United States Patent Office

Total Page:16

File Type:pdf, Size:1020Kb

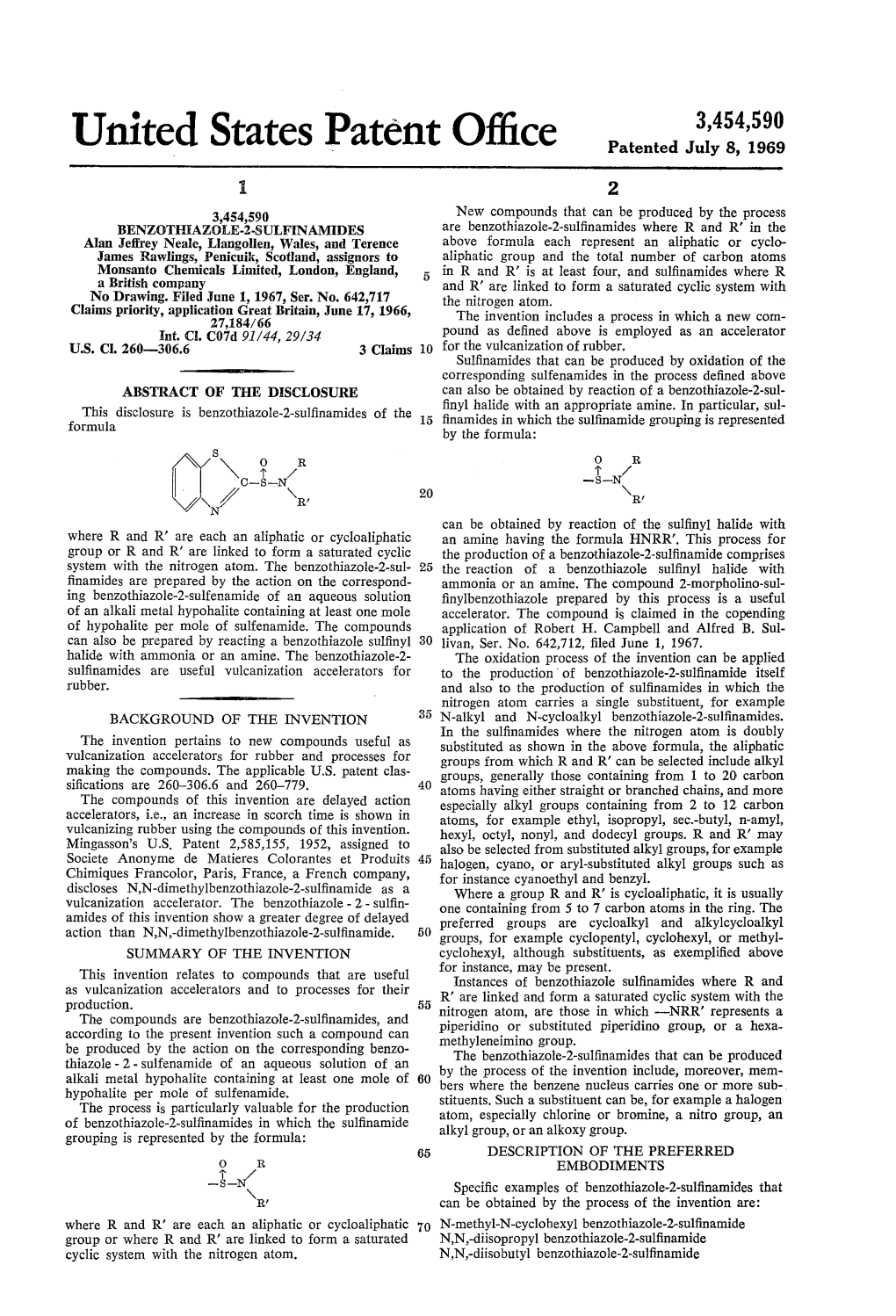

Load more

Recommended publications

-

Vulcanization & Accelerators

Vulcanization & Accelerators Vulcanization is a cross linking process in which individual molecules of rubber (polymer) are converted into a three dimensional network of interconnected (polymer) chains through chemical cross links(of sulfur). The vulcanization process was discovered in 1839 and the individuals responsible for this discovery were Charles Goodyear in USA and Thomas Hancock in England. Both discovered the use of Sulfur and White Lead as a vulcanization system for Natural Rubber. This discovery was a major technological breakthrough for the advancement of the world economy. Vulcanization of rubbers by sulfur alone is an extremely slow and inefficient process. The chemical reaction between sulfur and the Rubber Hydrocarbon occurs mainly at the C = C (double bonds) and each crosslink requires 40 to 55 sulphur atoms (in the absence of accelerator). The process takes around 6 hours at 140°C for completion, which is uneconomical by any production standards. The vulcanizates thus produced are extremely prone to oxidative degradation and do not possess adequate mechanical properties for practical rubber applications. These limitations were overcome through inventions of accelerators which subsequently became a part of rubber compounding formulations as well as subjects of further R&D. Following is the summary of events which led to the progress of ‘Accelerated Sulfur Vulcanization'. Event Year Progress - Discovery of Sulfur Vulcanization: Charles Goodyear. 1839 Vulcanizing Agent - Use of ammonia & aliphatic ammonium derivatives: Rowley. 1881 Acceleration need - Use of aniline as accelerator in USA & Germany: Oenslager. 1906 Accelerated Cure - Use of Piperidine accelerator- Germany. 1911 New Molecules - Use of aldehyde-amine & HMT as accelerators in USA & UK 1914-15 Amine Accelerators - Use of Zn-Alkyl Xanthates accelerators in Russia. -

