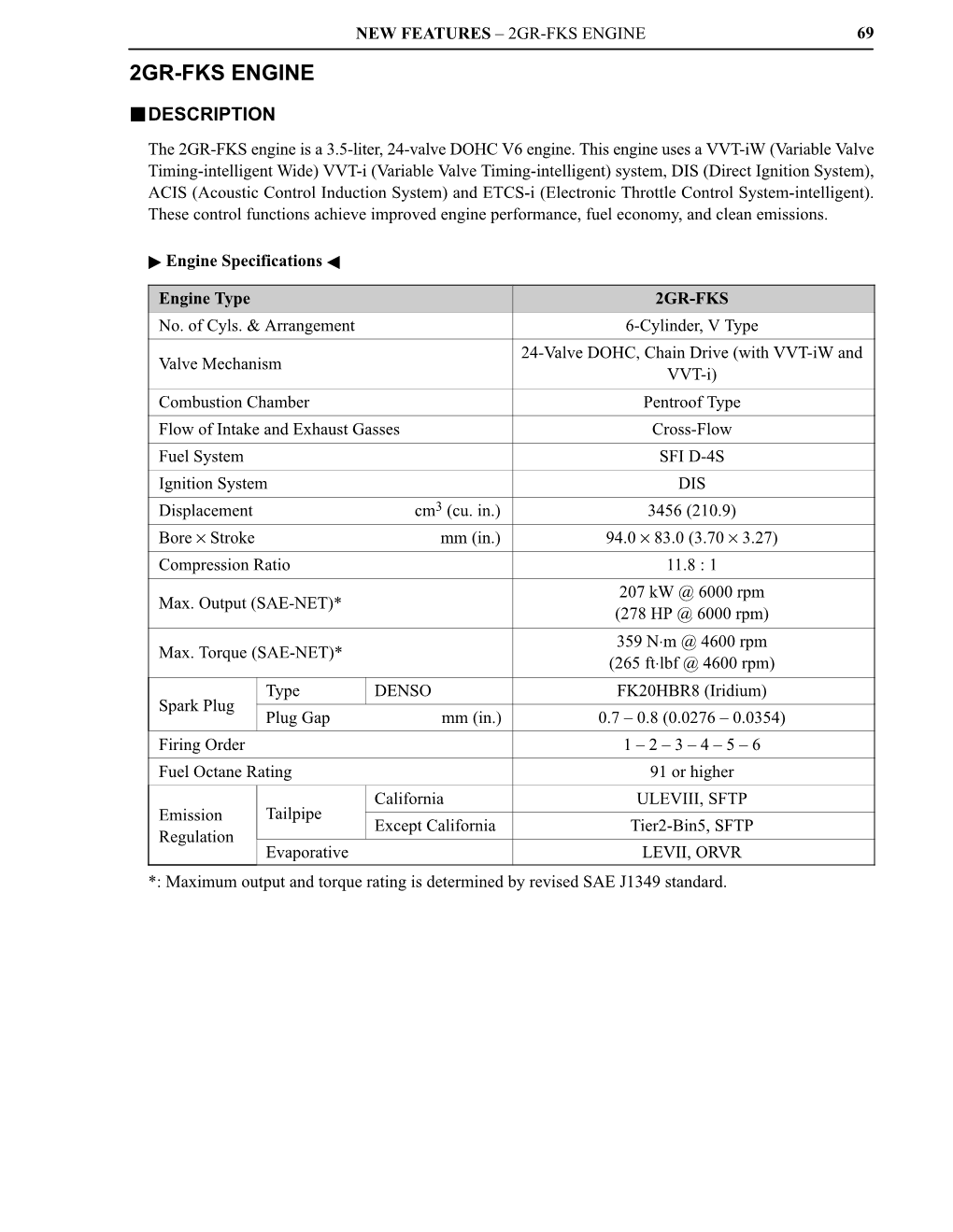

2Gr-Fks Engine 69 2Gr-Fks Engine

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Mr. Gasket Catalog

Restore. Restyle. Relive. PRODUCT CATALOG THE MR. GASKET STORY Back in 1964, Joe Hrudka was a drag racer in Northern Ohio who was looking to solve a problem that parts manufacturers had not addressed. Using his own 1957 Chevy drag race car as a test vehicle, he created a line of engine gaskets and fasteners proven to seal and withstand extreme temperatures, pressures and stresses created by high performance engines. This product line that was developed by a drag racer would evolve into a brand of legendary proportions over the next 50 years. Mr. Gasket started with Joe’s ‘57 Chevy and has continued to advance and expand with application coverage and even more new products for muscle cars. Head gaskets, exhaust gaskets and oil pan gaskets were just the beginning. The Mr. Gasket brand develops and distributes a variety of performance parts for your vehicle including: carburetor and fuel accessories, chrome-plated accessories, cooling system accessories, engine components, fuel additives, shifter accessories, specialty tools, suspension and driveline components. Located in Cleveland, Ohio, the Mr. Gasket team continues to design, develop, manufacture and distribute products that bring back the luster and performance that everyone remembers to a variety of auto projects. It may have started with a Chevrolet, but when you are ready to Restore, Restyle and Rebuild your car, Mr. Gasket is who you can trust to have the parts and advice you need to complete your project. Find out about all of the Mr. Gasket products and applications at www.mr-gasket.com www.mr-gasket.com TABLE OF CONTENTS CHEMICALS ....................................................................... -

Property of ICOM North America

