Conveying the Bene栛쉬ts of Automation

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

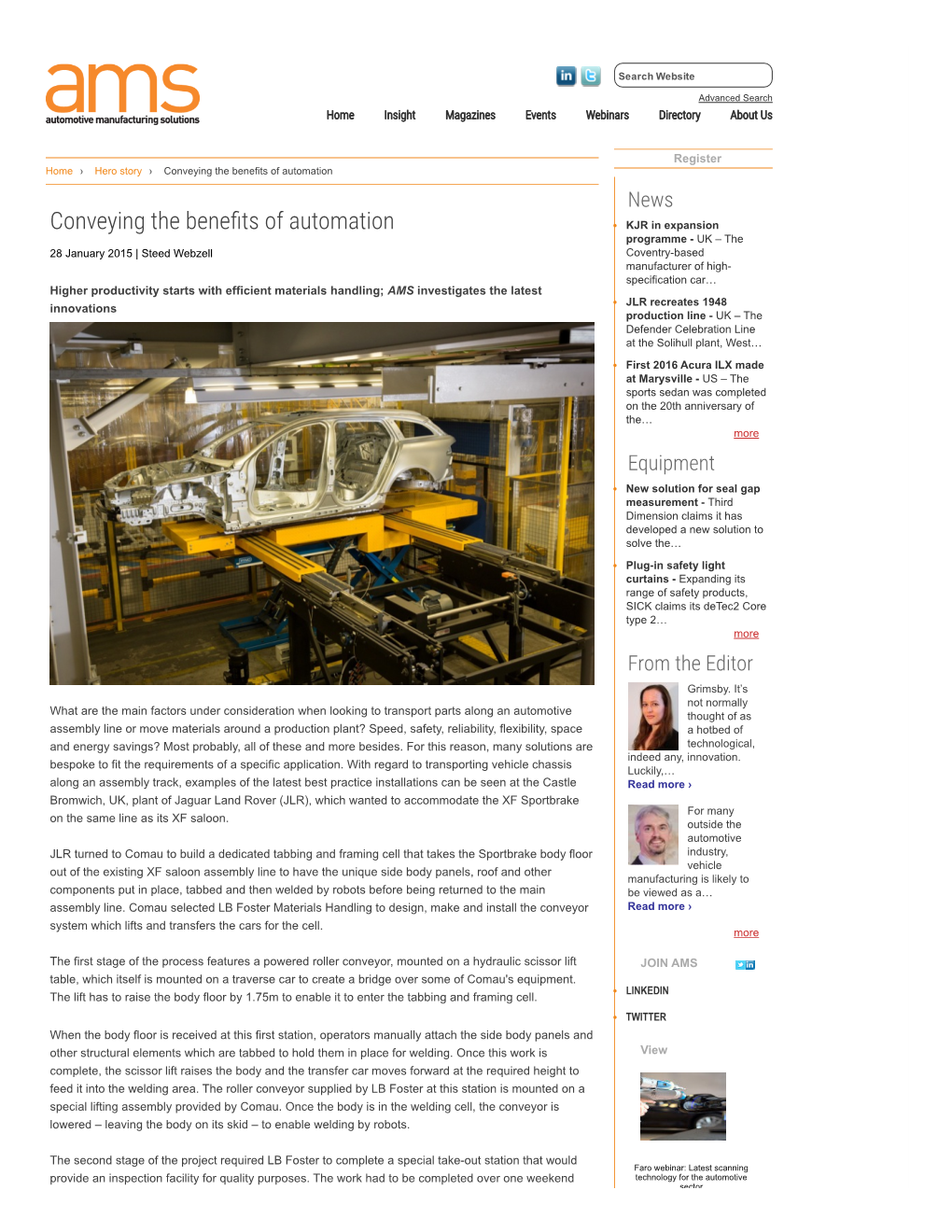

-

Jaguar Land Rover Operational Excellence Our Journey to Date

JAGUAR LAND ROVER OPERATIONAL EXCELLENCE OUR JOURNEY TO DATE Nigel Blenkinsop April 2017 Confidential ©2017 11th June 2013 We had a plan Our Driver: From no engine manufactured in Jaguar land rover for over 16 years to Engine Self Sufficient by 2020 The JLR Enterprise Strategy plans to build 3 Engine Plants (UK, China & India) by 2018 This required a Sustainable Powertrain Manufacturing Capability to be developed from scratch − 2011 - 3 heads & 1 Consultant − 2012 - 120 heads − 2015 - 500 heads (Job #1 Jan 2015) − 2017 - 1400 heads − 2020 – 2000+ heads (UK only) Creates a requirement to Manufacture 700,000+ engines a year (I4, I3, I6, V8) £800million investment in Global Powertrain Manufacturing With high expectations We had too: Execute a Flawless Launch (Quality, Cost, Schedule) Spend £500million Capital Efficiently – Maximise the return from Investment The Stretch: Create Something Special (World Class) and shift the JLR Operations paradigm How – when we face the perfect storm ? New Engine Design New Factory New People New Customer (x760) Assessment of My Organisation - Day 1 August 2012 FUTURE STATE Manuf Eng. Manuf Eng. Production 60+ Heads OP X Production Lean Systems Lean Systems ALIGNMENT & INTEGRATION What Does Great Look Like ? Senior Team – US Study Tour Nov 2012 They all had a burning platform to initiate the journey Everywhere we visited had an air of calm from shop-floor personnel to Senior Leadership Development of their people was key from Leader to Associate – not only via training but by quality 1:1’s too! Complete Leadership buy-in with evidence of buy-in within the whole organisation (with relatively few casualties) Everybody in the organisations had clarity of their purpose: Values, Mission, Vision, Goals They all had a dedicated Continuous Improvement departments Key to develop at least as many ‘problem solvers’ as ‘problem finders’ Time allocated in the standard day to develop and deploy improvement activities Very visible Leadership ! For example, go-look-see walks, 1:1’s, Process Confirmation etc. -

