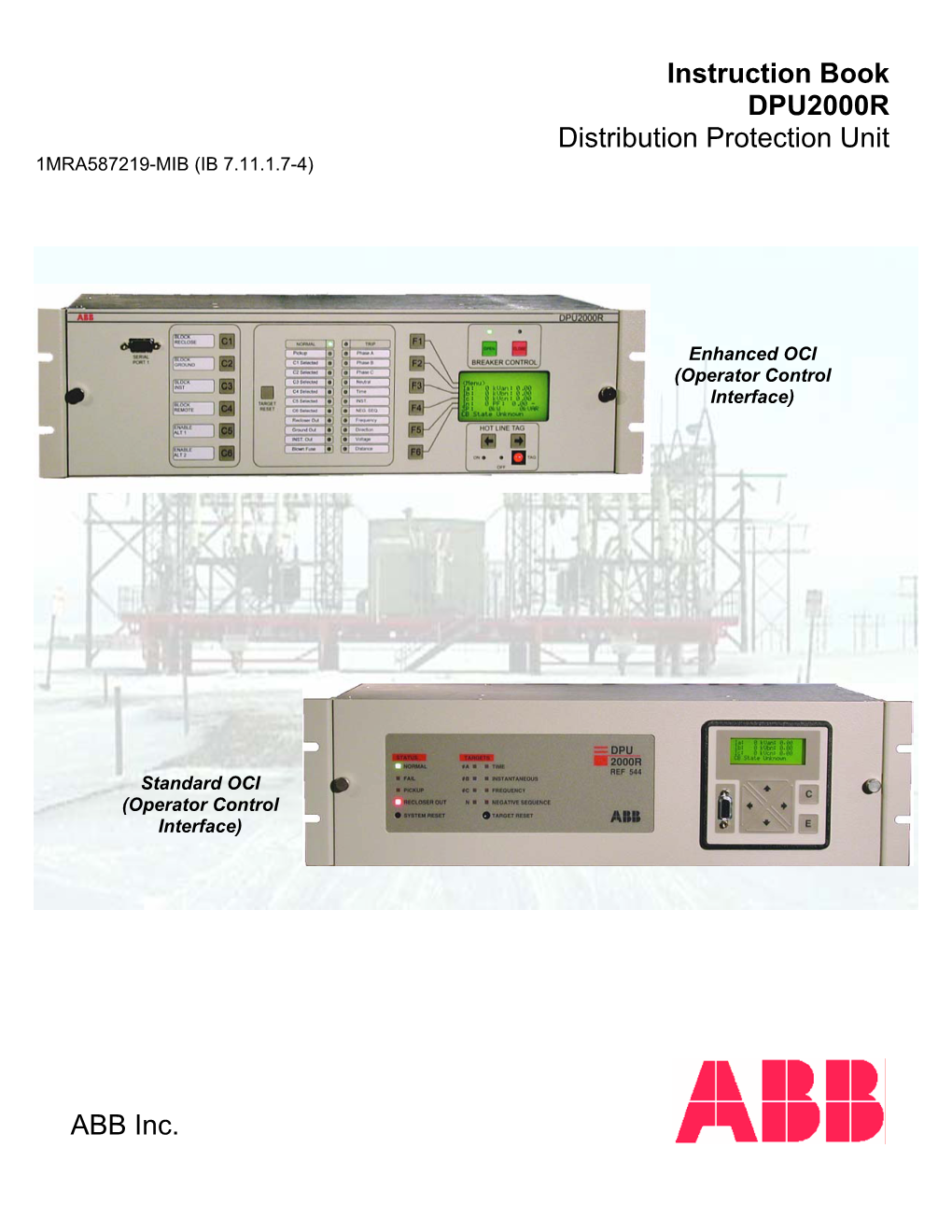

DPU200R Instruction Booklet

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Space Administration

https://ntrs.nasa.gov/search.jsp?R=19700024651 2020-03-23T18:20:34+00:00Z TO THE CONGRESSOF THE UNITEDSTATES : Transmitted herewith is the Twenty-first Semiannual Repol* of the National Aeronautics and Space Administration. Twen~-first SEMIANNUAL REPORT TO CONGRESS JANUARY 1 - JUNE 30, 1969 NATIONAL AERONAUTICS AND SPACE ADMINISTRATION WASHINGTON, D. C. 20546 Editors: G. B. DeGennaro, H. H. Milton, W. E. Boardman, Office of Public Affairs; Art work: A. Jordan, T. L. Lindsey, Office of Organiza- tion and Management. For sale by the Superintendent of Documents, U.S. Government Printing Office Washington, D.C. 20402-Price $1.25 THE PRESIDENT May 27,1970 The White House I submit this Twenty-First Semiannual Report of the National Aeronautics and Space Aldministration to you for transmitttal to Congress in accordance with section 206(a) of the National Aero- nautics and Space Act of 1958. It reports on aotivities which took place betiween January 1 and June 30, 1969. During this time, the Nation's space program moved forward on schedule. ApolIo 9 and 10 demonstrated the ability of ;the man- ned Lunar Module to operate in earth and lunar orbit and its 'eadi- ness to attempt the lunar landing. Unmanned observatory and ex- plorer class satellites carried on scientific studies of the regions surrounding the Earth, the Moon, and the Sun; a Biosatellite oarwing complex biological science experiment was orbited; and sophisticated weather satellites and advanced commercial com- munications spacecraft became operational. Advanced research projects expanded knowledge of space flighk and spacecraft engi- neering as well as of aeronautics. -

