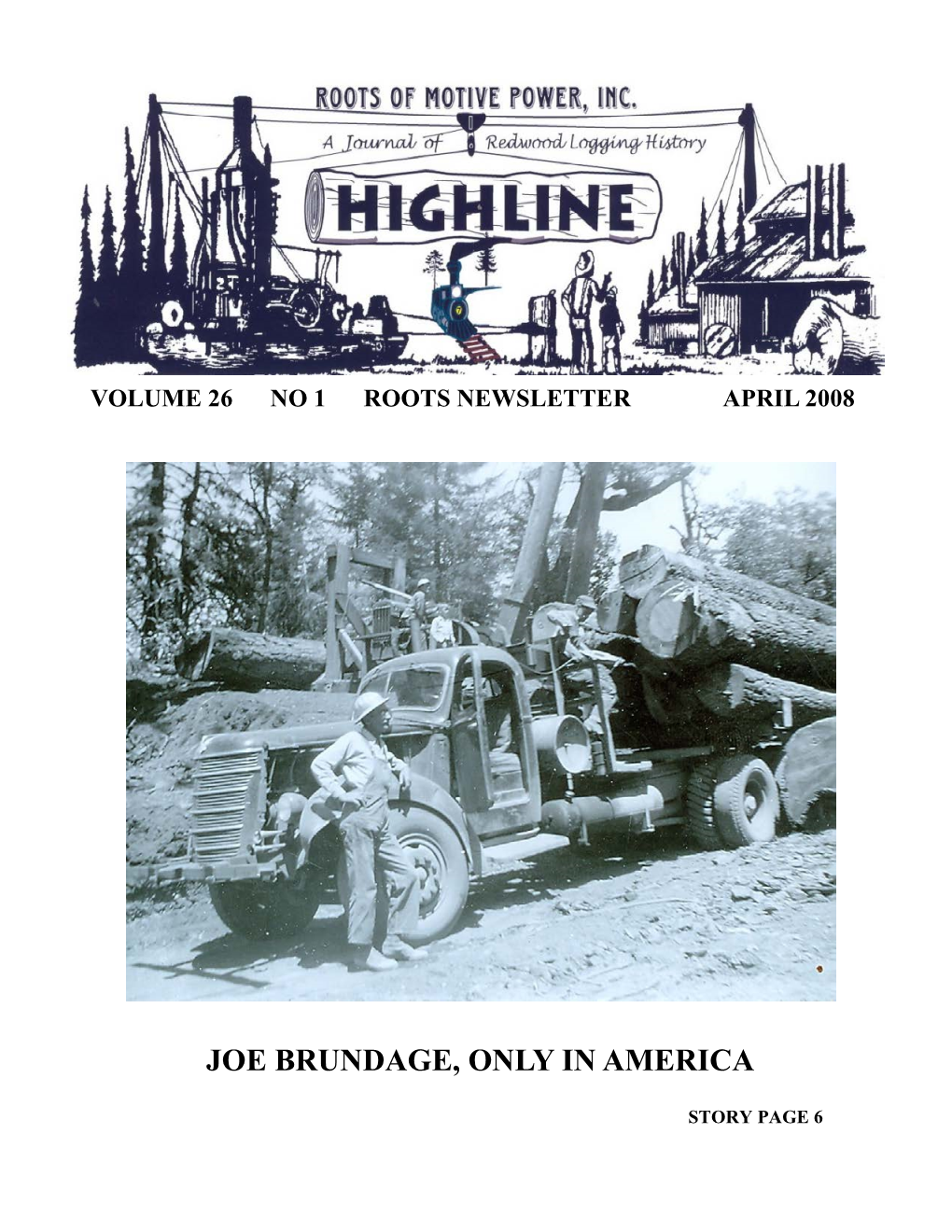

Joe Brundage, Only in America

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Campbell Interurban Press. I