Triumphs Around Georgian Bay

T HE M AGAZINE O F T HE T O R O N to T RIU M PH C LUB S U mm ER 2 0 1 1 Precious Cargo Triumphs Around Georgian Bay Triumph Rallying • Reliable Standards • Bonnet Release Fix PARTS & ACCESSORIES FREE CATALOGS 17 contents Summer 2011 18 Member’s Pages From the Editor......................5 From the President ..................7 Club Hub.........................9-11 Owner’s Manual . .15 Activities Events: Calendar .......................12/13 Features “Keep’em On The Road”™ 24 Marque My Words: Tale of Two Fours ...................17 Quality Parts & Accessories Cover Story: Fully illustrated catalogs with the parts you need. Around Georgian Bay...........18-21 Specify your make and model to get a FREE catalog. Historically Speaking: Fast Service, Simple Ordering and Convenient, Quick Delivery. Triumphs in Rallying Pt2.........22/23 T HE M AGAZINE O F T HE T O R O N TO T RIU M PH C LUB S U MM ER 2 0 1 1 Reliable Standards ..............24-27 22 Restoration: TR2, TR3, TR4, TR4A MGA 100-4, 100-6, 3000 TR250, TR6 TR6 Engine Rebuild.............28/29 MGB, MGC Sprite TR7, TR8 Midget Been There Fixed That: GT6, Spitfire Alpine, Tiger On the Cover Precious Shafted by a Yoke ...............31-36 Patrick Caria’s 1974 1/2 Broken Bonnet Fix ..............37/38 TR6 leads a line up of TRs Cargo Triumphs around www.VictoriaBritish.com aboard the Chi-Cheemaun Georgian Bay ferry to Tobermory Shop Online ... Fast, Simple & Safe Orders - Catalog Request -Status Photo by Andrew Grace Trimph Rallying • Reliable Standards • Bonnet Release Fix 1-800-255-0088 11 Ragtop.2.02.indd 1 11-07-20 2:44 PM RAGTOP SUMMER 2011 www.TorontoTriumph.com 3 VICTORIA BRITISH LTD.® PO Box 14991, Lenexa, Kansas 66285-4991 I I INSURANCEINSURANCE ANTIQUE, CLASSICANTIQUE, AND SPECIAL CLASSIC INTEREST AND SPECIAL INTEREST TM TM AUTOMOBILE INSURANCEAUTOMOBILE TM INSURANCE TM from the editor SUBMISSIONS INSURANCE Format: MS Word files are preferred. -