Rediscovering Sulfinylamines As Reagents for Organic Synthesis Thomas Q

Minireview Chemistry—A European Journal doi.org/10.1002/chem.202100321 Rediscovering Sulfinylamines as Reagents for Organic Synthesis Thomas Q. Davies[a] and Michael C. Willis*[a] Chem. Eur. J. 2021, 27, 1–11 1 © 2021 The Authors. Chemistry - A European Journal published by Wiley-VCH GmbH These are not the final page numbers! �� Wiley VCH Dienstag, 25.05.2021 2199 / 204270 [S. 1/11] 1 Minireview Chemistry—A European Journal doi.org/10.1002/chem.202100321 Abstract: Sulfinylamines (RÀ N=S=O), monoaza analogues of of their use in the one-pot syntheses of sulfoximines and sulfur dioxide, have been known for well over a century, and sulfonimidamides. Also covered are the reactions of sulfinyl- their reactivity as sulfur electrophiles and in Diels-Alder amines with carbon-centred radicals, their use for formation reactions is well-established. However, they have only rarely of heterocycles through cycloadditions, and catalytic enantio- been used in organic synthesis in recent decades despite the selective allylic oxidation of alkenes via a hetero-ene reaction. increasing prominence of compounds containing N=S=O These examples highlight the different reactivity modes of functionality, such as sulfoximines and sulfonimidamides. This sulfinylamines and their underappreciated potential for Minireview aims to bring wider visibility to the unique forming molecules which contain high- or low-valent sulfur, chemistry enabled by this class of compounds. We focus on or even no sulfur at all. advances from the last 10 years, including the first examples -

