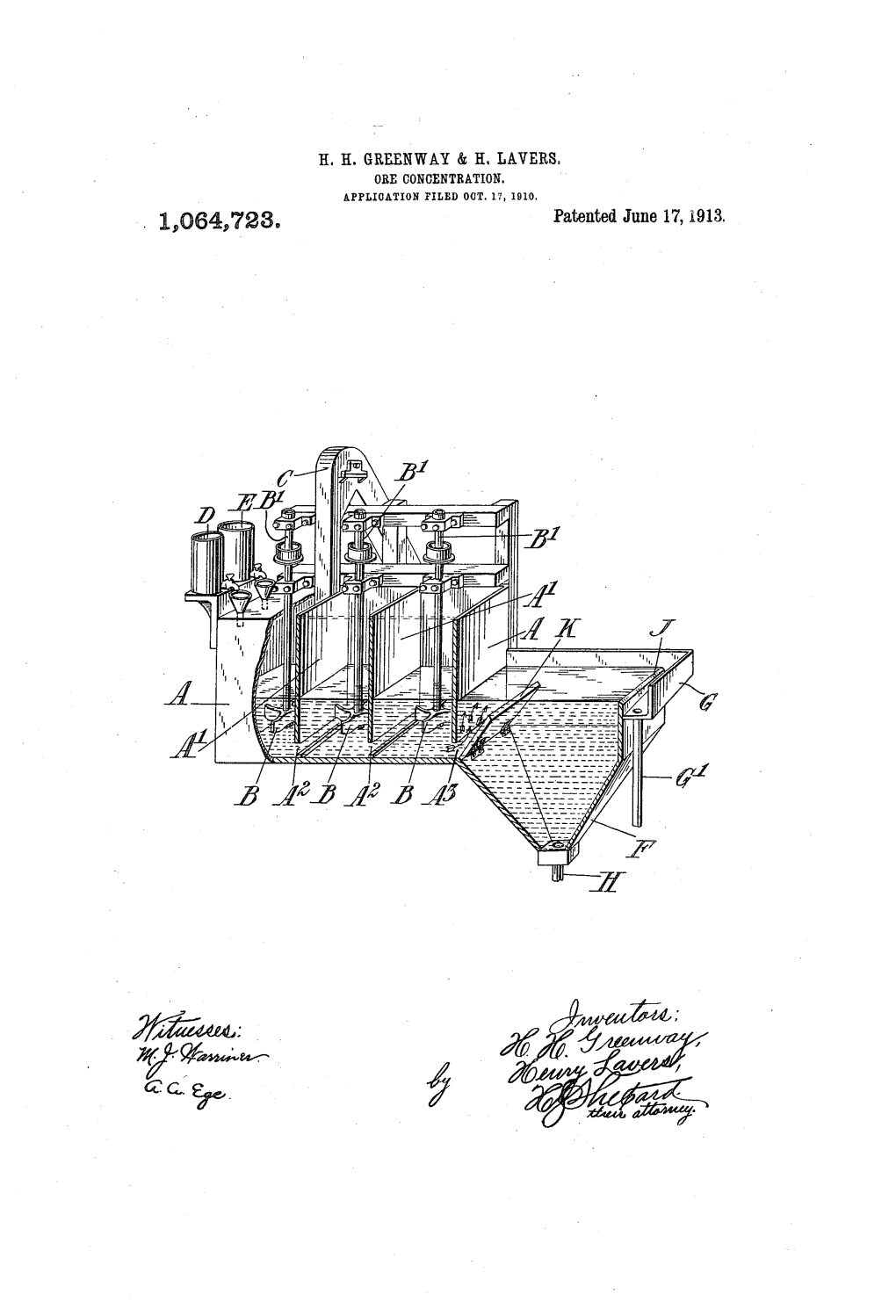

1,064,723, Patented June 17, 1913

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

SA Police Gazette 1937

This sampler file contains various sample pages from the product. Sample pages will often include: the title page, an index, and other pages of interest. This sample is fully searchable (read Search Tips) but is not FASTFIND enabled. To view more samplers click here www.gould.com.au www.archivecdbooks.com.au · The widest range of Australian, English, · Over 1600 rare Australian and New Zealand Irish, Scottish and European resources books on fully searchable CD-ROM · 11000 products to help with your research · Over 3000 worldwide · A complete range of Genealogy software · Including: Government and Police 5000 data CDs from numerous countries gazettes, Electoral Rolls, Post Office and Specialist Directories, War records, Regional Subscribe to our weekly email newsletter histories etc. FOLLOW US ON TWITTER AND FACEBOOK www.unlockthepast.com.au · Promoting History, Genealogy and Heritage in Australia and New Zealand · A major events resource · regional and major roadshows, seminars, conferences, expos · A major go-to site for resources www.familyphotobook.com.au · free information and content, www.worldvitalrecords.com.au newsletters and blogs, speaker · Free software download to create biographies, topic details · 50 million Australasian records professional looking personal photo books, · Includes a team of expert speakers, writers, · 1 billion records world wide calendars and more organisations and commercial partners · low subscriptions · FREE content daily and some permanently The resolution of this sampler has been reduced from the original on CD to keep the file smaller for download. South Australian Police Gazette 1937 Ref. AU5103-1937 ISBN: 978 1 921494 27 7 This book was kindly loaned to Archive CD Books Australia by the South Australia Police Historical Society www.sapolicehistory.org Navigating this CD To view the contents of this CD use the bookmarks and Adobe Reader’s forward and back buttons to browse through the pages. -

