United States Patent Office

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

UNITED STATES PATENT of FICE 2,262,743 PROCESS for BREAKING PETROLEUR EMUSIONS Melvin De Groote, University City, and Bernhard Keiser and Charles M

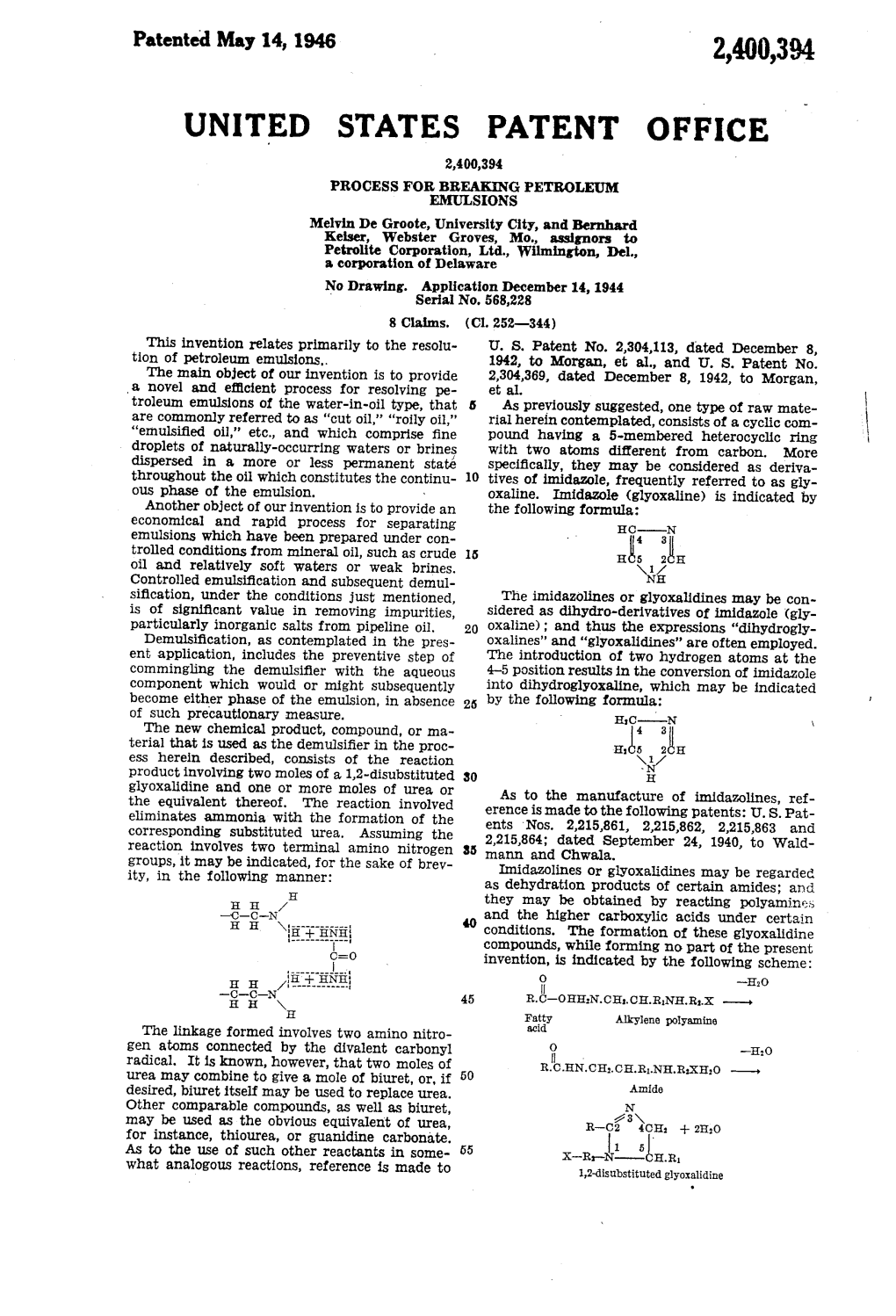

Patented Nov. 11, 1941 2,262,743 UNITED STATES PATENT of FICE 2,262,743 PROCESS FOR BREAKING PETROLEUR EMUSIONS Melvin De Groote, University City, and Bernhard Keiser and Charles M. Blair, Jr., Webster Groves, Mo., assignors to Petroite Corporation, Ltd., Wilmington, Del, a corporation of Dela Ware No Drawing. Application May 12, 194i, Serial No. 393,128 4 Claims. (C1. 252-344) This invention relates primarily to the resolu ous chemical compounds adapted for use in tion of petroleum emulsions, our present appli breaking oil field emulsions, reference was made cation being a continuation, in part, of Our co to a type exemplified by the following formula: pending application Serial No. 342,716, filed June. N-CH 27, 1940. 2 One object of our invention is to provide a Ciuc, novel process for resolving petroleum emulsions NH-CI of the water-in-oil type that are commonly re In regard to such compounds, it is pointed out ferred to as 'cut oil,' 'roily oil,' 'emulsified oil,' in said co-pending application Serial No. 342,716, etc., and which comprise fine droplets of nat 10 that the oxyalkylated derivatives may be emi urally-occurring waters or brines dispersed in a ployed, This fact is stated in the following.lan more or less permanent state throughout the oil guage: which constitutes the continuous phase of the "Also, as is well known, any of the diamines emulsion. w of the kind previously described containing at Another object of our invention is to provide s least one amino hydrogen atom may be con a: economical and rapid process for separating verted into hydroxylated derivatives by reaction emulsions which have been prepared under con with an alkylene oxide, such as ethylene oxide, trolled conditions from mineral oil, such as crude propylene Oxide, glycidol, epichlorhydrin, and the petroleum and relatively soft waters or weak like. -

