PPE Vertical Recommendation for Use Sheets (Rfus)

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Product Certification

Product Certification A comprehensive guide to BSI’s product certification services KITEMARK™ Table of contents 1 BSI Overview - NRTL service for the US and Canada in coalition with MET labs 2.15 - RADMAC - EN 442 radiators and convectors 2.16 BSI Overview 1.1 - STB Mark - certification in Belarus 2.16 What is Product Certification? 1.2 - Keymark - EU construction standards 2.16 Why choose BSI for Product Certification? 1.3 - REAS - Electrical Products to Australia & New Zealand Market 2.17 - EFSG - European Fire & Safety Group 2.17 - VCA certification - Vehicle Certification Agency 2.18 2 Product Certification Schemes and Services - NCS International 2.18 BSI Kitemark 2.2 Benchmark 2.4 3 Section 3 – EU directives CE marking 2.5 ATEX Equipment Directive (94/9/EC) | (99/92.EC) 3.1 Verification Certificate 2.7 Boiler Efficiency Directive (92/42/EEC) 3.2 Green Deal 2.9 Gas Appliances Directive (GAD - 2009/142/EC ) 3.3 GS Certification (pending) 2.10 Lift Directive (LD 95/16/EC) 3.4 Gap Analysis 2.10 Marine Directive (MED 96/98/EC) 3.5 Other Schemes BSI can offer: 2.11 - IEC Certification Schemes for Electronic Products 2.11 Low Voltage Directive (2006/95/EC) 3.6 - IEC Quality Assessment System for Electrtronic Components 2.12 Non Automatic Weighing Instruments Directive (NAWI) - CCA certification - CENELEC Certification Agreement 2.14 90/384/EEC | 93/68/EEC | SI 2000/323) 3.7 - ENEC mark - applicable for Electro technology 2.14 Personal Protective Equipment Directive (PPE 89/686/EEC) 3.8 >> ii Pressure Equipment Directive (PED 97/23/EC) -

Příloha Č. 3; NV Č

Příloha je nedílnou součástí osvědčení o akreditaci č.: 262/2020 ze dne: 21. 4. 2020 Akreditovaný subjekt podle ČSN EN ISO/IEC 17065:2013: Strojírenský zkušební ústav, s.p. Certifikační orgán certifikující produkty Hudcova 424/56b, 621 00 Brno Pracoviště certifikačního orgánu: 1. pracoviště Brno Hudcova 424/56b, 621 00 Brno 2. pracoviště Jablonec nad Nisou Tovární 89/5, 466 01 Jablonec nad Nisou Certifikace produktů (zahrnuje hmotné produkty, procesy, služby) Hmotné produkty Pořadové Specifikace norem 1) Název produktu/skupiny produktů Certifikační schéma číslo (normativních dokumentů) 1* Strojní zařízení 1.0 Stroje pro výrobu a užití mechanické energie kromě motorů NV č. 176/2008 Sb., § 5 pro letadla, automobily a motocykly odst. (2), odst. (3) a), § 6; směrnice Stroje a zařízení pro všeobecné účely 2006/42/ES, čl. 12 odst. Obráběcí stroje, lisy apod. strojní zařízení 2 a 3a), čl. 13; ČSN EN Stroje pro určitá hospodářská odvětví ISO/IEC 17067:2014, schéma 1a ČSN EN ISO 13857 ČSN EN 349+A1 ČSN EN ISO 13850 ČSN EN 547-1+A1 ČSN EN 547-2+A1 ČSN EN 547-3+A1 ČSN EN ISO 13732-1 ČSN EN 574+A1:2008 ČSN EN ISO 13851 ČSN EN 614-1+A1 ČSN EN ISO 14123-1 ČSN EN 842+A1 ČSN EN 894-1+A1 ČSN EN 894-2+A1 ČSN EN 894-3+A1 ČSN EN ISO 14120 ČSN EN ISO 13849-1 ČSN EN ISO 14159 ČSN EN 981+A1 ČSN EN ISO 4413 ČSN EN ISO 4414 ČSN EN ISO 13855 ČSN EN ISO 14118 ČSN EN ISO 14119 ČSN EN 12254 ČSN EN ISO 13856-1 ČSN EN ISO 13856-2 ČSN EN 60204-1 ed.2 ČSN EN 60204-1 ed.3 Strana 1 z celkového počtu 78 stran 11_01-P508_V-20190513 Příloha je nedílnou součástí osvědčení o akreditaci č.: 262/2020 ze dne: 21. -

Progress File (Standards Publications)