The Aboriginal Protectorate on the Mornington Peninsula

Bibliography Manuscript sources Aboriginal Affairs Records, microfilm VPRS 4467, Public Records Office of Victoria (PROV). Barwick, Diane E, Papers, Ms 13521, State Library of Victoria (SLV). Cheeseman, HA, ‘A short Historical Sketch of the District’, talk given to the Gardenvale Historical Society, 2 March 1925, in Cheeseman Family Papers, Brighton Historical Society, Victoria. Cooper, John B, ‘The History of Brighton 1842–1925’, Ms, Brighton City Library, Victoria. D’Arcy, Jacqueline, 8 October 2009, The Problem with Louisa Briggs, Draft Ms. Dredge, James, Diaries, Ms 5244, SLV. Franklin, Lady Jane, ‘Diary of a Journey from Port Phillip to Sydney 3 April to 27 May 1839’, xerox copy (original in NLA), Ms 7942, Box 640/10, SLV. Haydon, George Henry, ‘The Australian diaries and sketches of George Henry Haydon 1840–1845’, microfilm July 1967, National Library of Australia (NLA). Hobson Family Papers, Ms 8457, Box 865/3A, SLV. Hollinshed, CN, undated, ‘A History of the Mornington Peninsula to 1900’, Typescript, Time Booksellers. Kenyon, AS, Papers, Ms 7597, Ms 12173, SLV. Lang, JD, Papers, A 2229, vol 9, CY 900, Mitchell Library, Sydney. La Trobe, Charles Joseph, ‘Memoranda of Journeys, excursions and absences, 1839–1854’, Ms 130003, SLV. Lilly, George, Papers, Ms 11879, Box 2400/2 (a–c), SLV. McCrae, George Gordon, ‘Reminiscences, vols 2, 3, 4’, Ms 12018, Box 2523/4/ items b and c and Box 2523/5/d, SLV. Meyrick, Henry Howard, Letters, Ms 7959, Box 654, SLV. NSW and Port Phillip General Post Office Directory for 1839, 1987, Microfiche, NLA. 401 ‘I Succeeded Once’ Nicholson, Ian, undated, ‘Ships of the “Colonial Marine”, i.e. -

Following the Water: Environmental History and the Hydrological Cycle in Colonial Gippsland, Australia, 1838–1900

