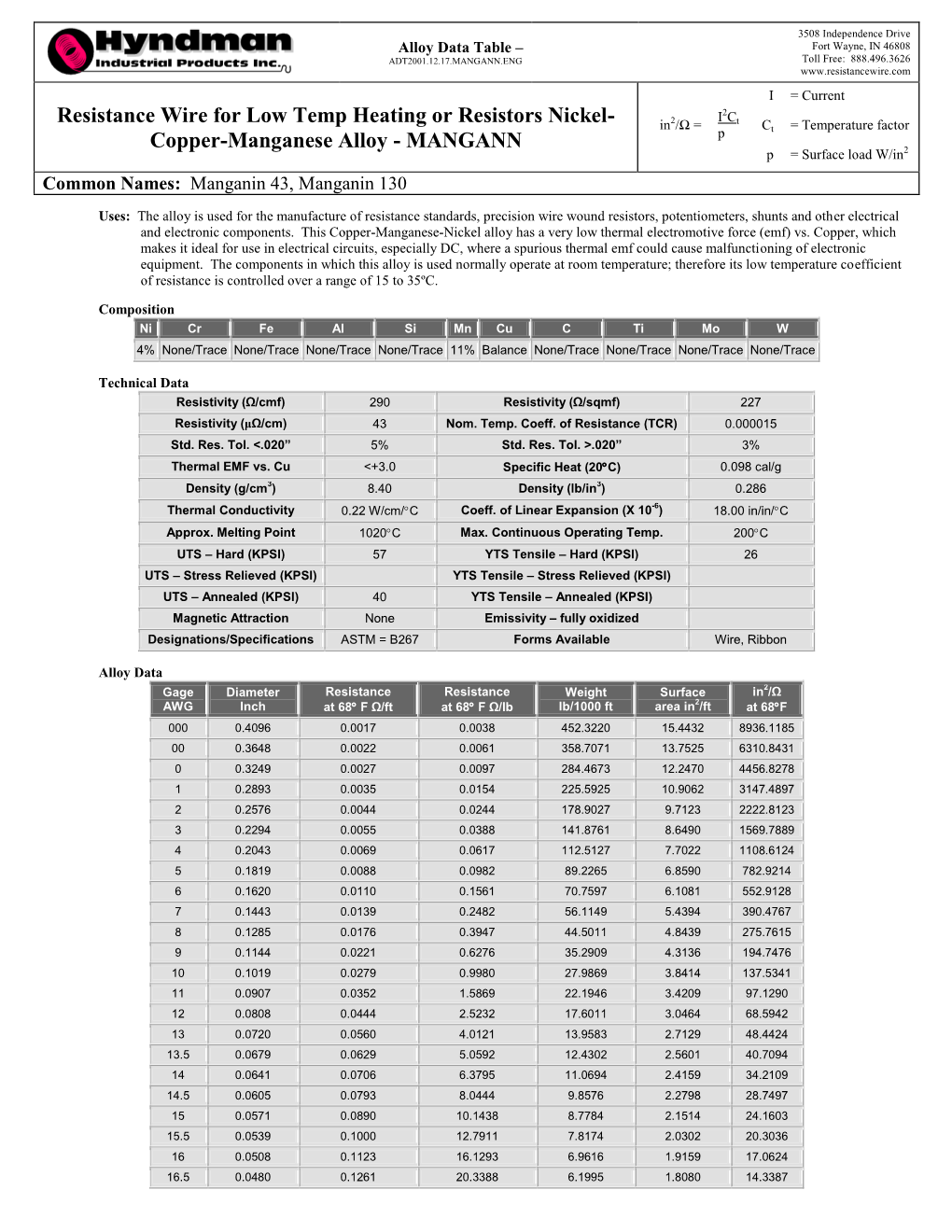

Resistance Wire for Low Temp Heating Or Resistors Nickel- Copper-Manganese Alloy

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

THERMO POWER of Kr IMPLANTED MANGANIN- Cu THERMOCOUPLE T

Solid State Physics ANNUAL REPORT 2005 THERMO POWER OF Kr IMPLANTED MANGANIN- Cu THERMOCOUPLE T. WilczyĔ ska, R. WiĞ niewski, K. Wieteska Institute of Atomic Energy Low electric thermo power of manganin (Cu- junctions were placed into small glass containers insu- Mn_Ni alloy) relative to the copper is an advantage of lated thermally from each other by polystyrene box. The manganin alloy. The aim of this investigation was to hot junction container had suitable electrical heater. check if electric thermo power remains low after im- Temperature of the junctions was measured with mer- plantation with Kr ions. The work described is part of cury micro thermometer or an additional constantan- wide projected concerned with studies on properties of copper thermocouple. manganin implanted with various heavy ions [1]. Our measurements revealed that implantation of The 10P m thick stripe samples of 1 × 75mm were manganin with Kr ions reduces its thermo power rela- implanted with Kr ions in Laboratory of Nuclear Reac- tive to copper by ~50%. Another result of our study is tion at Joint Institute for Nuclear Research, Dubna. A that thermo power of non implanted manganin relative moderation aluminum foil of 11P m thick and 3mm to Cu is a little lower than given in literature. width was used. According to modeling performed with To assess the origin of such significant decrease in TRIM code [2] implantation produced the enhanced thermo EMF after implantation the thermally forced deposition layer near the back side of sample (Fig. 1). electron diffusion in junctions, contact potential and After implantation the samples were annealed for 100h o phonon forced electron drag components of the Seebeck at 130 - 150 C. -

