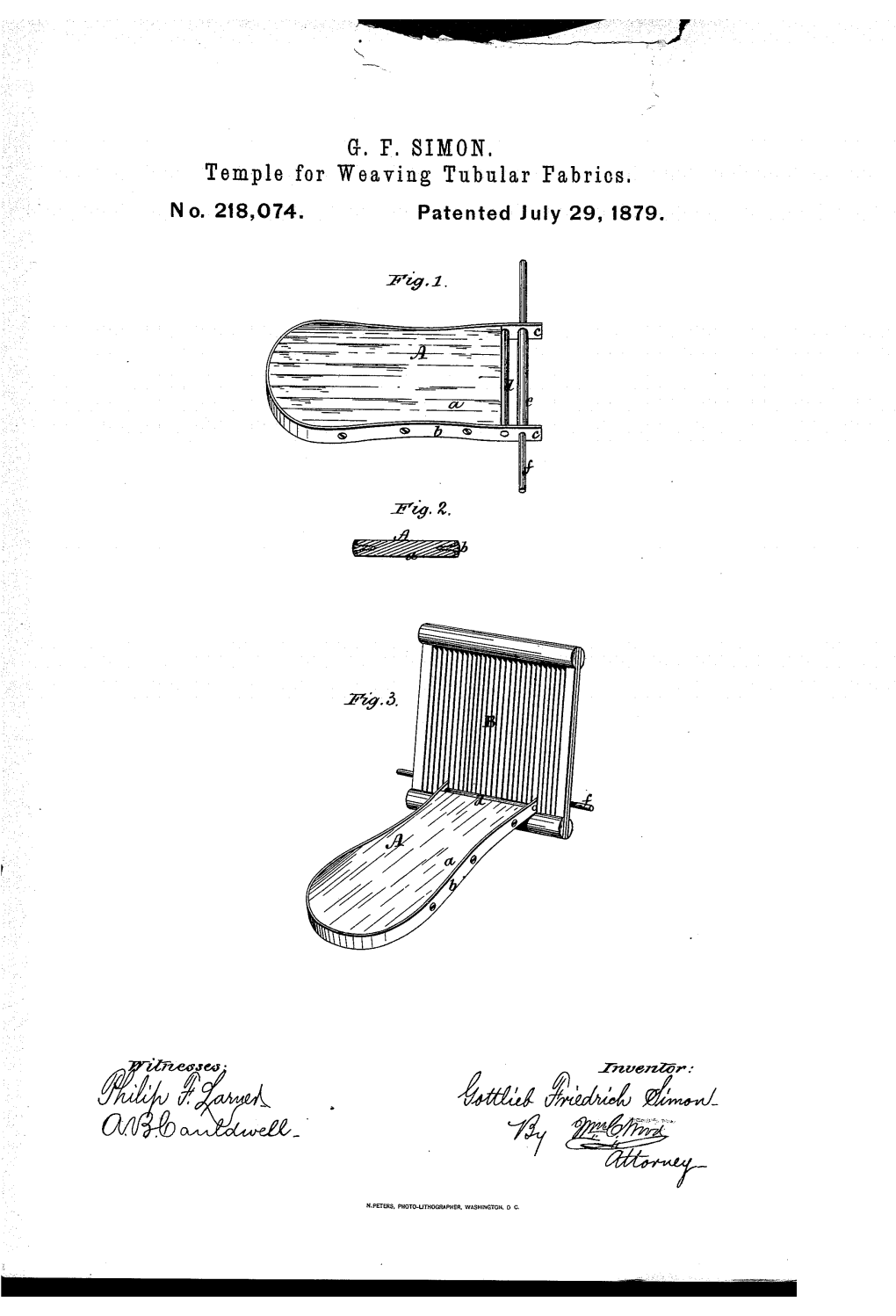

Temple for Weaving Tubular Fabrics. No

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Simply Schools 2020–21

2020 Learning with Museums & –2021 Galleries across Lancashire www.simplyschools.org.uk Welcome to Welcome to the Simply Schools 2020–21 brochure, we are confident that you will find ideas and inspiration from our Heritage Learning site activities, CPD, loans boxes and outreach, and from those activities delivered by our wider museum partners. Heritage Learning is back for 2020/2021 It gives me the greatest pleasure to with new sessions, projects and announce that the Heritage Learning programmes. Last year the Heritage Team will be delivering the learning Learning Team delivered site sessions, programmes on behalf of the Harris outreach and loans boxes that engaged Museum, Art Gallery and Library in with over 35,000 school children Preston from September 2020. across Lancashire. We have once again David Brookhouse worked with schools on some amazing As part of the national DfE funded Heritage Learning Manager projects including ‘Lancashire Sparks’ Museums and Schools Programme, we an exploration of Lancashire’s intangible are always keen to work with teachers 01772 535075 heritage through clog dancing, music and schools to develop our learning and literacy. The TIME project continues offer. Our themes for this year are STEM, to work successfully with schools Literacy and teacher development. embedding the creative arts into the curriculum. Please contact us if you The funding for Heritage Learning comes would like more information about our from a de-delegated budget which range of new school projects. schools vote to continue each year. This funding allows the team to deliver Once again our teacher CPD, twilight award winning, high quality cultural and INSET programmes have grown from learning across Lancashire. -

The Textile Museum Thesaurus

The Textile Museum Thesaurus Edited by Cecilia Gunzburger TM logo The Textile Museum Washington, DC This publication and the work represented herein were made possible by the Cotsen Family Foundation. Indexed by Lydia Fraser Designed by Chaves Design Printed by McArdle Printing Company, Inc. Cover image: Copyright © 2005 The Textile Museum All rights reserved. No part of this document may be reproduced, stored in a retrieval system, or transmitted in any form or by any means -- electronic, mechanical, photocopying, recording or otherwise -- without the express written permission of The Textile Museum. ISBN 0-87405-028-6 The Textile Museum 2320 S Street NW Washington DC 20008 www.textilemuseum.org Table of Contents