FOLLOWING THE WATER ENVIRONMENTAL HISTORY AND THE HYDROLOGICAL CYCLE IN COLONIAL GIPPSLAND, AUSTRALIA, 1838–1900 FOLLOWING THE WATER ENVIRONMENTAL HISTORY AND THE HYDROLOGICAL CYCLE IN COLONIAL GIPPSLAND, AUSTRALIA, 1838–1900 KYLIE CARMAN-BROWN In memory of Mum and Dad Published by ANU Press The Australian National University Acton ACT 2601, Australia Email: [email protected] Available to download for free at press.anu.edu.au ISBN (print): 9781760462840 ISBN (online): 9781760462857 WorldCat (print): 1122806616 WorldCat (online): 1122806567 DOI: 10.22459/FW.2019 This title is published under a Creative Commons Attribution-NonCommercial- NoDerivatives 4.0 International (CC BY-NC-ND 4.0). The full licence terms are available at creativecommons.org/licenses/by-nc-nd/4.0/legalcode Cover design and layout by ANU Press This edition © 2019 ANU Press Contents List of maps, figures and tables . ix Acknowledgements . xiii Maps. .. xv 1 . Introduction . 1 2 . Making the circle round: Perceptions of hydrology through time . 21 3 . The earth’s thoughtful lords? Nineteenth-century views of water and nature . 39 4 . ‘Notwithstanding the inclemency of the weather’: The role of precipitation in the catchment . 85 5 . ‘Fair streams were palsied in their onward course’: The desirability of flowing waters . 127 6 . ‘A useless weight of water’: Responding to stagnancy, mud and morasses . .. 167 7 . Between ‘the water famine and the fire demon’: Drying up the catchment . 213 8 . Mirror, mirror? The reflective catchment . 255 Bibliography . 263 Index . 291 List of maps, figures and tables Maps Map 1: Gippsland Lakes catchment area . xv Map 2: East Gippsland locations . xvi Map 3: West Gippsland locations . -

Latrobe Valley Social History

Latrobe Valley Social History History Social Valley Latrobe Latrobe Valley Social History Celebrating and recognising Latrobe Valley’s history and heritage Celebrating and recognising Latrobe Valley’s history heritage and Latrobe Valley’s recognising and Celebrating Contents Acknowledgements 2 Chapter 3: Communities 69 First peoples 70 Acronyms 3 Co-existence, the mission era and beyond 71 Preface 5 Settler communities 72 Small towns and settlements 73 Introduction 7 Large town centres 74 Housing 77 Chapter 1: Land and Water 9 Town and community life 80 Evolution of a landscape 12 The importance of education 82 Ancient land, ancient culture 14 Sport, recreation and holidays 84 Newcomers 19 Women’s social networks 86 Frontier conflict 21 Church communities 87 Mountain riches 24 Health and hospitals 88 A ‘new province’ 25 Migration 91 Responses to the landscape 28 Don Di Fabrizio: From Italy to Morwell 95 Access to the Valley 30 Lost places 96 Fire and flood 33 Looking back, looking forwards 98 Transforming the land 35 Pat Bartholomeusz: Dedicated to saving a town Hazelwood Pondage 37 and a community 99 Reconnecting to Country 100 Chapter 2: Work and Industry 39 Conclusion 101 Introduction 40 Aboriginal workers 41 Bibliography 103 Mining and timber-cutting 42 Primary sources 104 Farming and the growth of dairying 44 Maps and Plans 104 The promise of coal 46 Published Works 104 A State-run enterprise for winning coal 49 Industrial History 105 Ray Beebe: a working life with the SEC 52 Government Reports, Publications and Maryvale paper mill -

