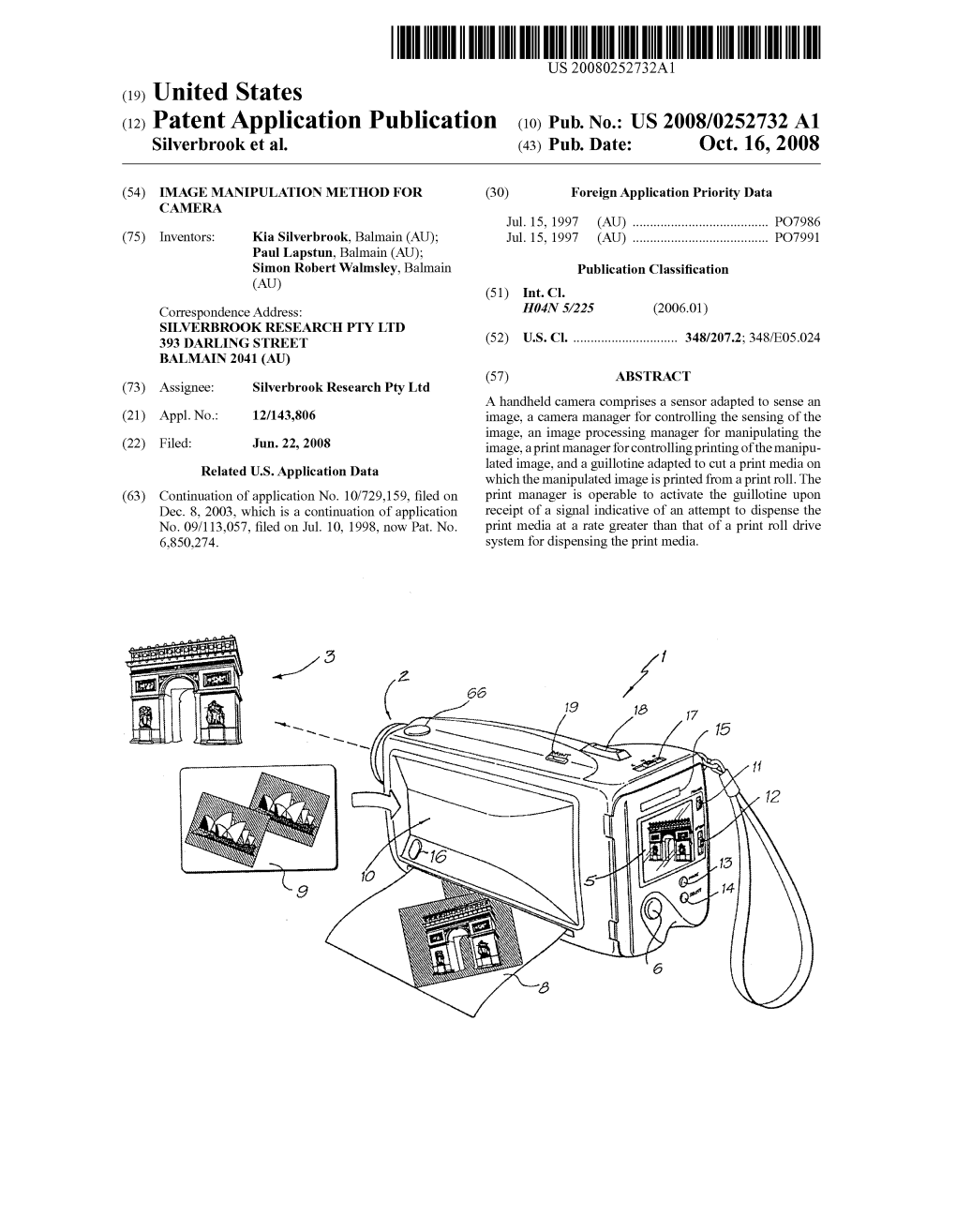

(12) Patent Application Publication (10) Pub. No.: US 2008/0252732 A1 Silverbrook Et Al