Campbell Interurban Press. Fourteenth Year. CAMPBELL, SANTA CLARA COUNTY, CALIFORNIA, FRIDAY, AUGUST 30, 1907. No. 10. C AMRBELL ¡NTERURBAN PRESS CIIAS. W. DAVISON Practical Sympathy. Attorney at Law PUBLISHED EVERY FRIDAY BY Dr. Edward Everett Rale called up Room 10 City Hall, San Jose. Phone, Brown 632 ELGIN C. IIURLBERT Editor and Proprietor on the editor of a paper In a small New England town. In the course of Subscription. $1.01 a Year in Advance Advertising Rates. .Vic. an Inch per menth conversation tl^e editor told how he GEORGE W. WALDORF Locals, .it' a lino each insertion Resolutions of respecl and condolence,5c a lino. was worrying about his wife, how he Attorney at Law Cards of thanks, 50c. Notices of entertainments, where a charge is made, 5c a line. had sent her to the country for her Telephone—Office Main 271 health, how she was growing worse The Rea Building San Jose, Cal. Entered as second-class nAtter September 30. 1904. at the Postofflce at Campbell, California, under the Act of Congress of March 3, 1879 rather than better, how his heart urg ed him to go to her and how the neces JOHN F. DUNCAN sity of grinding out his editorials day Notary Public The Agricultural Department of the United States is constant by day was keeping him from her bed Office: Batik of Campbell Hot Weather Foods ly increasing the variety of food stuffs and medicines of the coun side. Dr. Hale returned to bis hotel and called for writing materials. After F. B. BROWN Full line cereal foods, Just try by the introduction of new plants from foreign countries to several hours he returned to the editor Attorney at Law i the thing for hot weather, sections adapted to them, says the Morgan Hill Times. -

Black Butte Wild and Scenic River Comprehensive River Management Plan Environmental Assessment

Black Butte Wild and Scenic River Comprehensive River Management Plan Environmental Assessment Recreation & Visual Resource Report Prepared by: Shannon Pozas For: Covelo Ranger District Mendocino National Forest Service 1 August 2017 Contents 1.0 INTRODUCTION .................................................................................................................. 3 1.1 Project Description .............................................................................................................. 3 1.2 Purpose and Need................................................................................................................ 4 1.3 Overview of Issues & Issue Indicators ................................................................................... 4 1.4 Methodology ...................................................................................................................... 4 1.5 Mendocino National Forest Land and Resource Management Plan – LRMP .............................. 5 1.6 Forest Niche ....................................................................................................................... 5 2.0 AFFECTED ENVIRONMENT ................................................................................................ 6 2.1 Black Butte River and Cold Creek Segments .......................................................................... 6 2.2 Recreation Opportunity Spectrum ...................................................................... 6 2.3 Visual Quality Objectives .................................................................................................. -

Campbell Interurban Press

Campbell Interurban Press. Fourteenth Year. CAMFBELLi, SANTA CLARA COUNTY, CALIFORNIA, FRIDAY, JULY 12, 1907. FRUITGROWERS HOLD MOST IMPORTANT MEETING Promotion and General News Administration Is Memorialized to OUR BAY OFFERS Delay Action in Regard to Con VITAL TO DRIED FRUIT request of the committee, Mr. Grif demning Sulphur-Preserved Fruit California Wines. j Good Words for the Prune. GREAT ADVANTAGES INTERESTS OF CALIFORNIA fin, one of the representatives at the California wines are becoming; If lhere ever was a mallgned( original hearing above referred to. Fruitgrowers and packers from recognized everywhere as the only slandered and unjustly treated veg SUGGESTIONS FOR THE DEVEL has gone to Washington fully pre throughout the state held a meetin Concerted Effort Is Required to Pre pure wines served. This superiority! etable, it is the prune. From time OPMENT OF WATER TRASPOR- pared to make such a presentation in San Francisco yesterday after of our wines over those of France ' j TATION FOR THIS SECTION. vent the Condemnation of Fruit morial joke-writers have coupled as will, in the opinion of the com noon under the auspices of the Cal is graphically illustrated in a That Has Been Sulphured. the prune with mother-in-law, an- mittee, show that the proposed de ifornia promotion committee and or toon by McCutcheon, in the Chicago gnlar landlady, star boarder and the Alture Growth of Peninsula Ihrom- cision is manifestly ill advised and ganized the Dried Fruit Protective rrilmne of June 12th. The cartoon | other perennials. There isn’t a ises Great Opportunities for the unjust, first and foremost from An appeal has been made by the Association of California. -