Ferntree Gully Cemetery Register2

Ferntree Gully Cemetery Register Interred Year Surname Given Names Type Location Age Father Mother Where reg. Reg. No. 23-Aug 1967 AARTS CORNELUS B RC C 8 02 25-Nov 1980 ABBOTT MONA B PBL 091 5-Apr 1988 ABBOTT THOMAS B PBL 091 12-Jan 1965 ACKERS LILIAN B RC C 6 15 29-Sep 1971 ADAMS DOROTHY B LS F 177 19-Aug 1994 ADAMS GEORGE A. B LS F 177 7-Feb 1955 ADAMS HONORAH B RC B 7 11 80 William Rigby Mary O'Reagan Camberwell 1576 4-Sep 1978 ADAMS JOYCE B NLA 132 28-Jul 1992 ADAMS KENNETH V. B NLA 132 26-Feb 1975 ADAMS MARGUERITE B LS F 529 18-Sep 1986 ADAMS ROBERT C WR KK 05 28-Aug 1888 ADAMS WILLIAM B NK 14d Alfred Adams Eliza Pert Scoresby 11347 30-Jun 1981 ADAMS WILLIAM B PBL 390 11-Jan 1916 ADDISON ELIZABETH BNK 60John Kerr Agnes McGaw Sherbrooke 3655 28-Jun 1966 ADOLPHSON ANNIE ELIZABETH B COE G 2 11 16-Aug 1951 ADOLPHSON EVELYN IDA C 38 Frederick Adolphson Sarah Lovett Melbourne 1531 9-Oct 1916 ADOLPHSON FREDERICK B COE G 1 11 58 Adolph Adolphson Augusta Olsen East Melbourne 15110 31-Dec 1946 ADOLPHSON GEORGE FREDERICK B COE G 2 10 49 Frederick George Adolphson Sarah Ann Lovett Ringwood 17264/47 19-Feb 1934 ADOLPHSON JOAN MARGARET B COE G 2 10 4 George Frederick Adolphson Annie Elizabeth Ellis Ringwood 13227 25-Jun 1927 ADOLPHSON SARAH B COE G 1 11 54 William Henry Lovett Mary Ann Sheppard Prahran 7391 29-Dec 1980 AGER FREDERICK B LS F 310 7-Apr 1994 AGIUS VINCENT B ND 29 16-Sep 1996 AINGER JOAN C RG 163 9-Sep 1996 AINGER JOHN C RG 162 14-Feb 1978 AINGER NESTA C WR G 11 16-Apr 1895 AINSWORTH JANE B COE A 3 02 18 John Ainsworth Mary Ann Jefferson -

Wilberforce: Slavery, Religion and Politics, Series One, Parts 1 to 3

Wilberforce: Slavery, Religion and Politics, Series One, Parts 1 to 3 WILBERFORCE: SLAVERY, RELIGION AND POLITICS Series One: The Wilberforce Papers from the Bodleian Library, Oxford Part 1: The Papers of William Wilberforce (1759-1833) and Robert Isaac Wilberforce (1802-1857) Part 2: The Papers of Samuel Wilberforce (1818-1873) Part 3: The Papers of Samuel Wilberforce cont (1818-1873) Contents listing PUBLISHER'S NOTE CONTENTS OF REELS - PART 1 CONTENTS OF REELS - PART 2 CONTENTS OF REELS - PART 3 DETAILED LISTING - PART 1 DETAILED LISTING - PART 2 DETAILED LISTING - PART 3 INDEX OF CORRESPONDENTS Wilberforce: Slavery, Religion and Politics, Series One, Parts 1 to 3 Publisher's Note Articles, pamphlets, reviews, letters, letters that grew into books - William Wilberforce spent much of his life writing. He kept a diary for most of his adult life and filled various journals with his religious thoughts. Faced with a difficult decision he would set down both sides of the argument on paper. He wrote memoranda on different subjects, the most famous being his unfinished sketch of Pitt - but the sheer volume of his correspondence alone would have buried most men. He often wrote and received as many as twenty letters a day, and few of them were short. In addition to his own papers, two of his sons kept notes of his conversations in their commonplace books. Here, in Wilberforce: Slavery, Religion and Politics, Series One, Parts 1-3, we are able to make available a complete microfilm edition of the Wilberforce Papers from the Bodleian Library, Oxford. This project unites the separate collections of William Wilberforce’s sons, Robert and Samuel, enabling us to piece back together the Papers of William, Robert and Samuel. -

