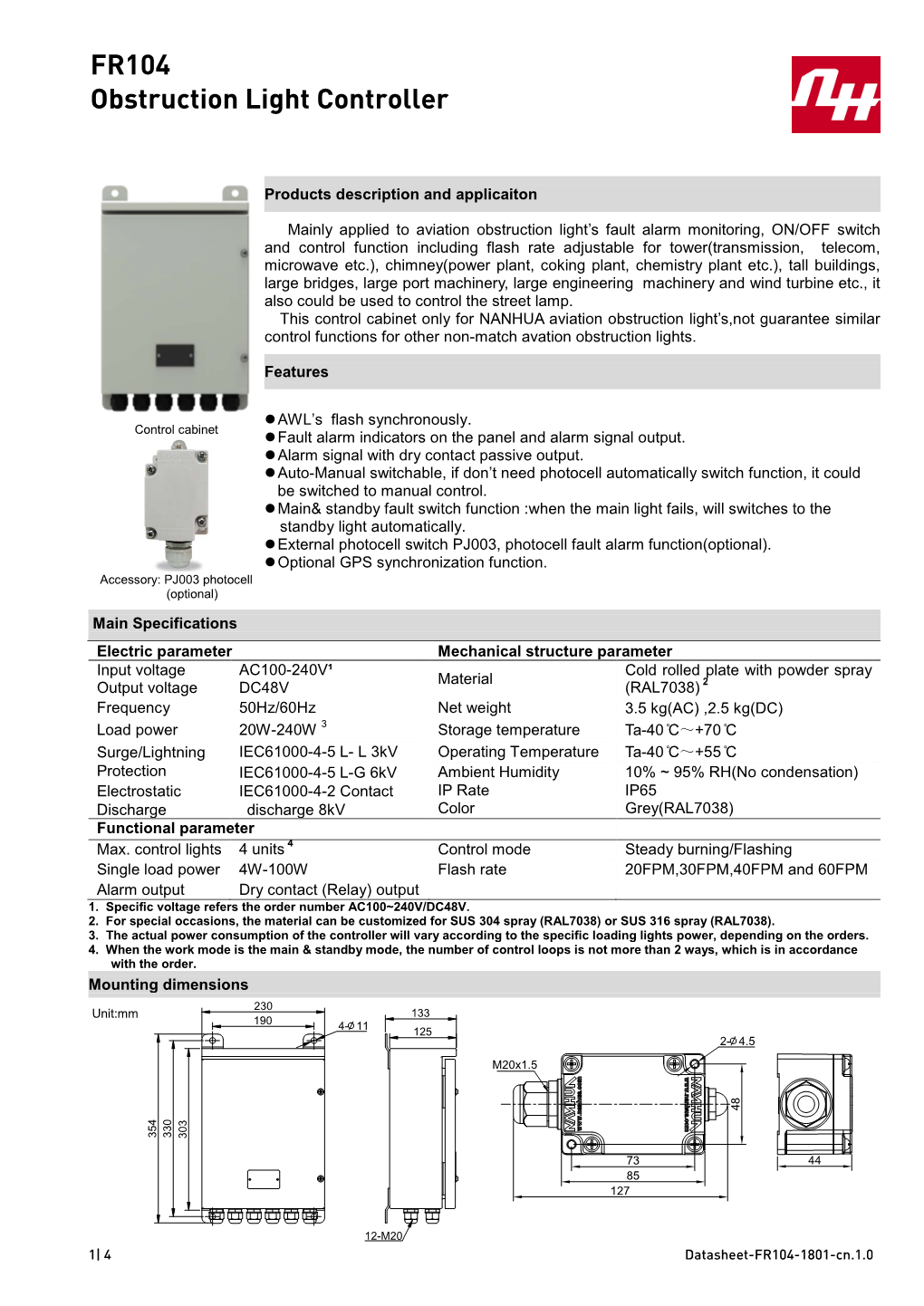

FR104 Obstruction Light Controller

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Schmersal Protect Safety Controllers