Eel River Cooperative Cyanotoxin Analysis Summary 2013-2017

Eel River Cooperative Cyanotoxin Analysis Summary 2013-2017 By: Eli Asarian and Patrick Higgins Edited by: Diane Higgins Performed for: The Eel River Recovery Project August 2018 Business Sponsors of ERRP Cyanotoxin Analysis Thanks to Individual Crowdfunding Donors and Those Who Contributed Off-line to Support ERRP Cyanotoxin Work: Barbara & David Sopjes Dr. Andrew Stubblefield Mary Power Ree Slocum Bill Dietrich Ben Middlemiss Dean & Sharon Edell Judy Schriebman Jack Crider Daron Pedroja Tim Talbert Gil Anda Ken Miller Will Parrish Dani Walthall Chris McBride Zane and Amanda Ruddy Christina Tran Brett Lovelace Sarah Ottley Ken Vance-Borland Karen & Scott Welsh Thomas Daugherty Pureum Kim Keith Bouma-Gregson Alex Christie Lee McClellan Matthew Amberg Charlie Liphart Eric Damon Walters April Mason Amy Collette Jason Hartwick Marissa Adams Kristin McDonald John Filce Carl Zichella Robert Leher Thanks also to experiment.com, our crowdfunding host that raises funds for scientific research throughout the World: https://experiment.com/projects/when-does-the-eel-river-turn-toxic- patterns-in-cyanotoxin-occurrence-2013-2016. This study was postponed a year so we could collect 2017 cyanotoxin data. Thanks for your patience. Contents Acknowledgements ....................................................................................................................................... 1 Executive Summary ....................................................................................................................................... 2 Background -

Cultural and Historic Resources Assessment and Management Plan Analysis Report (R2018050800003)

1 Cultural and Historic Resources Assessment and Management Plan Analysis Report (R2018050800003) Black Butte River and Cold Creek Segments Black Butte River Wild and Scenic River Mendocino National Forest November 2017 Purpose The comprehensive Management Plan for the Black Butte and Cold Creek Wild and Scenic River (WSR) establishes programmatic management direction for the WSR corridor. It has been developed to implement the direction of the Wild and Scenic River Act of 1968 as amended in the 2006 Northern California Coastal Wild Heritage Wilderness Act (Public Law 109-362) to include 19.5 miles of the Black Butte River and 1.5 miles of Cold Creek. The WSR Act established a system for preserving outstanding free-flowing rivers. A defined section in Section 1(b) of the WSR Act: “certain selected rivers of the Nation which, with their immediate environments, possess outstandingly remarkable scenic, recreations, geologic, fish and wildlife, historic, cultural, or other similar values, shall be preserved in free-flowing condition, and that they and their immediate environments shall be protected for the benefit and enjoyment of present and future generations” (PL 90-542, 1968). The WSR Act requires the Forest Service to develop a comprehensive WSR Management Plan for the Black Butte and Cold Creek to protect and enhance the outstandingly remarkable fish and cultural/historic values. The WSR Management Plan will guide all development, management, and restoration activities within the WSR corridor. It includes standards and guidelines from the Proposed Action Alternative, an Implementation Plan with a list of possible projects, and a Monitoring Plan. The standards and guidelines are a statement of the WSR Management Plan’s management direction; however, the potential projects from the implementation plan are estimates and depend on site-specific NEPA (National Environmental Policy Act) analysis and the agency’s budgeting process. -