MM2EMD L7.Pdf

University of Nottingham Electromechanical devices MM2EMD Lecture 7 – Transistors - Switching high voltage things on with a low voltage Dr. Roderick MacKenzie [email protected] Summer 2015 @rcimackenzie Released under Outline of the lecture •No recap of last lecture :) •Transistor basics •Relays (Mechanical transistor) •NPN Bipolar Junction Transistors •PNP Bipolar Junction Transistors •MOSFETs •Push pull pairs to drive MOSFETs •One last thing •Summary 2 Roderick MacKenzie MM2EMD Electromechanical devices Outline of the lecture •No recap of last lecture :) •Transistor basics •Relays (Mechanical transistor) •NPN Bipolar Junction Transistors •PNP Bipolar Junction Transistors •MOSFETs •Push pull pairs to drive MOSFETs •One last thing •Summary 3 Roderick MacKenzie MM2EMD Electromechanical devices Roderick MacKenzie Roderick electrical devices suchas motors. high voltage control electronics • This lecture is making low voltageThis lecture Think back to lecture 1. lecture Think backto Dave Jones Smart Electronic Circuits (low voltage) Circuits voltage) (high S.J. de Waard Simple Simple Electrical MM2EMD Electromechanical devices 4 Think about an AND gate chip And gate Biro •Look at the tiny thin pins which are used to carry current in and out of the chip. •These pins can supply 25 mA @ 5V at the most. 5 Roderick MacKenzie MM2EMD Electromechanical devices But why is this? i •If we take the top off the chip h p o with acid. G ● Look how much small the actual chip is and look at the tiny bond wires (25 mA @ 5V max!!!) 6 Roderick MacKenzie MM2EMD Electromechanical devices Roderick MacKenzie Roderick 500 V • It needsIt Now think about this motor. this about Now think to run.to 10 Amps 10 at CMBJ the current. -

