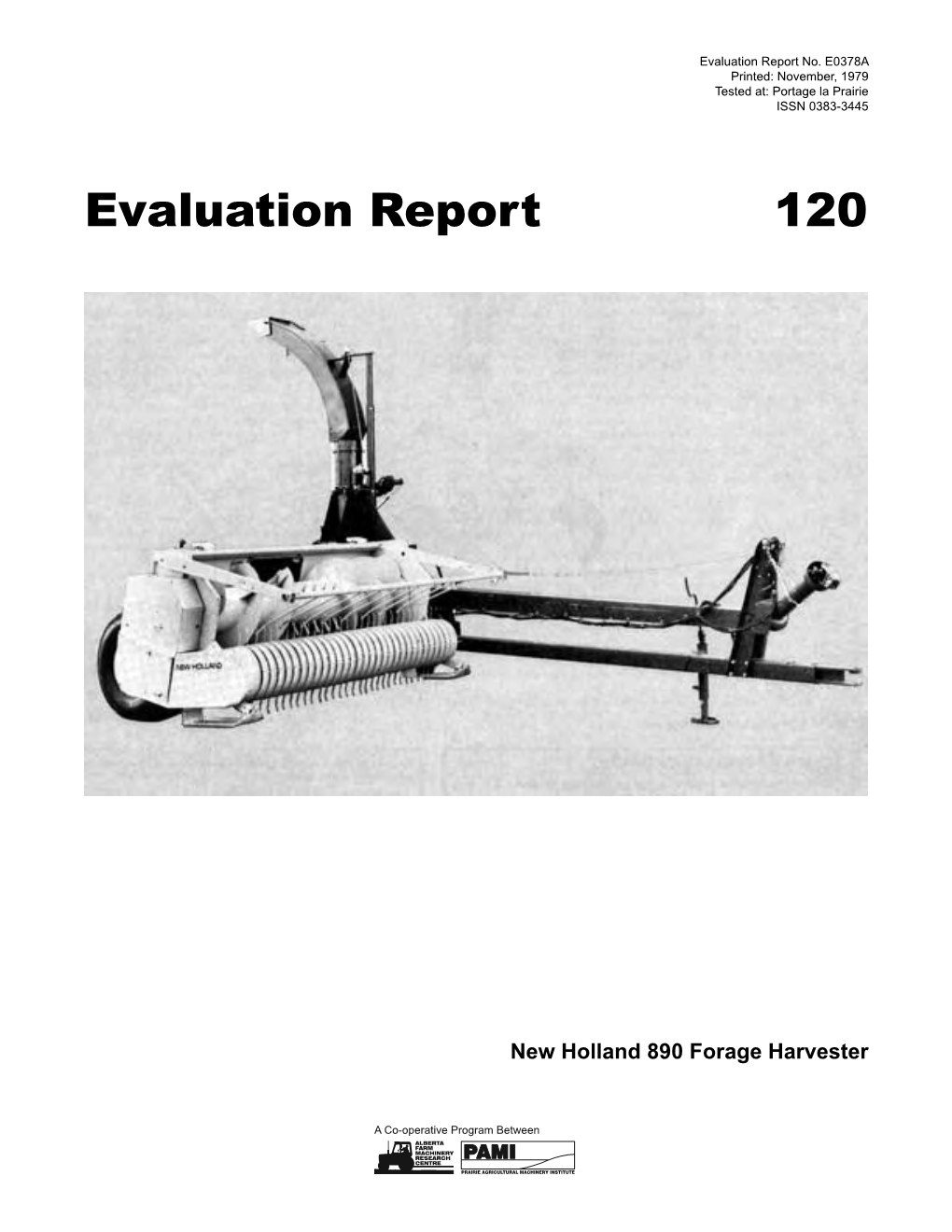

120 New Holland 890 Forage Harvester (1979)

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

We Know Agriculture Annual Report 2010 2 AGCO // Annual Report 2010

We Know Agriculture ANNUAL REPORT 2010 2 AGCO // Annual Report 2010 AGCO AT A GLANCE As the world’s largest manufacturer focused purely on agricultural equipment, AGCO is uniquely positioned to increase farm productivity through high-tech solutions for professional farmers feeding the world. KEY BUSINESS FIGURES in million $ – except per share amounts 2010 2009 Change Net sales 6,896.6 6,516.4 5.8% Income from operations 324.2 218.7 48.2% Net income attributable to AGCO Corporation and subsidiaries 220.5 135.7 62.5% Total assets 5,436.9 4,998.9 8.8% Stockholders’ equity 2,659.2 2,394.4 11.1% Earnings per share(1) 2.29 1.44 59.0% Adjusted earnings per share(2) 2.32 1.55 49.7% (1) On a diluted basis. (2) For a reconciliation of adjusted earnings per share, see footnote 2 on page 37. SALES BY PRODUCT in % Tractors 15% Parts Combines 68% 6% Application equipment 4% 4% Implements and other 3% Hay and forage SALES BY GEOGRAPHIC REGION ADJUSTED EARNINGS PER SHARE in million $ in $ (1) NA 22% 2010 2.32 SA(2) 25% 2009 1.55 EAME(3) 49% ROW(4) 4% 2008 3.95 (1) North America (3) Europe, Africa, Middle East (2) South America (4) Rest of World: Asia, Australia/New Zealand, Eastern Europe ON THE COVER In 2010, AGCO made solid progress toward meeting its long-term growth objectives. Among other things, it was a year marked by numerous combine launches and the announcement of a strategic acquisition of a state-of-the-art combine facility, proof of our accelerated commitment towards improving harvesting productivity. -

Development of Corn Stover Harvesting and Densification Systems