1,2,4-Triazine Sulfonamides: Synthesis by Sulfenamide Intermediates, in Vitro Anticancer Screening, Structural Characterization, and Molecular Docking Study

molecules Article 1,2,4-Triazine Sulfonamides: Synthesis by Sulfenamide Intermediates, In Vitro Anticancer Screening, Structural Characterization, and Molecular Docking Study Danuta Branowska 1, Zbigniew Karczmarzyk 1,*, Ewa Woli ´nska 1, Waldemar Wysocki 1, Maja Morawiak 2 , Zofia Urba ´nczyk-Lipkowska 2 , Anna Bielawska 3 and Krzysztof Bielawski 3 1 Faculty of Exact and Natural Sciences, Siedlce University of Natural Sciences and Humanities, 3 Maja 54, 08-110 Siedlce, Poland; [email protected] (D.B.); [email protected] (E.W.); [email protected] (W.W.) 2 Institute of Organic Chemistry, Polish Academy of Sciences, Kasprzaka 44/52, 01-224 Warsaw, Poland; [email protected] (M.M.); zofi[email protected] (Z.U.-L.) 3 Medical University of Bialystok, Department of Medicinal Chemistry and Drug Technology, J. Kilinskiego 1, 15-089 Bialystok, Poland; [email protected] (A.B.); [email protected] (K.B.) * Correspondence: [email protected]; Tel.: +48-25-643-1017 Received: 24 March 2020; Accepted: 14 May 2020; Published: 16 May 2020 Abstract: In this study, we synthesized novel sulfonamides with a 1,2,4-triazine moiety according to pharmacophore requirements for biological activity. All the synthesized compounds were tested in vitro to verify whether they exhibited anticancer activity against the human breast cancer cell lines MCF-7 and MDA-MB-231. Among them, two most active ones, having IC50 values of 50 and 42 µM, respectively, were found to show higher anticancer activity than chlorambucil used as the reference in the in vitro tests. In addition, two other compounds, which had IC50 values of 78 and 91 µM, respectively, exhibited a similar level of activity as chlorambucil. -

Reduction of Organic Functional Groups Using Hypophosphites Rim Mouselmani

Reduction of Organic Functional Groups Using Hypophosphites Rim Mouselmani To cite this version: Rim Mouselmani. Reduction of Organic Functional Groups Using Hypophosphites. Other. Univer- sité de Lyon; École Doctorale des Sciences et de Technologie (Beyrouth), 2018. English. NNT : 2018LYSE1241. tel-02147583v2 HAL Id: tel-02147583 https://tel.archives-ouvertes.fr/tel-02147583v2 Submitted on 5 Jun 2019 HAL is a multi-disciplinary open access L’archive ouverte pluridisciplinaire HAL, est archive for the deposit and dissemination of sci- destinée au dépôt et à la diffusion de documents entific research documents, whether they are pub- scientifiques de niveau recherche, publiés ou non, lished or not. The documents may come from émanant des établissements d’enseignement et de teaching and research institutions in France or recherche français ou étrangers, des laboratoires abroad, or from public or private research centers. publics ou privés. THESE de DOCTORAT DE L’UNIVERSITE DE LYON EN COTUTELLE AVEC L'UNIVERSITÉ LIBANAISE opérée au sein de l’Université Claude Bernard Lyon 1 École Doctorale de Chimie-École Doctorale des Sciences et Technologies Discipline : Chimie Soutenue publiquement le 07/11/2018, par Rim MOUSELMANI Reduction of Organic Functional Groups Using Hypophosphites Devant le jury composé de Mme. Micheline DRAYE Université Savoie Mont Blanc Rapporteure M. Mohammad ELDAKDOUKI Université Arabe de Beyrouth Rapporteur Mme. Emmanuelle SCHULZ Université Paris 11 examinatrice M. Abderrahmane AMGOUNE Université Lyon 1 Président M. Mahmoud FARAJ Université Internationale Libanaise examinateur Mme. Estelle MÉTAY Université Lyon 1 Directrice de thèse M. Ali HACHEM Université Libanaise Directeur de thèse M. Marc LEMAIRE Université Lyon 1 Membre invité M. -

