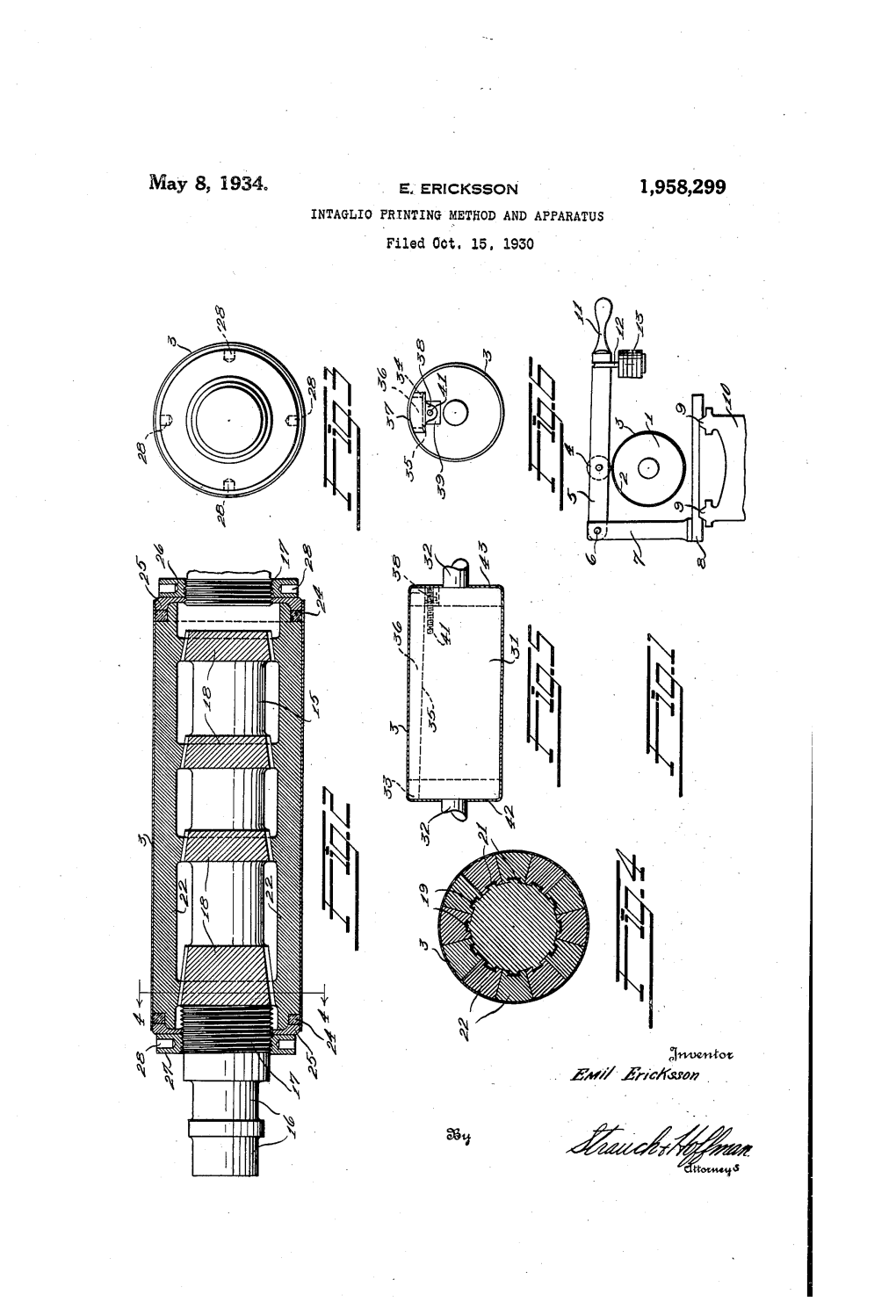

May 8, 19340 ; Aemcksson 1,958,299 INTAGLIO PRINTING METHOD and APPARATUS

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Printmaking Through the Ages Utah Museum of Fine Arts • Lesson Plans for Educators • March 7, 2012