Wellington Cultural History Bibliography

Cultural Heritage of Wellington Shire: A Bibliography The Smith family of Cowwarr, then Newry, c.1919-1922 2nd Edition 2012 Wellington Shire Heritage Network Cultural Heritage of Wellington Shire: A Bibliography First Edition Compiled by Linda Kennett Centre for Gippsland Studies Monash University For Wellington Shire Council 1999 Second Edition Updated by Linda Barraclough For Wellington Shire Heritage Network and Wellington Shire Library Service Foster Street, Sale 2012 Please note: a small number of the difficult-to-find titles have notes at the very end of the item in [square brackets] to show where the item may be consulted. Most are held at the Centre for Gippsland Studies, or in the Wellington Library Service. Please consult the online Wellington Library Service catalogue to enquire further. For corrections and to add details of further or new books, please e-mail Linda at [email protected] Further copies are available from Wellington Shire Heritage Network C/ Post Office, BOISDALE, 3860 Acknowledgements 2 nd Edition Melva James (Yarram and District Historical Society) Ann and Peter Synan Judy Hirst (Sale and District Family History Group) John Little (Maffra and District Historical Society) Dr Julie Fenwick, Centre for Gippsland Studies, Monash University. Cover Photographs “First and Second editions”: The Smith children, from Cowwarr and then “Parrambeen” at Newry. The parents were Horace Digby Smith and Catherine Maude nee Murphy. It is the same patient pony in both, name not recorded. The second photograph may have been taken at the Newry School, but confirmation is sought. (Courtesy Terry Hore) Table of Contents General Histories ............................................................................................................. 7 Aboriginal History ......................................................................................................... -

The Howard Genealogy : Descendants of John Howard of Bridgewater

G^N / ^^ GENEALOGYGENEA] JMjy((y\M-£^ yVj-H^U ^^#1^)^ H834H I THE Howard Genealogy DESCENDANTS OF JOHN HOWARD BRIDGEWATER, MASSACHUSETTS FROM 1643 TO 1903 BY HEMAN HOWARD Copyrighted, 1903, by Heman Howard. Printed by The Standard Printing Co., Brockton, Mass. CONTENTS. 1157706 Preface, ...... Historical Sketch of Bridgewater, Mass., Howard Seminary, .... xm The Old Bridgewater Historical Society Building, xiv Letter from Mary Hayward to John Hayward, . xvi The Howard Genealogy, -262 Supplement—Corrections—Additions, . 263 Index of Christian Names of Howards, 267 Index of Names other than Howard, 287 INDEX OF ILLUSTRATIONS. Heman Howard, portrait, .... Frontispiece Howard Seminary, .... Old Bridgewater Historical Society building, Mary Hayward's letter to John and George Hayward, Coat of Arms, ..... Site of the first John Howard's house, Jonathan Howard house, Elijah Howard's first house, . Benjamin Beal Howard house, Nehemiah Howard house, George Howard house, . Barnabas Howard house, Daniel Howard house, Abigail Howard tombstone, Gamaliel Howard house, Galen Howard house, Nathan Howard house, . THE HOWARD GENEALOGY. Salmon Howard house, . Jesse Howard house, Ethan Howard house, Jeptha Howard house, . Roland Howard house, Elijah Howard, Jr., house, Edwin Howard, portrait. Col. Caleb Howard house, Edwin Howard house, George Howard, Jr., house, Oliver Howard house, Capt. Eliakim Howard house. Col. Joshua Howard, portrait, John Howard house, Blanche Willis (Howard) von Truffel, portrait, Nathan Howard house, . Thaddeus Howard house, Howard House, Randolph, Mass., 129 Caleb Howard, Jr., house, 132 William Alanson Howard, portrait, 140 Elijah Howard's second house, George Howard house, . Thomas Jefferson Howard house. 156 Major Gen. Oliver Otis Howard, portrait, 193 Gen. Charles Henry Howard, portrait, 196 Rev. -