THE CHEMISTRY of SULFENIMIDES by Barbara Ann Orwig a Thesis

THE CHEMISTRY OF SULFENIMIDES by Barbara Ann Orwig A thesis submitted to the Faculty of Graduate Studies and Research in partial fulfilment of the requirements for the degree of Master of Science Department of Chemistry McGill University Montreal, P.Q. Canada May 1971 @) Barbara Ann Orwig 1972 Dedicated to My Parents Il Thanx Il i ACKNOWLEDGEMENTS 3l MY thanks to Dr. D.F.R. Gilson for the p nmr spectra, to Victor Yu for the A-60 nmr spectra, and to Peter Currie for the mass spectra. For helpful discussions and worthwhile suggestions l thank David Ash 1 Errol Chang 1 and John Gleason. For his guidance and help as my research director l thank Dr. David N. Harpp. And to Elva and Hermann Heyge go special thanks for their help and for "putting up wi th œil. TABLE OF CONTENTS Page ACKNOWLEDGEMENTS i INTRODUcrION 1 EXPERIMENTAL SECTION 22 RESULTS AND DISCUSSION 42 TABLES 1 Preparation of Sulfenyl Chlorides 72 2 Preparation of N-(alkyl/aryl thio)phthalimides 73 3 Desulfurization Reactions of N-(alkyl/aryl thio)phthalimides 76 4 Mass Spectra of N-(alkyl/aryl thio)phthalimides 77 FIGURES (Spectra) 78 - 87 BIBLIOGRAPHY 88 INTRODUcrION AND BACKGROUND Sulfenic acids Cl), in which sulfur exists in its R-S-OH l lcwest oxidation state, are highly lmstable compolmds and only a few l have been isolated. The derivatives of sulfenic acid {~.> however, are generally isolable and usually stable. 2 R-S-Y 2 When Y is -NH ' -~HR, or -NR ' the resulting class of compolmds is 2 2 ter.med sulfenamides. -

Tert-Butanesulfinamides As Nitrogen Nucleophiles in Carbon-Nitrogen

tert-Butanesulfinamides as Nitrogen Nucleophiles in Carbon-Nitrogen Bond Forming Reactions Johana Ramirez Hernandez, Fabrice Chemla, Franck Ferreira, Olivier Jackowski, Julie Oble, Alejandro Perez-Luna, Giovanni Poli To cite this version: Johana Ramirez Hernandez, Fabrice Chemla, Franck Ferreira, Olivier Jackowski, Julie Oble, et al.. tert-Butanesulfinamides as Nitrogen Nucleophiles in Carbon-Nitrogen Bond Forming Reactions. CHIMIA, Schweizerische Chemische Gesellschaft, 2016, 70 (1), pp.84-92. 10.2533/chimia.2016.84. hal-01292458 HAL Id: hal-01292458 https://hal.sorbonne-universite.fr/hal-01292458 Submitted on 23 Mar 2016 HAL is a multi-disciplinary open access L’archive ouverte pluridisciplinaire HAL, est archive for the deposit and dissemination of sci- destinée au dépôt et à la diffusion de documents entific research documents, whether they are pub- scientifiques de niveau recherche, publiés ou non, lished or not. The documents may come from émanant des établissements d’enseignement et de teaching and research institutions in France or recherche français ou étrangers, des laboratoires abroad, or from public or private research centers. publics ou privés. 84 CHIMIA 2016, 70, No. 1/2 The French connecTion doi:10.2533/chimia.2016.84 Chimia 70 (2016) 84–92 © Swiss Chemical Society tert-Butanesulfinamides as Nitrogen Nucleophiles in Carbon–Nitrogen Bond Forming Reactions Johana Ramirez Hernandez, Fabrice Chemla, Franck Ferreira, Olivier Jackowski, Julie Oble, Alejandro Perez-Luna*, and Giovanni Poli Abstract: The use of tert-butanesulfinamides as nitrogen nucleophiles in carbon–nitrogen bond forming reac- tions is reviewed. This field has grown in the shadow of the general interest in N-tert-butanesulfinyl imines for asymmetric synthesis and occupies now an important place in its own right in the chemistry of the chiral amine reagent tert-butanesulfinamide. -

UNDERSTANDING SULFUR BASED REDOX BIOLOGY THROUGH ADVANCEMENTS in CHEMICAL BIOLOGY by THOMAS POOLE a Dissertation Submitted to T

UNDERSTANDING SULFUR BASED REDOX BIOLOGY THROUGH ADVANCEMENTS IN CHEMICAL BIOLOGY BY THOMAS POOLE A Dissertation Submitted to the Graduate Faculty of WAKE FOREST UNIVERSITY GRADUATE SCHOOL OF ARTS AND SCIENCES in Partial Fulfillment of the Requirements for the Degree of DOCTOR OF PHILOSOPHY Chemistry May 2017 Winston-Salem, North Carolina Approved By: S. Bruce King, Ph.D., Advisor Leslie B. Poole, Ph.D., Chair Patricia C. Dos Santos, Ph.D. Paul B. Jones, Ph.D. Mark E. Welker, Ph.D. ACKNOWLEDGEMENTS First and foremost I would like to thank professor S. Bruce King. His approach to science makes him an excellent role model that I strive to emulate. He is uniquely masterful at parsing science into important pieces and identifying the gaps and opportunities that others have missed. I thank him for the continued patience and invaluable insight as I’ve progressed through my graduate studies. This work would not have been possible without his insight and guiding suggestions. I would like to thank our collaborators who have proven invaluable in their support. Cristina Furdui has provided the knowledge, context, and biochemical support that allowed our work to be published in esteemed journals. Leslie Poole has provided the insight into redox biology and guidance towards appropriate experiments. I thank my committee members, Mark Welker and Patricia Dos Santos who have guided my graduate work from the beginning. Professor Dos Santos provided the biological perspective to evaluate my redox biology work. In addition, she helped guide the biochemical understanding required to legitimize my independent proposal. Professor Welker provided the scrutinizing eye for my early computational work and suggested validating the computational work with experimental data. -

Syntheses and Reactions of Sulfinimines

i SYNTHESIS AND REACTIONS OF SULFINIMINES Leonid Kotei Sasraku-Neequaye This thesis is submitted in partial fulfilment of the requirements for the degree of Doctor of Philosophy at the University of East Anglia June, 2010 © This copy of the thesis has been supplied on condition that anyone who consults it is understood to recognise that its copyright rests with the author and that no quotation from this thesis or any information derived thereof may be published without the author’s prior written consent ii DECLARATIONS I declare that the work contained within this thesis, submitted by myself for the degree of Doctor of Philosophy is my own original work, except where due reference is made and has not previously been submitted by me for a degree at this or any other university. Leonid Kotei Sasraku-Neequaye iii ABSTRACT A large majority of drugs and drug candidates incorporate amine functionality and these include important compounds such as morphine, quinine and nicotine. N-Sulfinyl-imines (sulfinimines) are a versatile class of intermediates in organic synthesis particularly for the preparation of amines and amine derivatives. We herein report an efficient and cost effective one-pot synthesis of sulfinimines in enantiopure form (>99.8% ee) and in relatively high yields. In our investigations, we developed the scheme that involves the use of 1,2,3- oxathiazolidine-2-oxide derived from (1R, 2S)-(-)-norephedrine as a chiral auxiliary. Opening of the 1,2,3-oxathiazolidine-2-oxide with a mesityl Grignard reagent followed by treatment of the crude mixture with lithium hexamethyldisilasane afforded the mestyl sulfinamide in 72% yield and 76% recovery of the chiral auxiliary. -

Diastereoselective Synthesis of 2,4,6-Trisubstituted Piperidines Via Aza-Prins Cyclization