Chapter 25 Resistance and Current

Chapter 25 Resistance and Current Current in Wires • We define the Ampere (amp) to be one Coulomb of charge flow per second • A Coulomb is about 7 x 1018 electrons (or protons) of charge • For reference a “mole” is about 6.02 x 1023 units • Thus a “mole” of Copper 63.5 g/mole (z=29, A=63 (69.15% - 34 Neutrons, A=65 ( 30.85% - 36 Neutrons ) • Contains about 3 x 106 Coulombs BUT only outer electrons are free to move (4S1 state) – one electron per Cu atom in “valence band” • Density of Copper is about 8.9 g/cm3 • Density of free electrons in Cu ~ 1.4 x 104 Coul/cm3 • Or density of free electrons ~ 1023 e/cm3 A bit of History • chalkos (χαλκός) in Greek • Cyprium in Roman times as it was found in Cyprus • This was simplified to Cuprum in Latin and then • Copper in English • Copper mined in what is now Wisconsin 6000-3000 BCE • Copper plumbing found in Egyptian pyramid 3000 BCE • Small amount of Tin (Sn) helps in casting – Bronze (Cu-Sn) Ancient mine in Timna Valley – Negev Israel Current in wire • Lets assume a metal wire has n free charges/ vol • Assume the wire has cross sectional area A • Assume the charges (electrons) move at “drift speed” vd • Lets follow a section of charge q in length x • q = n*A*x (n*volume)e • Where e = electron charge • This volume move (drifts) at speed vd • This charge moves thru x in time • t = x/vd • The current is I= q/t = n*A*x*e/ (x/vd ) = nAvde , Wire gauges AWG – American Wire Gauge • Larger wire gauge numbers are smaller size wire • By definition 36 gauge = 0.005 inches diam • By definition 0000 gauge “4 -