WO 2019/008101 Al 10 January 2019 (10.01.2019) W !P O PCT

(12) INTERNATIONAL APPLICATION PUBLISHED UNDER THE PATENT COOPERATION TREATY (PCT) (19) World Intellectual Property Organization International Bureau (10) International Publication Number (43) International Publication Date WO 2019/008101 Al 10 January 2019 (10.01.2019) W !P O PCT (51) International Patent Classification: UG, ZM, ZW), Eurasian (AM, AZ, BY, KG, KZ, RU, TJ, A61K 9/28 (2006 .0 1) A61K 31/198 (2006 .0 1) TM), European (AL, AT, BE, BG, CH, CY, CZ, DE, DK, A61K 9/50 (2006 .0 1) A61K 31/202 (2006 .0 1) EE, ES, FI, FR, GB, GR, HR, HU, IE, IS, IT, LT, LU, LV, MC, MK, MT, NL, NO, PL, PT, RO, RS, SE, SI, SK, SM, (21) International Application Number: TR), OAPI (BF, BJ, CF, CG, CI, CM, GA, GN, GQ, GW, PCT/EP20 18/068261 KM, ML, MR, NE, SN, TD, TG). (22) International Filing Date: 05 July 2018 (05.07.2018) Published: — with international search report (Art. 21(3)) (25) Filing Language: English (26) Publication Language: English (30) Priority Data: 201731023754 06 July 2017 (06.07.2017) 17186984.5 2 1 August 2017 (21.08.2017) (71) Applicant: EVONIK TECHNOCHEMIE GMBH [DE/DE]; GutenbergstraBe 2, 69221 Dossenheim (DE). (72) Inventors: GUHA, Ashish; Excellencia - A, 803 Casabel- la Shil-road, Mumbai, Dombivali (E) 421204 (IN). KAN- ERIA, Vishal; Rajkamal Bayside - 2/504, Sector 15, Palm Beach Road, CBD Belapur, Navi Mumbai 400614 (IN). JOSHI, Shraddha; Flat no 1203, 13th floor, Newa Gar den, Phase 1, Sector 20A, Plot 1, Airoli, Navi Mumbai 400708 (IN). BHOSALE, Suraj; A-1902, CIELO, LOD- HA Splendora, Bhayenderpada, Ghodbunder road, Thane (W) 400607 (IN). -