Victorian Railways Co:Nijviissioners

1893. VICTORIA. VICTORIAN REPORT OF THE VICTORIAN RAILWAYS CO:NIJVIISSIONERS ~'OR 'l'HE YEAH ENDING 30TH JUNE, 18~3. PHES"ENTED TO BOTH HOUSES OF l'.ARLTAJ.VmNT PURSUANT TO THE ACT 54 YWTORI.A No. 1135. 1;)1 aut~orif)l: ROBT. S. BRAIN, GOVERN~IE:"'T PRINTER, MELBOURNE. No. 43.-[ls. !Jd.]-6666. APPROXIMATE COST 0~' REPORT. £ s. d. l'repamtion-Not gh·en. Printing (1,160 copies) 93 0 0 REP 0 R rr. VICTORIAN HAlLWAYS, 19th September, I893· To the Honomble the lVIinister qf Railways. SIR, In accordance with the provisions of the 59th section of the Hailways Act, No. II35, we have the honour to submit, for the information of Parliament, our Report upon the proceedings of the Railway Department for the year ending 3oth June, I 893. DEBENTURE CAPITAL. The amount of borrowed capital was, on 3oth June last, £35,8o6,977 7s. I Id. Details of this amount are given in the following table, tog·ether with the interest payable and accruing thereon for the year:- Amount rif' Interest on Railwa,1j Loans for the Year ending 3oth June, I 893. ! Loans. Debentures at Par. ' Period. Rate. Inwreot. ~--- -···- Per £ s. d. £ s. d. J\Ionths. Cent. £ s. d. 32 Vict. No. 33I ... z,Io7,ooo 0 0 42 Vict. No. 6I7 (Hobson's Bay) ... ... I 5•h900 0 0 ,--------- 2,26I,900 0 0 I2 5 II3,095 0 0 4z Vi et. No. 6o8 ... ... 4,I s6,573 12 2 12 I87,045 16 3 36 Vict. No. 439 ... i 88,872 IS 0 37 Vict. -

G. Tregear (1888), A

(1887), G. Tregear (1888), A. Percv Wats- by him before he went to Gpelong. He ford (1887). entered Wesley College as a State School Of these Bullas is the senior, having en scholar. tered the Ministry in 1872, and the latest Victory war medals were presented by recruit is Chaston, 1922, the Governor-General to Major-General E. Tasmania.^John S. Fletcher (1909), Tivey, C.B., C.M.G., D.S.O., V.D. (1880), William J. Palamountain (1886), Percy O. and to Brigadier-General K. H. Fetherston, Parnaby (1910), John W. Rowse (1885). V.D., Colonial Auxiliary Forces Decoration New South Wales.—Wallis W. Danks (1875). (1895). Eric NaU (1904), ex-master Scotch Col South Australia.—^G. Keysell Haslam lege, and now of Geelong Grammar School, (1896), S. R. Rooney (1886). has exchanged positions with a master in Queensland.—W. Stanlev Bath, B.A. England for one year. (1886). Dr. F. McCallum, M.B., B.S., D.P.H. West Australia.—John W. Grove, M.A., (1907) has been appointed to a travelling LL.B. (1883). scholarship, given by the International New Zealand.—E. O. Blamires (1894). Health Board of the Rockefeller Founda tion, U.S.A. He left Melbourne on 16th Fiji.—C. Oswald Lelean (1881), Arthur August, and while in New York will de G. Adamson, M.A., Dip. Ed. (1901), Leslie vote his time to tuition and research in M. Thompson, M.A., Dip. Ed. (1900). general epidemiology and tropical hygiene. England.—Henry Howard (1878). The scholarship is tenable for one year, all The following are deceased:—^Revs. -

Wilberforce: Slavery, Religion and Politics, Series One, Parts 1 to 3 – Index to Correspondents