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Higgs Windows to New Physics Through D= 6 Operators: Constraints

November 19, 2013 Higgs windows to new physics through d = 6 operators: Constraints and one-loop anomalous dimensions J. Elias-Mir´oa;b, J.R. Espinosab;c, E. Massoa;b, A. Pomarola a Dept. de F´ısica, Universitat Aut`onomade Barcelona, 08193 Bellaterra, Barcelona b IFAE, Universitat Aut`onomade Barcelona, 08193 Bellaterra, Barcelona c ICREA, Instituci´oCatalana de Recerca i Estudis Avan¸cats,Barcelona, Spain Abstract The leading contributions from heavy new physics to Higgs processes can be cap- tured in a model-independent way by dimension-six operators in an effective Lagrangian approach. We present a complete analysis of how these contributions affect Higgs cou- plings. Under certain well-motivated assumptions, we find that 8 CP-even plus 3 CP-odd Wilson coefficients parametrize the main impact in Higgs physics, as all other coefficients are constrained by non-Higgs SM measurements. We calculate the most relevant anoma- lous dimensions for these Wilson coefficients, which describe operator mixing from the heavy scale down to the electroweak scale. This allows us to find the leading-log correc- tions to the predictions for the Higgs couplings in specific models, such as the MSSM or composite Higgs, which we find to be significant in certain cases. arXiv:1308.1879v2 [hep-ph] 17 Nov 2013 1 Introduction The resonance observed at around 125 GeV at the LHC [1] has properties consistent with the Standard Model Higgs boson. More precise measurements of its couplings will hopefully provide information on the origin of electroweak symmetry breaking (EWSB) in the Standard Model (SM). All natural mechanisms proposed for EWSB introduce new physics at some scale Λ, not far from the TeV scale, that generates deviations in the SM Higgs physics. -

Eugenio Maria De Hostos Charter School

Charter Schools Institute State University of New York EUGENIO MARIA DE HOSTOS CHARTER SCHOOL FINAL CHARTERED AGREEMENT Sec. 2852(5) Submission to the Board of Regents VOLUME > OF REDACTED COP 74 North Pearl Street, 4m Floor, Albany, NY 12207 tel: (518) 433-8277 fax: (518) 427-6510 e-mail: [email protected] www.newyorkcharters.org OMU NO. 1646-0047 Form 990 Return of Organization Exempt From Income Tax Under section 501(c) of the internal Revenue Code (except black lung benefit 97 trust or private foundation) or section 4847(a)(1) nonexempt charitable trust TMaFotmla 0*#*m**of@*Tmm*y OpMtoPutofle torn* Rtwnw Swvica Hetr. reorganization may have to uso a copy rfthb return to salty stata reportw InmpmcUon A For tha 1997 calendar year, OH tax year period beginning /^^r^. / , 1997, and ending Af*,*-ts.A*B I . 19 ?g B Chock* C Ntm* of organization MentmcaBon number UMIRS O Change of iddren taMor ^e.*. W4~ >c D Initial return printer Numbar and atroat (or P.O. box if mall la not daUvarad to street addreaa) Room/suits DP*. DfinaJ return City or town, stata or country, and ZIP+4 D Amandad return Inttrue- F Check »- D if exemption application (raqulrad aJao for Stata reporting) /V£&S a pending Q Type of organization—*>^ Exempt under section 501 (c)( 3 ) + (Insert number) OR • • section 4947(aK1) nonexempt charitable trust Note: Section 501(c)(3) exempt onjanfeanoni and 4947(a)(1) nonaxempt charitable trusts MUST attach a completed Schedule A (Fom 990). H|a) la thia a group return filed for affiliates? .• Yes IS No I If either box In His checked "Yea," enter fouwllgit group exemption number (GEN) • j/.J.d (b) If "Yea." enter the number of efflUatee for whlchthia return la filed:. -