Co-Olefinic Fatty Acids

SOME STUDIES ' N FATTY ACID SER ES PART TWO CO-OLEFINIC FATTY ACIDS NATIONAL CHEMICAL LABORATORY, POONA- 8. - (1965 ) C 0 T E T S Page CHAPTER I limOiXJCTION 25-34 w-Olefinic fatty acids 25 Methods of synthesis 25 Methods utilising components 28 in which the co-olefinic group is already present. Methods in which the w-olefinic 30 group is produced by an elimiaation reaction. Other methods 31 References 33 CHAPTER II PYROLYSIS OF MAiiY-MEMBERED 36 - 130 LACTONESj A UEJJHIAL METHOD 1T(B THE SYNTHESIS OF «-0LEFiiac f a t t y a c i d s . Preliminary investigations 36 Pyrolysis of many-membered 43 lactones Preparation of ^J^-hydroxy 45 fatty acids Preparation of lactones 52 Pyrolysis of lactones 62 Discussion 67 Experimental 75 Summary 126 References 127 Page CHAPTER III SYSrmTIC 131 - 153 CHAM-SHOHTENIiia OF W-OLEb*INIC f a t t y a c id s Chain-shortening by 132 one carbon Chain-shortening 133 two carbons Chain-shortening by 136 three carbons Experimental 141 Summary 150 References 151 CHAPTER I INTRODUCTION 2 5 oj-OLH^’INIC FATTY AGIDS I.{TRQJUCTIQN The work described in this Part deals with the development of general method for the preparation of long chain co-olefinic fatty acids. cu-Olefinic acids offer an unique opportunity for degrading the molecule from one end in bits of one or more carbon atoms at a time. This work was of interest in comiection with the possible utilization of kamlolenic acid: H0CH2(CH2)3CH=CHCH=CH-CH=CH(CH2)7C00H the major component of the o il from the seeds of Mallotus phllippinensis. -

WO 2013/184908 A2 12 December 2013 (12.12.2013) P O P C T

(12) INTERNATIONAL APPLICATION PUBLISHED UNDER THE PATENT COOPERATION TREATY (PCT) (19) World Intellectual Property Organization I International Bureau (10) International Publication Number (43) International Publication Date WO 2013/184908 A2 12 December 2013 (12.12.2013) P O P C T (51) International Patent Classification: Jr.; One Procter & Gamble Plaza, Cincinnati, Ohio 45202 G06F 19/00 (201 1.01) (US). HOWARD, Brian, Wilson; One Procter & Gamble Plaza, Cincinnati, Ohio 45202 (US). (21) International Application Number: PCT/US20 13/044497 (74) Agents: GUFFEY, Timothy, B. et al; c/o The Procter & Gamble Company, Global Patent Services, 299 East 6th (22) Date: International Filing Street, Sycamore Building, 4th Floor, Cincinnati, Ohio 6 June 2013 (06.06.2013) 45202 (US). (25) Filing Language: English (81) Designated States (unless otherwise indicated, for every (26) Publication Language: English kind of national protection available): AE, AG, AL, AM, AO, AT, AU, AZ, BA, BB, BG, BH, BN, BR, BW, BY, (30) Priority Data: BZ, CA, CH, CL, CN, CO, CR, CU, CZ, DE, DK, DM, 61/656,218 6 June 2012 (06.06.2012) US DO, DZ, EC, EE, EG, ES, FI, GB, GD, GE, GH, GM, GT, (71) Applicant: THE PROCTER & GAMBLE COMPANY HN, HR, HU, ID, IL, IN, IS, JP, KE, KG, KN, KP, KR, [US/US]; One Procter & Gamble Plaza, Cincinnati, Ohio KZ, LA, LC, LK, LR, LS, LT, LU, LY, MA, MD, ME, 45202 (US). MG, MK, MN, MW, MX, MY, MZ, NA, NG, NI, NO, NZ, OM, PA, PE, PG, PH, PL, PT, QA, RO, RS, RU, RW, SC, (72) Inventors: XU, Jun; One Procter & Gamble Plaza, Cincin SD, SE, SG, SK, SL, SM, ST, SV, SY, TH, TJ, TM, TN, nati, Ohio 45202 (US). -