Property of ICOM North America First: Propane can reduce emissions by up to 60% & ZERO Particular matter Second: The USA and CANADA have abundant Propane and Natural Gas Resources! Third: NO WARS!!! Energy Security Fleets can often dramatically reduce their fuel costs by using propane autogas! $$$savings$$$ $$$ Substantial fuel cost savings as compared to gasoline or diesel Reduce emissions of toxins by up to 30-90% compared to gasoline Domestic – Propane is produced in North America, with large reserves in the U.S. and Canada $$$ Lower maintenance cost Greenhouse gas emissions are reduced approximately 20% Maintains the torque, horsepower, and drivability you would feel in a gasoline vehicle Courtesy of PERC For some more information on propane please visit the U.S. Department of Energy, Energy Efficiency and Renewable Energy website or contact your local American Lung Association office. What is Propane? Propane is liquefied petroleum gas that consists of propane, propylene, butane, and butylenes in various mixtures. In the United States, propane is the primary ingredient. Propane is a by-product of natural gas processing and petroleum refining and it is stored under moderate pressure to maintain its liquid state. Why is Propane a Clean Air Choice? Propane vehicles produce less tailpipe emissions of virtually all pollutants associated with automobile vehicles that use gasoline or diesel. According to the U.S. Environmental Protection Agency, a typical four-horsepower gasoline lawnmower engines generates almost six times as much volatile organic compound (VOCs) per hour of use as a typical car. Converting small utility engines such as lawnmowers to burn propane can reduce emissions of ozone precursors by one third and increase fuel economy by 14 percent. -

Installation Instructions Two Barrel, Throttle Body Fuel Injection for Oldsmobile V8 Engines in Gmc Motor Homes