GK-2 CATALOG-HANDBOOK FIFTH EDITION FOR MONITORING & CONTROL OF MACHINE GUARDING SAFETY SYSTEMS USING: . Safety Interlock Switches . Safety Limit Switches . Safety Light Curtains . E-Stop Pushbuttons . Cable-Pull Switches . Two-Hand Controls . Safety Mats . Safety Edges . Signals for Safe Speeds and Standstill Monitoring Safety Controllers Courtesy of Steven Engineering, Inc. - (800) 258-9200 - [email protected] - www.stevenengineering.com Schmersal Safety Controllers What are Safety Controllers? Safety controllers are connected between machine guarding devices such as keyed interlocks, non-contact sensors, light curtains, etc. and the machine’s stop control elements such as a motor contactor or control relay. These controllers contain redundant, self-checking monitoring circuits and positive-guided relays and/or solid state outputs. Each is designed to detect faults in the safety system’s components and interconnection wiring, and their own internal monitoring circuits and output. Detection of a fault, or of an open machine guard, disables the controller’s output signal(s) facilitating machine stoppage, and/or prevents the restarting of the machine until the fault has been corrected. Units are available for use with guard interlock switches, coded-magnet sensors, safety edges, two-hand controls, light curtains, E-stops and emergency cable-pull switches to satisfy a broad range of application requirements. What are their functions? In addition to detecting open guards and/or actuated safety input devices, safety controllers are capable of detecting the following types of safety system faults: guard monitoring switch/sensor failure, “open-circuit” in interconnection wiring, “short-circuit” in interconnection wiring, “short-to-ground” in interconnection wiring, “cross-short” between channels, welded contact in controlled output device (such as positive-guided motor contactor), failure of safety controller’s positive-guided relay(s), fault in safety system monitoring circuit, and insufficient operating voltage. -

Time Delay Relays – Application Data

Time Delay Relays – Application Data Definition: Time Delay is defined as the controlled period between the functioning of two events. A Time Delay relay is a combination of an electromechanical output relay and a control circuit. The control circuit is comprised of solid state components and timing circuits that control operation of the relay and timing range. Typical time delay functions include On-Delay, Repeat cycle (starting off), Interval, Off-Delay, Retriggerable One Shot, Repeat cycle (starting on), Pulse Generator, One Shot, On/Off Delay, and Memory Latch. Each function is explained in the table below. Time delay relays have a broad choice of timing ranges from less than one second to many days. There are many choices of timing adjustments from calibrated external knobs, DIP switches, thumbwheel switches, or recessed potentiometer. The output contacts on the electromechanical output relay are direct wired to the output terminals. The contact load ratings are specified for each specific type of time delay relay. Understanding the differences between all the functions available in time delay relays can sometimes be a daunting task. When designing circuits using time delay relays questions such as: “What initiates a time delay relay?” “Does the timing start with the application or release of voltage?” “When does the output relay come on?” must be asked. Time delay relays are simply control relays with a time delay built in. Their purpose is to control an event based on time. The difference between relays and time delay relays is when the output contacts open & close: on a control relay, it happens when voltage is applied and removed from the coil; on time delay relays, the contacts will open or close before or after a pre-selected, timed interval. -

