Stainless Steel

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

The White Book of STEEL

The white book of STEEL The white book of steel worldsteel represents approximately 170 steel producers (including 17 of the world’s 20 largest steel companies), national and regional steel industry associations and steel research institutes. worldsteel members represent around 85% of world steel production. worldsteel acts as the focal point for the steel industry, providing global leadership on all major strategic issues affecting the industry, particularly focusing on economic, environmental and social sustainability. worldsteel has taken all possible steps to check and confirm the facts contained in this book – however, some elements will inevitably be open to interpretation. worldsteel does not accept any liability for the accuracy of data, information, opinions or for any printing errors. The white book of steel © World Steel Association 2012 ISBN 978-2-930069-67-8 Design by double-id.com Copywriting by Pyramidion.be This publication is printed on MultiDesign paper. MultiDesign is certified by the Forestry Stewardship Council as environmentally-responsible paper. contEntS Steel before the 18th century 6 Amazing steel 18th to 19th centuries 12 Revolution! 20th century global expansion, 1900-1970s 20 Steel age End of 20th century, start of 21st 32 Going for growth: Innovation of scale Steel industry today & future developments 44 Sustainable steel Glossary 48 Website 50 Please refer to the glossary section on page 48 to find the definition of the words highlighted in blue throughout the book. Detail of India from Ptolemy’s world map. Iron was first found in meteorites (‘gift of the gods’) then thousands of years later was developed into steel, the discovery of which helped shape the ancient (and modern) world 6 Steel bEforE thE 18th cEntury Amazing steel Ever since our ancestors started to mine and smelt iron, they began producing steel. -

Basic Facts About Stainless Steel

What is stainless steel ? Stainless steel is the generic name for a number of different steels used primarily for their resistance to corrosion. The one key element they all share is a certain minimum percentage (by mass) of chromium: 10.5%. Although other elements, particularly nickel and molybdenum, are added to improve corrosion resistance, chromium is always the deciding factor. The vast majority of steel produced in the world is carbon and alloy steel, with the more expensive stainless steels representing a small, but valuable niche market. What causes corrosion? Only metals such as gold and platinum are found naturally in a pure form - normal metals only exist in nature combined with other elements. Corrosion is therefore a natural phenomena, as nature seeks to combine together elements which man has produced in a pure form for his own use. Iron occurs naturally as iron ore. Pure iron is therefore unstable and wants to "rust"; that is, to combine with oxygen in the presence of water. Trains blown up in the Arabian desert in the First World War are still almost intact because of the dry rainless conditions. Iron ships sunk at very great depths rust at a very slow rate because of the low oxygen content of the sea water . The same ships wrecked on the beach, covered at high tide and exposed at low tide, would rust very rapidly. For most of the Iron Age, which began about 1000 BC, cast and wrought iron was used; iron with a high carbon content and various unrefined impurities. Steel did not begin to be produced in large quantities until the nineteenth century. -

What Is Stainless Steel? Table of Contents

eBOOK WHAT IS STAINLESS STEEL? TABLE OF CONTENTS INTRODUCTION ...................................................................................................................................................................3 DISCOVERY OF STAINLESS STEEL .........................................................................................................................4 WHAT IS STAINLESS STEEL ..........................................................................................................................................5 CLASSIFICATIONS .........................................................................................................................................................6–9 Austenitic ......................................................................................................................................................................................6 Ferritic ............................................................................................................................................................................................6 Duplex ............................................................................................................................................................................................7 Martensitic ....................................................................................................................................................................................7 Precipitation Hardening............................................................................................................................................................8 -

Birth of Stainless

By an unknown writer The development of stainless steel The inventor of stainless steel, Harry Brearley, was born in Sheffield, England in 1871. His father was a steel melter, and after a childhood of considerable hardship, he left school at the age of twelve to get a job washing bottles in a chemical laboratory. By years of private study and night school he became an expert in the analysis of steel and its production. Having already established his reputation for solving metallurgical problems, Brearley was given the opportunity in 1908 to set up the Brown Firth Laboratories, which was financed by the two leading Sheffield steel companies of the day. This was a highly innovative idea for its time; research for its own sake on the problems of steel making. In 1912 Brearley was asked to help in the problems being encountered by a small arms manufacturer, whereby the internal diameter of rifle barrels was eroding away too quickly because of the action of heating and discharge gases. Brearley was therefore looking for a steel with better resistance to erosion, not corrosion. As a line of investigation he decided to experiment with steels containing chromium, as these were known to have a higher melting point than ordinary steels. Chromium steels were already at that time being used for valves in aero engines. Iron has an atomic weight of 56, chromium 52, so chromium steel valves are lighter than their carbon steel counterparts, another reason why they were adopted so quickly by the emerging aircraft industry. Using first the crucible process, and then more successfully an electric furnace, a number of different melts of 6 to 15% chromium with varying carbon contents were made. -