Iowa State University Capstones, Theses and Retrospective Theses and Dissertations Dissertations 1-1-2002 Development of corn stover harvesting and densification systems Thomas J. Tuetken Iowa State University Follow this and additional works at: https://lib.dr.iastate.edu/rtd Recommended Citation Tuetken, Thomas J., "Development of corn stover harvesting and densification systems" (2002). Retrospective Theses and Dissertations. 21338. https://lib.dr.iastate.edu/rtd/21338 This Thesis is brought to you for free and open access by the Iowa State University Capstones, Theses and Dissertations at Iowa State University Digital Repository. It has been accepted for inclusion in Retrospective Theses and Dissertations by an authorized administrator of Iowa State University Digital Repository. For more information, please contact [email protected]. Development of corn stover harvesting and densification systems by Thomas J. Tuetken A thesis submitted to the graduate faculty in partial fulfillment of the requirements for the degree of MASTER OF SCIENCE Major: Agricultural Engineering (Agricultural Power and Machinery) Program of Study Committee: Graeme R. Quick, Co-Major Professor Steven J. Hoff, Co-Major Professor Ronald E. Deiter Norman K. Olson Iowa State University Ames, Iowa 2002 11 Graduate College Iowa State University This is to certify that the master's thesis of Thomas J. Tuetken has met the thesis requirements of Iowa State University Signatures have been redacted for privacy 111 TABLE OF CONTENTS CHAPTER 1. INTRODUCTION 1 CHAPTER 2. OBJECTIVES 4 CHAPTER 3. LITERATURE REVIEW 5 Combine Attachments 9 Collecting Heads 13 Whole Plant Harvest 19 CHAPTER 4. EQUIPMENT DEVELOPMENT AND TESTING 26 High Capacity Wagon for Stover Transportation 26 Two-Tier Harvesting Head 29 Field Testing of Stover Trailer and Plot Harvester 31 Large Scale Equipment Development 33 Hesston 10 Stakhand 33 International Harvester 1460 Harvester 35 Plot Harvester 37 Stover Caddy 40 CHAPTER 5. -

Innovative Methods for Corn Stover Collecting, Handling, Storing and Transporting