SOUTHERN at ARKANSAS 28 Sat NORTH TEXAS SECN Plus W 69 54 Fayetteville, Ark

2020-21 SCHEDULE / RESULTS NOVEMBER 2-0 25 Wed MISSISSIPPI VALLEY STATE SECN Plus W 142 62 Fayetteville, Ark. • Bud Walton Arena/Nolan Richardson Court GAME 5: SOUTHERN AT ARKANSAS 28 Sat NORTH TEXAS SECN Plus W 69 54 Fayetteville, Ark. • Bud Walton Arena/Nolan Richardson Court Dec. 9, 2020 • Wednesday • 7:00 pm • Fayetteville, Ark. • Bud Walton Arena (19,200)/Nolan Richardson Court DECEMBER (All TIMES CT) ARKANSAS RAZORBACKS OVERALL 4-0 SEC 0-0 SERIES INFO: 2 Wed UT ARLINGTON SEC Network W 72 60 Eric Musselman (San Diego ‘87) at UA: 24-12 (2nd) Collegiate: 134-46 (6th) OVERALL .......ARK Leads .............2-0 Fayetteville, Ark. • Bud Walton Arena/Nolan Richardson Court Home: ............ARK Leads ................... 1-0 Away: .............ARK Leads .....................-- 5 Sat LIPSCOMB SECN Plus W 86 50 Neutral: .........ARK Leads ................... 1-0 Fayetteville, Ark. • Bud Walton Arena/Nolan Richardson Court SOUTHERN JAGUARS OVERALL 0-2 SWAC 0-0 Sean Woods (Kentucky ‘92) at SU: 17-41 (3rd) Overall: 151-192 (12th) 8 Tues at Tulsa ESPN+ Postponed SERIES HISTORY: Tulsa, Okla. • Donald W. Reynolds Center 9 Wed SOUTHERN SECN Plus 7:00 pm SEC NETWORK 11/29/85 W 76-75 (PB) N Fayetteville, Ark. • Bud Walton Arena/Nolan Richardson Court Brett Dolan (PxP) 11/13/15 W 86-68 H 12 Sat CENTRAL ARKANSAS SECN Plus 7:00 pm Manuale Watkins (Analyst) Fayetteville, Ark. • Bud Walton Arena/Nolan Richardson Court 20 Sun ORAL ROBERTS SEC Network 2:00 pm RAZORBACK SPORTS NETWORK SATELLITE RADIO Fayetteville, Ark. • Bud Walton Arena/Nolan Richardson Court Chuck Barrett (PxP) XM: TBA • Sirius: -- 22 Tues ABILENE CHRISTIAN SECN Plus 7:00 pm Matt Zimmerman (Analyst) Online Channel: TBA Fayetteville, Ark. -

Asia Expat TV Complete Channel List

Asia Expat TV Complete Channel List Australia FOX Sport 502 FOX LEAGUE HD Australia FOX Sport 504 FOX FOOTY HD Australia 10 Bold Australia SBS HD Australia SBS Viceland Australia 7 HD Australia 7 TV Australia 7 TWO Australia 7 Flix Australia 7 MATE Australia NITV HD Australia 9 HD Australia TEN HD Australia 9Gem HD Australia 9Go HD Australia 9Life HD Australia Racing TV Australia Sky Racing 1 Australia Sky Racing 2 Australia Fetch TV Australia Live 1 HD (Live During Events Only) Australia AFL Live 2 HD (Live During Events Only) Australia AFL Live 3 HD (Live During Events Only) Australia AFL Live 4 HD (Live During Events Only) Australia AFL Live 5 HD (Live During Events Only) Australia AFL Live 6 HD (Live During Events Only) Australia AFL Live 7 HD (Live During Events Only) Australia AFL Live 8 HD (Live During Events Only) Australia AFL Live 9 HD (Live During Events Only) Australia NRL Live 1 HD (Live During Events Only) Australia NRL Live 2 HD (Live During Events Only) Australia NRL Live 3 HD (Live During Events Only) Australia NRL Live 4 HD (Live During Events Only) Australia Live 5 HD (Live During Events Only) Australia NRL Live 6 HD (Live During Events Only) Australia NRL Live 7 HD (Live During Events Only) Australia NRL Live 8 HD (Live During Events Only) Australia NRL Live 9 HD (Live During Events Only) Australia NRL Rugby League 1 HD (Only During Live Games) Australia NRL Rugby League 2 HD (Only During Live Games) Australia NRL Rugby League 3 HD (Only During Live Games) Australia VIP NZ: TVNZ 1HD Australia VIP NZ: TVNZ 2HD Australia -