Table of Contents

TABLE OF CONTENTS PAGE ABOUT US (i) FACTS ABOUT DVDs / POSTAGE RATES (ii) LOOKING AFTER YOUR DVDs (iii) Greg Scholl 1 Pentrex (Incl.Pentrex Movies) 9 ‘Big E’ 32 General 36 Electric 39 Interurban 40 Diesel 41 Steam 63 Modelling (Incl. Allen Keller) 78 Railway Productions 80 Valhalla Video Productions 83 Series 87 Steam Media 92 Channel 5 Productions 94 Video 125 97 United Kindgom ~ General 101 European 103 New Zealand 106 Merchandising Items (CDs / Atlases) 110 WORLD TRANSPORT DVD CATALOGUE 112 EXTRA BOARD (Payment Details / Producer Codes) 113 ABOUT US PAYMENT METHODS & SHIPPING CHARGES You can pay for your order via VISA or MASTER CARD, Cheque or Australian Money Order. Please make Cheques and Australian Money Orders payable to Train Pictures. International orders please pay by Credit Card only. By submitting this order you are agreeing to all the terms and conditions of trading with Train Pictures. Terms and conditions are available on the Train Pictures website or via post upon request. We will not take responsibility for any lost or damaged shipments using Standard or International P&H. We highly recommend Registered or Express Post services. If your in any doubt about calculating the P&H shipping charges please drop us a line via phone or send an email. We would love to hear from you. Standard P&H shipping via Australia Post is $3.30/1, $5.50/2, $6.60/3, $7.70/4 & $8.80 for 5-12 items. Registered P&H is available please add $2.50 to your standard P&H postal charge. -

Black Butte River Proposed Wilderness Area

Proposed Wilderness Pattison Northern California Mountains and Rivers Black Butte River Proposed Wilderness Area Description Quick Facts The Wild and Scenic Black Butte River flows northwest for almost 30 Management Agency: miles from the crest of the northern Coast Range to the Wild and U.S. Forest Service, Scenic Middle Fork Eel River downstream. Mendocino National Forest The proposed wilderness is situated in the river’s V-shaped, rugged Location: canyon, where it hosts resident trout, Chinook salmon, and winter-run Mendocino County, CA; nd steelhead. Downstream, the Middle Fork Eel supports what is 2 Congressional District presently considered to be the southernmost population of summer- run steelhead on the West Coast and the largest single run of summer Watershed: Black Butte River, a steelhead in the state. Rich oak forests, meadows, and abundant tributary of the Middle Fork Eel ancient pine, fir and cedar forest grace the slopes above the river. The River Forest Service notes that the region contains so many pristine Size: 24,621 acres archeological sites that it is of “exceptional” cultural importance. The Black Butte has been rated as a class IV+ stream (very difficult) by Recreational Uses: Fishing, American Whitewater for those brave enough to kayak it. kayaking, hiking, horseback riding, important historical sites The Bauer brothers had this to say in American Whitewater Journal after running the stream in the 1970s: “The Black Butte is an all-time Ecological Values: classic! We all agreed that we had never experienced a better Ancient conifer and hardwood combination of fantastic rapids, beautiful scenery, abundant wildlife, forests, critically-important salmon and isolation from humanity. -

Salmonid Habitat and Population Capacity Estimates for Steelhead Trout and Chinook Salmon Upstream of Scott Dam in the Eel River, California