April 2004 • NREL/SR-510-33893 Innovative Methods for Corn Stover Collecting, Handling, Storing and Transporting March 2003 J.E. Atchison Atchison Consultants, Inc. J. R. Hettenhaus Chief Executive Assistance, Inc. Charlotte, North Carolina National Renewable Energy Laboratory 1617 Cole Boulevard, Golden, Colorado 80401-3393 303-275-3000 • www.nrel.gov Operated for the U.S. Department of Energy Office of Energy Efficiency and Renewable Energy by Midwest Research Institute • Battelle Contract No. DE-AC36-99-GO10337 April 2004 • NREL/SR-510-33893 Innovative Methods for Corn Stover Collecting, Handling, Storing and Transporting March 2003 J.E. Atchison Atchison Consultants, Inc. J. R. Hettenhaus Chief Executive Assistance, Inc. Charlotte, North Carolina NREL Technical Monitor: S.R. Thomas Prepared under Subcontract No. ACO-1-31042-01 National Renewable Energy Laboratory 1617 Cole Boulevard, Golden, Colorado 80401-3393 303-275-3000 • www.nrel.gov Operated for the U.S. Department of Energy Office of Energy Efficiency and Renewable Energy by Midwest Research Institute • Battelle Contract No. DE-AC36-99-GO10337 This publication was reproduced from the best available copy Submitted by the subcontractor and received no editorial review at NREL NOTICE This report was prepared as an account of work sponsored by an agency of the United States government. Neither the United States government nor any agency thereof, nor any of their employees, makes any warranty, express or implied, or assumes any legal liability or responsibility for the accuracy, completeness, or usefulness of any information, apparatus, product, or process disclosed, or represents that its use would not infringe privately owned rights. Reference herein to any specific commercial product, process, or service by trade name, trademark, manufacturer, or otherwise does not necessarily constitute or imply its endorsement, recommendation, or favoring by the United States government or any agency thereof. -

Orps Explains Revised

>0@ 1s@ 2s. tO 0 24' 24, 24 30o @ 3 )0 @ 18 14th year no. 13 May 28, 1968 )0@ 18 the loan volume of last year. But with corn prices rising and >0@ 18. A Big Corn Carryover holding near the loan rate since @ February, the pace of loan plac- The government forecasts ahas been slightly above last ing has slackened. 70 heavy carryover of around 1,-year it failed to offset reduced l00 1 100,000,000 to1,200,000,000bil- use of other feed grains. With 30p lion bushels of corn next Octo-the indicated slowdown of do- 1 ber 1 despite increased domes-mestic use total carryover of $197,000 For tic use and exports before thisall feed grains before the next .0 (a year's crop is harvested. harvest is estimated at 47 mil- )5 This would compare to stockslion tons, an increase of aboutMarshall Co. Land IS of 823 million bushels at the 10 million tons over stocks at MARYSVILLE -A thousand 30 end of last summer and indi-the start of this year. acres of Marshall county land >0 p 1 eDavy Is Fun Day cates to the Agriculture depart- Feed grain exports for the came close to bringing an aver- .5 @ 16 What's more fun than going to a sale with Dad? ment the probability of lower crop year are put at 23 millionage $200 per acre at auction @ 16 last week. ?s o rk and Gail Anderson spent the day with their average prices for the next fewtons, about 5 per cent more than months of 1968. -