6201 Industrial Way * Marine City, MI 48039 * Phone 8107655100 * Fax 8107651503 INSTALLATION INSTRUCTIONS TWO BARREL, THROTTLE BODY FUEL INJECTION FOR OLDSMOBILE V8 ENGINES IN GMC MOTOR HOMES KIT COMPONENTS: 1. Two barrel TBI unit with integral TPS and Idle Air Control. 2. Electronic control Module (ECM) GM PN 1227747. 3. Howell wiring harness connecting engine to vehicle ECM. 4. Calibration Prom matching TBI to Olds 455 or 403 engine. 5. Calpack (V8), for limphome operation. 6. Manifold vacuum sensor (MAP). 7. Engine coolant sensor & 3/8” to ½” NPT bushing adaptor. 8. Exhaust Oxygen sensor & 18MM mounting bung. 9. Electric fuel pump—high pressure, inline. 10. High flow fuel filter, inline. 11. Fuel line kit. 12. Fuel pump relay. 13. Small parts kit for routing and mounting components. 14. Service manualbasic troubleshooting and operating information. THIS SYSTM IS BASED ON THE PRODUCTION GM (Chevrolet or GMC) THROTTLE BODY FUEL INJECTION AND ELECTRONICS USED FROM 19871989, ON 454 CID V8 ENGINES. ALL BACKUP SYSTEMS AND “ON VEHICLE” DIAGNOSTICS FUNCTION SIMILAR TO THOSE MODEL YEAR PACKAGES. THIS SYSTEM DOES NOT CONTROL SPARK TIMING AS ON 8789 GM ENGINES, BUT RELIES ON A TACH SIGNAL FROM THE PRODUCTION OLDS HEI ELECTRONIC IGNITION FOR RPM INPUT TO THE ECM. Installation procedure will be separated into the following categories: 1. Preparation of motor home for TBI installation. 2. Removal of nonrequired parts from carbureted engine. 3. Installation of TBI and engine hardware. 4. Installation of Electronic components and wiring harness. 5. -

Fuel System Delivery Overview — Guide to Successful Fuel System Repairs 2 1 10 3

Fuel System Delivery Overview — Guide To Successful Fuel System Repairs 2 1 10 3 9 5 4 8 6 7 1 Fuel Filler Cap responsible for 20% of fuel pump product Tight seal is critical to proper OBD system failures. operation. A loose cap can lead to a DTC that will set the “Check Engine” light. 6 Supply and Return Lines Deliver fuel to and from the engine. Check 2 Fuel Tank Pressure Sensor for kinks or restrictions. Monitors fuel tank evaporative pressure for emissions control purposes. 7 Fuel Filter Protects injectors and engine from con- 3 Fuel Pump tamination not caught by the fuel pump The heart of the fuel delivery system, the fuel strainer. Important to replace as a part of pump delivers fuel to the engine. Airtex fuel routine maintenance as well as with any pumps are designed to meet or beat OE specs fuel system service. and are 100% tested to ensure performance and long-life. 8 Oxygen (02) Sensor Checks exhaust gases and sends signal to 4 Fuel Strainer ECM to adjust fuel mixture for emissions The pump’s first line of defense against con- control purposes. taminated fuel. Failure to replace the fuel strainer will void fuel pump warranty. 9 Fuel Pressure Regulator Controls fuel pressure to fuel injectors. 5 Fuel Tank The fuel pump on most modern vehicles is 10 Fuel Injectors housed in the fuel tank. Tanks must be clean Deliver fuel to engine combustion and free of contamination before a new fuel chambers. pump is installed. Contaminated fuel is It's important to note that the fuel pump is one part of a complex fuel delivery system. -