The Soviet Space Program

C05500088 TOP eEGRET iuf 3EEA~ NIE 11-1-71 THE SOVIET SPACE PROGRAM Declassified Under Authority of the lnteragency Security Classification Appeals Panel, E.O. 13526, sec. 5.3(b)(3) ISCAP Appeal No. 2011 -003, document 2 Declassification date: November 23, 2020 ifOP GEEAE:r C05500088 1'9P SloGRET CONTENTS Page THE PROBLEM ... 1 SUMMARY OF KEY JUDGMENTS l DISCUSSION 5 I. SOV.IET SPACE ACTIVITY DURING TfIE PAST TWO YEARS . 5 II. POLITICAL AND ECONOMIC FACTORS AFFECTING FUTURE PROSPECTS . 6 A. General ............................................. 6 B. Organization and Management . ............... 6 C. Economics .. .. .. .. .. .. .. .. .. .. .. ...... .. 8 III. SCIENTIFIC AND TECHNICAL FACTORS ... 9 A. General .. .. .. .. .. 9 B. Launch Vehicles . 9 C. High-Energy Propellants .. .. .. .. .. .. .. .. .. 11 D. Manned Spacecraft . 12 E. Life Support Systems . .. .. .. .. .. .. .. .. 15 F. Non-Nuclear Power Sources for Spacecraft . 16 G. Nuclear Power and Propulsion ..... 16 Te>P M:EW TCS 2032-71 IOP SECl<ET" C05500088 TOP SECRGJ:. IOP SECREI Page H. Communications Systems for Space Operations . 16 I. Command and Control for Space Operations . 17 IV. FUTURE PROSPECTS ....................................... 18 A. General ............... ... ···•· ................. ····· ... 18 B. Manned Space Station . 19 C. Planetary Exploration . ........ 19 D. Unmanned Lunar Exploration ..... 21 E. Manned Lunar Landfog ... 21 F. Applied Satellites ......... 22 G. Scientific Satellites ........................................ 24 V. INTERNATIONAL SPACE COOPERATION ............. 24 A. USSR-European Nations .................................... 24 B. USSR-United States 25 ANNEX A. SOVIET SPACE ACTIVITY ANNEX B. SOVIET SPACE LAUNCH VEHICLES ANNEX C. SOVIET CHRONOLOGICAL SPACE LOG FOR THE PERIOD 24 June 1969 Through 27 June 1971 TCS 2032-71 IOP SLClt~ 70P SECRE1- C05500088 TOP SEGR:R THE SOVIET SPACE PROGRAM THE PROBLEM To estimate Soviet capabilities and probable accomplishments in space over the next 5 to 10 years.' SUMMARY OF KEY JUDGMENTS A. -

What Are Electronic Timing Relays? a Relay Is an Electromagnetic Switch Which Operates on a Small Electric Current

What Do You Know About Electronic Timing Relays? There are certain components that form the core of the modern control systems. One such important component used in many applications is an Electronic Timing Relay (ETR). Let us start by understanding some basics. What are Electronic Timing Relays? A relay is an electromagnetic switch which operates on a small electric current. These switches are used to turn on or off a circuit of higher amperage. When electricity is applied, the electromagnetic coil causes the armature to move, opening or closing the contacts, controlling the flow of electricity from a high current source connected to the load side of the relay. Relays act as bridges that activate larger currents using smaller ones. This allows you to use a relay to safely switch on and off different devices. An Electronic Timing Relay has circuitry integrated which controls the armature motion upon input voltage being applied. This addition gives the relay the property of time-delay actuation. Electronic Timing Relays are constructed to delay armature motion on coil energization, de-energization, or both. ETRs provide a wide range of selectable functions so that users can customize their specific machine operation. Relay Components and Operation What are the Best Features of Electronic Timing Relays? Electronic timing relays are used in a number of electronic applications, owing to the unending list of their features, which are as follows: • Multi-function timer, which allows the user to adjust between multiple timing functions. • High duty cycle applications. • DIN rail or panel mounting. • Resistant to mechanical shock and vibration. -