Installation Instructions

T P --- P R H --- A , --- B , T P --- N R H --- A , --- B Performance™ Series Edger Thermidistat™ Control Installation Instructions A07049 A07048 Programmable Control Non--Programmable Control Designed and Assembled in the USA. NOTE: Read the entire instruction manual before starting the installation. US patents: US7287709 B2, US20080147242 A1, USD582800 SI, US20060165149 A1, US6956463 B2. TABLE OF CONTENTS PAGE SAFETY CONSIDERATIONS................................ 1 INTRODUCTION.......................................... 2 INSTALLATION CONSIDERATIONS.......................... 3 INSTALLATION........................................... 7 SYSTEM START--UP AND CHECKOUT...................... 45 OPERATIONAL INFORMATION............................ 55 TROUBLESHOOTING..................................... 60 WIRING DIAGRAMS...................................... 64 THERMIDISTAT CONTROL CONFIGURATION RECORD....... 84 SAFETY CONSIDERATIONS Read and follow manufacturer instructions carefully. Follow all local electrical codes during installation. All wiring must conform to local and national electrical codes. Improper wiring or installation may damage Thermidistat Control. Recognize safety information. This is the safety--alert symbol . When you see this symbol on the equipment and in the instruction manual, be alert to the potential for personal injury. Understand the signal words DANGER, WARNING,andCAUTION.These words are used with the safety--alert symbol. DANGER identifies the most serious hazards which will result in severe personal injury or death. -

Lighting Controls

LIGHTING CONTROLS HUMIDITY CONTROLS LIGHTING Kele Provides System and Zone Controls, with a Wide Variety of Peripheral Sensors and Switches. DLM Series | p. 615 AF16 Series | p. 664 LX-24 | p. 624 WSD Series | p. 637 CI-24 | p. 626 ET Series | p. 674 LIGHTING CONTROLS Products manufactured MODEL/SERIES PAGE in the United States Emergency Lighting Control ELCU-100 — WattStopper Emergency Lighting Control . 666 Products that are ELCU-200 — Emergency UL924 Bypass/ Shunt Relays . 668 new to the catalog ESR Series — Functional Devices UL924 Emergency Bypass / Shunt Relays . 670 Light Sensors MK7-B Series — PLC-Multipoint Celestial Self-Contained Ambient Light Sensors, Voltage Based . 643 PSR-1, PSR-1-T — Kele Photo-Sensitive Resistor . 645 K, LC Series — Photo Switches . 647 EM Series — Photo Switches . 649 MAS Series — PLC-Multipoint Self-Contained Ambient Light Sensors, Current Based . 650 Lighting Contactors and Relays HDR — Relay 5 Wire with Override and Connector . 660 RR-7, RR-9 — GE Lighting Relays . 661 2R7CDD, 2R9CDD — ILC Lighting Relays . 663 AF16 Series — ABB Lighting Contactors . 664 LIGHTING CONTROLS LS7K Series — AEG Lighting Contactors . 665 LMCP Series | p. 613 Lighting Panels and Control Products RP Basic Series — BlueRidge Relay Panels . 609 ZC Basic Series — BlueRidge Lighting Zone Controller . 611 LMCP Series — WattStopper Lighting Integrator Panels with Digital Lighting Management (DLM) Support . 613 DLM Series Digital Lighting Management — Digital Lighting Controls . 615 LC8 Series — WattStopper Modular Contractor Panel . .. 618 CX Series Commercial Lighting Control Panels — Standalone Programmable Lighting Control Panel . 620 ILC Apprentice II — Programmable Lighting Control Panel . 622 PIL-1 — Kele Pulse Initiator . 658 LDIM2 — Kele Fluorescent Dimming Control Module . -

Float Type Level Switches Contents Page Start Single Point Small Size Engineered Plastic

INTRODUCTION Float Type Level Switches Contents Page Start Single Point Small Size Engineered Plastic ........................................... A-2 GEMS Level Switches operate on a direct, Alloy ........................................................................ A-8 simple principle. In most models, a float encircling a stationary stem is equipped Large Size PERMANENT with powerful, permanent magnets. As MAGNET Engineered Plastic .........................................A-12 the float rises or lowers with liquid level, Alloy ......................................................................A-13 the magnetic field generated from within FLOAT the float actuates a hermetically sealed, Specialty Switches ...............................................A-20 magnetic reed switch mounted within the HERMETICALLY stem. The stem is made of non-magnetic SEALED MAGNETIC REED SWITCH Leak Detection .......................................................A-22 metals or rugged, engineered plastics. When mounted vertically, this basic design provides a consistent accuracy of ±1/8 inch. Multi-station versions use a separate reed switch for each level point being monitored. Side-mounted units use different actuation methods because of their horizontal attitude. The basic principle, however, is the same: as a direct result of rising or falling liquid, a magnetic field is moved into the proximity of a reed switch, causing its actuation. N Reed Switch Reliability – SINGLE POINT LEVEL SWITCHES GLASS The durable construction of these reed switch designs ensures long, trouble- REED SWITCH ENVELOPE free service. Because the effects of shock, wear and vibration are minimized, these hermetically sealed switches provide precise S repeatability with no more than 1% deviation. The switch actuation points N S remain constant over the life of the unit. See “Reed Switch Protection” in MAGNET Appendix X for information on extending the life of GEMS Level Switches. -