Article 2: F1600/F2000 2021 Technical Specifications

ARTICLE 2: F1600/F2000 2021 TECHNICAL SPECIFICATIONS ! ARTICLE 2.1: F1600/F2000/Technical Specifications…...........pgs 2-28 Update 4-20-21 — 2.2.25.1 & 2.2.26.1 ARTICLE 2.2: Mazda MZR F2000/Technical Specifications…pgs 29-37 ! ! Article 2.1: F1600/F2000 Technical Specifications - 2021 ____________________________________________________________ These specifications are part of Formula Race Promotions (FRP) Competition Rules and all automobiles shall conform with these Specifications and FRP Pro Racing Rules (PRR). F1600, F2000, is intended to provide competitors and interested manufacturers with the opportunity to compete in purpose built, highly modified open wheel single seat cars. FRP may alter or adjust specifications and require, permit, or restrict certain specific components to equate competitive potential as deemed necessary. In an effort to control shock/damper technology and cost to a level reasonable for competitive racing, any fluid dampers are allowed, with the following restrictions: 1. Maximum of 4 dampers/shock absorbers per vehicle. 2. Dampers must be independent from each other with no interconnectivity. However, data acquisition is permissible, as long as it serves no other purpose. 3. Dampers must be manually adjustable only. 4. Mechatronic valves, G valves, hybrid inerters, inerters and mass dampers are prohibited. 5. Electro/Magnetic shock fluid is prohibited. F1600 and F2000 PREPARATION RULES - 2021 Definitions a. F1600: A formula for single-seat, tubular frame, flat bottom, open-wheel racing cars using standard Ford 1600 “crossflow” pushrod engines, or a Honda Fit 1500 (L15A7) overhead cam engine, with firewall, floor, and safety equipment conforming to the FRP PRR. b. F2000: A formula for single-seat, tubular frame, flat bottom, open-wheel racing cars using the Ford 2 liter single overhead camshaft “NE” series engine, the 1971-74 Pinto/Capri 2 liter single overhead camshaft engine, or the Ford Zetec ZX-3 2 liter dual overhead camshaft engine. -

Wideband O2 Sensors and Air/Fuel (A/F) Sensors

Home, Auto Repair Library, Auto Parts, Accessories, Tools, Manuals & Books, Car BLOG, Links, Index Wideband O2 Sensors and Air/Fuel (A/F) Sensors by Larry Carley copyright 2019 AA1Car.com Wideband Oxygen sensors (which may also be called Wide Range Air Fuel (WRAF) sensors) and Air/Fuel (A/F) Sensors, are replacing conventional oxygen sensors in many late model vehicles. A wideband O2 sensor or A/F sensor is essentially a smarter oxygen sensor with some additional internal circuitry that allows it to precisely determine the exact air/fuel ratio of the engine. Like an ordinary oxygen sensor, it reacts to changing oxygen levels in the exhaust. But unlike an ordinary oxygen sensor, the output signal from a wideband O2 sensor or A/F sensor does not change abruptly when the air/fuel mixture goes rich or lean. This makes it better suited to today's low emission engines, and also for tuning performance engines. Oxygen Sensor Outputs An ordinary oxygen sensor is really more of a rich/lean indicator because its output voltage jumps up to 0.8 to 0.9 volts when the air/fuel mixture is rich, and drops to 0.3 volts or less when the air/fuel mixture is lean. By comparison, a wideband O2 sensor or A/F sensor provides a gradually changing current signal that corresponds to the exact air/fuel ratio. Another difference is that the sensor's output voltage is converted by its internal circuitry into a variable current signal that can travel in one of two directions (positive or negative). -

Your Vacuum Gauge Is Your Friend

WRENCHIN’ @ RANDOM YOUR VACUUM GAUGE IS YOUR FRIEND Two Essential Diagnostic Tools No Hot Rodder Should Be Without, and How to Use Them Marlan Davis hI’ve been answering read- ers’ Pit Stop tech questions for decades, explaining how to improve performance, troubleshoot pesky problems, or recommend a better combina- tion. Yet rarely do any of these problem- solving requests include information on the problem combo’s vacuum reading. That’s unfor- tunate, as [Above: Two essential diagnostic tools no hot rodder should be with- vacuum out, from left: a Mityvac handheld can tell vacuum pump for testing vacuum you a heck of a lot about an consumers (some models will even engine’s condition, without the aid in brake bleeding), and a large, easy-to-read vacuum gauge like need to invest in a bunch of this one by OTC (this model also high-tech diagnostic tools. includes a pressure gauge for even So what’s the deal on more test possibilities). vacuum? Consider an internal- [Left: Knowing how to use a combustion engine as basically vacuum gauge is the key to a giant air pump that operates diagnosing many performance under the principles of pres- problems. It aids in tuning your sure differential. The difference motor to the tip of the pyramid. It even helps diagnose problems not between normal atmospheric seemingly engine-related, such as pressure (14.7 psi at sea level a weak power-brake system. Add at standard temperature and one to your toolbox today. pressure) and how hard this “pump” sucks under various engine-management system). -