Acknowledgements....................................................................................... v Introduction ..................................................................................................vii How to Use this Document.........................................................................xiii Hierarchy Overview ....................................................................................... 1 Object Hierarchy............................................................................................ 3 Material Hierarchy ....................................................................................... 47 Structure Hierarchy ..................................................................................... 55 Technique Hierarchy .................................................................................. -

Henry James and Romantic Revisionism: the Quest for the Man of Imagination in the Late Work

HENRY JAMES AND ROMANTIC REVISIONISM: THE QUEST FOR THE MAN OF IMAGINATION IN THE LATE WORK A Dissertation Submitted to the Temple University Graduate Board In Partial Fulfillment of the Requirements for the Degree DOCTOR OF PHILOSOPHY (OF ENGLISH ) By Daniel Rosenberg Nutters May 2017 Examining Committee Members: Daniel T. O’Hara, Advisory Chair, English Alan Singer, English Steve Newman, English Robert L. Caserio, External Member, Pennsylvania State University Jonathan Arac, External Member, University of Pittsburgh © Copyright 2017 by Daniel Rosenberg Nutters All Rights Reserved ii ABSTRACT This study situates the late work of Henry James in the tradition of Romantic revisionism. In addition, it surveys the history of James criticism alongside the academic critique of Romantic-aesthetic ideology. I read The American Scene, the New York Edition Prefaces, and other late writings as a single text in which we see James refashion an identity by transforming the divisions or splits in the modern subject into the enabling condition for renewed creativity. In contrast to the Modernist myth of Henry James the master reproached by recent scholarship, I offer a new critical fiction – what James calls the man of imagination – that models a form of selfhood which views our ironic and belated condition as a fecund limitation. The Jamesian man of imagination encourages the continual (but never resolvable) quest for a coherent creative identity by demonstrating how our need to sacrifice elements of life (e.g. desires and aspirations) when we confront tyrannical circumstances can become a prerequisite for pursuing an unreachable ideal. This study draws on the work of post-war Romantic revisionist scholarship (e.g. -