Valorization of Tomato Processing By-Products: Fatty Acid Extraction and Production of Bio-Based Materials

materials Article Valorization of Tomato Processing by-Products: Fatty Acid Extraction and Production of Bio-Based Materials José J. Benítez 1,* , Paula M. Castillo 1, José C. del Río 2 , Manuel León-Camacho 3, Eva Domínguez 4 , Antonio Heredia 4,5, Susana Guzmán-Puyol 6, Athanassia Athanassiou 6 and José A. Heredia-Guerrero 6,* 1 Instituto de Ciencia de Materiales de Sevilla, Centro Mixto CSIC-Universidad de Sevilla, Américo Vespucio 49, E-41092 Seville, Spain; [email protected] 2 Instituto de Recursos Naturales y Agrobiología de Sevilla-CSIC, Avenida Reina Mercedes 10, 41012 Seville, Spain; [email protected] 3 Instituto de la Grasa, CSIC, 41006 Seville, Spain; [email protected] 4 Instituto de Hortofruticultura Subtropicaly Mediterránea La Mayora, Universidad de Málaga-CSIC, E-29071 Málaga, Spain; [email protected] (E.D.); [email protected] (A.H.) 5 Departamento de Biología Molecular y Bioquímica, Universidad de Málaga, E-29071 Málaga, Spain 6 Smart Materials, Istituto Italiano di Tecnologia, 16163 Genova, Italy; [email protected] (S.G.-P.); [email protected] (A.A.) * Correspondence: [email protected] (J.J.B.); [email protected] (J.A.H.-G.); Tel: +34-95448-9551 (J.J.B.); +39-0107-1781-276 (J.A.H.-G.) Received: 17 October 2018; Accepted: 6 November 2018; Published: 7 November 2018 Abstract: A method consisting of the alkaline hydrolysis of tomato pomace by-products has been optimized to obtain a mixture of unsaturated and polyhydroxylated fatty acids as well as a non-hydrolysable secondary residue. Reaction rates and the activation energy of the hydrolysis were calculated to reduce costs associated with chemicals and energy consumption. -

Lipid Glossary 2 Was Published by the Oily Press in 2004 and Is Available Free of Charge from the Publisher's Web Site

This electronic version of Lipid Glossary 2 was published by The Oily Press in 2004 and is available free of charge from the publisher's web site. A printed and bound hardback copy of the book can also be purchased from the web site: www.pjbarnes.co.uk/op/lg2.htm LIPID GLOSSARY 2 Frank D. Gunstone Honorary Professor, Scottish Crop Research Institute, Dundee, UK Bengt G. Herslöf Managing Director, Scotia LipidTeknik AB, Stockholm, Sweden THE OILY PRESS BRIDGWATER ii Copyright © 2000 PJ Barnes & Associates PJ Barnes & Associates, PO Box 200, Bridgwater TA7 0YZ, England Tel: +44-1823-698973 Fax: +44-1823-698971 E-mail: [email protected] Web site: http://www.pjbarnes.co.uk All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted by any form or by any means, electronic, mechanical, photocopying, recording or otherwise, without prior permission in writing from the publisher. All reasonable care is taken in the compilation of information for this book. However, the author and publisher do not accept any responsibility for any claim for damages, consequential loss or loss of profits arising from the use of the information. ISBN 0-9531949-2-2 This book is Volume 12 in The Oily Press Lipid Library Publisher's note: Lipid Glossary 2 is based on A Lipid Glossary, which was published by The Oily Press in 1992 (ISBN 0-9514171-2-6). However, Lipid Glossary 2 is more than simply a revised and updated edition of the earlier book — it is also much extended, with more than twice as many pages, and a much greater number of graphics (see Preface). -