Emily J. Cooper1, Alison P. O’Dowd, and James J. Graham, Humboldt State University, 1 Harpst Street, Arcata, California 95521 Darren W. Mierau, California Trout, 615 11th Street, Arcata, California 95521 William J. Trush, Humboldt State University, 1 Harpst Street, Arcata, California 95521 and Ross Taylor, Ross Taylor and Associates, 1660 Central Avenue # B, McKinleyville, California 95519 Salmonid Habitat and Population Capacity Estimates for Steelhead Trout and Chinook Salmon Upstream of Scott Dam in the Eel River, California Abstract Estimating salmonid habitat capacity upstream of a barrier can inform priorities for fisheries conservation. Scott Dam in California’s Eel River is an impassable barrier for anadromous salmonids. With Federal dam relicensing underway, we demonstrated recolonization potential for upper Eel River salmonid populations by estimating the potential distribution (stream-km) and habitat capacity (numbers of parr and adults) for winter steelhead trout (Oncorhynchus mykiss) and fall Chinook salmon (O. tshawytscha) upstream of Scott Dam. Removal of Scott Dam would support salmonid recovery by increasing salmonid habitat stream-kms from 2 to 465 stream-km for steelhead trout and 920 to 1,071 stream-km for Chinook salmon in the upper mainstem Eel River population boundaries, whose downstream extents begin near Scott Dam and the confluence of South Fork Eel River, respectively. Upstream of Scott Dam, estimated steelhead trout habitat included up to 463 stream-kms for spawning and 291 stream-kms for summer rearing; estimated Chinook salmon habitat included up to 151 stream-kms for both spawning and rearing. The number of returning adult estimates based on historical count data (1938 to 1975) from the South Fork Eel River produced wide ranges for steelhead trout (3,241 to 26,391) and Chinook salmon (1,057 to 10,117). -

Los Angeles Bibliography

A HISTORICAL BIBLIOGRAPHY OF THE BUILT ENVIRONMENT IN THE LOS ANGELES METROPOLITAN AREA Compiled by Richard Longstreth 1998, revised 16 May 2018 This listing focuses on historical studies, with an emphasis is on scholarly work published during the past thirty years. I have also included a section on popular pictorial histories due to the wealth of information they afford. To keep the scope manageable, the geographic area covered is primarily limited to Los Angeles and Orange counties, except in cases where a community, such as Santa Barbara; a building, such as the Mission Inn; or an architect, such as Irving Gill, are of transcendent importance to the region. Thanks go to Kenneth Breisch, Dora Crouch, Thomas Hines, Greg Hise, Gail Ostergren, and Martin Schiesl for adding to the list. Additions, corrections, and updates are welcome. Please send them to me at [email protected]. G E N E R A L H I S T O R I E S A N D U R B A N I S M Abu-Lughod, Janet, New York, Chicago, Los Angeles: America's Global Cities, Minneapolis: University of Minnesota Press, 1999 Adler, Sy, "The Transformation of the Pacific Electric Railway: Bradford Snell, Roger Rabbit, and the Politics of Transportation in Los Angeles," Urban Affairs Quarterly 27 (September 1991): 51-86 Akimoto, Fukuo, “Charles H. Cheney of California,” Planning Perspectives 18 (July 2003): 253-75 Allen, James P., and Eugene Turner, The Ethnic Quilt: Population Diversity in Southern California Northridge: Center for Geographical Studies, California State University, Northridge, 1997 Avila, Eric, “The Folklore of the Freeway: Space, Culture, and Identity in Postwar Los Angeles,” Aztlan 23 (spring 1998): 15-31 _________, Popular Culture in the Age of White Flight: Fear and Fantasy in Suburban Los Angeles, Berkeley: University of California Pres, 2004 Axelrod, Jeremiah B. -