Accessories 143143

Wire IntroductionAccessories 143143 Wire Abbreviations used in this section American wire gauge AWG Single lead wire SL Duo-Twist™ wire DT Quad-Twist™ wire QT Quad-Lead™ wire QL Specifications Phosphor bronze Copper Nichrome Manganin Melting range 1223 K to 1323 K 1356 K 1673 K 1293 K Coefficient of thermal expansion 1.78 × 10-5 20 × 10-6 — 19 × 10-6 Chemical composition (nominal) 94.8% copper, 5% tin, 0.2% — 80% nickel, 20% chromium 83% copper, 13% manganese, phosphorus 4% nickel Electrical resistivity 11 µΩ·cm 1.7 µΩ·cm 120 µΩ·cm 48 µΩ·cm (at 293 K) Thermal 0.1 K NA 9 NA 0.006 conductivity 0.4 K NA 30 NA 0.02 (W/(m·K)) 1 K 0.22 70 NA 0.06 4 K 1.6 300 0.25 0.5 10 K 4.6 700 0.7 2 20 K 10 1100 2.6 3.3 80 K 25 600 8 13 150 K 34 410 9.5 16 300 K 48 400 12 22 AWG Resistance (Ω/m) Diameter Fuse Fuse current Number Name Insulated Insulation type Insulation Insulation (mm) current vacuum (A) of leads diameter thermal breakdown 4.2 K 77 K 305 K air (A) (mm) rating (K) voltage (VDC) Phosphor 1 SL-32 0.241 Polyimide bronze 2 DT-32 0.241 Polyimide 32 3.34 3.45 4.02 0.203 4.2 3.1 493 400 QT-32 0.241 Polyimide 4 QL-32 0.241 Polyimide 1 SL-36 0.152 Formvar® 368 250 2 DT-36 0.152 Polyimide 493 400 36 8.56 8.83 10.3 0.127 2.6 1.4 QT-36 0.152 Formvar® 368 250 4 QL-36 0.152 Polyimide 493 400 Nichrome 32 33.2 33.4 34 0.203 2.5 1.8 1 NC-32 0.241 Polyimide 493 400 Copper 30 0.003 0.04 0.32 0.254 10.2 8.8 1 HD-30 0.635 Teflon® 473 250 34 0.0076 0.101 0.81 0.160 5.1 4.4 2 CT-34 0.254 Teflon® 473 100 Manganin 30 8.64 9.13 9.69 0.254 4.6 4.3 1 MW-30 0.295 Heavy Formvar® 400 32 13.5 14.3 15.1 0.203 3.8 3.5 1 MW-32 0.241 Heavy Formvar® 378 400 36 34.6 36.5 38.8 0.127 2.6 2.5 1 MW-36 0.152 Heavy Formvar® 250 Lake Shore Cryotronics, Inc. -

Manganina 43 Resistance Heating Wire and Resistance Wire Datasheet

MANGANINA 43 RESISTANCE HEATING WIRE AND RESISTANCE WIRE DATASHEET Manganina 43 is a copper-manganese-nickel alloy (CuMnNi alloy) for use at room temperature. The alloy is characterized by very low thermal electromotive force (emf) compared to copper. Manganina 43 is typically used for the manufacturing of resistance standards, precision wire wound resistors, potentiometers, shunts and other electrical and electronic components. The alloy's low emf vs. copper makes it ideal for use in electrical circuits, especially D.C., where a spurious thermal emf could cause malfunctioning of electronic equipment. Due to the low operating temperature, the temperature coefficient of resistance is controlled to be low over a range of 15 to 35°C (59 to 95°F) CHEMICAL COMPOSITION Ni % Mn % Cu % Nominal composition 4.0 11.0 Bal. MECHANICAL PROPERTIES Wire size Yield Strength Tensile Strength Elongation Hardness Ø Rp0.2 Rm A mm (in) MPa (ksi) MPa (ksi) % Hv 1.00 (0.04) 180 (26) 390 (57) 30 110 PHYSICAL PROPERTIES Density g/cm3 (lb/in3) 8.4 (0.303) Electrical resistivity at 20°C Ω mm2/m (Ω circ. mil/ft) 0.43 (259) Temperature coefficient of resistance (15 - 35 °C) (x 10-6/K) 0 ± 15 COEFFICIENT OF THERMAL EXPANSION Temperature °C (°F) Thermal Expansion x 10-6/K (10-6 /°F) 20 - 100 (68-212) 18 (10) THERMAL CONDUCTIVITY Datasheet updated 2/4/2021 1:31:17 PM (supersedes all previous editions) 1 MANGANINA 43 Temperature °C (°F) 20 (68) W m-1 K-1 (Btu h-1ft-1°F-1) 22 (12.7) SPECIFIC HEAT CAPACITY Temperature °C (°F) 20 (68) kJ kg-1 K-1 (Btu lb-1 °F-1) 0.410 (0.10) Melting point °C (°F) 1020 (1868) Max continuous operating temperature in air °C Room temperature Magnetic properties The material is non-magnetic Disclaimer: Recommendations are for guidance only, and the suitability of a material for a specific application can be confirmed only when we know the actual service conditions. -