WO 2013/007653 Al O© O

(12) INTERNATIONAL APPLICATION PUBLISHED UNDER THE PATENT COOPERATION TREATY (PCT) (19) World Intellectual Property Organization I International Bureau (10) International Publication Number (43) International Publication Date WO 2013/007653 Al 17 January 2013 (17.01.2013) P O P C T (51) International Patent Classification: AO, AT, AU, AZ, BA, BB, BG, BH, BR, BW, BY, BZ, A61L 29/08 (2006.01) A61L 29/16 (2006.01) CA, CH, CL, CN, CO, CR, CU, CZ, DE, DK, DM, DO, DZ, EC, EE, EG, ES, FI, GB, GD, GE, GH, GM, GT, HN, (21) International Application Number: HR, HU, ID, IL, IN, IS, JP, KE, KG, KM, KN, KP, KR, PCT/EP2012/063301 KZ, LA, LC, LK, LR, LS, LT, LU, LY, MA, MD, ME, (22) International Filing Date: MG, MK, MN, MW, MX, MY, MZ, NA, NG, NI, NO, NZ, 6 July 2012 (06.07.2012) OM, PE, PG, PH, PL, PT, QA, RO, RS, RU, RW, SC, SD, SE, SG, SK, SL, SM, ST, SV, SY, TH, TJ, TM, TN, TR, (25) Filing Language: English TT, TZ, UA, UG, US, UZ, VC, VN, ZA, ZM, ZW. (26) Publication Language: English (84) Designated States (unless otherwise indicated, for every (30) Priority Data: kind of regional protection available): ARIPO (BW, GH, PCT/EP20 11/003564 8 July 201 1 (08.07.201 1) EP GM, KE, LR, LS, MW, MZ, NA, RW, SD, SL, SZ, TZ, UG, ZM, ZW), Eurasian (AM, AZ, BY, KG, KZ, RU, TJ, (71) Applicant (for all designated States except US): CARDI- TM), European (AL, AT, BE, BG, CH, CY, CZ, DE, DK, ONOVUM SP.Z.O.O. -

OF FATTY ACIDS* Part I

STUDIES IN THE nI:ELECTRIC CONSTANTS .( OF FATTY ACIDS* Part I. A Comparative Study of the Equations of Onsager and of J atkar in Relation to Experimental Data on Pure Liquids By R. S. PHADKE (Department of General Chemistry, Indian Institute of Science, Bangalore-3) INTRODUCTION The dielectric propertieR of fatty acids have attracted the attention 0 a large number of workers since 1930 when Smyth and Rogers' measurec the dielectric constants of acetic and butyric acids and concluded that th, two acids formed dimers in the pure liquid state as also in benzene solutions The dimers were found to have a zero moment. In the same year Zahn 2 measured the dielectric constant of acetic acic vapour at relatively high temperatures and under low pressures and confirmec the value obtained by Smyth and Rogers.' Zahn found that the momen of acetic acid increased with a rise in temperature. He at first attributec this to increased vibration of the OH group in the molecule but later con eluded3 that the change was due to the effect of temperature on the associa tion of acetic acid molecules. He also studied the moments of formic ane propionic acids. Investigations on the dipole moments of formic, acetic propionic, n-butyric and iso-valerie acids in benzene solutions, were publishec in 1930 by Wolf.' and Briegleb." In calculating the dipole moments, Wolf' ignored the association of the fatty acids in benzene solutions. Briegleb' however assumed the formation of dimers in such solutions. Eucken6 (1932) attempted a correlation between the dissociation con stants of certain aliphatie and aromatic acids and the corresponding electril moments, dielectric constants, Raman frequency and optical rotation Many irregularities were noticed. -