Uninterruptible Power Supply

UPS UNINTERRUPTIBLE POWER SUPPLY CATALOGUE COMPANY PROFILE Inform Electronic, one of the European leading power solution specialist, is established in 1980 with the aim of designing and building industrial electronic systems. Soon after, it diversified into the production, and marketing of standard professional electronic equipment, and special projects. The company always combines its experience with its innovative identity and is recognized by its worldwide technology leading character. Right business understanding of Inform makes the company one of the most wanted brands in the world with its exceptional growth ratio. The Company has 31,000 m² closed production area, committed to the manufacturing of electrical products and electronic equipments. Analysing infrastructural conditions, and customer needs, the company decided to provide complete solutions. Inform product range varies from Uninterruptible Power Supply (UPS) Systems, Voltage Regulators, to DC Power Supply, Telecom Equipments, Battery chargers, Inverters, 19” rack cabinets and other electrical products and electronic equipments. Since its foundation, INFORM ELECTRONIC has based its strategy on below main policies: Quality understanding for its products and services, Tailored solutions to specific customer needs, Customer satisfaction and happiness, After sales service and support Continuous improvement for operational excellence and advanced technology Inform is an official ISO certified company. The company has also Gost, Soncap, and CE certifications. All the Inform products are designed and produced with the worldwide quality understanding, and ISO rules. Inform was acquired by Legrand Group in 2010. Legrand is global specialist in electrical and digital building infrastructures. The Group has direct presence in more than 70 countries and number of employee is more than 31.000 people. -

Room Humidistat Specification & Installation Instructions

Room Humidistat Specification & Installation Instructions Features: HRO20 • Attractive modern look with large LCD and backlight • Icons driven information and 1 line of text • External humidity sensor input • Humidification and dehumidification indicator • Multi level lockable access menu • Lockable Set point / Control mode • Window/outside temperature sensor input • Celsius or Fahrenheit scale selectable Technical Data HRO20 Actual humidity (0-100 %RH), 0-10 Vdc / 2-10 Vdc Humidity set point (0-100 %RH), 0-10 Vdc / 2-10 Vdc Humidification proportional control signal, 0-10 Vdc / 2-10 Vdc Outputs Dehumidification proportional control signal, 0-10 Vdc / 2-10 Vdc Humidification dry contracts 24 Vac, 1 A max, 3 A in-rush Dehumidification dry contracts 24 Vac, 1 A max, 3 A in-rush Window temperature sensor or outside temperature sensor (10 KΩ) External set point from Neptronic humidifier, Inputs external humidity sensor (0-10 Vdc / 2-10 Vdc) or high limit (0-10 Vdc / 2-10 Vdc) 1 alarm status digital input (24 Vac or dry contact) Power supply 22 to 26 Vac 50/60 Hz or 28 to 32 Vdc Power consumption 1 VA Set point range 10 - 90 %RH (in 1% increments) Sensor precision ± 3 % or better at 40 %RH and 23 ºC [73 ºF] Proportional band 2 % - 10 % for control signal Electrical connection 0.8 mm2 [18 AWG] minimum Operating condition 0 ºC to 40 ºC [32 ºF to 104 ºF], 0-95 %RH Storage condition -10 ºC to 50 ºC [14 ºF to 122 ºF], 0-95 %RH temperature compensation Automatic readjustment of set point from a window temperature sensor (SHW0-11) reset feature or external temperature sensor (STC8-11) Housing degree of protection IP 30 (EN 60529) Weight 80 g. -