Records of Wolverton Carriage and Wagon Works

Records of Wolverton Carriage and Wagon Works A cataloguing project made possible by the Friends of the National Railway Museum Trustees of the National Museum of Science & Industry Contents 1. Description of Entire Archive: WOLV (f onds level description ) Administrative/Biographical History Archival history Scope & content System of arrangement Related units of description at the NRM Related units of descr iption held elsewhere Useful Publications relating to this archive 2. Description of Management Records: WOLV/1 (sub fonds level description) Includes links to content 3. Description of Correspondence Records: WOLV/2 (sub fonds level description) Includes links to content 4. Description of Design Records: WOLV/3 (sub fonds level description) (listed on separate PDF list) Includes links to content 5. Description of Production Records: WOLV/4 (sub fonds level description) Includes links to content 6. Description of Workshop Records: WOLV/5 (sub fonds level description) Includes links to content 2 1. Description of entire archive (fonds level description) Title Records of Wolverton Carriage and Wagon Works Fonds reference c ode GB 0756 WOLV Dates 1831-1993 Extent & Medium of the unit of the 87 drawing rolls, fourteen large archive boxes, two large bundles, one wooden box containing glass slides, 309 unit of description standard archive boxes Name of creators Wolverton Carriage and Wagon Works Administrative/Biographical Origin, progress, development History Wolverton Carriage and Wagon Works is located on the northern boundary of Milton Keynes. It was established in 1838 for the construction and repair of locomotives for the London and Birmingham Railway. In 1846 The London and Birmingham Railway joined with the Grand Junction Railway to become the London North Western Railway (LNWR). -

Michael Banfield Collection

The Michael Banfield Collection Friday 13 and Saturday 14 June 2014 Iden Grange, Staplehurst, Kent THE MICHAEL BANFIELD COLLECTION Friday 13 and Saturday 14 June 2014 Iden Grange, Staplehurst, Kent, TN12 0ET Viewing Please note that bids should be ENquIries Customer SErvices submitted no later than 16:00 on Monday to Saturday 08:00 - 18:00 Thursday 12 June 09:00 - 17:30 Motor Cars Thursday 12 June. Thereafter bids +44 (0) 20 7447 7447 Friday 13 June from 09:00 +44 (0) 20 7468 5801 should be sent directly to the Saturday 14 June from 09:00 +44 (0) 20 7468 5802 fax Please call the Enquiries line Bonhams office at the sale venue. [email protected] when out of hours. +44 (0) 20 7468 5802 fax Sale times Automobilia Please see page 2 for bidder We regret that we are unable to Friday 13 June +44 (0) 8700 273 619 information including after-sale Automobilia Part 1 - 12 midday accept telephone bids for lots with collection and shipment a low estimate below £500. [email protected] Saturday 14 June Absentee bids will be accepted. Automobilia Part 2 - 10:30 Please see back of catalogue New bidders must also provide Motor Cars 15:00 (approx) for important notice to bidders proof of identity when submitting bids. Failure to do so may result Sale Number Illustrations in your bids not being processed. 22201 Front cover: Lot 1242 Back cover: Lot 1248 Live online bidding is CataloguE available for this sale £25.00 + p&p Please email [email protected] Entry by catalogue only admits with “Live bidding” in the subject two persons to the sale and view line 48 hours before the auction to register for this service Bids +44 (0) 20 7447 7448 +44 (0) 20 7447 7401 fax To bid via the internet please visit www.bonhams.com Bonhams 1793 Limited Bonhams 1793 Ltd Directors Bonhams UK Ltd Directors Registered No. -