Printmaking through the Ages Utah Museum of Fine Arts • www.umfa.utah.edu Lesson Plans for Educators • March 7, 2012 Table of Contents Page Contents 2 Image List 3 Printmaking as Art 6 Glossary of Printing Terms 7 A Brief History of Printmaking Written by Jennifer Jensen 10 Self Portrait in a Velvet Cap , Rembrandt Written by Hailey Leek 11 Lesson Plan for Self Portrait in a Velvet Cap Written by Virginia Catherall 14 Kintai Bridge, Province of Suwo, Hokusai Written by Jennifer Jensen 16 Lesson Plan for Kintai Bridge, Province of Suwo Written by Jennifer Jensen 20 Lambing , Leighton Written by Kathryn Dennett 21 Lesson Plan for Lambing Written by Kathryn Dennett 32 Madame Louison, Rouault Written by Tiya Karaus 35 Lesson Plan for Madame Louison Written by Tiya Karaus 41 Prodigal Son , Benton Written by Joanna Walden 42 Lesson Plan for Prodigal Son Written by Joanna Walden 47 Flotsam, Gottlieb Written by Joanna Walden 48 Lesson Plan for Flotsam Written by Joanna Walden 55 Fourth of July Still Life, Flack Written by Susan Price 57 Lesson Plan for Fourth of July Still Life Written by Susan Price 59 Reverberations, Katz Written by Jennie LaFortune 60 Lesson Plan for Reverberations Written by Jennie LaFortune Evening for Educators is funded in part by the StateWide Art Partnership and the Professional Outreach Programs in the Schools (POPS) through the Utah State Office of Education 1 Printmaking through the Ages Utah Museum of Fine Arts • www.umfa.utah.edu Lesson Plans for Educators • March 7, 2012 Image List 1. Rembrandt Harmensz van Rijn (1606-1669), Dutch Self Portrait in a Velvet Cap with Plume , 1638 Etching Gift of Merrilee and Howard Douglas Clark 1996.47.1 2. -

In Otherworlds: 18 N

In Otherworlds: 18 N. St. Clair Street, Toledo, Ohio 43604 419-241-2400 18 N. St. Clair Street, Toledo, Ohio 43604 419-241-2400 20northgallery.com — [email protected] Craig Fisher & Dan Hernandez 20northgallery.com — [email protected] July 7 – September 30, 2017 An exhibition of new and existing works featuring fantastical, intricate and meticulously rendered images of mystical, otherworldly themes—all incorporating classical symbolism to reference contemporary thought, culture and technology The intaglio etchings and aquatint prints by Craig Fisher blend classic architectural and landscape imagery that transitions from mechanical to organic to supernatural, on both macro and micro scale. The acrylic and inkjet transfer paintings by Dan Hernandez intermingle the iconic imagery of European Renaissance and classical Asian painters with early video game design, portraying figures engaged in vibrant and energetic conflict. Despite the dramatic differences in media, visual style and subject matter, the works of these two distinguished area artists juxtapose like themes of science & technology with spirituality, as well as the combination of old and new media, to explore the metaphysical concept of the “otherworld”—the varying layers of existence between humankind’s experience of the “real” world and the world of belief. This combination creates an intriguing, thought-provoking and unquestionably beautiful exhibit. 1 Craig Fisher Toledo, Ohio Artist Biography Craig Fisher received his Bachelor of Arts in fine art from The University of Toledo, School of Design in 1976, following two years of additional study in The Netherlands at the Pascal College, Zaandam, North Holland. He has worked in various positions as a technical Illustrator, graphic designer and, more recently, as a concept artist. -

Baldwins Ink Grounds MATERIAL SAFETY DATA SHEET

MATERIAL SAFETY DATA SHEET Edition: November 2017 36 KINGSTHORPE ROAD HOVE BN3 5HR Baldwins Ink Grounds Tel 01273 260 260 Fax 01273 260 270 (TNL 17271—17291) E-mail [email protected] SECTION 1. CHEMICAL PRODUCT AND COMPANY IDENTIFICATION PRODUCT NAME: Baldwins Ink Ground APPLICATION OF SUBSTANCE: To be used as an etching ground for Intaglio printmaking. MANUFACTURED BY: Trefeglwys Printmakers Trefeglwys Powys, SY17 5 PH CONTACT INFORMATION: CONTACT: Andrew Baldwin TELEPHONE NUMBER: +44 1686 430623 EMAIL: [email protected] SECTION 2. HAZARDS IDENTIFICATION The Mixtures, as mentioned in Section 16 are not classified as dangerous according to Directive 67/548/EEC and 1999/45/EC and their amendments. HAZARDS TO HUMAN HEALTH: Can cause skin and eye irritation. CONTACT WITH SKIN: Prolonged contact may cause irritation. CONTACT WIT EYES: Direct contact can cause irritation. INHILATION: - SWALLOWING: - HAZARDS TO THE ENVIRONMENT: Not likely when professionally used. Do not allow material to enter drains or waterways. SECTION 3. COMPOSITION/ INFORMATION ON INGREDIENTS CHEMICAL DESCRIPTION: Mixture of Organic and/or Anorganic Pigments and Carbon Black; (Synthetic) Resins; Vegetables—and/or Mineral Oils and additives. DANGEROUS COMPONENTS: None. Mineral Oils are not classified as dangerous according to Directive 67/548/EEC, Annex 1: note H, L or H, N. ADDITIONAL INFORMATION: Explanation of Note H, L and H, N: see Section 16. SECTION 4. FIRST-AID MEASURES GENERAL DIRECTIONS: Remove all contaminated clothing. CONTACT WITH SKIN: Wash with water and soap. CONTACT WITH EYES: Flush with plenty of water for at least 15 minutes. If irritation persists, seek medi cal attention. -

PRINTS, DRAWINGS, PAINTING and OTHER WORKS on PAPER August 2014

PRINTS, DRAWINGS, PAINTING AND OTHER WORKS ON PAPER August 2014 1. (1948 Campaign Poster) Henry A. Wallace, Glen Taylor and Rockwell Kent. LABOR! VOTE LABOR. American Labor Party Poster for the Presidential campaign of 1948, including the candidacies of Henry A, Wallace for President, Glen Tayor for Vice President and Rockwell Kent for Congress. 17 x 11 inches. Letterpress reading as follows: "LABOR!/Vote Labor/Wallace for President/Taylor for Vice Presdident/Rockwell Kent for Congress/VOTE ROW C/American Labor Party." The candidates were running on the Progressive Party ticket, which was supported by the American Labor Party. Wallace had been Vice President under FDR, Glen Taylor was the incumbent Senator from Idaho (and a former country singer), and Rockwell Kent was, of course a well known artist and author with extremely liberal politcal views; Kent had a dairy farm in AuSable Forks, NY at the time of this campaign, and presumably ran for Congress in the district in which the farm was located. In nice condition, with minor browning at the edges. Very rare. $1500.00 2. Abeles, Sigmund. PHILOSOPHY STUDENT. Wood engraving, not dated. Inscribed "artist proof" and signed in pencil. 9 x 12 inches. In excellent condition. $300.00 3. Abramovitz, Albert (American, born Latvia, 1879-1963). STRIKE. Linoleum cut on wove paper, c. 1930s. Signed in pencil, and monogrammed "AA" in the block. Edition size not known. 11 5/8 x 9 7/8 inches, 321 x 252 mm., plus wide margins. This print is likely one that Aramovitz did for the WPA Federal Arts Project between 1935 and 1939. -

Maps and Meanings: Urban Cartography and Urban Design

Maps and Meanings: Urban Cartography and Urban Design Julie Nichols A thesis submitted in fulfilment of the requirements of the degree of Doctor of Philosophy The University of Adelaide School of Architecture, Landscape Architecture and Urban Design Centre for Asian and Middle Eastern Architecture (CAMEA) Adelaide, 20 December 2012 1 CONTENTS CONTENTS.............................................................................................................................. 2 ABSTRACT .............................................................................................................................. 4 ACKNOWLEDGEMENT ....................................................................................................... 6 LIST OF FIGURES ................................................................................................................. 7 INTRODUCTION: AIMS AND METHOD ........................................................................ 11 Aims and Definitions ............................................................................................ 12 Research Parameters: Space and Time ................................................................. 17 Method .................................................................................................................. 21 Limitations and Contributions .............................................................................. 26 Thesis Layout ....................................................................................................... 28 -

The-Gutenberg-Museum-Mainz.Pdf

The Gutenberg Museum Mainz --------------------------------------------------------------------- Two original A Guide Gutenberg Bibles and many to the other documents from the dawn of the age of printing Museum ofType and The most beautiful Printing examples from a collection of 3,000 early prints Printing presses and machines in wood and iron Printing for adults and children at the Print Shop, the museum's educational unit Wonderful examples of script from many countries of the world Modern book art and artists' books Covers and illustrations from five centuries Contents The Gutenberg Museum 3 Johannes Gutenberg- the Inventor 5 Early Printing 15 From the Renaissance to the Rococo 19 19th Century 25 20th Century 33 The Art and Craftmanship of the Book Cover 40 Magic Material Paper 44 Books for Children and Young Adults 46 Posters, Job Printing and Ex-Libris 48 Graphics Techniques 51 Script and Printing in Eastern Asia 52 The Development of Notation in Europe and the Middle East 55 History and Objective of the Small Press Archives in Mainz 62 The Gutenberg Museum Print Shop 63 The Gutenberg Society 66 The Gutenberg-Sponsorship Association and Gutenberg-Shop 68 Adresses and Phone Numbers 71 lmpressum The Gutenberg Museum ~) 2001 The Cutcnlx~rg Museum Mainz and the Cutcnbc1g Opposite the cathedral in the heart of the old part ofMainz Spons01ship Association in Germany lies the Gutenberg Museum. It is one of the oldest museums of printing in the world and This guide is published with tbc kind permission of the attracts experts and tourists from all corners of the globe. Philipp von Zahc1n publisher's in Mainz, In r9oo, soo years after Gutenberg's birth, a group of citi with regard to excLrpts of text ;md illustrations zens founded the museum in Mainz. -

History of the Book in China Oxford Reference

9/1/2016 40 The History of the Book in China Oxford Reference Oxford Reference The Oxford Companion to the Book Edited by Michael F. Suarez, S.J. and H. R. Woudhuysen Publisher: Oxford University Press Print Publication Date: 2010 Print ISBN13: 9780198606536 Published online: 2010 Current Online Version: 2010 eISBN: 9780199570140 40 The History of the Book in China J. S. EDGREN 1 The book before paper and printing 2 Tang to Yuan (7th–14th centuries) 3 Ming to Qing (14th–19th centuries) 4 The 20th century 1 The book before paper and printing nd th Although the early invention of true paper (2 century BC) and of textual printing (late 7 century) by *woodblock printing profoundly influenced the development of the book in China, the materials and manufacture of books before paper and before printing also left some traces. Preceding the availability of paper as a writing surface, the earliest books in China, known as jiance or jiandu, were written on thin strips of prepared bamboo and wood, which were usually interlaced in sequence by parallel bands of twisted thongs, hemp string, or silk thread. The text was written with a *writing brush and lampblack *ink in vertical columns from right to left—a *layout retained by later MSS and printed books—after which the strips were rolled up to form a primitive *scroll binding (see 17). The surviving specimens of jiance are mostly the result of 20th th rd century scientific archaeological recovery, and date from around the 6 century BC to the 3 century AD. -

Metaphor and the Limits of Print in Ezra Pound's Cantos

intervalla: Vol. 4, 2016 ISSN: 2296-3413 METAPHOR AND THE LIMITS OF PRINT IN EZRA POUND’S CANTOS Claire Battershill Simon Fraser University ABSTRACT Ezra Pound’s collected Cantos presents textual scholars with a challenge. Parts of the poem were published in little magazines, in newspapers, in fragments and in deluxe editions. No definitive edition of the Cantos exists, and the poem’s difficulty, though often figured as an interpretive difficulty, was just as much a textual difficulty. Just as the text of the poem itself is complex, so Pound’s own metaphors about the nature of print, textuality, and poetry are multifarious and shifting throughout the poem. This essay reads Pound’s own language of textuality and orality in the Cantos alongside his comments on modernist print culture in order to argue that Pound consistently tested the limits of material textuality even as he drew metaphorical power from the language of book history and print culture. Keywords Book History, Print Culture, Textual Studies, Metaphor, Modernism, Orality, Ezra Pound Copyright 2016 © (Battershill). Licensed under the Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International (CC by-nc-nd 4.0). Battershill Metaphor and the Limits of Print in the Cantos “And even I can remember A day when the historians left blanks in their writings, I mean for things they didn’t know But that time seems to be passing.” —Ezra Pound, Canto XIII 601 The tremendous number of instructional books about “how to read” Ezra Pound’s Cantos is indicative of more than an attempt to simplify “modernist difficulty.”2 These texts and, indeed, Pound’s own instructive projects in ABC of Reading (1960) and Guide to Kulchur (1952), offer ways of narrowing the epic down into a manageable reading experience. -

Pellissippi State Community College Master Syllabus

PELLISSIPPI STATE COMMUNITY COLLEGE MASTER SYLLABUS INTAGLIO PRINTMAKING ARTP 2620 Class Hours: 0.0 Credit Hours: 3.0 Lab Hours: 6.0 Revised: Spring 2012 Catalog Course Description: Metal plate intaglio printing in traditional and contemporary techniques of etching; soft-ground, drypoint, mezzotint, aquatint, open bite process and collograph plate construction. May be repeated, maximum 6 credits. Entry Level Standards: ARTP 1010 Drawing I (Art majors only) Prerequisite: None Textbook(s) and Other Course Materials: None required Suggested Library Reserve: Non-Toxic Printmaking, by Keith Howard and The Complete Printmaker, by Ross and Romano, revised and expanded edition. I. Week/Unit/Topic Basis: As an art studio course, problems are introduced in a sequential manner over a 15 week semester period. Work progresses based on degree of difficulty and student's ability to understand and master techniques as introduced. Periodic critiques are scheduled to assist in evaluation by both student and instructor. Week Topic 1 Introduction to course, policies and requirements. Overview and history of print-making. Examples of prints shown, and plate demonstration. 2 Drypoint process; press-bed set-up, types of paper, printing demonstration. Introduction of first project: Test Plate Series; five small plates exploring each of the five etching techniques. 3 Line etch: application of hard ground resist, etching demonstration, timed etch and multiple stop-out etching. 4 Aquatint: plate preparation, air-brush resist application, etching times. 5 Soft Ground: application, manipulation; image transfer techniques by hand and press-run, etching times. 6 Open bite: explanation of multiple level printing techniques, litho crayon resist. 7 Critique: Test Plate Series; Demonstration of alternative processes, large black and white plate and multiple process plate. -

Epigraphic Bulletin for Greek Religion

Kernos Revue internationale et pluridisciplinaire de religion grecque antique 8 | 1995 Varia Epigraphic Bulletin for Greek Religion Angelos Chaniotis and Eftychia Stavrianopoulou Electronic version URL: http://journals.openedition.org/kernos/605 DOI: 10.4000/kernos.605 ISSN: 2034-7871 Publisher Centre international d'étude de la religion grecque antique Printed version Date of publication: 1 January 1995 Number of pages: 205-266 ISSN: 0776-3824 Electronic reference Angelos Chaniotis and Eftychia Stavrianopoulou, « Epigraphic Bulletin for Greek Religion », Kernos [Online], 8 | 1995, Online since 11 April 2011, connection on 16 September 2020. URL : http:// journals.openedition.org/kernos/605 Kernos Kernos, 8 (1995), p, 205-266. EpigrapWc Bulletin for Greek Religion 1991 (EBGR) This fifth issue of BEGR presents the publications of 1991 along with several addenda to BEGR 1987-1990. The division of the work between New York and Heidelberg, for the first time this year, caused certain logistical prablems, which can be seen in several gaps; some publications of 1991 could not be considered for this issue and will be included in the next BEGR, together with the publications of 1992. We are optimistic that in the future we will be able to accelerate the presentation of epigraphic publications. The principles explained in Kernos, 4 (991), p. 287-288 and Kernos, 7 (994), p. 287 apply also to this issue, The abbreviations used are those of L'Année Philologique and the Supplementum Bpigraphicum Graecum. We remind our readers that the bulletin is not a general bibliography on Greek religion; works devoted exclusively to religious matters (marked here with an asterisk) are presented very briefly, even if they make extensive use of inscriptions, In exceptional cases (see n° 87) we include in our bulletin studies on the Linear B tablets. -

F) Smith So Nian

f) Smith sonian Freer Gallery of Art 1'<'1 Freer Gallery of Art and Arthur M. Sack/er Gallery Completed: 11 October 2007 F1968.18 Last updated: 06 May 2010 Trad. attrib. to: Li Gonglin 李公麟 (ca. 1049–1106) Title: The Drunken Monk 《醉僧圖》 Zuiseng tu Dynasty/Date: Southern Song, mid-12th–mid-13th century Format: Handscroll Medium: Ink and color on paper Dimensions: 32.5 x 60.8 cm (12-13/16 x 23-15/16 in) Credit line: Gift of Eugene and Agnes E. Meyer Accession no.: F1968.18 Provenance: Eugene (1875–1959) and Agnes E. Meyer (1887–1970) Physical description: Outside label slip of light brown paper, with signature and seal. Inside label slip of sutra paper, with two (2) imperial seals; mounted on first short section of champagne-colored silk. Frontispiece of separately mounted white paper; signed and dated, with four (4) imperial seals. Colophon 1 written on sutra paper, mounted on second short section of champagne-colored mounting silk; signed and dated, with three (3) imperial seals. Painting: ink and body color on separately mounted white paper, with interpolated signature. Two signed and dated inscriptions, with five (5) imperial seals, and one unsigned undated inscription, with two (2) imperial seals. Third short section of champagne-colored silk, with two (2) imperial and three (3) collector seals. Colophons 2–5: two joined sheets of white paper, separately mounted, bearing four undated colophons with no calligrapher seals, plus one dated colophon, with two (2) imperial seals. Total seals: 108, including forty-three (43) imperial seals (42 Qianlong; 1 Jiaqing), and sixty-five (65) non-imperial collector seals, of which fifteen (15) are half-seals. -

Printmaking Courses (Art and Art History) (PRNT) 1

Printmaking Courses (Art and Art History) (PRNT) 1 PRNT:3680 Silkscreen 4 s.h. Photographic, nonphotographic stencil techniques for Printmaking Courses silkscreen printing. Prerequisites: PRNT:2610. Requirements: ARTS:1510, ARTS:1520, and PRNT:2610 for art majors; (Art and Art History) ARTS:1010 and ARTS:1050 for nonmajors; or B.F.A. candidacy in any area; or graduate standing. (PRNT) PRNT:4610 Advanced Printmaking 4 s.h. Print media (i.e., intaglio, lithography, relief, screenprint); This is a list of all printmaking courses. For more information, emphasis on individual technical and conceptual growth and see Art and Art History. development of independent studio practices. Prerequisites: PRNT:2610 Introduction to Printmaking 3 s.h. PRNT:2610 and (PRNT:3620 or PRNT:3630 or PRNT:3640 or Introduction to methods, materials, and concepts of PRNT:3680). printmaking. Prerequisites: ARTS:1510 and ARTS:1520. PRNT:4670 Foil Imaging II 4 s.h. Requirements: art major. GE: Engineering Be Creative. Advanced aesthetic and technical research for creation of PRNT:3600 Textile Printing and Surface Design 4 s.h. original prints and other works of fine art using hot stamped Introduction to screen printing and block printing on textiles, foil and other printmaking techniques; individual instruction. including image generation and digital techniques from Prerequisites: PRNT:3670. start to finish; effective use of design principles; application PRNT:4799 Undergraduate Individual of a conceptual approach to work; possibilities of working Instruction 1-3 s.h. with textiles. Prerequisites: ARTS:1510 and ARTS:1520 and Individual instruction in printmaking; for advanced students. PRNT:2610. PRNT:6675 Graduate Print Workshop 3-4 s.h.