201 Hesston 7160 Forage Harvester

Evaluation Report No. E0180B Printed: June, 1981 Tested at: Portage La Prairie ISSN 0383-3445 Evaluation Report 201 Hesston 7160 Forage Harvester A Co-operative Program Between ALBERTA FARM MACHINERY PAMI RESEARCH CENTRE PRAIRIE AGRICULTURAL MACHINERY INSTITUTE HESSTON 7160 FORAGE HARVESTER 4. Modifying the header attachments to allow easier installation and removal. MANUFACTURER: 5. Modifying the three-row row crop head to allow easier Hesston Corporation lubrication. Hesston, Kansas 6. Modifying the operator manual to include SI units of 67062 U.S.A. measurement. 7. Modifying the discharge spout to increase the distance the DISTRIBUTOR: forage is blown. Hesston Industries Chief Engineer -- E.O. Nyborg 920-26 Street N.E. Senior Engineer -- J.C. Thauberger Calgary, Alberta Project Engineer -- C.W. Chapman T2A 2M4 RETAIL PRICE: $23,853 (May 1981, f.o.b. Portage la Prairie, with remote controls, THE MANUFACTURER STATES THAT 2.1 m (7 ft) windrow pickup and three-row row crop head. With regard to recommendation number: 1. The 1981 three-row 38” corn head has been redesigned to improve performance in adverse fi eld conditions. Also, an update kit may be purchased for modifying prior year models. 2. Improvement of electric actuator is under consideration. 3. A Product Bulletin has been issued to cover critical chain and sheave adjustment on feedroll drives. Also lower feed-rolls have been modifi ed to reduce wrapping. 4. A new quick attach head system will be available on the 1982 model. Also parts will retrofi t older units. 5. Improvement in lubrication accessibility on the row heads are under consideration. -

Part 2. Timeline in the Development of Agricultural Field Implements, Related Apparatus, and Equipment

Part 2. Timeline in the Development of Agricultural Field Implements, Related Apparatus, and Equipment Note: the italic letters at the end of each entry refer to the references. 70 A. D. Elder Pliny reported to Roman leaders the use of a wooden cart with comb-like bars pushed by animals for reaping wheat. In first century A. D. in Gaul, in perhaps a mo- nument to the world’s first agricultural engineers, a harnessed mule is shown pushing a wooden harvester through a field of wheat, a model of which is at ASABE headquarters, courtesy of Wayne Worthington. The German Society of Agricultural Engineers constructed a similar model of a stripper-reaper from remnants they could identify from stone carvings. Based on a display at ASABE Headquarters 1545 Universal joint designed by Italian Geronimo Cardano, 1501-1576. SWABI 1566 Seed drill patented by Venetian (Italian) Camillo Torello. EAM 1653 First known treatise on plow construction, The English Improver Improved, by Walter Blith in England, printed for J. Wright. EAM NUC WABI 1701 Practical machine seed drill, consisting of a cylinder and regularly spaced holes that caught the seeds from the hopper above and dropped them into a special furrow below, developed by Englishman Jethro Tull, 1674-1741. BDPE EAM MWBD 1720 First English patent for plow, by Englishman Joseph Foliambe. HFP c. 1730ff. Mechanical principles applied to plow design; the cast iron curved moldboard developed by James Small, Berwick, England. EAM 1731 Horse-drawn cultivator introduced to English farming by Englishman Jethro Tull, 1674-1741. Patented in 1733. CLAA DNB 1731 Improved seed drill and cultivator introduced to English farming by Englishman Jeth- ro Tull, 1674-1741. -

Forage Harvester Operation R

393 ISSN 0704-3457 GLEANINGS 85 02 FORAGE HARVESTER OPERATION R. R. HOCHSTEIN -- PORTAGE STATION Operating efficiency and fuel consumption have always been OPERATING CONDITIONS important considerations in the purchases and operation of farm What should a farmer know about operating the forage har- machinery. Recent rises in fuel prices and production costs have vester. What adjustments best suit his specific needs. caused farmers to consider these factors more carefully than ever. Machine Efficiency: The efficiency of the forage harvester may Some cattle farmers, who once fed their cattle baled hay, are be expressed as specific capacity, (t/hp-h) defined as the mass of forage chopped per unit of energy supplied to the harvester. now investigating more prod uctive systems. They are attracted to silage systems due to the ease of handling and better overall feed Forage refinement, achieved either by adjusting the machine to a shorter cut length setting or by installing a recutter screen, re- nutrient utilization. When converting to a silage system, familiar- suits in a reduction in machine efficiency. ity with all aspects of the system is important, to get maximum benefit. This article deals with the operation of the forage har- vester, the key machine in the operation. THE FORAGE HARVESTER The most common types of forage harvesters (APPENDIX I) use a cylindrical cutterhead. These harvesters are provided with ad- justments to vary forage cut length by varying the speed of the feedrolls, relative to the cutterhead.* This permits the cutting of forage to suit specific requirements. Two variations of this type of harvester are in common use: 1. -