Ud5020-February-2020.Pdf

2 | | UD5020 UD5020 | | 3 DISTRICT COUNCIL OFFICERS 2019-2020 GOVERNOR Maureen Fritz-Roberts (Comox) UNITE - It is all about serving C: 250-897-0776 E: [email protected] Highlighting inspirational news and successes to UNITE Rotarians with a common mission CHIEF OF STAFF T. Dale Roberts (Comox Valley) within District 5020. C: 250-897-0726 E: [email protected] COUNCIL CHAIR Corey Lopardi (Hawks Prairie-Lacey) C: 360-259-6672 Caleb Summerfelt Rotary of Kingston North Kitsap E: p [email protected] UD5020 EDITOR GOVERNOR ELECT Greg Horn (Lakewood) C: 253-228-0134 E: [email protected] GOVERNOR NOMINEE Lorna Curtis (Oak Bay) C: 778-967-1556 E: [email protected] IMMEDIATE PAST GOVERNOR Craig Gillis (Campbell River Daybreak) C: 250-203-6330 E: [email protected] SECRETARY Judith Marriott (Courtenay) C: 250-897-6157 ON THE COVER E: [email protected] The Australia Rotary District Governors have formed a committee which will decide TREASURER Janet Detering (Parkland-Spanaway) where the funds are to be distributed. We would typically utilize local Rotary Clubs on B: 253-537-5312 the ground in affected areas to identify those E: [email protected] families, Individuals and small businesses in most need... 4 | | UD5020 UD5020 | | 5 DISTRICT 5020 CLUB NEWS TABLE OF CONTENTS $25 GIVES A CHILD A YEAR OF BOOKS - HONOURING MEMBERS ........................................................ 69 IMAGINATION LIBRARY ........................................................ 36 BY KEVIN HILGERS FEATURE ARTICLES ON THE COVER ������������������������������������������������������������������������ 3 BY NATALIE JOHNSON (DAILY CHRONICLE) …COMES AROUND .............................................................. 70 FEBRUARY GOVERNORS MESSAGE ..................................... 6 ROTARY CLUB OF YELM COUNTS BY CLAYTON CHING BY MO MAUREEN FRITZ-ROBERTS SUCCESSES, PLANS FUTURE DURING FIRST MEETING OF 2020 .................................................... -

Korean Broadcasting System

Not ogged in Ta k Contributions Create account Log in Artic e Ta k Read Edit Hiew history Search Wikipedia Korean Broadcasting System From Wikipedia, the free encyclopedia Coordinates : 3,.52538GN 12A.91A3A1GE This article may be expanded with text translated [show ] from the corresponding article in Korean . (September 2014) Click [show] for important translation instructions. Korean Broadcasting System ( KBS ) Korean Broadcasting System (KBS) Main page Contents (Hangul : 한국방송공사 ; Hanja : 韓 7eatured content Current e2ents 國放送公社 ; RR : Han-guk Bangsong Random artic e Ionate to Gongsa ; MR : Han'guk Pangsong Kongsa ) is 6ikipedia 6ikipedia store the national public broadcaster of South Korea . It was founded in 1927, and operates Logo used since 2 October 1984 1nteraction radio , television , and online services, being He p one of the biggest South Korean television About 6ikipedia Community porta networks . Recent changes Contact page Contents [ hide ] Too s 1 History 1.1 Beginnings in radio 6hat inks here Re ated changes 1.2 1950s–1960s - Move into Up oad K e television Specia pages Permanent ink 1.3 1970s - Expansion Page information 1.4 1980s - Advertising started after Main building of Korean Broadcasting System 6ikidata item controversial merger Native name 한국방송공사 Cite this page 1.5 1990s - SpinoE of EBS Hanja 韓國放送公社 Print/eCport 2 Structure Revised Han-guk Bangsong Gongsa Create a book 3 CEOs Romanization Iown oad as PI7 Printab e 2ersion 4 Channe s McCune– Han'guk Pangsong Kongsa 4.1 Terrestria te evision Reischauer 1n other projects -