Lancashire: a Chronology of Flash Flooding

LANCASHIRE: A CHRONOLOGY OF FLASH FLOODING Introduction The past focus on the history of flooding has been mainly with respect to flooding from the overflow of rivers and with respect to the peak level that these floods have achieved. The Chronology of British Hydrological Events provides a reasonably comprehensive record of such events throughout Great Britain. Over the last 60 years the river gauging network provides a detailed record of the occurrence of river flows and peak levels and flows are summaried in HiflowsUK. However there has been recent recognition that much flooding of property occurs from surface water flooding, often far from rivers. Locally intense rainfall causes severe flooding of property and land as water concentrates and finds pathways along roads and depressions in the landscape. In addition, intense rainfall can also cause rapid rise in level and discharge in rivers causing a danger to the public even though the associated peak level is not critical. In extreme cases rapid rise in river level may be manifested as a ‘wall of water’ with near instantaneous rise in level of a metre or more. Such events are usually convective and may be accompanied by destructive hail or cause severe erosion of hillsides and agricultural land. There have been no previous compilations of historical records of such ‘flash floods’or even of more recent occurrences. It is therefore difficult to judge whether a recent event is unusual or even unique in terms of the level reached at a particular location or more broadly of regional severity. This chronology of flash floods is provided in order to enable comparisons to be made between recent and historical floods, to judge rarity and from a practical point of view to assess the adequacy of urban drainage networks. -

Handwoven Marc/April 2010 Tricks of the Trade

Tricks of the Trade Getting into the Fold tips for doublewidth weaving from tom knisely Planning a doublewide fabric Weaving a fabric twice as wide as the weaving width of your loom is a thrilling experience. Many weavers miss out on it because they are afraid of the biggest challenge: weaving so that when the fabric is unfolded, there is no evidence that it ever was folded. This is difficult for several reasons: Draw-in causes threads to be denser at the selvedges, so the same thing will happen at the fold edge of a doublewide fabric. Avoiding draw-in by turning the weft loosely at the fold edge can cause weft loops and other irregularities there. Here are some things you can do to weave a smooth and invisible fold line. Choose warp stripes Stripes in the warp—even narrow stripes—draw the eye to the stripes instead of to irregularities created by crowded warp threads or too much or too little weft tension. If the warp stripes are wider than a thread or two (they are narrow for this blanket), make the stripe at the fold a dark color and Sleying the reed use a dark weft. Any differences in density or alignment show Loosen the sett at much less in dark colors. the fold edge Only sampling can help you determine the ideal sett at the fold for a particular yarn and weave structure. For the blanket on pages 30–32, sleying the last two ends singly instead of two per dent counteracts draw-in to create the right density at the fold. -

Mügrip® Mbj8 1/1380

TECHNICAL SPECIFICATION ® Reed width (max.) 1380 mm MÜGRIP MBJ8 1/1380 Nominal width (max.) 1346 mm Jacquard machine (sheeding device) SPE3 series Weave types Taff et Semi-Satin Satin Warp density (ends/cm) 54,6 88,82 109,2 Harness settings Label standards as per PZ 3003 Weft feeder Electronically controlled for up to 12 colours IRO Luna X3 Weft insert system Universal rapier for various yarn counts between 22 and 1400 dtex. Lightweight designed rapier head for outstanding long operational life Cross beam Rapier drive for smooth weft feeding with the unique vertical reed beat-up and for labels and high weft density fabrics optimised temple bar Machine control MLC machine control / network ready and MÜDATA® M series for the entire Label Weaving Machine machine monitoring and regulation Main drive VARISPEED – Energy-effi cient machine drive with programmable speed for labels and pictures with slit selvedges changes within the pattern design Fabric take-off drive VARIPICK – Energy-effi cient fabric take off drive for programmable weft density variations from 18 to 120 picks per cm within the pattern design Warp let-off drive Energy-effi cient and electronically controlled warp let-off drive with warp tension monitoring up to a warp beam diameter of 800 mm Selvedge formation TC2 cutting system for a good on loom selvedge quality starting from a minimum width of 6 mm. Due to the same electrical resistance an identical cutting temperature across the entire fabric width can be reached DIMENSIONS Width: 3940 mm (with thread feeder) 2955 mm (without thread feeder) Depth: 2030 mm Height: 3645 mm (machine) 3875 mm (room) Copyright @ 2019 by Jakob Müller AG Frick 5070 Frick Switzerland Fascination of Ribbons and Narrow Fabrics Printed in Italy. -