1.2 Low Temperature Properties of Materials

1.2 Low Temperature Properties of Materials Materials properties affect the performance of cryogenic systems. Properties of materials vary considerably with temperature Thermal Properties: Heat Capacity (internal energy), Thermal Expansion Transport Properties: Thermal conductivity, Electrical conductivity Mechanical Properties: Strength, modulus or compressibility, ductility, toughness Superconductivity Many of the materials properties have been recorded and models exist to understand and characterize their behavior Physical models Property data bases (Cryocomp®) NIST: www.cryogenics.nist.gov/MPropsMAY/material%20properties.htm What are the cryogenic engineering problems that involve materials? USPAS Cryogenics Short Course Boston, MA 6/14 to 6/18/2010 1 Cooldown of a solid component Cryogenics involves cooling things to low temperature. Therefore one needs to understand the process. If the mass and type of the object and its material are known, then the m Ti = 300 K heat content at the designated temperatures can be calculated by integrating 1st Law. ~ 0 dQ Tds= = dE+ pdv The heat removed from the component is equal to its change of T = 80 K m f internal energy, ⎛ Ti ⎞ EΔ m = ⎜ CdT⎟ ⎜ ∫ ⎟ ⎝ T f ⎠ Liquid nitrogen @ 77 K USPAS Cryogenics Short Course Boston, MA 6/14 to 6/18/2010 2 Heat Capacity of Solids C(T) General characteristics: The heat capacity is defined as the change in the heat content with temperature. The heat capacity at constant volume is, 0 300 ∂E ∂s T(K) Cv = and at constant pressure,CTp = ∂T v ∂T p 3rd Law: C 0 as T 0 rms of the heat capacity are oThese two f related through the following thermodynamic relation, 2 ∂v ⎞ ∂p ⎞ Tvβ 2 1 ∂v ⎞ 1 ∂v ⎞ CCT− = − = κ= − ⎟ β= − ⎟ p v ⎟ ⎟ v ∂p ⎟ v ∂T ∂T ⎠p∂v ⎠ T κ ⎠T ⎠ p Isothermal Volume Note: C –C is small except for p v compressibility expansivity gases, where ~ R = 8.31 J/mole K. -