Orange Shellac

Orange Shellac Handling/Processing 1 Identification of Petitioned Substance 2 3 Chemical Names: Orange shellac Trade Names:U-Beaut Orange Shellac, Grobet USA 12227 Shellac Flake, Kusumi Shellac Apple lustr, Other Name: APL-BRITE, Decco Lustr 602,SSB Splendid, SSB Orange shellac, shellac gum confectioner’s glaze, Polisho confectioner’s resin, resinous glaze, candy glaze, pure food glaze and natural glaze, Lac resin CAS Numbers:9000-59-3 Other Codes: EINECS 232-549-9, EEC E904 52 ACX1009325-9 4 5 Summary of Petitioned Use 6 The use of the substance is in coating of fruits (citrus, pome, and stone fruit) and vegetables (cucumbers, 7 bell peppers, eggplant, and potatoes). It may also be used in the pharmaceutical and confectionary 8 industry (lozenges, capsules, tablets) confectionary glazes (chocolates, coffee beans, candy). Shellac dye is 9 used as a food color. 10 11 Characterization of Petitioned Substance 12 Composition of the Substance: 13 Orange shellac is a resinous complex containing wax, dye and odoriferous components. The orange 14 shellac is a polyester type of material, comprised of long chain and sesquiterpenic acids (Perez-Gago, et 15 al. 2003). 16 17 Table 1. Composition of Orange Shellac (Bose and Sankaranarayan 1963) 18 Content Percentage 19 Lac resin 70-80 % 20 Coloring pigments 4-8 % 21 22 Lac wax 6-7 % 23 Inorganic salts, sugar, and odor substance 15-20 % 24 25 The polyester complex is comprised of straight-chain fatty acids (9, 10, 16 trihydroxyhexadecanoic 26 acid/aleuritic acid) and sesquiterpenic (jalaric) acid. Aleuritic acid is the main component among 27 aliphatic acids. -

W 2011/056572 Al

(12) INTERNATIONAL APPLICATION PUBLISHED UNDER THE PATENT COOPERATION TREATY (PCT) (19) World Intellectual Property Organization International Bureau (10) International Publication Number (43) International Publication Date 1 - - 12 May 2011 (12.05.2011) W 2011/056572 Al (51) International Patent Classification: AO, AT, AU, AZ, BA, BB, BG, BH, BR, BW, BY, BZ, G01N 33/68 (2006.01) CA, CH, CL, CN, CO, CR, CU, CZ, DE, DK, DM, DO, DZ, EC, EE, EG, ES, FI, GB, GD, GE, GH, GM, GT, (21) International Application Number: HN, HR, HU, ID, IL, IN, IS, JP, KE, KG, KM, KN, KP, PCT/US20 10/054096 KR, KZ, LA, LC, LK, LR, LS, LT, LU, LY, MA, MD, (22) International Filing Date: ME, MG, MK, MN, MW, MX, MY, MZ, NA, NG, NI, 26 October 2010 (26.10.2010) NO, NZ, OM, PE, PG, PH, PL, PT, RO, RS, RU, SC, SD, SE, SG, SK, SL, SM, ST, SV, SY, TH, TJ, TM, TN, TR, (25) Filing Language: English TT, TZ, UA, UG, US, UZ, VC, VN, ZA, ZM, ZW. (26) Publication Language: English (84) Designated States (unless otherwise indicated, for every (30) Priority Data: kind of regional protection available): ARIPO (BW, GH, 61/255,381 27 October 2009 (27.10.2009) US GM, KE, LR, LS, MW, MZ, NA, SD, SL, SZ, TZ, UG, 61/359,695 29 June 2010 (29.06.2010) US ZM, ZW), Eurasian (AM, AZ, BY, KG, KZ, MD, RU, TJ, TM), European (AL, AT, BE, BG, CH, CY, CZ, DE, DK, (71) Applicant (for all designated States except US): THE EE, ES, FI, FR, GB, GR, HR, HU, IE, IS, IT, LT, LU, BOARD OF TRUSTEES OF THE UNIVERSITY OF LV, MC, MK, MT, NL, NO, PL, PT, RO, RS, SE, SI, SK, ILLINOIS [US/US]; 506 South Wright Street, 352 A d SM, TR), OAPI (BF, BJ, CF, CG, CI, CM, GA, GN, GQ, ministration Building, Urbana, IL 61801 (US). -