Jaguar Land Rover to Pause Some UK Production on Chip Shortage

Jaguar Land Rover to pause some UK production on chip shortage 1 Jaguar Land Rover will pause production at two UK factories, partly because of a shortage of computer chips. in Automotive News Europe / Reuters , 22-04-2021 Production at Jaguar Land Rover's factory in Castle Bromwich, shown, will be stopped temporarily. Output at Castle Bromwich and Halewood will be temporarily halted starting on Monday due to supply chain disruption, including a lack of semiconductors, the automaker said on Thursday. "We have adjusted production schedules for certain vehicles which means that our Castle Bromwich and Halewood manufacturing plants will be operating a limited period of non-production from Monday 26th April," the Tata Motors- owned company said. The production stoppage was first reported by the Guardian newspaper. https://europe.autonews.com/automakers/jaguar-land-rover-pause-some-uk-production-chip-shortage The models affected by production shutdown will be the Jaguar XE and XF sedans and the F-Type sports car, all built at Castle Bromwich, and the Land Rover Discovery Sport and Range Rover Evoque built at Halewood, the paper said. The shutdown is scheduled to last at least a week, according to the report. 2 JLR's plant in Solihull plant, England, which builds Range Rover models and the Jaguar F-Pace, is unaffected so far, the Guardian reported. The company's factory in Slovakia, which produces the new Land Rover Defender, along with plants in Brazil and China, also are unaffected. https://europe.autonews.com/automakers/jaguar-land-rover-pause-some-uk-production-chip-shortage . -

Mark Et Repor T – Nov Emb Er 2018

MARKET REPORT NOVEMBER 2018 ECONOMY The UK economy – including retail and construction – grew nominally in Q3 2018. Uncertainty over Brexit is affecting business confidence and investment, as well as the FTSE indices. The UK economy grew 0.6% in Q3 2018, according to the ONS. Retail sales grew, and the construction sector recovered. Business investment 6% in machinery, research and development contracted by 1.2%, worse than expected. The value of non-EU car exports grew £1 billion and the value Growth of the UK of EU car imports fell £1.7 billion. Inflation remained unchanged at 2.4%. economy in Q3 Comparative costs of food, beverages, clothing and footwear all declined. A recent poll by accounting authorities showed UK business confidence to be at its lowest level since the 2008 financial crash. The FTSE 100 fell to 6,980 and the FTSE 250 to 18,480, near the lowest values this year. Sterling is trading at $1.27 and €1.13. ALUMINIUM NOVEMBER 2018 NOVEMBER – Primary aluminium production is breaking records, with Chinese dominance easing compared to recent years. The IAI’s October 2018 statistics for global primary production predict 64.1 million tonnes 64.1 million tonnes, another record year. China remains dominant, but Projected 2018 global using the data available for this year up to October, is only responsible primary production – a for 48% of the total – a much lower percentage compared to recent record year years. $1,912/tonne On the LME, primary aluminium started October at $1,967 per tonne and finished at $1,935. -

GATEWAY (12 Miles) Via A45 ADJOINING BIRMINGHAM PARK AIRPORT to LET High Quality Refurbished Warehouse/Production Units

M42 J6 M42 NEC Birmingham Airport A45 To Jaguar Land Rover 2 miles from the M42 J6, 2.5 miles from National Exhibition Centre and 1 Mile from Jaguar Land Rover Solihull Plant Benefi ts from airfi eld access to Birmingham Airport Close to Birmingham City Centre To Birmingham (7.4 miles) and Coventry City Centre GATEWAY (12 miles) via A45 ADJOINING BIRMINGHAM PARK AIRPORT TO LET High Quality Refurbished Warehouse/Production Units 1,400 - 60,900 sq ft (130 - 5,658 sq m) www.gatewaypark.co.uk STRATEGIC LOCATION • Adjacent to Birmingham Airport with airfi eld access • Accessed off the A45 Coventry Road • 2.5 miles from the National Exhibition Centre • 1 mile from Jaguar Land Rover Solihull Plant • Excellent access to M45 J6 and M6 J4a within 2 miles and 5 miles respectively • 7.4 miles from Birmingham City Centre • 12 miles from Coventry City Centre ESTABLISHED ESTATE • 29 modern production/warehouse units arranged in a courtyard formation totalling 217,075 sq ft (20,166 sq m) ranging from 1,400 - 60,900 sq ft (130 - 5,656 sq m) • 24 hour manned security gatehouse and barrier • CCTV • Large communal estate car park HIGH SPECIFICATION • Units refurbished to a high standard • Steel frame construction with block and brick infi ll • Externally part brick and clad with profi le metal sheet roofs • Concrete and brick surfaced service yards • Ground Level loading doors • Minimum working heights of 6 metres • Integral offi ces to units EXISTING OCCUPIERS INCLUDE: GATEWAY ADJOINING BIRMINGHAM PARK AIRPORT SECURITY The estate benefi ts from 24 hour security via a managed gatehouse, which is further supplemented by security patrols. -

Outback Odysseyodyssey

MARCH 2016 PRINT MASTER FINAL 28/3/16 6:12 PM Page 1 AUS $4.95 Inc GST OutbackOutback OdysseyOdyssey SIMPSONSIMPSON DESERTDESERT HAZARDOUSHAZARDOUS TREETREE REMOVALREMOVAL PROGRAMPROGRAM CROSSINGCROSSING OXFAMOXFAM CHRISTMASCHRISTMAS TREETREE RUNRUN TOPTOP CROSSINGCROSSING HUTHUT RESTORARESTORATIONTION GEELONGGEELONG WILDLIFEWILDLIFE RESCUERESCUE PORTPORT AUGUSTAAUGUSTA TOTO ALICEALICE SPRINGSSPRINGS ININ 19361936 LASTLAST LANDLAND ROVERROVER DEFENDERDEFENDER JEEPJEEP CELEBRACELEBRATETE 75TH75TH ANNIVERSARYANNIVERSARY MARCHMARCH 20162016 MARCH 2016 PRINT MASTER FINAL 29/3/16 7:53 PM Page 2 RV Storage Systems Drive Lights & Light bars MARCH 2016 PRINT MASTER FINAL 28/3/16 7:13 PM Page 3 From the President elcome to the March Trackwatch Association and Wand a happy new year to you all. members of the The start of this year heralds the begin- Taungurung Clans Aboriginal ning of a new era for the Association Corporation. with the establishment of the long We will also be meeting with the awaited ministerially appointed Four Environment Minister in late March to FOUR WHEEL DRIVE VICTORIA Wheel Drive Advisory Committee, of discuss the new advisory committee The peak representative body for all which Four Wheel Drive Victoria will be and to raise other matters of importance Victorian four wheel drivers since 1975 a key member. We look forward to to our Association, such as our ongoing representing our members in our funding arrangements and the proposed dealings with the rest of the committee Great Forest National Park. Victoria Association of Four Wheel Drive Clubs Inc. and with the Environment Minister who We finished the 2015 year with our usual PO Box 1015G Balwyn North VIC 3104 has sponsored this new committee until Phone 03 9857 5209 Oxfam Christmas Tree delivery event, the end of 2018. -

European Car and Light Commercial Vehicle Production Outlook

European Car and Light Commercial Vehicle Production Outlook December 2015 SMMT, the 'S' symbol and the ‘Driving the motor industry’ brandline are trademarks of SMMT Ltd Contents Introduction and analysis overviews Page Individual Vehicle Manufacturer reviews Page Introduction 2 BMW 39 Executive Summary 3 Daimler 41 The Outlook for 2016 – better than might be expected? 9 Fiat 43 Market Overview & Country Summary 13 Ford 45 Alternative Scenarios 14 GM 47 Country Analysis 18 Honda 49 UK and France comparison 23 Hyundai – Kia 50 Key Country Developments 24 PSA 51 UK 24 Renault-Nissan-Dacia 54 The 2m units question 29 Suzuki 57 France 31 Tata Jaguar Land Rover 58 Germany 32 Toyota 60 Italy 33 Volkswagen Group 61 Spain 34 Volvo 63 Production Summary 36 Aston Martin 64 Other VMs 65 EUROPEAN CAR AND LCV PRODUCTION OUTLOOK REPORT December 2015, Page 1 Introduction This report continues the new style of reporting which we adopted at the start of 2014. This is intended to be more manageable for readers; we now exclude much of the detail on historic developments at each vehicle company, information which can be found in previous editions of the report available on the SMMT website. www.smmt.co.uk. In addition, the model level information for vehicle production outside the UK is excluded from the current versions, although this data is available from Ian Henry of AutoAnalysis. Our focus is increasingly on developments in the UK, to make the report more relevant for UK suppliers; many of these companies should see major new business opportunities with increased sourcing at the tier 1 level in the UK especially, as well potential business too for smaller suppliers at the tier 2 and 3 level. -