Congressional Record-House House Of

.3578 CONGRESSIONAL RECORD-HOUSE MARCH 17 .sundry nominations, which were referred to the appropriate To be lieutenant colonels committees. Maj. William Donaldson Fleming, Medical Corps, from <For nominations this day received, see the end of Senate April 6, 1938. proceedings.) Maj. Samuel Demetrius Avery, Medical Corps, from April EXECUTIVE REPORTS OF COMMITTEES 9, 1938. Mr. LOGAN, from the Committee on :Military Affairs, re Maj. William Robert Lewis Reinhardt, Medical Corps, from ported favorably the nomination of Maj. Romeyn Beck April 9, 1938, subject to examination required by law. Hough, Jr., to be lieutenant colonel with temporary rank in Maj. Howard Moore Williamson, Medical Corps, from April the Air Corps, Regular Army, and also the nomination of 10, 1938, subject to examination required by law. Capt. Kenneth Campbell McGregor to be major, with tempo Maj. Francis Joseph Clune, Medical Corps, from April 10, rary rank in the Air Corps, Regular Army. 1938. He also, from the same committee, reported favorably the Maj. George Edward Lindow, Medical Corps, from April -nominations of sundry officers for promotion in the Regular 16, 1938. Army. Maj. Jaime Julian Figueras, Medical Corps, from April 20, Mr. McKELLAR, from the Committee on Post Offices and 1938. Post Roads, reported favorably the nominations of sundry To be majors postmasters. Capt. Stuart Gross Smith, Medical Corps, from April 1, The PRESIDENT pro tempore. The reports will be placed 1938. on the Executive Calendar. Capt. Lester Maris Dyke, Medical Corps, from April 24, If there be no further reports of committees, the clerk 1938, subject to examination reqUired by law. -

Channel Lineup Shenandoah County

2020 CHANNEL LINEUP SHENANDOAH COUNTY PREMIUM CHANNELS HBO*† 201 HBO 203 HBO2 205 HBO COMEDY 207 HBO ZONE 690 HBO HD 202 HBO FAMILY 204 HBO SIGNATURE 206 HBO Latino SHOWTIME & THE MOVIE CHANNEL*† 209 SHO BEYOND 212 SHOWTIME 215 SHO WOMEN 218 THE MOVIE CHANNEL 695 SHOWTIME HD 210 SHOWTIME SHOWCASE 216 SHOWTIME FAMILY 219 THE MOVIE CHANNEL 211 SHO 2 213 SHO EXTREME ZONE XTRA 214 SHO NEXT 217 FLIX CINEMAX*† 251 CINEMAX 253 ACTIONMAX 255 MOVIEMAX 257 5STARMAX 693 CINEMAX HD 252 MOREMAX 254 THRILLERMAX 256 MAX Latino 258 OUTERMAX ENCORE / STARZ*† 230 STARZ ENCORE 232 STARZ ENCORE 234 STARZ ENCORE BLACK 241 STARZ EDGE 245 STARZ COMEDY 231 STARZ ENCORE CLASSIC 235 STARZ ENCORE ACTION 242 STARZ KIDS & FAMILY 691 STARZ HD WESTERN 233 STARZ ENCORE 236 STARZ ENCORE FAMILY 243 STARZ IN BLACK SUSPENSE 240 STARZ 244 STARZ CINEMA FAN’S CHOICE*† 360 NFL RedZone HD 363 Fight Network HD 366 TVG2 369 Cars TV HD 361 Fox Soccer Plus HD 364 Game+ HD 367 Pursuit HD 370 Ride TV HD 362 ESPN Goal Line/ 365 World Fishing 368 Eleven Sports HD ESPN Bases Loaded HD Network HD SPANISH CHOICE*† PAY-PER-VIEW* / MUSIC CHANNELS* 504 ESPN Deportes 508 Telemundo 300-303 Pay-Per-View 401-450 Music Choice 506 MTV Tr3’s 512 NBC Universo STARTER* 2 Channel Guide (Washington DC) 80 ODAC Channel 602 INSP HD 609 CBS-WUSA 3 ABC-WHSV 10 The Weather Channel 96 Quick Tips 603 ABC-WHSV (Washington DC) HD (Harrisonburg) 11 The CW-WDCW 100 PBS-Kids-WVPT (Harrisonburg) HD 611 The CW-WDCW 4 NBC-WRC (Washington DC) 102 Create-WVPT 604 NBC-WRC (Washington DC) HD (Washington DC) 12 PBS-WVPT -