The University of Southern Mississippi The Aquila Digital Community Honors Theses Honors College Spring 5-2018 Diastereoselective Synthesis of 2,4,6-Trisubstituted Piperidines via aza-Prins Cyclization John A. Hood University of Southern Mississippi Follow this and additional works at: https://aquila.usm.edu/honors_theses Part of the Organic Chemistry Commons Recommended Citation Hood, John A., "Diastereoselective Synthesis of 2,4,6-Trisubstituted Piperidines via aza-Prins Cyclization" (2018). Honors Theses. 605. https://aquila.usm.edu/honors_theses/605 This Honors College Thesis is brought to you for free and open access by the Honors College at The Aquila Digital Community. It has been accepted for inclusion in Honors Theses by an authorized administrator of The Aquila Digital Community. For more information, please contact [email protected]. The University of Southern Mississippi Diastereoselective Synthesis of 2,4,6-Trisubstituted Piperidines via aza-Prins Cyclization by John A. Hood A Thesis Submitted to the Honors College of The University of Southern Mississippi in Partial Fulfillment of the Requirements for the Degree of Bachelor of Science in the Department of Chemistry and Biochemistry May 2018 ii Approved by: ____________________________________ Matthew G. Donahue, Ph.D., Thesis Advisor Department of Chemistry and Biochemistry ____________________________________ Vijay Rangachari, Ph.D., Chair Department of Chemistry and Biochemistry ____________________________________ Ellen Weinauer, Ph.D., Dean Honors College iii Abstract The nitrogen heterocycles are shared amongst 59% of Food and Drug Administration (FDA) approved small molecule pharmaceuticals with the six-membered piperidine representing the most common moiety. Given the versatility and potential to yield derivatives with broad biological activities, the discovery of new chemical methods to generate these heterocycles in a more time and cost-efficient manner is desired. -

Recent Advances in Sulfur–Nitrogen Bond Formation Via Cross-Dehydrogenative Coupling Cite This: RSC Adv.,2018,8, 18456 Reactions

RSC Advances View Article Online REVIEW View Journal | View Issue Recent advances in sulfur–nitrogen bond formation via cross-dehydrogenative coupling Cite this: RSC Adv.,2018,8, 18456 reactions Fatemeh Alsadat Hosseini Nasab,a Leila Zare Fekri,b Aazam Monfared,b *c b Received 12th January 2018 Akram Hosseinian and Esmail Vessally Accepted 12th April 2018 This focus-review surveys literature methods for the construction of sulfur–nitrogen bonds through cross- DOI: 10.1039/c8ra00356d dehydrogenative coupling reactions between thiols and N–H compounds with a particular emphasis on the rsc.li/rsc-advances mechanistic aspects of the reactions. The literature has been surveyed until the end of 2017. 1. Introduction 2 with trade name Topamax is a promising anticonvulsant medicine available in a number of countries worldwide. The 8 Needless to say, organosulfur compounds play a very important drug is also used for migraine prevention in adults. Folpet 3 is Creative Commons Attribution-NonCommercial 3.0 Unported Licence. role in various elds such as organic synthesis, materials a fungicide used for broad-spectrum control of fungal patho- 9 science, agriculture, and medicinal chemistry.1–4 Among them, gens. Sulfoxaor 4 is an insecticide with a sulfoximine motif, compounds bearing sulfur–nitrogen bonds are important this compound is very active against a wide range of sap-feeding 10 building blocks in a variety of biologically active substances. For insect pests and widely used around the world. Thus, instance, sultiame 1 (Fig. 1) with brand name Ospolot is construction of biologically and synthetically important sulfur– a synthetic sulfa-based drug marketed worldwide for the treat- nitrogen bonds is one of the essential transformations in ment of epilepsy.5,6 The drug works by reducing the activity of organic synthesis. -

2-Nitrophenylsulfenyl Chloride Into New Compounds with Potential Pesticidal Activity

