical potential and creates a favorable state for manner similar to the vacuum technique. -

Preparing Sodium Hydroxide Solutions Nov 2016

STANDARD OPERATING PROCEDURE: Preparing sodium hydroxide solutions Note: To be undertaken only by trained personnel in conjunction with a current Safety Data Sheet (SDS) and site-specific risk assessment. ___________________ 1. Introduction Sodium hydroxide (NaOH) is a hazardous chemical and must be treated with care. It is highly corrosive to skin and eyes and extremely toxic if ingested. The solid can be purchased as pellets, flakes or mini pearls. It is very hygroscopic (absorbs water from the air) and will also absorb carbon dioxide from the air and therefore cannot be used as a primary standard for titrations. To minimise its absorption of water and carbon dioxide, it should be kept in a tightly closed container and left open for as little time as possible. Dissolving sodium hydroxide in water is an exothermic (heat producing) reaction. Synonyms: caustic soda, lye, soda lye. 2. Context These instructions are for the use of experienced teachers and technicians only. Do not make up a solution for the first time without seeking practical advice from an experienced colleague. 3. Safety Notes This activity may only be carried out with appropriate facilities available i.e. running water, chemical safety/eyewash station and relevant Personal Protective Equipment (PPE) Conduct procedure in a well-ventilated area or fume cupboard. Avoid contact with skin and eyes, and avoid breathing fumes. The preparation of sodium hydroxide solutions liberates heat and may produce caustic fumes/vapours. Ensure that glassware is free from chips and cracks before use. For first aid, accident and spill procedures refer to SDS before making a solution. -

Elements of a Glovebox Glove Integrity Program

RESEARCH ARTICLE Elements of a Glovebox Glove Integrity Program Programmatic operations at the Los Alamos National Laboratory Plutonium Facility involve working with various amounts of plutonium and other highly toxic, alpha-emitting materials. The spread of radiological contamination on surfaces and airborne contamination and excursions of contaminants into the operator’s breathing zone are prevented through the use of a variety of gloveboxes. The glovebox gloves are the weakest part of this engineering control. As a matter of good business practice, a team of glovebox experts from Los Alamos National Laboratory has been assembled to proactively investigate processes and procedures that minimize unplanned openings in the glovebox gloves, i.e., breaches and failures. Working together, they have developed the key elements of an efficient Glovebox Glove Integrity Program (GGIP). In the following report, the consequences of a glove failure or breach are identified, the acceptable risk is clarified, and elements needed to implement an efficient GGIP are discussed. By Michael E. Cournoyer, INTRODUCTION Through an integrated approach, Julio M. Castro, controls have been developed and Michelle B. Lee, Plutonium requires a high degree of implemented that come from input Cindy M. Lawton, confinement and continuous control from glovebox workers, scientists, Young Ho Park, measures in nuclear research labora- health physicists, statisticians, and phy- Roy Lee, tories because of its extremely low sical therapists. Working together, they Stephen Schreiber permissible body burden.1 Methods have developed an efficient Glovebox and equipment must be designed Glove Integrity Program (GGIP). toward the ultimate accomplishment Recent accomplishes of this team have 2–5 Michael E. -

Degas Backfill Gas Selection for Micromeritics Gas Adsorption Instruments

Application Note 73 Degas Backfill Gas Selection for Micromeritics Gas Adsorption Instruments Introduction adsorbed gas is one type of contaminant that you Specific surface areas and pore volume distribu- wish to remove during degassing, using nitrogen tions are often determined using gas adsorption as the backfill gas partially defeats the purpose of techniques. Prior to analysis, any adsorbed gas or degassing. Obviously, nitrogen is not a true inert vapor phase (such as water or other volatiles) gas when it comes to microporous materials. should be removed from the sample. This process is often referred to as degassing the sample. Therefore, for materials which tend to adsorb nitrogen, helium is a better choice as the backfill Degassing usually involves either heating the gas. Helium adsorption at room temperature is sample or flowing an inert gas across the sample negligible, even in the high energy pores of most during evacuation. In either case, molecules being microporous samples. desorbed from the surface of the sample are removed from the sample tube. After degassing, There are some highly microporous materials in the sample tube can be sealed and removed in one which helium (if used as the backfill gas) is ex- of the following conditions: tremely difficult to remove due to diffusion. Complete removal requires great care as well as • Under vacuum using the TranSealTM, an appa- time-consuming tasks. Otherwise its presence can ratus which is inserted into the sample tube. It severely distort an adsorption isotherm. is designed to close when removed from the degassing port and open automatically when For samples where neither nitrogen nor helium are installed on the sample port, maintaining a ideal, a vacuum-sealed transfer is the most vacuum-tight seal. -