Photovoltaic Couplers for MOSFET Drive for Relays

Photocoupler Application Notes Basic Electrical Characteristics and Application Circuit Design of Photovoltaic Couplers for MOSFET Drive for Relays Outline: Photovoltaic-output photocouplers(photovoltaic couplers), which incorporate a photodiode array as an output device, are commonly used in combination with a discrete MOSFET(s) to form a semiconductor relay. This application note discusses the electrical characteristics and application circuits of photovoltaic-output photocouplers. ©2019 1 Rev. 1.0 2019-04-25 Toshiba Electronic Devices & Storage Corporation Photocoupler Application Notes Table of Contents 1. What is a photovoltaic-output photocoupler? ............................................................ 3 1.1 Structure of a photovoltaic-output photocoupler .................................................... 3 1.2 Principle of operation of a photovoltaic-output photocoupler .................................... 3 1.3 Basic usage of photovoltaic-output photocouplers .................................................. 4 1.4 Advantages of PV+MOSFET combinations ............................................................. 5 1.5 Types of photovoltaic-output photocouplers .......................................................... 7 2. Major electrical characteristics and behavior of photovoltaic-output photocouplers ........ 8 2.1 VOC-IF characteristics .......................................................................................... 9 2.2 VOC-Ta characteristic ........................................................................................ -

Experiment (1) Principles of Switching

Experiment (1) Principles of Switching Introduction When you use microcontrollers, sometimes you need to control devices that requires more electrical current than a microcontroller can supply; for this, electrical relays and transistors are used. In this experiment, we will investigate two types of switching; electromechanical switching and solid state switching. Objectives This experiment aims to: 1- Understand the basic principles of switching devices. 2- Introduction to electromechanical switching as well as solid state switching. 3- Understand the advantages and disadvantages of each type. 4- Study the relative speed of different type of switches. Theory Electromechanically Relays Relays are electromechanical devices that use an electromagnet to operate a pair of movable contacts from an open position to a closed position. The relay is a switch that is controlled by a small electric current. It can be used to control motors, heaters or lamps circuits which themselves can draw a lot more electrical power. Figure 1 shows the circuit symbol for a relay. Figure 1: Circuit symbol for a relay In figure 2, the relay’s coil is energized by the low-voltage (12 VDC) source, while the single- pole, single-throw (SPST) contact interrupts the high-voltage (480 VAC) circuit. It is quite likely that the current required to energize the relay coil will be hundreds of times less than the current rating of the contact. Typical relay coil currents are well below 1 amp, while typical contact ratings for industrial relays are at least 10 amps. Mechatronics Systems Design Lab Figure 2: Relay drive an AC load One relay coil/armature assembly may be used to actuate more than one set of contacts. -

IXYS Integrated Circuits Division Introduces High Current MOSFET Power Solid State Relay (SSR)

PRESS RELEASE Contact: Catherine Austin Ph: 978 - 524 - 6823 Fax: 978 - 524 - 4900 IXYS Integrated Circuits Division Introduces High Current MOSFET Power Solid State Relay (SSR) The CPC1 7 0 5Y is a 60V, DC - Only Power Relay , I deal for Variety of High Performance Reliable Switching Applications Beverly, MA – October 1 2, 2017. IXYS Integrated Circuits Division (ICD), Inc., a wholly owned subsidia ry of IXYS Corporation (NASDAQ: IXYS), announced the imm edi ate availability of the CPC1705Y, a 60V, 3.25A , DC - Switching Power SSR. This is the industry’s highest load current rating for a single - pole normally closed ( 1 - Form B) solid state relay using an opti c ally coupled, single MOSFET output switch architecture in a p ower IC package . T he CPC1705Y SSR provides 2500Vrms of input to output isolation and has a very low 0.09 o hms maximum on - r esistance. The relay output is constructed with an efficient MOSFET switch that utilizes I CD’s patented O ptoMOS architecture. The input contro ls the optically cou pled output requiring only 5mA of input current to activate the isolated DC switch. The device is offered in IXYS ICD’s 4 - pin Power Single In - line Package (Power SIP) (10.2 height X 21 .1 length X 3.3 width in mm) which facilitates multiple channel switching in dense printed circuit board design s and has an operational temperature range from - 40 to +85 Celsius. Off state leakage current is 1 microampere maximum at 25 Celsius. The CPC17 05Y 1 - Form - B SSR is complementary to IXYS ICD’s popular CPC1706Y Normally Open ( 1 - Form - A ) SSR with similar specifications. -