Intrinsically Safe Barrier Relays NY2 and 8501TO

Intrinsically Safe Barrier Relays NY2 and 8501TO Class/File 8501 CONTENTS Description . .Page NY2 General Information . .2 NY2 Ordering Information. .3 NY2 Specifications . .4 NY2 Approximate Dimensions and Wiring Recommendations. .5 NY2 Wiring Diagrams. .6 8501TO General Information . .7 8501TO Ordering Information, Application Data, Approximate Dimensions. .8 Intrisically Safe Barrier Relays NY2 – Relays For Hazardous Locations General Information Intrinsically Safe (IS) Explosion prevention is a prime consideration in plants and facilities containing hazardous atmospheres and explosion-proof housings. The main fault with the explosion-proof system is that a single human error could create a high explosion probability. Prime examples are failing to tightly replace covers on explosion-proof housings, failing to shut off the power before removing the covers, and damaging the specially machined surfaces of these covers. Intrinsically safe (IS) systems are a means of providing automated control functions in explosive environments. Because of the inherent parameters of electronic circuits, no energy is released, under normal or abnormal conditions, of sufficient magnitude to ignite a specified atmosphere mixture. To design an effective intrinsically safe system, energy that enters the hazardous area must be limited. For electronic instrumentation, this is accomplished by controlling the voltages and currents that may enter the hazardous area. In addition, stored electrical energy in field instruments is limited to levels that cannot ignite a given atmosphere. Intrinsically safe relays, such as the NY2 and the Class 8501 Type TO relays, act as an energy barrier, limiting the voltage and current available in the hazardous area. They can be connected with any device having a dry contact (limit switch, magnetic switch, pushbutton, pneumatic-electric interfaces, etc.) or with NAMUR sensors. -

Time Delay Relays – Application Data

Time Delay Relays – Application Data Definition: Time Delay is defined as the controlled period between the functioning of two events. A Time Delay relay is a combination of an electromechanical output relay and a control circuit. The control circuit is comprised of solid state components and timing circuits that control operation of the relay and timing range. Typical time delay functions include On-Delay, Repeat cycle (starting off), Interval, Off-Delay, Retriggerable One Shot, Repeat cycle (starting on), Pulse Generator, One Shot, On/Off Delay, and Memory Latch. Each function is explained in the table below. Time delay relays have a broad choice of timing ranges from less than one second to many days. There are many choices of timing adjustments from calibrated external knobs, DIP switches, thumbwheel switches, or recessed potentiometer. The output contacts on the electromechanical output relay are direct wired to the output terminals. The contact load ratings are specified for each specific type of time delay relay. Understanding the differences between all the functions available in time delay relays can sometimes be a daunting task. When designing circuits using time delay relays questions such as: “What initiates a time delay relay?” “Does the timing start with the application or release of voltage?” “When does the output relay come on?” must be asked. Time delay relays are simply control relays with a time delay built in. Their purpose is to control an event based on time. The difference between relays and time delay relays is when the output contacts open & close: on a control relay, it happens when voltage is applied and removed from the coil; on time delay relays, the contacts will open or close before or after a pre-selected, timed interval. -