The History of Stainless Steel (#05279G) the History of Stainless Steel

© 2010 ASM International. All Rights Reserved. www.asminternational.org The History of Stainless Steel (#05279G) The History of Stainless Steel Harold M. Cobb ASM International® Materials Park, Ohio 44073-0002 www.asminternational.org Copyright © 2010 by ASM International® All rights reserved No part of this book may be reproduced, stored in a retrieval system, or transmitted, in any form or by any means, electronic, mechanical, photocopying, recording, or otherwise, without the written permission of the copyright owner. First printing, June 2010 Great care is taken in the compilation and production of this book, but it should be made clear that NO WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, WITHOUT LIMITATION, WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, ARE GIVEN IN CONNECTION WITH THIS PUBLICATION. Although this information is believed to be accurate by ASM, ASM cannot guarantee that favorable results will be obtained from the use of this publication alone. This publication is intended for use by persons having technical skill, at their sole discretion and risk. Since the conditions of product or material use are outside of ASM’s control, ASM assumes no liability or obligation in connection with any use of this information. No claim of any kind, whether as to products or information in this publication, and whether or not based on negligence, shall be greater in amount than the purchase price of this product or publication in respect of which damages are claimed. THE REMEDY HEREBY PROVIDED SHALL BE THE EXCLUSIVE AND SOLE REMEDY OF BUYER, AND IN NO EVENT SHALL EITHER PARTY BE LIABLE FOR SPECIAL, INDIRECT OR CONSEQUENTIAL DAMAGES WHETHER OR NOT CAUSED BY OR RESULTING FROM THE NEGLIGENCE OF SUCH PARTY. -

Introduction

The History of Stainless Steel Copyright © 2010, ASM International® Harold M. Cobb All rights reserved. www.asminternational.org CHAPTER 1 Introduction “Starting from rust, men have produced something which looks like platinum and resists chemical attack like gold, and yet a square inch can support a quarter of a million pounds . this is the crowning achievement of metallurgy.” Stainless Steel—The Miracle Metal Carl Zapffe, metallurgical consultant, 1960 AS LATE AS the year 1910, the following statement appeared in the British journal The Corrosion and Preservation of Iron and Steel (Cush- man and Gardner): “The tendency to rust is a characteristic inherent in the element known as iron, and will, in all probability, never be to- tally overcome.” As the first hundred years of what may well be called “The Stainless Steel Age” draws to a close, it seems an appropriate time to tell the story of the remarkable discoveries of stainless steels and their myriad applications. There were quite a number of nonferrous metals that were available for use under certain corrosive conditions. They included nickel, nick- el silver (the nickel-copper-tin alloy that contained no silver but re- sembled it somewhat), copper, brass, and bronze. There were also two new alloys, aluminum and Monel, a nickel-copper alloy discovered in 1905 that was used for roofing the new Pennsylvania Railroad Station in New York City. The nonferrous metals served well, but they were more expensive than steel and not as strong. As a result, there was extensive use of ordinary steels with coatings to resist corrosion, coatings that often consisted of nonferrous metals such as zinc and tin, which could be 2 / The History of Stainless Steel applied by dipping the steel into the molten metals or by electroplat- ing the steel with copper, brass, tin, nickel, chromium, or zinc. -