TIMEPOINTS Volume 89 January/February/March 1996 Numbers 1, 2 & 3

TIMEPOINTS Volume 89 January/February/March 1996 Numbers 1, 2 & 3 Angels Flight™ Re-opens JANUARY/FEBRUARY/MARCH 1996 Page 1 ™ Timepoints January/February/March 1996 Angels Flight Reopens The Southern California Traction Review On February 23, 1996 at approximately 9:37am the offi- cial first run of the restored version of Angels Flight™ Always a Newsletter in sight produced by ended almost 27 years of “Flightless” activity between Hill The Electric Railway Historical Association & Olive Streets in downtown Los Angeles. of Southern California, Inc. TIMEPOINTS has already brought you extensive coverage Subscription included in membership. of the rebuilding process (see November 1991 issue, mov- ing the winch house and arch to Hill Street, March 1994 ERHA membership is $25.00 per year issue devoted to the restoration, January/February/March Editorial Mailing Address Circulation, ERHA Business 1995 issue, construction begins and July/August/Septem- Digital Realitites ERHA of SC ber 1995 Olivet & Sinai and more construction progress) John Heller 1 World Trade Center but the reopening of the Flight means much to Angelenos 7315 Melrose Avenue P.O. Box 32161 and is the closest thing to heritage trolley operation we Hollywood, CA 90046 Long Beach, CA 90832-2161 have... ERHA of SC1995 Board of Directors Service hours are President Alan Fishel 6AM to 10PM seven days/ Vice-President John Heller week (original hours Recording Secretary Jerry Pass were 6AM to 12:20AM Treasurer Jed Hughes seven day/week) Membership Secretary William Costley Restoration cost: $4.1 At-Large David Cameron million Paul Ward Funding: CRA and ÇPershing Square Red LineStation Contributors . -

MICROCOMP Output File

109TH CONGRESS 1ST SESSION S. 128 AN ACT To designate certain public land in Humboldt, Del Norte, Mendocino, Lake, and Napa Counties in the State of California as wilderness, to designate certain segments of the Black Butte River in Mendocino County, Cali- fornia as a wild or scenic river, and for other purposes. 1 Be it enacted by the Senate and House of Representa- 2 tives of the United States of America in Congress assembled, 3 SECTION 1. SHORT TITLE. 4 This Act may be cited as the ‘‘Northern California 5 Coastal Wild Heritage Wilderness Act’’. 2 1 SEC. 2. DEFINITION OF SECRETARY. 2 In this Act, the term ‘‘Secretary’’ means— 3 (1) with respect to land under the jurisdiction 4 of the Secretary of Agriculture, the Secretary of Ag- 5 riculture; and 6 (2) with respect to land under the jurisdiction 7 of the Secretary of the Interior, the Secretary of the 8 Interior. 9 SEC. 3. DESIGNATION OF WILDERNESS AREAS. 10 In accordance with the Wilderness Act (16 U.S.C. 11 1131 et seq.), the following areas in the State of California 12 are designated as wilderness areas and as components of 13 the National Wilderness Preservation System: 14 (1) SNOW MOUNTAIN WILDERNESS ADDITION.— 15 (A) IN GENERAL.—Certain land in the 16 Mendocino National Forest, comprising ap- 17 proximately 23,312 acres, as generally depicted 18 on the maps described in subparagraph (B), is 19 incorporated in and shall considered to be a 20 part of the ‘‘Snow Mountain Wilderness’’, as 21 designated by section 101(a)(31) of the Cali- 22 fornia Wilderness Act of 1984 (16 U.S.C. -

Land Areas of the National Forest System

United States Department of Agriculture Land Areas of the National Forest System As of September 30, 2012 Forest Service WO Lands FS-383 November 2012 United States Department of Agriculture Forest Service Land Areas of the WO, Lands National Forest FS-383 System January 2013 As of September 30, 2012 Published by: USDA Forest Service 1400 Independence Ave., SW Washington, D.C. 20250-0003 Web site: http://www.fs.fed.us/land/staff/lar/ Cover Photo: Mt. Edgecumbe, Kruzof Island, Alaska Courtesy of: Jeffery Wickett Table of Contents Table 1 – National and Regional Areas Summary ...............................................................1 Table 2 – Regional Areas Summary ....................................................................................2 Table 3 – Areas by Region...................................................................................................4 Table 4 – Areas by State ....................................................................................................17 Table 5 – Areas in Multiple States .....................................................................................51 Table 6 – NFS Acreage by State, Congressional District and County ..............................56 Table 7 – National Wilderness Areas by State ................................................................109 Table 8 – National Wilderness Areas in Multiple States .................................................127 Table 9 – National Wilderness State Acreage Summary .................................................130