A Dry Contact Is a Potential Free Contact a Dry Contact Is a Contact That Does

A dry contact is a potential free contact A dry contact is a contact that does not provide voltage. For instance, the push-to-talk switch of a microphone, which just closes a circuit without providing voltage. A wet contact is a contact that will provide voltage when closed, like the switch on the wall that activates the 110 VAC outlet to turn a lamp on in a room. Potential free contact, voltage free contact and dry contact, they all are same. The dry contact is the contact which is physically operated with the main device, but not electrically connected to it. It is a voltage free on/off contact and can be used in any system. The auxiliary contact of the motor contactor used for the motor run feed back is the example of the dry contact. The contacts of the interposing relays are also dry contacts. - MS Perhaps you mean "dry circuit"? Contacts which need to work in such circuits are generally gold-plated, since the current and voltage levels are too low to break down the contaminant layWhat is a volt free contact? Answer: A volt free contact is a set of contacts that uses a voltage source from another location. The contacts are used to tie two individual pieces of electrical equipment together so the action on one will cause the other piece of equipment to operate. It is just a new way of using the older terminology "dry contacts". An example of use is the diesel start contacts on an automatic transfer switch. When the transfer switch is in the utility (hydro) position the diesel start "dry contacts" located in the transfer switch are open. -

Phoenix Contact Measurement and Control Technology

52 PHOENIX CONTACT Courtesy of Steven Engineering, Inc. - (800) 258-9200 - [email protected] - www.stevenengineering.com Measurement and control technology The modular analog converters for mea- Product range overview surement and control technology prevent analog signals from being distorted by dis- Product overview 54 turbance variables. With accurate conver- sion, isolation, filtering or amplification of Selection guide for isolating amplifiers 56 analog signals, they secure and increase transmission quality and therefore the qual- Basics 58 ity of closed-loop control circuits. Highly compact isolating amplifiers – We offer the following product ranges: MINI Analog 64 Analog IN/Analog OUT 66 Highly compact isolating amplifiers – Temperature 76 MINI Analog Frequency 82 For significant space savings and efficiency Potentiometers 84 – Design width of just 6.2 mm – System cabling and multiplexer solutions Limit values 85 – 3-way electrical isolation Digital IN 86 Accessories 87 Isolating amplifiers with SIL functional safety – MACX Analog Isolating amplifiers with For maximum signal safety SIL functional safety – MACX Analog 100 – Consistent SIL certification Analog IN/Analog OUT 102 – Safe 3-way electrical isolation Temperature potentiometers/limit values 110 Digital IN 120 Isolating amplifiers, special types, and Accessories 126 digital displays – MCR Analog For special applications in signal processing Isolating amplifiers, special designs, and – Electrical isolation digital displays – MCR Analog 130 – Record and convert temperatures -

VH7200 Humidistat Series for Humidification & Dehumidification

VH7200 Humidistat Series For Humidification & Dehumidification Control For Commercial HVAC Applications Apply to Box Label Date Code 1507 and newer (028-0208 R8) Product overview The VH7200 humidity controller family is specifically designed for control of humidification and dehumidification equipment such as steam header direct injection, desiccant wheel, or stand-alone humidification / dehumidification equipment. The product features a complete embedded humidity control solution with an intuitive backlit LCD display that walks the installer through the configuration steps, making the process extremely simple. Accurate relative humidity control is achieved due to the product’s unique PI time proportional control algorithm, which virtually eliminates humidity offset associated with traditional, differential-based humidity controllers. All models contain a binary input, which can be set by the user to monitor an electrode humidifier canister service status or may be used as a general purpose service indicator. Models are available which contain more advanced features such as discharge humidity proportional high limit, and indoor humidity setpoint reset based upon outdoor air temperature to conserve energy and eliminate condensation on windows and structure. Fig.1 VH7200 series humidistats The additional following documents are available at: www.viconics.com Information on the BACnet models (VH72xxX1000B), is available on document ITG-VH7200-BAC-Exx Models available Humidification Dehumidification Application Model Number Output(s) Output 0-10 Vdc & Model with Outdoor reset & Proportional High Limit VH7270K1000 (X) On-Off 24 Vac On/Off 24 Vac Model with Outdoor reset & Proportional High Limit VH7270F1000 (X) 0-10 Vdc On-Off 24 Vac Model with outdoor reset only VH7200A1000 (X) On/Off 24 Vac On-Off 24 Vac (X) model number represents available communication options: X=none for Stand-alone and X=B for BACnet MS-TP.