Estimating the Energy Requirements and Co2 Emissions from Production of the Perennial Grasses Miscanthus, Switchgrass and Reed Canary Grass

ESTIMATING THE ENERGY REQUIREMENTS AND CO2 EMISSIONS FROM PRODUCTION OF THE PERENNIAL GRASSES MISCANTHUS, SWITCHGRASS AND REED CANARY GRASS ETSU B/U1/00645/REP DTI/Pub URN 01/797 Contractor ADAS Consulting Ltd Prepared by M Bullard P Metcalfe The work described in this report was carried out under contract as part of the Sustainable Energy Programmes, managed by ETSU on behalf of the Department of Trade and Industry. The views and judgements expressed in this report are those of the contractor and do not necessarily reflect those of ETSU or the Department of Trade and Industry. First published 2001 © Crown copyright 2001 EXECUTIVE SUMMARY Miscanthus, reed canary grass and switchgrass are three herbaceous perennial grasses that are currently being grown commercially, or evaluated, as energy crops for the UK. All are harvested annually and require low inputs of agrochemical fertilisers and pesticides. The research reported aimed to calculate the energy ratios and carbon ratios of the three crops. The energy ratio is the ratio of energy contained in the biomass upon delivery to the power station, to energy input in all phases of growing the crop. Similarly the carbon ratio is the ratio of carbon (C) contained in biomass upon delivery to the power station, to C (in CO2) emitted as a result of operations during all phases of growing the crop. In the first instance, base-case scenarios were developed for each species and the energy ratios calculated for these. For all crops, a productive lifespan of 20 years was assumed. In the cases of miscanthus and switchgrass this length of time was attained from planting in the first season only, for reed canary grass, re-sowing was estimated to be required every five years. -

Brochure John Deere 7080I Pro Drive All Models English

Explore iT – real forage quality Self propelled forage harvesters 7080 series Discover the exceptional new KernelStar! See page 42 2 | OptionalJohn Deere Model SPFH Descriptor – Optional Section Information Optional Section Information – Optional ModelJohn Deere Descriptor SPFH | 3 CONTENTS Making the right choice 4 1. Explore and experience 8 Silage expertise 10 Forage professionals 12 Our heritage 14 Worldwide testing & production 16 2. Explore real business 18 Unrivalled choice 20 The intelligent forage harvester 22 Cab 24 Crop versatility 26 Crop flow 34 Precision cutting 36 Roller processor 40 KernelStar 42 Engines and propulsion 44 i-Series package 50 Crop analysis 52 Guidance 54 Business management tools 56 3. Explore it yourself 56 Customer experiences 60 Dealer support 64 4. Explore your specification 68 Accessories 70 Specification 74 4 | John Deere SPFH Making the right choice You are about to make an important decision. A decision that will affect your business for the next 3 - 4 years. It’s easy to focus on facts and figures like engine horsepower, header width and top speed but don’t forget about the issues that really matter. A forage harvester is not just a machine. It is a powerful business tool which strongly influences the level of silage quality, customer service and, ultimately, your profitability. This book is about answering the questions that really matter and helping you to make the right choice. John Deere SPFH | 5 7 reasons to choose John Deere … Forage perfection World-class support The 7080 Series is the result of more than 40 years forage harvester We have an extensive dealer network with John Deere trained experience. -