Experimental Determination Op the Specific Heats of Sodium

EXPERIMENTAL DETERMINATION OP THE SPECIFIC HEATS OF SODIUM, COBALT, MANGANESE, AND COBALT-IRON BELOW 1°K. DISSERTATION Presented in Partial Fulfillment of the Requirements for the Degree Doctor of Philosophy in the Graduate School of The Ohio State University By ROGER EDGAR GAUMER, B. S. The Ohio State University 1959 Approved by Adviser Department of Hiysics and Astronomy ACKNOWLEDGEMENTS I wish to acknowledge my debt to Dr. C. V. Heer for his continued support and guidance throughout the course of these investigations. Dr. R. A. Erickson should be acknowledged for a variety of invaluable suggestions concerning experimental procedures. To my fellow graduate student, Mr. David Murray, I extend sincere thanks for all manner of help. Finally, I wish to express gratitude to my wife, Suzanne Morrison Gaumer, for unfailing moral support during these lean years. This work was supported in part by funds granted to The Ohio State University by the Research Foundation and by a contract between the Air Force Office of Scientific Research and The Ohio State University Research Foundation. ii TABLE OF CONTENTS ACKNOWLEDGMENTS..................... * » . LIST OF TABLES .............................. LIST OF ILLUSTRATIONS ....................... INTRODUCTION ................................ Chapter I. THEORY OF THE SPECIFIC HEAT OF SOLIDS . Lattice Specific Heat Electronic Specific Heats in Metals II. EXPERIMENTAL TECHNIQUES ............... Cooling Above 1°K. Cooling Below 1°K. Apparatus Thermometry Vapor Pressure Thermometry Sampe Preparation III. EXPERIMENTAL RESULTS.................. General Methods Thermometer Calibration Copper Sodium Cobalt Manganese Cobalt-Iron Alloy IV. INTERPRETATION OF R E S U L T S ............. Section 1t Copper and Sodium Section 2* Cobalt, Cobalt-Iron Alloy, and Manganese LIST OF REFERENCES LIST OP TABLES Table Page 1* Uanganese Deviation Curve D a t a ........... -

Cartech Guide.9.29.03BLK

2009 Guide to Selecting Carpenter Specialty Alloys CARPENTER: A LEADING PRODUCER AND SUPPLIER OF SPECIALTY ALLOYS For more than a century, Carpenter’s high-performance specialty alloys have been meeting the difficult challenges of advancing technologies. Carpenter is around you every day. You’ll find that these high-performance materials have been used in jet engines, automotive components, high-definition televisions, medical implants and instruments, and many other demanding applications. Carpenter serves the aerospace, automotive, consumer products, defense, energy, industrial and medical markets. Carpenter manufactures hundreds of grades of specialty cast-wrought and powder metallurgy alloys including stainless steels, high temperature (nickel-, iron- and cobalt-base) alloys, high strength steels, magnetic and controlled expansion alloys, tool steels and other special purpose alloys. As a result, Carpenter can offer specialty alloy users many unique advan - tages—from skilled sales, service and technical professionals to 24/7 access to technical data at www.cartech.com to outstanding quality and reliable delivery—wherever and whenever you need high-quality specialty alloys. In this book, select from stainless steels, superior corrosion-resistant alloys, high-temperature alloys, magnetic and controlled-expansion alloys, tool and die steels and many other special purpose grades. Carpenter alloys are available in a variety of product forms, including bar, rod, wire, fine wire and ribbon, strip, plate, special shapes, hollow bar and billet. Get instant access to technical data covering Carpenter’s wide range of specialty alloys from anywhere in the world, 24 hours a day, at www.cartech.com. Click on Tech Center. Registration is easy, fast and free. -

Appendix C: Sensor Packaging and Installation

176 Appendices Appendix C: Sensor Packaging and Installation Appendix C: Sensor Packaging and Installation Installation General installation considerations Once you have selected a sensor and it has been calibrated by Lake Shore, some potential Even with a properly installed temperature difficulties in obtaining accurate temperature measurements are still ahead. The proper sensor, poor thermal design of the overall installation of a cryogenic temperature sensor can be a difficult task. The sensor must be apparatus can produce measurement errors. mounted in such a way so as to measure the temperature of the object accurately without interfering with the experiment. If improperly installed, the temperature measured by the sensor Temperature gradients may have little relation to the actual temperature of the object being measured. Most temperature measurements are made on the assumption that the area of interest Figure 1—Typical sensor installation on a mechanical refrigerator is isothermal. In many setups this may not be the case. The positions of all system elements—the sample, sensor(s), and the temperature sources—must be carefully examined to determine the expected heat flow patterns in the system. Any heat flow between the sample and sensor, for example, will create an unwanted temperature gradient. System elements should be positioned to avoid this problem. Optical source radiation An often overlooked source of heat flow is simple thermal or blackbody radiation. Neither the sensor nor the sample should be in the line of sight of any surface that is at a significantly different temperature. This error source is commonly eliminated by installing a radiation shield around the sample and sensor, either by wrapping super-insulation (aluminized Mylar®) around the area, or Figure 1 shows a typical sensor installation on a mechanical refrigerator. -