Hands on Relay School Transformer Protection Open Lecture Hands on Relay School Transformer Protection Open Lecture

Hands On Relay School Transformer Protection Open Lecture Hands On Relay School Transformer Protection Open Lecture Class Outline • Transformer protection overview • Review transformer connections • Discuss challenges and methods of current differential Protection • Discuss other protective elements used in transformer protection Scott Cooper [email protected] (727)415-5843 Eastern Regional Manager 204 37th Avenue North #281 Manta Test Systems Saint Petersburg, FL 33704 Transformer Protection Overview Transformer Protection Zones Types of Protection Mechanical Protection • Analysis of Accumulated Gases – Looks for arcing by‐products • Sudden Pressure Relays – Orifice allows for normal thermal expansion/contraction. Arcing causing pressure waves in oil or gas space overwhelming the orifice and actuating the relay. • Thermal – Caused by overload, over excitation, harmonics and geo magnetically induced currents • Hot spot temperature • Top Oil • LTC Overheating Types of Protection Relay Protection • Internal Short Circuit – Phase: 87HS, 87T – Ground: 87HS, 87T, 87GD • System Short Circuit Back Up Protection – Phase and Ground Faults • Buses: 50, 50N, 51, 51N, 46 • Lines: 50, 50N, 51, 51N, 46 Types of Protection Relay Protection • Abnormal Operating Conditions – Open Circuits: 46 – Overexcitation: 24 – Undervoltage: 27 – Abnormal Frequency: 81U – Breaker Failure: 50BF, 50BF‐N Phase Differential Overview • What goes into a “unit” comes out of I + I + I = 0 a “unit” 1 2 3 • Kirchoff’s Law: The sum of the I I 1 UNIT 2 currents entering and -

ON Semiconductor Is

ON Semiconductor Is Now To learn more about onsemi™, please visit our website at www.onsemi.com onsemi and and other names, marks, and brands are registered and/or common law trademarks of Semiconductor Components Industries, LLC dba “onsemi” or its affiliates and/or subsidiaries in the United States and/or other countries. onsemi owns the rights to a number of patents, trademarks, copyrights, trade secrets, and other intellectual property. A listing of onsemi product/patent coverage may be accessed at www.onsemi.com/site/pdf/Patent-Marking.pdf. onsemi reserves the right to make changes at any time to any products or information herein, without notice. The information herein is provided “as-is” and onsemi makes no warranty, representation or guarantee regarding the accuracy of the information, product features, availability, functionality, or suitability of its products for any particular purpose, nor does onsemi assume any liability arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages. Buyer is responsible for its products and applications using onsemi products, including compliance with all laws, regulations and safety requirements or standards, regardless of any support or applications information provided by onsemi. “Typical” parameters which may be provided in onsemi data sheets and/ or specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be validated for each customer application by customer’s technical experts. onsemi does not convey any license under any of its intellectual property rights nor the rights of others. -

Design Considerations for Solid State Relays Application Note 5452

Design Considerations for Solid State Relays Application Note 5452 Introduction Solid State Relay and Electromechanical Relay For low voltage signaling applications or low power Comparison switching applications, optically isolated solid state relays A solid state relay offers significant advantages to the (SSRs) with MOSFET outputs provide significant advan- designer. Paramount amongst these advantages is the tages over traditional electromechanical relays (EMRs). almost infinite switching cycles an SSR can perform since In this application note, novel input LED drive current there are no mechanical parts or mechanisms to wear-out. circuits that ensure proper SSR turn-on and turn-off are The solid state reliability and billions of switching cycles discussed. Design techniques for paralleling SSRs for are the SSRs most significant features. Other advantages higher load current or for stacking SSRs for higher load include no contact bounce, the ability to handle relatively withstand voltages are also shown. Finally, example high inrush currents, and immunity to EMI and RFI. applications will show where the strengths of SSRs can be There are no mechanical parts inside SSRs and as a result particularly well used. they are essentially immune to shock, vibration and acceleration. Optically isolated solid state relays are classified as: Form A, single pole, single-throw, normally open; Form B, single Some disadvantages of the SSR include a small but finite pole, single throw, normally closed; and Form C, single off-state leakage current and relatively higher output on pole, double throw with one contact closed and the resistance compared to EMRs. In addition, it is difficult to other contact open. -