Science and Innovation KS3 / LESSONS 1-5 WORKSHEETS

WWI: Science and Innovation KS3 / LESSONS 1-5 WORKSHEETS IN ASSOCIATION WITH LESSON 1: WORKSHEET Harry Brearley Harry Brearley was born on 18 February 1871 in Sheffield. Like many children who grew up in the city, Harry was the son of a steelworker. When he left school at the age of twelve (leaving school at an early age to get a job was not uncommon in this age) he became a labourer at his father’s steelworks. In later years he would be promoted to the post of general assistant in the company’s chemical laboratory, where metals were turned into useful parts. Harry worked hard at the lab but also studied at home and in evening classes, learning how to specialize in steel production techniques and chemical analysis. By his early thirties Harry had earned a good reputation in the industry. Industrial change All through the 19th century, Europe had seen a massive industrial transformation which helped to bring about many new scientific inventions. Developments in metallurgy (the study of metals), chemistry and electricity led to new forms of explosives, made firearms more reliable and also made communication by telegraph possible. It was in 1908, when two of Sheffield’s two biggest steelworks decided to jointly launch a new research laboratory, that Harry was asked to lead on the project. He went on to join Brown Bayley’s Steel Works (also in Sheffield) and he became a director of the firm in 1925. The science of war Britain began manufacturing large quantities of weapons before WW1, but there was a problem when they were used in battle – the barrels of the guns eroded. -

Dr. WH Hatfield

716 NATURE DECEMBER 18, 1943, VoL: 152 sitization. A similar disease is known in cattle. brite', became the most widely used of this series of (3) Porphyria acuta appears later in life. There is no alloys, and its success was largely due to the energetic bone pigmentation or photosensitivity, but much efforts of Hatfield. He made a detailed study of porphyrin is excreted during attacks. Other sets of the properties of the austenitic stainless steels, symptoms may predominate and the disease is especially of the intercrystall-ine corrosion to which usually fatal. they. were liable under certain conditions, as when Porphyrins are to be regarded as products of welded. This difficulty was overcome partly by keep deranged haimoglobin synthesis rather than as ing the carbon content low and partly by adding degradation products. Further knowledge of haimo carbide-forming elements, such as titanium. The globin synthesis will no doubt help to elucidate the activities of his own firm, of which he became a problems of the abnormal production of porphyrins. director, led him to give .much attention to steels for This meeting was very successful, but could have guns, aircraft and marine forgings, and his later been improved by the allotment of more time for researches dealt mainly with alloy steels,. especially discussion of the many interesting points raised by with mechanical properties, behaviour at high tem each contributor. Sir Joseph Barcroft, in his con peratures, resistance to creep, and corrosion. cluding remarks, expressed the hope that the pro As a result of experiences in the War of 1914-18, ceedings would be published in extenso to allow a certain research committees were set up by the Iron more careful study of a valuable contribution to our and Steel Institute, but after the first enthusiasm knowledge of the tetrapyrrolic pigments. -

Pipe Fabrication Institute Engineering Standard ES-50 Internal Oxidation for Piping Welds

Pipe Fabrication Institute Engineering Standard ES-50 Internal Oxidation for Piping Welds Walter J. Sperko, P.E. Sperko Engineering Services, Inc. Greensboro, NC [email protected] Origins of PFI ES-50 Stainless Steel was developed at Brown Firth Research Laboratories in Sheffield, England by Harry Brearley. The first heat of stainless steel was melted on 13 August 1913; it contained 12.8% chromium. Its primary use was in making rustproof cutlery. Origins of PFI ES-50 Sheffield Stainless Multi-tool from the 1920s Origins of PFI ES-50 • Austenitic Stainless Steel was developed by W. H. Hatfield at Firth-Vickers in 1924 and was marketed under the trade name "Staybrite 18/8” • That’s type 304. Origins of PFI ES-50 What makes stainless steel “rustproof?” • Chromium oxide film on the surface. It forms naturally with exposure to the atmosphere. • The oxide layer “passivates” the underlying steel making it resistant to further oxidation and chemical attack in aggressive environments. • In mild environments like potable water, surface contaminants can set up corrosion cells that lead to pitting attack. Origins of PFI ES-50 The outlet was made using plasma to cut the hole in the type 316L header so that the branch pipe could be welded to the header. The cutting Origins of PFI ES-50 dross was not removed. Service was potable water. Origins of PFI ES-50 After 2 months in service, leaks were noticed. Examination showed pitting around the cutting dross. Origins of PFI ES-50 Plasma cutting slag deposited on the inside of a 316L potable water line caused pitting Origins of PFI ES-50 Plasma cutting slag deposited on the inside of a 316L potable water line caused pitting that led to leaks at each branch location. -