Computer Simulation Applied to Studying Continuous Spirit Distillation and Product Quality Control

View metadata, citation and similar papers at core.ac.uk brought to you by CORE provided by Elsevier - Publisher Connector Food Control 22 (2011) 1592e1603 Contents lists available at ScienceDirect Food Control journal homepage: www.elsevier.com/locate/foodcont Computer simulation applied to studying continuous spirit distillation and product quality control Fabio R.M. Batista, Antonio J.A. Meirelles* Laboratory EXTRAE, Department of Food Engineering, Faculty of Food Engineering, University of Campinas e UNICAMP, Campinas, Brazil article info abstract Article history: This work aims to study continuous spirit distillation by computational simulation, presenting some Received 7 June 2010 strategies of process control to regulate the volatile content. The commercial simulator Aspen (Plus and Received in revised form dynamics) was selected. A standard solution containing ethanol, water and 10 minor components rep- 2 March 2011 resented the wine to be distilled. A careful investigation of the vaporeliquid equilibrium was performed Accepted 8 March 2011 for the simulation of two different industrial plants. The simulation procedure was validated against experimental results collected from an industrial plant for bioethanol distillation. The simulations were Keywords: conducted with and without the presence of a degassing system, in order to evaluate the efficiency of Spirits fi Distillation this system in the control of the volatile content. To improve the ef ciency of the degassing system, fl Simulation a control loop based on a feedback controller was developed. The results showed that re ux ratio and Aspen Plus product flow rate have an important influence on the spirit composition. High reflux ratios and spirit Degassing flow rates allow for better control of spirit contamination. -