Throttle Body EFI

Throttle Body EFI What is the operating fuel pressure What’s the smallest and largest of the TBI? engine displacement that can be It depends on your fuel system. When using a returnless selected? (Pulse Width Modulate) system, the fuel pressure will The Atomic EFI will support engines with a minimum of vary between 30-75psi. If you are using a regulated 100ci to a maximum of 800ci. return system the pressure required will depend on horsepower. Most vehicles will require 45psi while engines pushing 600hp will need closer to 70psi. What are the horsepower capabilities of the system and If I already have a fuel system what are the limiting factors? what pressure do I set? With a large fuel pump the maximum output of the Dependent on horsepower, most cars will require 45psi Atomic is 625 HP. This will go down when using boost unless you are putting out very high horsepower. There due to a richer A/F requirement. The limiting factor is the is a DTC (diagnostic trouble code) that indicates 100% injector size. injector duty cycle. If this condition is hit, you will need to increase your fuel pressure by a slight amount (5-10psi) and try again. Please see instruction page 6 for more Can I run boost or Nitrous with information. the system? Yes. The Atomic TBI will support both nitrous and boost up to 2-bar and is compatible with blow-through and What’s the CFM of the throttle draw-through systems. body? The Atomic EFI throttle body can flow approximately 930 CFM. -

FUEL SYSTEM Misdiagnosis

6810 Misdiagnosis Flyer 2/1/11 1:53 PM Page 1 TM AIRTEX Product Information Sheet FUEL SYSTEM Misdiagnosis Airtex fuel pumps are 100% tested before they leave the factory. That’s why it’s a good idea to check out everything else first before suspecting the fuel pump. In fact, 50% of all fuel pumps returned for warranty consideration meet all manufacturer’s specifications when tested. Nearly 75% of all aftermarket fuel pump failures are caused by: – Misdiagnosis – Vehicle related electrical wiring or connector issues – Contaminated vehicle fuel systems Misdiagnosis Misdiagnosis is the leading cause of fuel pump returns. If the engine runs but displays driveability symptoms that you suspect are fuel- related (hard starting, hesitation, misfiring, power loss), first attempt to eliminate other possible causes of the problem. Make sure the engine is in good mechanical condition. An engine may not start or run properly for many reasons. BE SURE TO CHECK: • Fuel in the vehicle tank is adequate (add 2 to 3 gallons as needed). • Fuel is fresh and of good quality. • Fuel system has no leaks. • Fuel filter has been replaced. • Fuel delivery electrical system checks OK. • Engine mechanical systems check OK. • Engine electrical system checks OK. • Ignition system checks OK. • Charging system checks OK. • Battery voltage is at least 12.4 volts. • Cranking voltage at the starter is at least 9.6 volts. • Inertia switch is reset (typical of Ford applications). • Oil pressure and RPM signals are present (various applications). THE MOST COMMON REASONS FOR REPEAT FUEL PUMP FAILURE ARE: • Misdiagnosis: Pump is OK, fault lies elsewhere! • Not measuring fuel volume. -

Ml7,™ the Fp Diesel® 7-Layer Head Gasket That Seals Rebuilt Engines Better!