View Our Sustainability Report

C P EXIT Our plan for Sustainability Jaguar Land Rover Sustainability Report 2009/2010 JAGUAR LAND ROVER SUSTAINABILITY 01.12.10 © JAGUAR LAND ROVER JAGUAR LAND ROVER SUSTAINABILITY01.12.10 © XX Contents C About this report 3 About Jaguar Land Rover 4 Introduction 7 Our approach to sustainability 8 Sustainable Development Policy 9 P Managing sustainability 10 Environmental Innovation 11 EXIT Stakeholder engagement 14 Business ethics 15 Responsible products 17 Tailpipe CO2 emissions 18 Renewable and recycled materials 27 Safety 31 Engaging customers on sustainability 33 CO2 offset programme 34 Responsible operations 36 Environmental management 37 Performance 39 Supply chain 48 Our people 51 Health, safety and wellbeing 52 Diversity 55 Training and development 56 Employee engagement 57 Union consultation 59 Community 60 Investing in local communities 61 Charity support 63 Employee volunteering 65 Performance summary 66 Contacts 67 JAGUAR LAND ROVER SUSTAINABILITY 01.12.10 © JAGUAR LAND ROVER JAGUAR LAND ROVER SUSTAINABILITY01.12.10 © XX2 Navigation Contents page C Next page Back a page Previous page viewed Print document P Exit document EXIT Here we outline our commitment and approach to sustainability, provide information on our performance on key social and environmental issues, and set out our goals at a corporate level. Case studies and examples throughout the report offer insight into how these are put into practice across the company and in the development and manufacture of both Jaguar and Land Rover vehicles. We appreciate your views on this report and our performance. Please send your feedback to Jaguar at [email protected] or Land Rover at [email protected]. -

The OVLR Newsletter

15 June 1999 www.ovlr.org Volume XVI, Number 6 The OVLR Newsletter EDITOR: Dixon Kenner PO Box 36055, 1318 Wellington Street, ([email protected]) Ottawa, Ontario, CANADA K1Y 4V3 (h) 613-722-1336 General Information PRODUCTION EDITOR: Ottawa Valley Land Rovers is the oldest and largest Land Rover club in Spencer Norcross Canada. Membership is open to all Land Rover enthusiasts. Executive meetings ([email protected]) are held on the first Monday of every month. Social meetings are held on the (h) 703-516-9899 (w) 703-243-3733 third Monday of every month, generally at the Prescott Hotel on Preston Street. ONTRIBUTORS OVLR offers a monthly newsletter and a variety of activities throughout the C : year, from mechanical seminars and off-road rallies to social events and family Mike Rooth,T.A. Pennell, Eric Marr oriented outings. Members receive discounts on parts from a number of North OTHER HELP: American suppliers. Off-road activities come in several categories.The light ver- sion, which is usually entertainment during a rally or at one of our family sum- Murray Jackson,Andrew Finlayson, mer events, consists of a little “mud bogging” or tours along country lanes.The Christine Rose. heavy stuff, which is usually several days across public lands navigating by com- pass, topographical maps and aerial photos, involves bridge building, river barg- ing, and driving conditions ranging from cedar swamp to rocky hill winching. Membership: Those joining throughout the year pay a flat $25 per year, membership expires one year from the last dues submission. The OVLR Executive: The Ottawa Valley Land Rovers Newsletter ISSN 1203-8237 President is published twelve times per year for club members. -

Jaguar Land Rover PLC Interim Report

Jaguar Land Rover PLC Interim Report for the three months and nine months ended 31 December 2011 TABLE OF CONTENTS Page KEY METRICS ................................................................................................................................ ..............2 KEY EVENTS FOR QUARTER 3 2011/12 ................................................................ ................................ 3 AWARDS AND RECOGNITIONS FOR QUARTER 3 2011/12 ………………………………………. 3 MANAGEMENT'S DISCUSSION AND ANALYSIS OF FINANCIAL CONDITION AND RESULTS OF OPERATIONS General trends in performance (including results of operations) ................................ ...........................4 Business risks and mitigating factors ................................................................ ................................ 7 Employees ................................................................................................................................ .............7 Liquidity and capital resources ................................................................................................ ..............7 Acquisitions and disposals ................................................................................................ .....................8 Off-balance sheet financial arrangements ................................................................ .............................8 Board of Directors ................................................................................................ ................................ 8 CONDENSED