Technical Explanation for General-Purpose Relays

Technical Explanation for General-purpose Relays CSM_GeneralRelay_TG_E_10_2 Introduction Sensors What Is a Relay? Basically, a Relay is a device with contacts that opens and closes a switch as the result of an input signal (voltage or current) applied to a coil. Signal applied to Electromagnetism The output Switches Safety Components Relays Control Components Automation Systems Motion / Drives an input coil. operates a motion. contacts operate. Motion is transferred. Output Other Names • Electromagnetic relay Input • Auxiliary relay • Miniature relay •Power relay etc. Electromagnetic section Switch (coil) (contact structure) To get an idea of what relays are, think of a children's athletic carnival. The baton Little A holds on tightly to the baton and passes it to the big B. is the signal. This is a relay. Little A Big B Energy Conservation Support / Environment Measure Equipment Power Supplies / In Addition Others Common 1 Technical Explanation for General-purpose Relays Applications for Relays Sensors Relays are widely used in most machines and devices that use electricity. Refrigerators Home electrical appliances Washing machines, etc. Switches Safety Components Relays Control Components Automation Systems Motion / Drives Molding equipment Packing machinery Industrial machinery Industrial robots Programmable controllers, etc. Chemical plants Shale gas plants Plants Control panels at power stations and transformer substations Control panels for building management, etc. Relay Applications Scientific equipment Constant temperature tanks, etc. Automatic vending machines Vending machines and entertainment equipment Amusement machines, etc. Energy Conservation Support / Environment Measure Equipment Communications and Measurement equipment, etc. measurement equipment Power Supplies / In Addition OA devices Copy machines, etc. Others Common 2 Technical Explanation for General-purpose Relays Types of Relays Sensors There are mainly two types of relays: mechanical relays and solid state relays. -

R842 Electronic Relay for Electric Baseboards

R842 Electronic Relay For Electric Baseboards • Built-in transformer • Universal replacement part • Compatible with electronic T186 room sensor Description Viconics’ innovative R842 electronic relay has been designed for silent control of high voltage resistive heater loads (120V to 600 Vac) from a low voltage control circuit. Typical applications include control of electric baseboard and cabinet heaters in commercial buildings. Inductive motor loads can also be controlled (120 and 240 Vac models only). Using advanced microprocessor-based circuitry, the R842 is capable of handling greater than 500,000 cycles (typical). It has a built-in transformer and is compatible with most industry standard electromechanical or electronic thermostats with on/off outputs. A unique feature of product is that it can operate with a value priced Viconics’ T186 electronic PI (proportional and integral) room thermostat with setpoint capability, providing exceptional accuracy, comfort, and energy savings. Fig.1 - R842 relay for electric baseboards Features Benefits ⇒ Permits fully electronic PI control • Unique compatibility with Viconics’ own designer ⇒ Improved accuracy (+/-0.3ºC) and comfort electronic thermostat ⇒ Energy savings ⇒ Aesthetically pleasing thermostat • Reliable microprocessor-based design ⇒ Long life • Compatible with all standard 24 V thermostats ⇒ Adds flexibility ⇒ Not affected by ambient temperatures typically • Constant 10 second time delay found in older, thermal type baseboard relays ⇒ Less inventory to stock • Built-in transformer