CM 11-1001 Technical Bulletin ML7,™ THE FP DIESEL® 7-L AYER HEAD GASKET THAT SEALS REBUILT ENGINES BETTER! ™ Sealing the most demanding area in a commercial engine – it takes today’s FP DIESEL SMART TIP Cummins® utilizes several types of valve stem seals most advanced gasket design. on the 24 valve ISB engines, depending on the FP Diesel® has introduced a highly advanced multi-layer-core head gasket fuel system. Please review the references below to assist you in ordering the correct valve stem seals. technology that will bring significantly enhanced combustion and fluid sealing capabilities and temperature resistance to a broad range For 1998-2002 engines using the VP44 of high-output commercial diesel engines: The ML7 head gasket. Injection Pump, with serial number 46239408 and below use: As commercial engine rebuilders look for the latest and best engine sealing solutions, FP Diesel’s ML7 gasket provides a new generation of head gaskets. BODY CONSTRUCTION The ML7 head gasket’s 7-layer construction features an advanced graphite material INTAKE VALVE STEM SEAL over a thicker, perforated stainless steel Yellow Viton® Center core for significantly increased rigidity. Part No. FP-3942989 The key to determining the thickness of the gasket body, armor and wire is achieving optimal load balance among the components and materials. The result is a much more solid and durable part. EXPANDED LOW-CARBON STEEL WIRE GRAPHITE FACING EXHAUST VALVE STEM SEAL Copper flash-coated low-carbon steel (LCS) The ML7’s resilient, conformable Green Viton® Center wire ring offers the ability to absorb stress graphite facing provides excellent Part No. -

Pro Copper HG Inst

Installation Instructions for: Pro Copper (”P” Prex) Head Gaskets For best results SCE Pro Copper Series (P prefix) Copper Head Gaskets should be used with sealant (if liquid cooled use Copper Coat, SCE p/n G1612) and o-ringed block or heads. 1. Before installing the gasket, perform a visual check to insure that no damage occurred during shipping, the gasket(s) should be flat and free of scratches. 2. SCE Copper head gaskets are annealed in a vacuum oven after punching to provide soft malleable gaskets which are ready to use, do not use a torch to soften the gaskets. 3. Pro Copper series head gaskets (P prefix) require the use of a sealant for coolant and oil passages and o-ring combustion seals installed in the head or block. (P/N 31542 o-ring kit). 4. If you are installing o-rings make sure that the o-ring diameter and location accommodates both bore opening and combustion chamber shape. This will determine the minimum inside diameter of the o-ring. 5. If the combustion chamber or bore is so large that o-rings must be placed less than .100” apart between cylinders, it is advisable to use a “figure 8” pattern for o-rings (see figure #2). This allows for more even clamp load over the entire head surface. 6. Recommended o-ring protrusion is not more than 25% of gasket thickness. Example: Gasket thickness .043”, o-ring height is .008” to .010”. Gasket thickness .050”, o-ring height is .010” to .012”. NOTE: For extreme boost or heavy nitrous an O-ring-Receiver-Groove arrangement is recom- mended (see figure #3). -

Mike Mavrigian Special Firing Order Camshafts Allow the Performance

Performance Perspectives Special firing order camshafts allow the performance engine builder to create a smoother-running engine, with improved fuel distribution and enhanced crankshaft and main bearing durability. his article falls under the category for the same reasons...to smooth out the harmon- of “thinking outside the box.” It’s a ics in the pursuit of greater engine durability and trite phrase, I know, but the point to potentially generate more power. is that we don’t need to always Power gain potential aside, the primary reason think of an OE carmaker’s engine to address (and alter) cylinder firing order is to Mike firing order specification as gospel. achieve a smoother-running engine (a smoother, Mavrigian In certain racing applications, a special firing or- more lineal acceleration ramp), with less harmonic Tder (SFO) camshaft can be used as a tuning aid, effect (and crank deflection) on the crankshaft and [email protected] allowing the competition engine builder to fur- its main bearings. In theory, virtually all engines can ther address combustion heat and crankshaft dis- benefit from this. The engines that can most bene- turbance (harmonic) issues. fit include those that run at or near peak rpm levels In essence, the goal in changing the firing or- for long periods of time, such as oval track, road der is to create a smoother-running engine and race and marine engine applications, as well as en- more even fuel distribution, with enhanced gines that are called upon to produce maximum crankshaft and main bearing durability. In the power in a very short period of time (drag race).