Metallurgy Lane (January, 2015): Stainless Steel: the Steel That Does

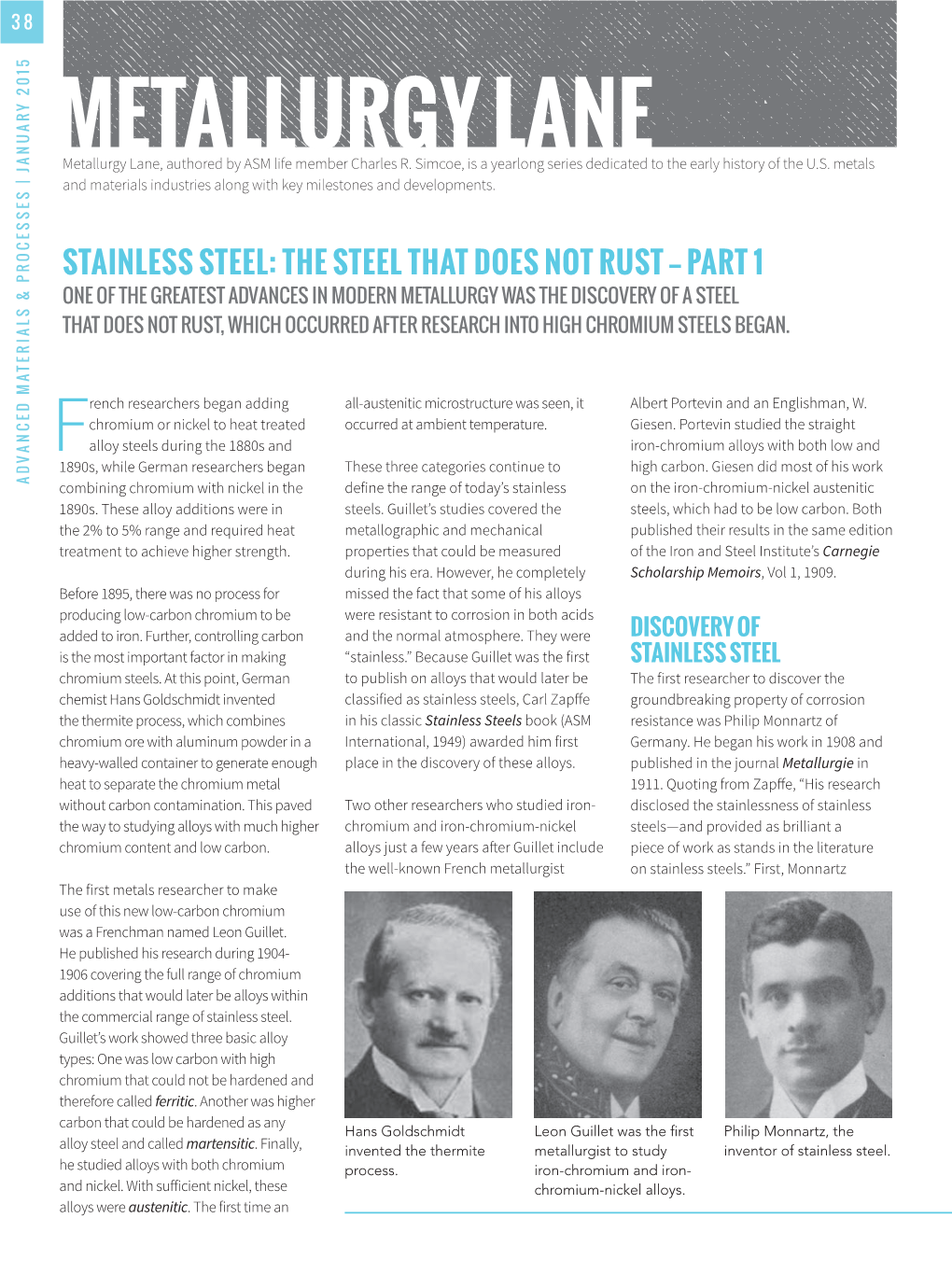

Royal Belgian Institute of Marine Engineers STAINLESS STEEL: THE STEEL THAT DOES NOT RUST — PART 1 ONE OF THE GREATEST ADVANCES IN MODERN METALLURGY WAS THE DISCOVERY OF A STEEL THAT DOES NOT RUST, WHICH OCCURRED AFTER RESEARCH INTO HIGH CHROMIUM STEELS BEGAN. Metallurgy Lane, authored by ASM life member Charles R. Simcoe, is a yearlong series dedicated to the early history of the U.S. metals and materials industries along with key milestones and developments. rench researchers began adding all-austenitic microstructure was seen, it Albert Portevin and an Englishman, W. chromium or nickel to heat treated occurred at ambient temperature. Giesen. Portevin studied the straight Falloy steels during the 1880s and iron-chromium alloys with both low and 1890s, while German researchers began These three categories continue to high carbon. Giesen did most of his work combining chromium with nickel in the define the range of today’s stainless on the iron-chromium-nickel austenitic 1890s. These alloy additions were in steels. Guillet’s studies covered the steels, which had to be low carbon. Both the 2% to 5% range and required heat metallographic and mechanical published their results in the same edition treatment to achieve higher strength. properties that could be measured of the Iron and Steel Institute’s Carnegie during his era. However, he completely Scholarship Memoirs, Vol 1, 1909. Before 1895, there was no process for missed the fact that some of his alloys producing low-carbon chromium to be were resistant to corrosion in both acids added to iron. Further, controlling carbon and the normal atmosphere. -

The Life of Harry Brearley (1871–1948)*

The History of Stainless Steel Copyright © 2010, ASM International® Harold M. Cobb All rights reserved. www.asminternational.org CHAPTER 5 The Life of Harry Brearley (1871–1948)* “The reader will observe that my early work on high chromium steels was not inspired by any intention or hope on my part of dis- covering a stainless steel.” Harry Brearley, Torquay, 1929 BREARLEY’S AUTOBIOGRAPHICAL NOTES were written in 1929, when he was 58 years old and convalescing from an illness at Torquay, a seaside resort in Devon. The papers were bound and sent to his only son, Leo. In 1988, at the time of the 75th anniversary of Brearley’s discovery of stainless steel, British Steel Stainless planned a commem- oration and began collecting memorabilia concerning Brearley and his work. Brearley’s notes were found in Australia in the possession of his grandson, Basil. The