Wilberforce: Slavery, Religion and Politics, Series One, Parts 1 to 3 – Index to Correspondents IABBOT, Charles, 1st Baron of Colchester, 17571829. 3 letters to W Wilberforce (1806, 1811, 1822) d. 13, fo 12; d. 17, fo 172; c. 44, fo 1. ABERCORN, Earl of, see HAMILTON. ABERDEEN, Earl of, see GORDON. ACLAND, Sir Henry Wentworth. Letter to S Wilberforce (1854), c. 11, fos 112114. ACLAND, Sir Thomas Dyke, 17871871. Letter to W Wilberforce [1813?] d. 17 fo 227. ADAMS, Coker. Letter to R G Wilberforce (1881) c. 27 fos 114115. ADDERBURY, Oxon. Letter concerning the parish (1864) c. 22, fos 12. ADDERLEY, Charles Bowyer, 1st Baron Norton, 18141905. Letter to S Wilberforce (n.d.) c. 20, fos 106107. ADDERLEY, R B, of the Exchequer Seal Office. Letter to W Wilberforce (1825) c. 3, fo 177. ADDINGTON, Baron, see HUBBARD ADDINGTON, Henry, 1st Viscount Sidmouth, 17571844. 2 letters to W Wilberforce (1801, 1798) d. 13, fo 9; d. 17, fo 88. Letters from Wilberforce (17871788, 1807) c. 44, fos 25; d. 16, fo 61. ADDINGTON, Miss, daughter of Henry Addington, Viscount Sidmouth. Letter to Robert Wilberforce (1834) c. 65, fos 117118. ADELAIDE, Queen, wife of William IV. Facsimile of her directions for her funeral (1841), d. 17, fo 244. AFRICA, Central. Letters to S Wilberforce concerning missions in (18601866), c. 19, fos 139. AFRICA, South. Letters to S Wilberforce concerning the church in (18561873), c. 19, fos 40113. AINSWORTH, William Harrison, novelist. Signature (n.d.) d. -

MARTIN FAMILY PRG 550/ Special Lists

MARTIN FAMILY PRG 550/ Special Lists SERIES 3 : PHOTOGRAPHS Arrangement of the records follows that imposed by D.M. Martin. (See introduction). 1/100 1. Emily Rose - Mrs Burden. 2. Interior scene (not identified). 3. Ruins of large building (not identified) See also 1/100/10. 4. Emily Martin and Agnes Cartwell (?) in buggy. 5. Family group at Evesham - A. Herbert Martin, Miss Hutton, Mrs A.H.M., Dora, Edward and Rosamund. c. 1883. 6. House (not identified). 7. House (not identified). 8. Frank Burden & Emily Martin (Burden). 9. Katherine Cook, Moxon Cook, Rose Clark, Frank Clark, Mrs Frank Clark (Edie), Rose and Birdie Clark. 10. Ruins (not identified). See also 1/100/3. 11. Lithograph of war scene "Pour la patrie" by Lionel Royer. 12. Theodora Martin aged 60. May 1947. 13. Photo. of classical painting (not identified). 14. River scene (not identified) (Badly damaged). 15. Group of fir trees; Beechcombe. 16. Photo of an old painting "Beatrice Cenci" by Guido Reni. 17. Gresham, 1875. 18. Beechcombe. 19. Pieter Botte Mountain, Sth Africa. 20. River Scene (not identified) (Badly damaged - 3 copies). 21. Machinery (not identified) PRG 5503-21 Special lists Page 1 of 21 22. Beach scene (not identified. 23. River scene (not identified) 24. River scene (not identified) 25. Seascape 26. Man on horse (not identified) 27. Garden scene (not identified) 28. Seascape 29. Seascape 30. Man (not identified) 31. Dog (not identified) 32. Beech walk, Beechcombe. 1/101 Album of the Cook family, relatives and friends 1874-1886. 48 prints. See Special List for this item after Series 3 Special List.