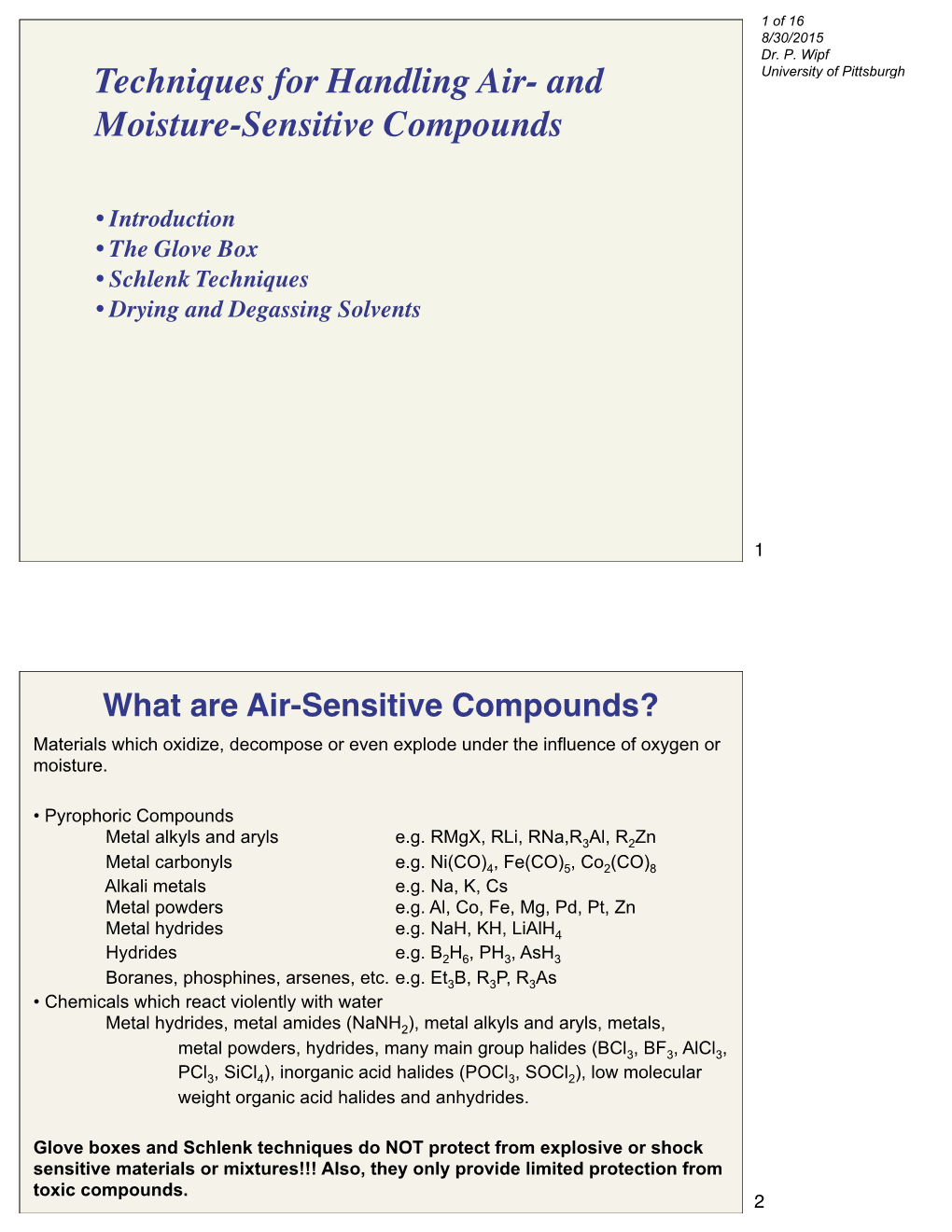

Chem 1140; Techniques for Handling Air-Sensitive Compounds

P. Wipf 1 Chem 1140 Chem 1140; Techniques for Handling Air-Sensitive Compounds • Introduction • The Glove Box • Schlenk Techniques • Drying and Degassing Solvents What are Air-Sensitive Compounds? Materials which oxidize, decompose or even explode under the influence of oxygen or moisture. • Pyrophoric Compounds Metal alkyls and aryls e.g. RMgX, RLi, RNa,R3Al, R2Zn Metal carbonyls e.g. Ni(CO)4, Fe(CO)5, Co2(CO)8 Alkali metals e.g. Na, K, Cs Metal powders e.g. Al, Co, Fe, Mg, Pd, Pt, Zn Metal hydrides e.g. NaH, KH, LiAlH4 Hydrides e.g. B2H6, PH3, AsH3 Boranes, phosphines, arsenes, etc. e.g. Et3B, R3P, R3As • Chemicals which react violently with water Metal hydrides, metal amides (NaNH2), metal alkyls and aryls, metals, metal powders, hydrides, many main group halides (BCl3, BF3, AlCl3, PCl3, SiCl4), inorganic acid halides (POCl3, SOCl2), low molecular weight organic acid halides and anhydrides. Glove boxes and Schlenk techniques do NOT protect from explosive or shock sensitive materials or mixtures!!! Also, they only provide limited protection from toxic compounds. P. Wipf 2 Chem 1140 The Glove Box • The best way to keep things away from atmospheric oxygen and water is to work in a fully enclosed “bench top,” containing an “inert atmosphere,” which one could reach into with gloves. Such a device is called a “glove box” or a “dry box”. There are also cheap “glove bags”, bags you can fill with inert gas and reach into with attached gloves. The Glove Box A glove box has four important components: 1. The actual “box” is a large aluminum chamber with a plastic front window and two impressive looking gloves.