IRISH STANDARDS PUBLISHED BASED ON CEN/CENELEC STANDARDS 1. I.S. CEN TR 15352:2006 Date published 23 APRIL 2012 Bitumen and bituminous binders - Development of performance- related specifications: status report 2005 2. I.S. EN 60335-2-7:2010 Date published 20 JUNE 2012 Household and similar electrical appliances - Safety - Part 2-7: Particular requirements for washing machines 3. I.S. EN 61347-2-12:2005/A1:2010 Date published 7 MARCH 2012 Lamp controlgear -- Part 2-12: Particular requirements for d.c. or a.c. supplied electronic ballasts for discharge lamps (excluding fluorescent lamps) (IEC 61347-2 -12:2005/A1:2010 (EQV)) 4. I.S. EN 61347-2-1:2001/AC:2010 Date published 19 APRIL 2012 Lamp controlgear -- Part 2-1: Particular requirements for starting devices (other than glow starters) (IEC 61347-2-1:2000 (EQV)) 5. I.S. EN 61347-2-2:2001/AC:2010 Date published 19 APRIL 2012 Lamp controlgear -- Part 2-2: Particular requirements for d.c. or a.c. supplied electronic step-down convertors for filament lamps (IEC 61347-2-2:2000 (EQV)) 6. I.S. EN 61347-2-3:2001/AC:2010 Date published 19 APRIL 2012 Lamp controlgear -- Part 2-3: Particular requirements for a.c. supplied electronic ballasts for fluorescent lamps (IEC 61347-2-3:2000 (EQV)) 7. I.S. EN 61347-2-4:2001/AC:2010 Date published 19 APRIL 2012 Lamp controlgear -- Part 2-4: Particular requirements for d.c. supplied electronic ballasts for general lighting (IEC 61347-2-4:2000 (EQV)) 8. I.S. EN 61347-2-5:2001/AC:2010 Date published 19 APRIL 2012 Lamp controlgear -- Part 2-5: Particular requirements for d.c. -

Progress File (Standards Publications)

IRISH STANDARDS PUBLISHED BASED ON CEN/CENELEC STANDARDS 1. I.S. EN 2336:1988/AC1:1988 Date published 1 JANUARY 2006 Aerospace Series - Bearings, Spherical Plain in Steel with Assembly Slots - Dimensions and Loads 2. I.S. EN 28378-1:1989/AC1:1989 Date published 1 JANUARY 2006 Information Processing - Data Interchange on 130 mm (5.25") Flexible Disk Cartridges Using Modified Frequency Modulation Recording at 7958 ftprad, 3.8 tpmm (96 tpi), on Both Sides - Part 1: Dimensional, Physical and Magnetic Characteristics. (ISO 8378-1, 1st Edition, 3. I.S. HD 1215-2:1988/AC1:1989 Date published 1 JANUARY 2006 Thermostatic Radiator Valves - Part 2 : Dimensions and Details on Connection 4. I.S. EN 50203:1996/A1:1999 Date published 2 FEBRUARY 2006 Automatic channel installation (ACI) 5. I.S. EN 54-2:1999 Date published 1 JANUARY 2006 Fire detection and fire alarm systems - Part 2: Control and indicating equipment 6. I.S. EN 12737:2004 Date published 28 JULY 2006 Precast concrete products - Floor slats for livestock 7. I.S. EN 61009-1:1994/A13:2004 Date published 2 FEBRUARY 2006 Electrical accessories - Residual current operated circuit-breakers with integral overcurrent protection for household and similar uses (RCBO's) -- Part 1: General rules 8. I.S. EN 50091-1-1:2004 Date published 2 FEBRUARY 2006 Uninterruptible power systems (UPS) -- Part 1-1: General and safety requirements for UPS used in operator access areas 9. I.S. EN 60432-1:2004 Date published 2 FEBRUARY 2006 Incandescent lamps - Safety specifications -- Part 1: Tungsten filament lamps for domestic and similar general lighting purposes (IEC 60432-1:1999 (MOD)) 10. -

PPE Vertical Recommendation for Use Sheets (Rfus)