Synthesis and transformation of 4-dichloromethylsulfonyl-2-nitrophenylsulfenyl... 5 Pestycydy/Pesticides, 2009, (1-4), 5-14. ISSN 0208-8703 Synthesis and transformation of 4-dichloromethylsulfonyl- 2-nitrophenylsulfenyl chloride into new compounds with potential pesticidal activity Zbigniew OCHAL, Wojciech BIAŁKOWSKI and Łukasz BANACH Warsaw University of Technology, Faculty of Chemistry, 3 Noakowskiego St., 00-664 Warsaw, Poland e-mail: [email protected] Abstract: The synthesis of 4-dichloromethylsulfonyl-2-nitrophenylsulfenyl chloride and its transformation into new compounds with promising pesticidal activity is reported. The title compounds were obtained by a three-step synthesis, starting from 4-dichloromethylchlorophenyl sulfone. It was nitrated and then subjected to the SNAr reaction with sodium disulfide to give proper diphenyl disulfide, which was next chlorinated by chlorine. The obtained phenylsulfenyl chloride was transformed into sulfenamide derivatives by reactions with amines. Keywords: 4-chlorophenyldichloromethyl sulfone, sulfenyl chloride, sulfenamides, pesticides INTRODUCTION Some sulfenamide derivatives are known as the non-systemic fungicides widely used to control foliage and fruit diseases of tomatoes, coffee berry, potato and many other fruits and vegetables [1, 2]. Galactofuranosyl-N,N-dialkyl sulfenamides displayed an antimycobacterial activity [3]. Some N-sulfenyl heterocycles are effective sulfenylating agents of aromatic amines [4]. In addition, they are the important intermediates in many reactions, promising in the prodrug technologies [5, 6]. On the other hand, it is well known that chemical compounds with chloromethyl groups show an interesting biological activity [1]. We have proved in our previous investigations that chloro- and dichloromethylsulfonyl 6 Z. Ochal, W. Białkowski, Ł. Banach groups in aromatic compounds were favorable to pesticidal activities [7-11]. -

United States Patent Office Patented Apr

3,658,828 United States Patent Office Patented Apr. 25, 1972 2 3,658,828 R R UNSYMMETRICAL DIALKYL THAZOLE / SULFENAMIDES T-S -N-ce John Joseph D'Amico, Akron, Ohio, assignor to R3 Monsanto Company, St. Louis, Mo. 5 wherein T is benzothiazolyl or substituted benzothiazolyl, No Drawing. Filed Nov. 19, 1969, Ser. No. 878,243 where the substituents are chloro, bromo, fluoro, iodo, ni Int, C. C07d 91/44 tro or lower alkoxy, R is tertiary-alkyl of 4-12 carbon U.S. C. 260-306.6A 5 Claims atoms, R2 and R3 are alkyl of 1-8 carbon atoms or to gether with the carbon atom to which they are attached O form cycloalkyl of 5-8 carbon atoms. ABSTRACT OF THE DISCLOSURE Examples of tertiary-alkyl radicals suitable for the prac Unsymmetrical dialkyl thiazole sulfenamides of the tice of this invention are tertiary-butyl, tertiary-amyl, formula tertiary-hexyl, tertiary-octyl, tertiary-nonyl, tertiary-decyl and tertiary-dodecyl. A tertiary-alkyl radical has its first 5 carbon atom linked to three other carbon atoms. The aliphatic groups from which R2 and R can be Selected include alkyl groups containing from 1-8 car bon atoms having straight or branched chains, for ex wherein T is benzothiazolyl or substituted benzothiazolyl, ample, methyl, ethyl, propyl, isopropyl, butyl, secondary where the substituents are chloro, bromo, fluoro, iodo, 20 butyl, amyl, hexyl and octyl. Cyclopentyl, cyclohexyl and nitro or lower alkoxy, R is tertiary-alkyl of 4-12 carbon cyclooctyl are examples of radicals when R2 and R3 to atoms, R2 and R3 are alkyl of 1-8 carbon atoms or to gether with the carbon to which they are attached form gether with the carbon atom to which they are attached cycloalkyl.