notes were published as Harry Brearley— Stainless Pioneer by British Steel Stainless and the Kelham Island In- dustrial Museum in time for the 75th anniversary celebration. Readers will discover how Brearley’s early life and experience led him to become a self-trained chemist and metallurgist. Outokumpu Sheffield (a successor company to British Steel Stainless) has kindly granted permission to quote portions of Brearley’s autobiography. The Early Years “I was born on February 18, 1871, in a backyard off Spital Street, Sheffield, in what was called a ‘House, Chamber and Garret’ dwelling. *Permission granted by Louise Fairweather, Outokumpu-Sheffield (successor company to British Steel Stainless), to use excerpts from Harry Brearley—Stainless Pioneer, published by British Steel Stainless, 1988 34 / The History of Stainless Steel The house would be less than twelve foot square. -

Stainless Steel - St St Introduction

Stainless Steel - St St Introduction Stainless steel is not a single material but the name for CORROSION RESISTANCE a family of corrosion resistant steels. Like many scientific discoveries the origins of stainless steel lies in All stainless steels are iron-based alloys that contain a a serendipitous accident. In 1913 Sheffield, England, minimum of around 10.5% Chromium. The Chromium Harry Brearley was investigating the development of in the alloy forms a self-healing protective clear oxide new steel alloys for use in gun barrels. He noticed that layer. This oxide layer gives stainless steels their some of his samples didn’t rust and were difficult to corrosion resistance. The self healing nature of the etch. These alloys contained around 13% chromium. oxide layer means the corrosion resistance remains The first application of these steels was in cutlery for intact regardless of fabrication methods. Even if the which Sheffield subsequently became world famous. material surface is cut or damaged, it will self heal and Simultaneous work in France led to the development of corrosion resistance will be maintained. the first austenitic stainless steels. Conversely, normal carbon steels may be protected Worldwide demand for stainless steel is increasing at a from corrosion by painting or other coatings like rate of about 5% per annum. Annual consumption is galvanising. Any modification of the surface exposes now well over 20 million tonnes and is rising in areas the underlying steel and corrosion can occur. such as the construction industry and householdThe corrosion of different grades of stainless steel will appliances. New uses are being continuously found for differ with various environments.