Inventario De Ingredientes Cosméticos Adoptado Por Decisión De La

5.4.2006 ES Diario Oficial de la Unión Europea L 97/1 II (Actos cuya publicación no es una condición para su aplicabilidad) COMISIÓN DECISIÓN DE LA COMISIÓN de 9 de febrero de 2006 que modifica la Decisión 96/335/CE, por la que se establece un inventario y una nomenclatura común de ingredientes empleados en los productos cosméticos (Texto pertinente a efectos del EEE) (2006/257/CE) LA COMISIÓN DE LAS COMUNIDADES EUROPEAS, Visto el Tratado constitutivo de la Comunidad Europea, Vista la Directiva 76/768/CEE del Consejo, de 27 de julio de 1976, relativa a la aproximación de las legislaciones de los Estados miembros en materia de productos cosméticos (1), y, en particular, su artículo 5 bis, apartado 3, y su artículo 7, apartado 2, Una vez consultado el Comité científico de productos cosméticos y productos no alimentarios destinados al consumidor, Considerando lo siguiente: (1) Con arreglo a la información facilitada por las industrias interesadas, es necesario actualizar el inventario y la nomenclatura común de ingredientes empleados en los productos cosméticos que figuran en el anexo de la Decisión 96/335/CE de la Comisión (2). (2) Debería actualizarse la sección I del anexo de la Decisión 96/335/CE para garantizar la precisión y validez científicas de algunas entradas existentes y de las nuevas entradas, así como para mejorar las entradas botánicas, las definiciones y las clases de las funciones. (3) Se ha demostrado que es necesario revisar a fondo las Convenciones de Nomenclatura que figuran en el anexo de la Decisión 96/335/CE con el fin de hacerlas más claras y adaptarlas a los cambios que se han producido en la Nomenclatura internacional de ingredientes cosméticos (International Nomenclature Cosmetic Ingredient, INCI). -

Milk Phospholipids a New Ingredient for Formulation of Functional Foods with Bioactivity

inform August 2009 www.aocs.org Volume 20 (8) 489–552Volume International News on Fats, Oils, and Related Materials ALSO INSIDE: Message from AOCS’ President Taking another look at global oil yields Annual Meeting award addresses Milk phospholipids A new ingredient for formulation of functional foods with bioactivity www.aocs.org !UGUST 6OLUME n Departments Milk phospholipids and Information (ANS "URLING ±KE .ILSSON AND ,ENA /HLSSON EXAMINE A NEW ingredient from milk for formulation of functional foods with 490 Index to Advertisers bioactivity. 490 Calendar Global oil yields: Have we got it seriously wrong? 493 Message from the Denis J. Murphy details recent research that calls into question the President assumptions surrounding global oil yields and the part they have to play in biofuels and food production. Marketplace: Omega-3 fatty acid profiling and dietary forensics 505 News & Noteworthy Ken D. Stark presents his AOCS Young Scientist Research Award 511 Biofuels News !DDRESS DELIVERED AT THE TH !/#3 !NNUAL -EETING %XPO HELD IN /RLANDO &LORIDA 53! -AY n 517 Health & Nutrition News Minutes for the 2009 AOCS business meeting 521 Biotechnology News Emerging research in insect lipids 525 S&D News Brent Sørensen presents a field of research that remains relatively 529 People News/ unexplored. Inside AOCS Regiospecific quantification of triacylglycerols in castor oil containing ricinoleate and dihydroxy 503 Classified Advertising fatty acids by mass spectrometry *IANN 4SYH +EN ,IN PRESENTS HIS (ERBERT * $UTTON !WARD 510 Classified Advertising