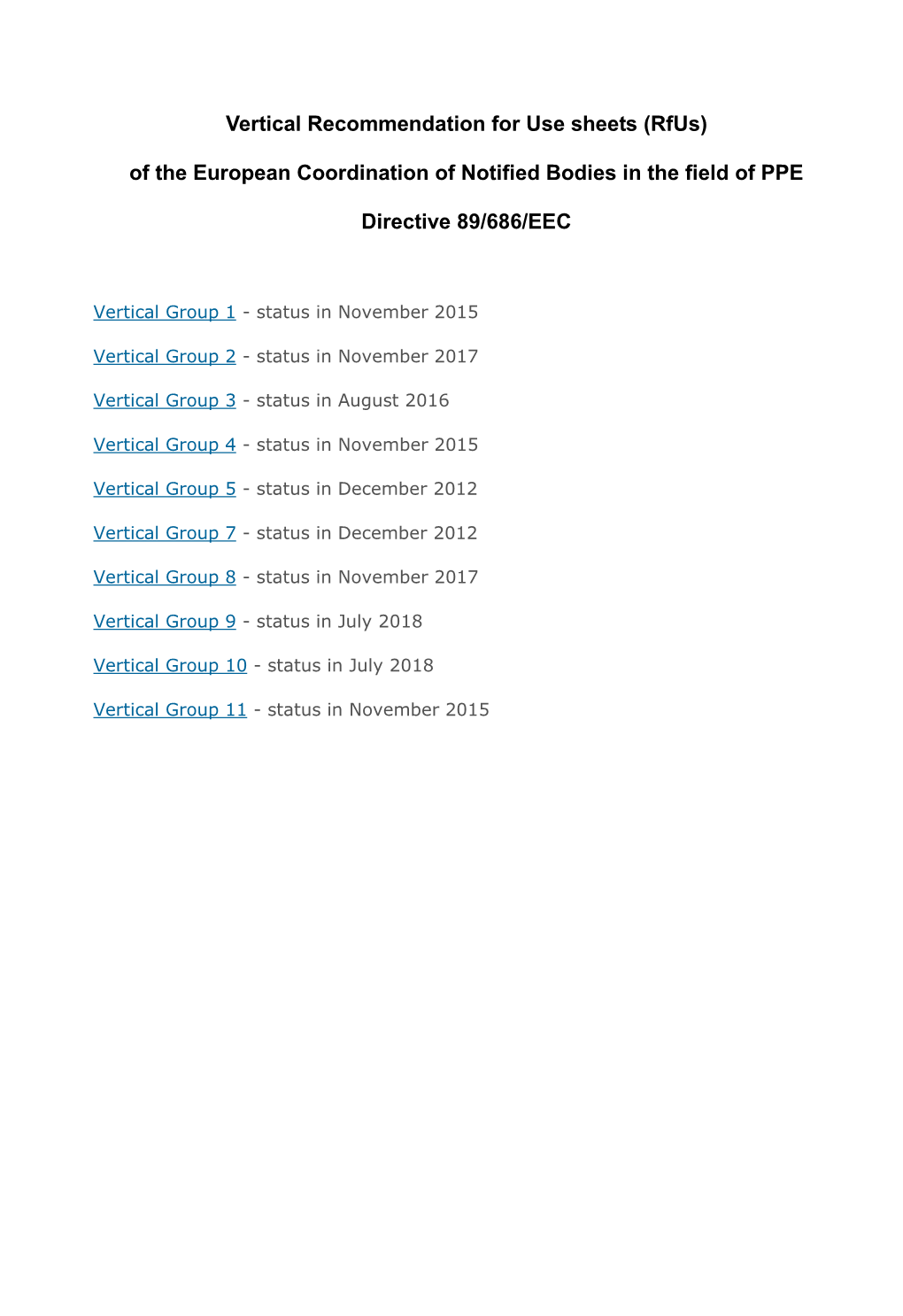

Vertical Recommendation for Use sheets (RfUs) of the European Coordination of Notified Bodies in the field of PPE Vertical Group 1 - status in November 2015 Vertical Group 2 - status in November 2015 Vertical Group 3 - status in March 2013 Vertical Group 4 - status in November 2015 Vertical Group 5 - status in December 2012 Vertical Group 7 - status in December 2012 Vertical Group 8 - status in November 2015 Vertical Group 9 - status in November 2015 Vertical Group 10 - status in November 2015 Vertical Group 11 - status in November 2015 Vertical Recommendation for Use sheets (RfUs) of Vertical Group 1 “Head Protection” of the European Coordination of Notified Bodies in the field of PPE No. Version Reference Key words Approved Approved by Approved by by Vertical Horizontal PPE Expert Group 1 Committee Group 01.001 02 EN 397:1995 (+A1) & Industrial helmet, lateral 18/04/2012 12/12/2012 12/03/2013 EN 397:2012, Clause deformation test, test 6.11.2 procedure 01.002 04 EN 812:2012 Industrial bump caps, 18/07/2014 30/12/2014 19/09/2015 ventilation 01.003 04 Various Shock absorption, 08/05/2014 30/12/2014 19/09/2015 falling headform, alignment, procedure 01.004 02 EN 1384:1996, EN Helmets for equestrian 22/04/2013 30/12/2014 19/09/2015 1384:2012 activities, peak, deflection 01.005 00 General Helmet sizing 31/05/2010 15/06/2011 15/05/2012 01.006 04 Various Kerbstone anvil 08/05/2014 30/12/2014 19/09/2015 01.007 00 All Test method standards 31/05/2010 15/06/2011 15/11/2012 01.008 00 EN 443:2008, Clause Retention system 31/05/2010 15/06/2011 15/11/2012 -

BSI Assurance UK Limited

Schedule of Accreditation issued by United Kingdom Accreditation Service 2 Pine Trees, Chertsey Lane, Staines-upon-Thames, TW18 3HR, UK BSI Assurance UK Limited Issue No: 218 Issue date: 16 September 2021 Kitemark Court Sales Enquiry Tel: +44 (0)845 080 9000 Davy Avenue Fax: +44 (0)1908 228060 Knowlhill Sales Enquiry Email: [email protected] 0003 Milton Keynes BSI Website: www.bsigroup.com Accredited to MK5 8PP Regulatory Contact: Maria Crane ISO/IEC 17065:2012 to provide product Tel: +44 (0)1908 814724 conformity certification Email: [email protected] Locations where certification activities covered by the above Accreditation Standard are undertaken Kitemark Court Kitemark House Davy Avenue Maylands Avenue Knowlhill Hemel Hempstead Milton Keynes Hertfordshire MK5 8PP HP2 4SQ UNITED KINGDOM UNITED KINGDOM Holywell Park Room 1006-1011,10/F Ashby Road Ciro’s Plaza Loughborough 388 Nanjing W. RD Leicestershire Shanghai 200003 LE11 3AQ PR CHINA UNITED KINGDOM Say Building Suite 208 John M. Keynesplein 9, 4th floor Sultan Business Centre 1066 EP PO Box 49400 Amsterdam Dubai NETHERLANDS UNITED ARAB EMIRATES 210 Amarande Avenue Regus Business Park Menlyn Maine Waterkloof Ext 2 0181 SOUTH AFRICA Flexible Scope This Certification Body is additionally accredited to develop and add additional product standards within the highlighted product areas, having demonstrated competence in their design and development process for these areas. Assessment Manager: WC1 Page 1 of 120 Schedule of Accreditation issued by United Kingdom -

Příloha Č. 3; Spotřebičů Pro Domácnost a Podobné NV Č

Příloha je nedílnou součástí osvědčení o akreditaci č.: 260/2021 ze dne: 10. 5. 2021 Akreditovaný subjekt podle ČSN EN ISO/IEC 17065:2013: Strojírenský zkušební ústav, s.p. Certifikační orgán certifikující produkty Hudcova 424/56b, Medlánky, 621 00 Brno Pracoviště certifikačního orgánu: 1. pracoviště Brno Hudcova 424/56b, Medlánky, 621 00 Brno 2. pracoviště Jablonec nad Nisou Tovární 89/5, 466 01 Jablonec nad Nisou Certifikace produktů (zahrnuje hmotné produkty, procesy, služby) Hmotné produkty Pořadové Specifikace norem 1) Název produktu/skupiny produktů Certifikační schéma číslo (normativních dokumentů) 1* Strojní zařízení 1.0 Stroje pro výrobu a užití mechanické NV č. 176/2008 Sb., § 5 odst. (2), odst. energie kromě motorů pro letadla, (3) a), § 6; směrnice 2006/42/ES, čl. 12 automobily a motocykly odst. 2 a 3a), čl. 13 2) Stroje a zařízení pro všeobecné účely SZÚ-1a:2020.00 Obráběcí stroje, lisy apod. strojní zařízení (vychází ze schématu 1a ISO/IEC 17067, Stroje pro určitá hospodářská odvětví založeno na zkoušení a inspekci) ČSN EN ISO 13857:2008 ČSN EN ISO 13857 ČSN EN 349+A1:2008 ČSN EN ISO 13854 ČSN EN ISO 13850 ČSN EN 547-1+A1 ČSN EN 547-2+A1 ČSN EN 547-3+A1 ČSN EN ISO 13732-1 ČSN EN 574+A1:2008 ČSN EN ISO 13851 ČSN EN 614-1+A1 ČSN EN ISO 14123-1 ČSN EN 842+A1 ČSN EN 894-1+A1 ČSN EN 894-2+A1 ČSN EN 894-3+A1 ČSN EN ISO 14120 ČSN EN ISO 13849-1 ČSN EN ISO 14159 ČSN EN 981+A1 ČSN EN ISO 4413 ČSN EN ISO 4414 ČSN EN ISO 13855 ČSN EN ISO 14118 ČSN EN ISO 14119 ČSN EN 12254 ČSN EN ISO 13856-1 ČSN EN ISO 13856-2 Strana 1 z celkového počtu 77 stran Příloha je nedílnou součástí osvědčení o akreditaci č.: 260/2021 ze dne: 10.