Key Industrial Designated Heritage Sites

KEY INDUSTRIAL DESIGNATED HERITAGE SITES This document provides an overview of what type of industrial site each area of England is most famous for and provides some examples of those that are best known, both by locals and in terms of their historical and national significance. EAST MIDLANDS The region has a wide variety of sites ranging from the lead mines of the Peak District and the collieries of the East Midland coalfield to the textile mills and workshops of the Derwent valley, Nottinghamshire and Leicestershire and the renowned boot and shoe factories of Northamptonshire. Derwent Valley Mills World Heritage Site, Derbyshire The first successful water powered mechanisation of the textile industry was achieved in 1721 at the Lombe Brothers silk mills at Derby and even more significantly by Richard Arkwright with the water powered mechanisation of the cotton industry at Cromford. The subsequent development of the factory system changed society and the role of the mills has been recognised by the creation of a World Heritage Site stretching from Matlock Bath to Derby. Many of the most significant sites survive including Arkwright’s first mills at Cromford Mill and his associated village, his Masson Mill, the Strutt family mills and settlements at Belper and Milford and the Evans family mills and settlement at Darley Abbey. Nottingham Lace Market Nottingham was the centre of the East Midlands lace industry and a spectacular commercial precinct developed in the mid 19th century in the town. Ruddington Framework Knitters Workshops, Nottinghamshire Domestic based industry was a vital component of the textile industry and the workshops at Ruddington have been preserved as a museum to celebrate their significance. -

Ikat Sareesof Odisha

DOI: 10.15740/HAS/AJHS/12.1/193-200 esearch aper e ISSN-0976-8351 Visit us: www.researchjournal.co.in R P AsianAJHS Journal of Home Science Volume 12 | Issue 1 | June, 2017 | 193-200 Ikat sarees of Odisha MITALI DALAI AND SADHANA D. KULLOLI Received: 07.11.2016; Revised: 23.04.2017; Accepted: 10.05.2017 ABSTRACT : To document the different types of Sarees, motifs and their placement a self- structured interview schedule was used to elicit the information on the types of silk and cotton Sarees manufactured and motifs used in the popular Ikat sarees of Odisha. The most popular Sarees woven are Sambalpuri, Sakatapar, Passapali, Bapta and Bomkai both in cotton and See end of the paper for authors’ affiliations silk with 5.5 meters length and 1.2 meters width using 2/100s-2/120s cotton yarn and 20-22 denier SADHANA D. KULLOLI silk yarn. The variegated sarees are beautified with floral pattern, geometrical pattern, small Department of Textile and Apparel flower Buttis, human figure, Shankha, Chakra, animal and bird depictions. Designing, College of Rural Home Science, University of Agricultural KEY WORDS: Ikat sarees, Motifs, Cotton, Silk, Denier silk yarn Sciences, DHARWAD (KARNATAKA) INDIA HOW TO CITE THIS PAPER : Dalai, Mitali and Kulloli, Sadhana D. (2017). Ikat sarees of Odisha. Email : [email protected] Asian J. Home Sci., 12 (1) : 193-200, DOI: 10.15740/HAS/AJHS/12.1/193-200. he Saree is a traditional female garment in the rhythmic picking sound of fly shuttle in most of the rural Indian subcontinent consisting of a strip of huts indicates the importance of the handloom industry Tunstitched cloth ranging from four to nine meters and its role in the economy of Odisha. -