The Mounted Forage Harvester 02

The mounted forage harvester 02 More information: www.kemper-stadtlohn.de 03 Know-how and experience provide the basis for innovative solutions and superior quality. For more than 100 years we have produced and marketed the best possible technology for professional users – worldwide. Company site in Stadtlohn For us, “Made in Germany” is more than just a label. On a site extending over 100,000 m 2 in the Münsterland region, KEMPER employs a staff of about 250. Product development, customer care and production are closely linked in our company. This is what guarantees continuous further product development. Good harvest – good all round. › Success through continuity ‹ is the motto at KEMPER, the No. 1 in row-independent harvesting headers. 04 Even on the smallest model, the crop is fed parallel to the chopping blades. This delivers optimum chopping quality. The C 1200 is remarkably compact in construction. Even 90 h. p. tractors can drive the Mounting options 2-row model. Optimum cutting height is determined by the tractor hydraulics. The stabiliser wheel at the side protects the harvester from contact with the ground. Front mounting C 1200 Side mounting The compact, “small” mounted forage harvester with versatile mounting options. Rear mounting The C 1200 is also highly effective when used for whole crop silage. 05 Thanks to the horizontal feeding of the harvested material, both the “small” and the “large” models achieve perfect chopping quality. More information: www.kemper-stadtlohn.de 06 Whether mounted at the front or the rear, the C 2200 3-row model can chop maize. The gauge wheels at the side protect the harvester from contact with the ground. -

Analysis of Different Corn Stover Harvest Systems

LANDTECHNIK 71(6), 2016, 252–270 DOI:10.15150/lt.2016.3147 Analysis of different corn stover harvest systems Monika Fleschhut, Kurt-Jürgen Hülsbergen, Stefan Thurner, Joachim Eder Corn stover, with an accruing amount of approximately 3.8 Mt dry matter per year, is a pos- sible substrate for biogas production in Germany. However, using corn stover in the future will require knowledge about corn stover yield and suitable corn stover harvest systems. This study aimed to quantify, using field experiments, the harvest rates and losses of corn stover harvesting for eight harvest systems and various harvest conditions over the course of two years. From an average corn stover yield potential of 103.2 dt ha-1, 55.6 dt ha-1 of dry matter were windrowed and 46.8 dt ha-1 were harvested; as such, the harvest losses (56.4 dt ha-1) were higher than the harvested corn stover yield. Harvest rates of 41.4 to 49.1 % were ob- served for the harvest systems examined, and significant differences were observed between the windrowing technologies but not between the corn stover harvesting technologies. A longer field retention time for the corn stover had a mainly negative impact on the harvest rate, while different varieties of corn had no impact on the rate. With regard to quality, the dry matter content and ash content of the corn stover were, on average, 50.4 % and 7.0 %, respectively. Keywords Corn stover yield, windrowing technologies, harvest rate, harvest residues, raw ash content Bioenergy is an important renewable energy source and accounts for 75 % of renewable energies globally (IEA 2015) as well as 59 % in Germany (FNR 2015). -

Development and Evaluation of a Single Pass, Dual Stream Corn Stover Harvester Benjamin Joseph Schlesser Iowa State University

Iowa State University Capstones, Theses and Retrospective Theses and Dissertations Dissertations 2007 Development and evaluation of a single pass, dual stream corn stover harvester Benjamin Joseph Schlesser Iowa State University Follow this and additional works at: https://lib.dr.iastate.edu/rtd Part of the Agriculture Commons, and the Bioresource and Agricultural Engineering Commons Recommended Citation Schlesser, Benjamin Joseph, "Development and evaluation of a single pass, dual stream corn stover harvester" (2007). Retrospective Theses and Dissertations. 15487. https://lib.dr.iastate.edu/rtd/15487 This Thesis is brought to you for free and open access by the Iowa State University Capstones, Theses and Dissertations at Iowa State University Digital Repository. It has been accepted for inclusion in Retrospective Theses and Dissertations by an authorized administrator of Iowa State University Digital Repository. For more information, please contact [email protected]. Development and evaluation of a single pass, dual stream corn stover harvester by Benjamin Joseph Schlesser A thesis submitted to the graduate faculty in partial fulfillment of the requirements for the degree of MASTER OF SCIENCE Major: Agricultural Engineering (Advanced Machinery Engineering) Program of Study Committee: Stuart J. Birrell, Major Professor Carl J. Bern Loren W. Zachary Iowa State University Ames, Iowa 2007 Copyright © Benjamin Joseph Schlesser, 2007. All rights reserved. 2009 ii Table of Contents Introduction....................................................................................................................