Crossword Puzzle Tv A

25, 1C34 Pago 16 Daily Ncbraskan Wednesday, April --f vr--7 A2AZA2A?AZA7AZA2AZA2 for Let a new resume doors for WHITEWATER CANOEING - Two roommates nwded spaciou open youl ALPHA ZETA J 474-600- to On the San Juan River In Utah, May t house. $100 plus utilitios. Special rate graduating seniors. Actives Costello A Associates . 13- -20. $205 Include everything except AM3 & Coffeehouse Initiates 475-977- 7 Concert some moals. Canoeing instruction by 25 ( Meetinq Wednesday, April Summer roommate. Female. Close to fcWahn" "tiunJay 4.C J in the Union. A.C.A. certified InsUunur. Contact (ha Alumni sarvndt 29 st 7 is our ban- 6 30, In the Union CHLAP He NT. Cell 4M.o2. will ba Office of 1740 Vine, Sunday, April p.m. campus. Campus Recreation, 2201 This will be the timil meeting 472-346- 7 for more details. quet at the Knoll's, Old Cheney Typing Road. Contact Initiates or Stuhr Of the semester. IBM Word ProcMof FRANCHISE CLUB Hurryt Sign-u- p dea&ln la May 3 Boyd Responsible female to share two bed- (4 for tickets. Dissertations $1 50page MLETING room apartment wpool. By Holmes Lake. Theses GET INVOLVED! ). $l.50paga 7:00 $177.60 plus 12 electricity. Term Thursday, DESERT BACKPACKING UFC-Cit- y Is looking tor a chairperson Papers $1.0') (. ;s Student Union In the Badlands of South CLU3 tn RwsumBS Dakota, Way Officer for the Free University Committee lor $10.00 Everyone it welcome. 14- - 20. $100 covers Elections OWN Call 8364 between 7 a.m. and noon Only transportation, 6:15 coming year. -

Driver Faces Drug Charge in Fatal Crash Board To

-ooorn nanr o suDscnoe, ca 300 The^festfield Record 11, No. 34 Thursday, August 22,1996 A Forbes Newspaper 50 cents Driver faces drug charge in fatal crash Flea market The Westfield Neighbor New York State Trooper William Peck. Rubin was allegedly on his way home to Mr. LaFountain would not comment on tend Council (WNC) is spon- THS RECORD A passenger in the car — Joseph Scozio, Westfield. what sort of drug Mr. Rubin waa allegedly soring a Oea market 8 «JIL-4 21, of Oak Forest, 111. — was thrown from New York State Police Investigator Robert using at the time of the crash. am. Saturday at the Fan- Returning from an upstate New York con- the car, said the trooper. Passing motorists LaFountain told The Record the accident oc- "It is under investigation." he said. "We wood tnbi nation, Martinc cert aDegedry in a drug-induced haze, a attempted to resuscitate Mr. Scozio, but he curred shortly after 7 am. in the "very are doing a chemical analysis." and North Avenue*. Westflekl man drove his car off the road. His was pronounced dead shortly after being rural" town of Schroon, about 89 miles north Nor would the investigator discuss why a Vendon will tell an anort- passenger was thrown from the auto and rushed to a nearby hospital. of Albany. drug test was performed on Mr. Rubin. Such died at the scene, according to New York The roadway was dry, the sky was partly tests are not routine procedure, he said. intnt of merchandise, and Mr. Rubin was also brought to the hospital Stale Police. -