Auxiliary Motions of Loom

Auxiliary motions of loom: Part-1 MMFT In order to produce a good quality of cloth and to prevent damages it is necessary to have some stop motion provided on the loom. They can be termed as auxiliary motions. Auxiliary motions are added to a loom to get high productivity and good quality of fabric. These motions are useful but not absolutely essential. They are… 1. Warp stop motion: 2. Weft stops motion: 3. Weft replenishment motion: 4. Warp protector motion: 5. Weft mixing motion: 6. Feeler motion: 7. Brake motion: 8. Temple Warp stop motion: To stop the loom when a warp thread breaks or excessively loose. This motion is able to stop the loom when a warp thread breaks or get excessively loosened. When a drop wire fall as the result of end break. The broken end is repaired and handled by the operator. Weft replenishment motion It ensures a continuous supply of weft yarn to the loom whenever supply package exhausted. WEFT REPLENISHMENT This motion provides uninterrupted filling insertion by switching from a depleted to a full package. Weft stop motion: This motion able to stop the loom when a weft breaks or runs out of the pirn (weft package). In case the loom is allowed to run even after the weft breaks there will be no woven cloth except long threads of warp Warp protector mechanism: To protect the warp thread by stopping the loom when the weft fails to reach, and box properly into either the winder during picking. This motion protect the warp threads by stopping the loom when the shuttle fails to reach, the selvedge side and box properly into either the shuttle box during picking. -

Vävstuga Setts Page 1 Balanced Weaves in COTTON, COTTOLIN & TOW LINEN These Are Dense Setts - Plain Weave and Twill Probably Require Use of a Temple

Vävstuga Setts Page 1 Balanced weaves in COTTON, COTTOLIN & TOW LINEN These are dense setts - Plain weave and twill probably require use of a temple. Rep does not require the use of temple. YARN & STRUCTURE metric ends/ ends/ ends/ REED heddle dent inch 8/2 cotton - plain weave 45 1 2 22.5 8/2 cotton - twill 55 1 2 27.5 8/2 cotton - rep 60 2460 16/2 cotton - plain weave 701235 16/2 cotton - twill 801240 16/2 cotton - rep 902490 20/2 cotton - plain weave 901245 20/2 cotton - twill 110 1 2 55 24/2 cotton - plain weave 100 1 2 50 24/2 cotton - twill 120 1 2 60 30/2 cotton - plain weave 110 1 2 55 30/2 cotton - twill 90 1 3 67.5 22/2 cottolin - plain weave 401220 22/2 cottolin - twill 501225 8/1 tow linen - pl. weave 401220 8/1 tow linen - twill 55 1 2 27.5 6/1 tow linen - pl. weave 35 1 2 17.5 These setts represent the fabrics we weave on our Swedish looms and use at Vävstuga Weaving School. Many variations on these setts are possible, and sometimes desirable. Have fun and EXPERIMENT!! ©2017 Vävstuga LLC Vävstuga Setts Page 2 Balanced weaves in LINE LINEN These are dense setts and will require use of a temple. YARN & STRUCTURE metric ends/ ends/ ends / REED heddle dent inch 8/2 linen - plain weave 551114 8/2 linen - twill 301215 8/1 linen - plain weave 401220 8/1 linen - twill 55 1 2 27.5 12/2 linen - plain weave 301215 12/2 linen - twill 35 1 2 17.5 12/1 linen - plain weave 501225 12/1 linen - twill 65 1 2 32.5 16/2 linen - plain weave 401220 16/2 linen - twill 55 1 2 27.5 16/1 linen - plain weave 601230 16/1 linen - twill 801240 20/2 linen - plain weave 45 1 2 22.5 20/2 linen - twill 601230 20/1 linen - plain weave 701235 20/1 linen - twill 901245 28/2 linen - plain weave 501225 28/2 tow linen - twill 65 1 2 32.5 28/1 linen - plain weave 801240 28/1 linen - twill 100 1 2 50 35/2 linen - plain weave 601230 35/2 linen - twill 50 1 3 37.5 These setts represent the linens we weave on our Swedish looms and use at Vävstuga Weaving School. -

Section 3.4 Temple

Section 3.4 Temple Contents 3.4.1 Temple with Upper Cover ………………………………………………………………………………3.4-2 [1] Front-to-rear positioning ………………………………………………………………………………3.4-2 [2] Right-to-left positioning …………………………………………………………………………………3.4-3 [2.1] At the left-hand side of the machine …………………………………………………………3.4-3 [2.2] At the right-hand side of the machine …………………………………………………………3.4-3 [3] Adjusting the inclination of the templering ……………………………………………………………3.4-5 [4] Fitting the temple cover …………………………………………………………………………………3.4-5 [5] Positioning the fell plate ………………………………………………………………………………3.4-6 [6] Types of temples ………………………………………………………………………………………3.4-8 3.4.2 Temple with Lower Cover ……………………………………………………………………………3.4-10 [1] Positioning the fell support ……………………………………………………………………………3.4-10 [1.1] Up-down positioning …………………………………………………………………………3.4-10 [1.2] Front-to-rear positioning ………………………………………………………………………3.4-11 [1.3] Right-to-left positioning ………………………………………………………………………3.4-11 [2] Up-down positioning of temple ring …………………………………………………………………3.4-12 [3] Right-to-left positioning of temple ……………………………………………………………………3.4-13 [3.1] At the left-hand side of the machine …………………………………………………………3.4-13 [3.2] At the right-hand side of the machine ………………………………………………………3.4-13 [4] Types of temples ………………………………………………………………………………………3.4-14 3.4-1 Temple The temple prevents the woven fabric from shrinking in width and ensures stable cloth fell, by spreading the fabric in the direction of its width to an extent which does not influence the fabric quality. 3.4-1 3.4.1 Temple with Upper Cover 3.4.1 Temple with Upper Cover [1] Front-to-rear positioning (1) Set the crank angle at 0°. (2) Press the emergency stop button down until it locks itself and the machine. -

Sumatra and the Malay Peninsula the C Loth Trade in Jambi and Palembang Society During the Seventeenth and E Ighteenth C Enturies* 1

Sumatra and the Malay Peninsula The C loth Trade in Jambi and Palembang Society during the Seventeenth and E ighteenth C enturies* 1 Barbara Watson Andaya Anyone who has used Dutch East India Company (VOC) records2 will know that they are often stubbornly resistant to the historian's questions. The vast corpus of informa tion they contain, however, has provided the basis for a number of detailed studies of regional history in the Indonesian archipelago. What such studies have shown is that generalizations regarding social and economic change during the seventeenth and eigh draft of this paper was originally presented at the Asian Studies Association of Australia Bicentennial Conference held at the Australian National University in February 1988. The research on which it was based is part of a larger study on the history of Jambi and Palembang ca. 1600-1800. Research has been made possible through financial support from Auckland University, the Japan Society for the Promotion of Science, and the Joint Committee on Southeast Asia of the Social Sciences Research Council and the American Council of Learned Societies with funds provided by the Ford Foundation and the National Endowment for the Humanities. I am also most grateful to the personnel of the Indonesian Institute of Sciences, the State Archives in The Hague, the Koninklijk Instituut, and Leiden University Library for invaluable assistance. Without support from so many people it would have been impossible to undertake this study, and to them all I would like to express my deep gratitude. 2The primary Dutch sources for this period are located in the Koloniaal Archief section of the Algemeen Rijksarchief in The Hague.