Physical Properties of Materials

DEPARTMENT OF COMMERCE BUREAU OF STANDARDS CIRCULAR OF THE BUREAU OF STANDARDS, No. 101 PHYSICAL PROPERTIES OF MATERIALS I. STRENGTHS AND RELATED PROPERTIES OF METALS AND WOOD (Second Edition) April 23, 1924 WASHINGTON GOVERNMENT PRINTING OFFICE 1924 of left upper the in shown laboratories Standards. of industrial Bureau the the in of made are illustration. Laboratories woods this and Technical metals of 101 and properties No. Scientific Standards, physical of the on Bureau the Investigations of Circular DEPARTMENT OF COMMERCE BUREAU OF STANDARDS George K. Burgess, Director CIRCULAR OF THE BUREAU OF STANDARDS, No. 101 PHYSICAL PROPERTIES OF MATERIALS I. STRENGTHS AND RELATED PROPERTIES OF METALS AND WOOD (Second Edition) April 23, 1924 PRICE, 40 CENTS Sold only by the Superintendent of Documents, Government Printing Office Washington, D. C. WASHINGTON GOVERNMENT PRINTING OFFICE 1924 PHYSICAL PROPERTIES OF MATERIALS. I. STRENGTH AND RELATED PROPERTIES OF METALS AND WOOD. ABSTRACT. This circular contains the values for tensile, compressive, and shearing strengths; ductility; modulus of elasticity; and other related properties of pure metals and their alloys and of wood. In addition to these the properties of metals at elevated temperatures, their fatigue and impact properties, and the effect of heat treatment and cold working are given. Other properties and uses of less commonly used metals are described briefly. Graphical representation is used in many cases to show the change of the properties of a material with changing conditions. References to the sources are given for all values in this circular. I. Introduction 8 II. Scope of the work 8 III. Sources of included data 8 IV. -

Tension Amd Temperature Coefficients of the Resistivity of Some Metals Amd Alloys

University of Ghana http://ugspace.ug.edu.gh TENSION AMD TEMPERATURE COEFFICIENTS OF THE RESISTIVITY OF SOME METALS AMD ALLOYS BY VICTOR KODZO MAWU®NA^‘3i A THESIS SUBMITTED FOR THE DEGREE OF MASTER OF PHILOSOPHY IN PHYSICS AT THE UNIVERSITY OF GHANA, LEGON AUGUST, 1997 University of Ghana http://ugspace.ug.edu.gh (f 352717 TU 672. - t o fyq. THtCsr Roort University of Ghana http://ugspace.ug.edu.gh This work is dedicated to : Evelyn, Derrick and Fafa University of Ghana http://ugspace.ug.edu.gh DECLARATION Except for references to the work of other people, this thesis is the work of the author's own research under the supervision of Professor J. K. A. Amuzu. It has neither in part nor whole been presented elsewhere for the award of a degree. VICTOR KODZO MAWUENA PROF. J.K.A. AMUZU (STUDENT) (SUPERVISOR) DATE DATE University of Ghana http://ugspace.ug.edu.gh PREFACE I thank the Almighty God for making it possible for this work to come out successfully. It was not easy coming out with this work. I owe Prof. J. K. A. Amuzu, my supervisor an incalculable debt of gratitude. I will always remember him for his encouragement and good supervisory skills. I wish to thank my co-supervisors; Prof. R. D. Baeta and Dr. R. Kwaajo for their useful suggestions ana contributions. The kind assistance received from other lecturers of the department is greatly appreciated. My appreciation also go to the laboratory technicians for their contributions in making this work a success. This is an opportunity for me to express my sincere gratitude to my friends, colleagues and all others who in diverse ways have helped to bring this work to a successful completion. -

Technical Information

TECHNICAL INFORMATION The following chapter contains practical information on the A // The Electrical Resistance and its Temperature Coefficient behaviour, during and after subsequent treatment, of the alloys delivered by Isabellenhütte. This information is intended to assist B // Special Characteristics of Nickel-Chromium Alloys in selecting the correct alloy for the appropriate application. C // Surface Current-Carrying Capacity As a matter of fact, this information cannot handle all imaginable ▪ of wires applications in detail. For special questions, please contact our ▪ of flat wires experts for support. D // Technical Terms of Delivery and Tolerances A collection of the most important and most often used conversion tables concludes this chapter. E // Corrosion Resistance F // Instructions for Treatment G // Conversion Tables A // THE ELECTRICAL RESISTANCE AND ITS TEMPERATURE COEFFICIENT Resistivity RT = Resistance in Ω at temperature T -1 In accordance with the equation rel,T = Resistivity in Ω * mm² * m at temperature T = Weight in g r m Eq. 1: R = el, T * l r = Density in g/cm³ T A d l = Length in m the electrical resistance of a conductor at temperature T is propor- tional to its length and inversely proportional to its cross-sectional For countries using a different system of measurement the resistivity area on the condition that there is a constant cross-section over is expressed in units which must be converted when changing over the whole test length. from one system to another (see Annex “Conversion Values”). RT = Resistance in Ω at temperature T Resistance per Meter l = Length in m The resistance per meter of a conductor is determined by the A = Cross-Sectional area in mm² quotient of its resistivity and cross-sectional values. -

Alloy - Electrical Properties Electrical Resistivity Temperature Coefficient Mohmcm K-1

Goodfellow Corporation 125 Hookstown Grade Road, Coraopolis, PA 15108-9302. USA Tel: 1-800-821-2870 : Fax 1-800-283-2020 Alloy - Electrical Properties Electrical resistivity Temperature coefficient mOhmcm K-1 Alloy 825 131 - Ni39.5/Fe32/Cr22/Mo 3/Cu 2/ Ti Aluchrom O1 - Resistance 135-145 0.00007 Alloy Fe70/Cr25/Al 5 Aluminium alloy 6061 3.9-4.1 - Al97.5/Mg 1/Si 0.6/Fe 0.5/Cu 0.4 Aluminum alloy 2011 4.5 - Al93/Cu 5.3/Fe 0.7/Si 0.4/Pb 0.3/B Aluminum alloy 6082 3.8 - Al97.4/Si 1/Mg 0.9/Mn 0.7 Aluminum alloy 7075 5.15 - Al90/Zn 5.5/Mg 2.5/Cu 1.5/Si 0.5 Aluminum alloy EN AC 42100 4 - Al 91.7/Si 7/Mg 0.3 Aluminum/Magnesium/ 5.1 - Manganese/Chromium Al96.45/Mg 2.6/Mn 0.8/Cr 0.15 Aluminum/Magnesium/ 3.4-3.8 0.0030 Silicon Al98/Mg 1/Si 0.6 Aluminum/Magnesium/ 3.4-3.8 0.0031-0.0035 Silicon Al98/Mg 1/Si 1 Aluminum/Magnesium/ 3.2 - Silicon Al99/Mg 0.5/Si 0.5 Aluminum/Magnesium 5.6-6.1 0.0020 Al95/Mg 5 Aluminum/Magnesium 4.5-5.7 0.0019-0.0026 Al97/Mg 3 Aluminum/Magnesium 4.95 - Al97.5/Mg 2.5 Aluminum/Silicon/ 3.8 - Magnesium/Manganese Al97.5/Si 1.0/Mg 0.8/Mn 0.7 Aluminum/Silicon 5.56 - Al88/Si12 All information and technical data are given as a guide only.