Happy Summer We’Re Taking Our Usual Summer Break in August! Our Next Newsletter Will Be in Your Inbox on 6 September

12 July- 5 September C NTENT 2021 www.contentasia.tv l www.contentasiasummit.com Happy Summer We’re taking our usual Summer break in August! Our next newsletter will be in your inbox on 6 September. See you then! Bomanbridge backs The Mole Sonia Fleck’s indie brings N. Korean spy doc to Asia Bomanbridge Media is backing N. Korean undercover doc, The Mole: Un- dercover in North Korea, in a deal with Danish director Mads Brügger & Danish Broadcasting Corporation’s DR. The full story is on page 3 q Rick and Morty on fire in China Adult animation attracts 2x demand of rivals Adult animated series Rick and Morty is fire in China, registering nigh on double the demand of its closest competitors – Saturday Night Live and Disney+’s Loki, says Parrot Analytics. The full story is on page 20 C NTENTASIA 12 July-5 September 2021 Page 2. India streamlines filming Migo boosts movie slate in new deals approvals process; “all in Low-cost Indonesian streamer adds local, int’l titles one go” office set up, film officials say Indonesian service Migo has added hundreds of hours of local and Asian Indian authorities have promised an “all content to its low-cost platform in a raft in one go” approvals process for interna- of deals with domestic studios and pro- tional filmmakers via a new facilitation of- ducers as well as regional and interna- fice, officials said earlier this month during tional distributors. the opening of the virtual India Pavilion at The new agreements include box of- the Cannes Film Festivale. -

Saxon Math 5/4 3Rd Student Edition Stephen Hake

Student Edition SAXON MATH™ 5/4 b c = F 1 12 1% 12 2 % 2 1 1 12 % 1 8 8 1 2 2 1 1 8 12 % 8 8 12 % 12 8 1 1 2 8 1 8 2 1 1 12 % 12 1 2 12 % 12 2 12 % 12 1 1 1 – F = H = Hake g H Saxon M54 Title Pages Page 1 Friday, March 21, 2003 3:54 PM M54 Title Pages Page 2 Friday, March 21, 2003 3:54 PM Student Edition Stephen Hake John Saxon Saxon Publishers gratefully acknowledges the contributions of the following individuals in the completion of this project: Authors: Stephen Hake, John Saxon Consultants: Diane Blank, Shirley McQuade Davis Editorial: Chris Braun, Brian E. Rice, Mary Burleson, Matt Maloney, Sherri Little, Rodney Clint Keele, Bo Björn Johnson, Brian Smith, Brooke Butner, Dana Nixon, Andrew Kershen, Sean G. Douglas Editorial Support Services: Christopher Davey, Jay Allman, Susan Toth, Jean Van Vleck, Shelley Turner, Darlene C. Terry Production: Adriana Maxwell, Karen Hammond, Brenda Lopez, Debra Sullivan, Diane Readnour, Donna Jarrel, Ryan LaCroix, Alicia Britt, Nancy Rimassa, Cristi D. Whiddon Project Management: Angela Johnson, Becky Cavnar © 2004 Saxon Publishers, Inc., and Stephen Hake All rights reserved. No part of Saxon Math 5/4, Third Edition, Student Edition may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic, mechanical, photocopying, recording, or otherwise, without the prior written permission of the publisher. Address inquiries to Editorial Support Services, Saxon Publishers, Inc., 2600 John Saxon Blvd., Norman, OK 73071. Printed in the United States of America ISBN: