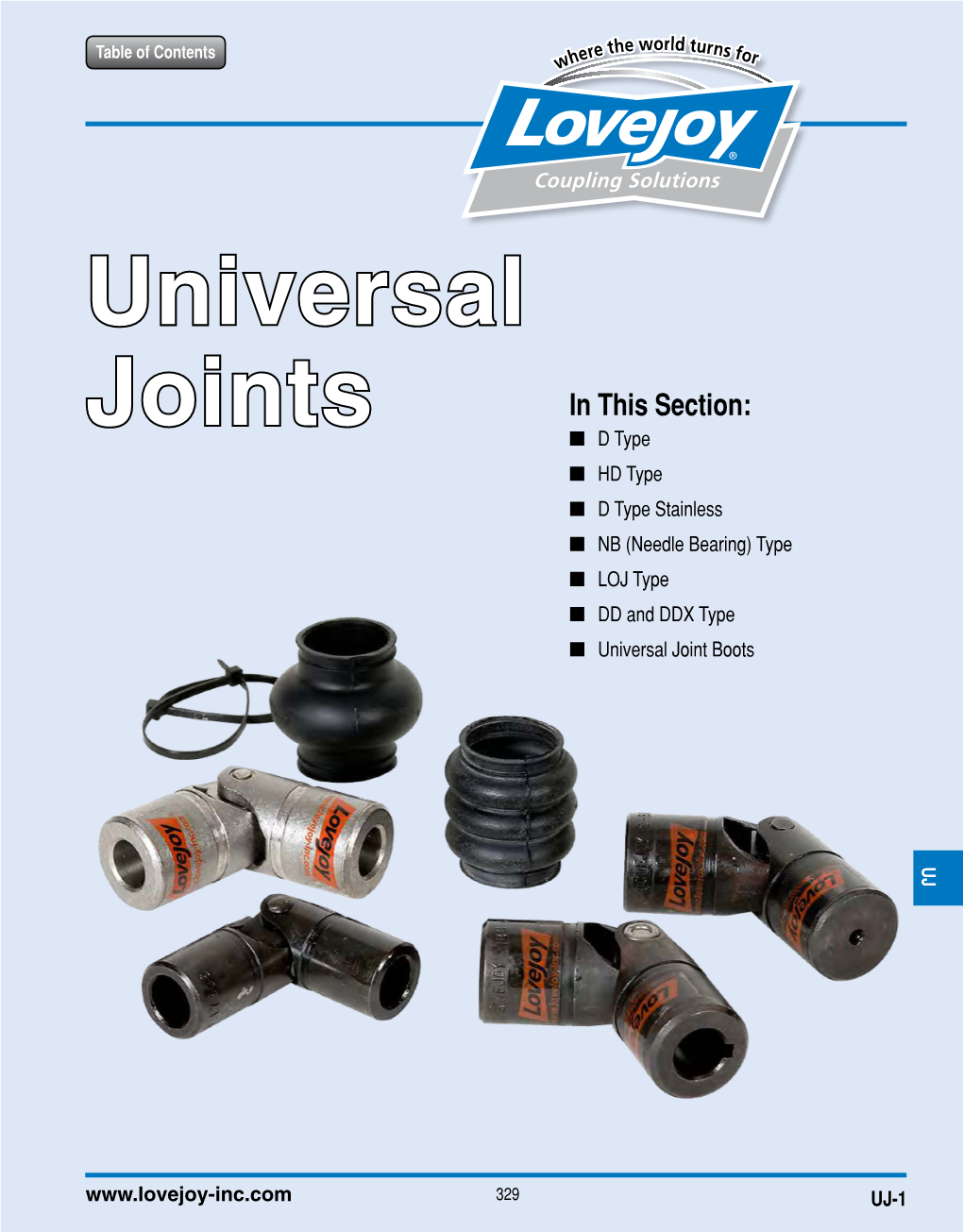

Universal Joints in This Section: ■ D Type ■ HD Type ■ D Type Stainless ■ NB (Needle Bearing) Type ■ LOJ Type ■ DD and DDX Type ■ Universal Joint Boots UJ

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Design and Analysis of Power-Train System of New Pure Electric City Bus

Advances in Engineering Research, volume 90 5th International Conference on Mechanical Engineering, Materials and Energy (ICMEME 2016) Design and Analysis of power-train system of New Pure Electric City Bus Xiao-ying LIU1, Kai WANG1, Li-ping ZHOU1, Ji-sheng WANG* 1Department of Mechanical Engineering, Xihua University, Chengdu, Sichuan 610039, China *Chengdu Medical College, Chengdu, Sichuan 610500, China Keywords: Pure electric city bus, Power-train system, Parametric modeling, Finite element analysis Abstract. Realizing the traffic energy diversification and low exhaust is important to promote competitiveness of the automobile industry in our country and realize sustainable development of the society . Due to the trips of pure electric city bus are relatively short and fixed, it has great application value in urban public transport industry where environmental protection is important. Based on operation characteristics of the pure electric city bus, the overall design of power-train system was completed. The motor was selected using MATLAB. The universal transmission shaft system, main retarder, differential mechanism, wheel drive, driving axle housing and so on were designed. Three-dimensional model of the transmission system was established and the parametric model of the general subsystems was established to facilitate its application in the expansion of the other models. Finally, the finite element analysis of the transmission device of wheel has been done. Introduction Auto demand is increasing rapidly, while the development of auto industry and increase of car ownership will lead to a series of energy and environmental issues directly. Currently, new energy vehicles are developing in worldwide, and there are diverse species such as pure electric vehicles, hybrid vehicles, extended range electric vehicles, fuel cell electric vehicles, and hydrogen engine cars, etc.[1]. -

Design and Analysis of Universal Coupling Joint Maram Venkata Sunil Reddy1, C

ISSN XXXX XXXX © 2016 IJESC Research Article Volume 6 Issue No. 12 Design and Analysis of Universal Coupling Joint Maram Venkata Sunil Reddy1, C. Raghunatha Reddy2 M.Tech Student1, Assistant Professor & H.O.D2 Department of Mechanical Engineering Tadipatri Engineering College, India Abstract: The power produced from an engine of automobile can be transferred to the drive wheel by power transmission system. To transmit the driving torque from the engine or gear unit to the final drive by the propeller shaft, we need at least one or two universal joints. Some common reasons for the failures may be manufacturing and design faults, maintenance faults, raw material faults, material processing faults as well as the user originated faults. In this study, fracture analysis of a universal joint yoke and a drive shaft of an automobile power transmission system are carried out. Spectroscopic analyses, metallographic analyses and hardness measurements are carried out for each part. For the determination of stress conditions at the failed section, stress analysis is also carried out by the finite element method. The common failure types in automobiles and revealed that the failures in the transmission system elements cover 1/4 of all the automobile failures. The failure is analyzed in the ANASYS with FEM. I. INTRODUCTION vehicle. A weld yoke incorporates a machined step, and is inserted into the end of the driveshaft and welded in place. The A coupling is a device used to connect two shafts together at cross trunnion is used to deliver rotation from one yoke to their ends for the purpose of transmitting power. -

Universal Joint Kits and Center Bearings for Passenger Cars and Trucks

Price $35.00 UNIVERSAL JOINT KITS AND CENTER BEARINGS FOR PASSENGER CARS AND TRUCKS K350-1-DSSP MAY 2008 Supersedes K350, Dated 1999 K350 Table of Contents Constant Velocity Centering Yokes ........................H CHEVROLET (Continued) Constant Velocity Centering Repair Kits .................J MONTE CARLO .................................................. 15 MONZA ...............................................................15 Passenger Car (PASS) NOVA ..................................................................15 VEGA ..................................................................15 ALFA ROMEO .........................................................1 CHRYSLER ...........................................................15 AMERICAN MOTORS ............................................. 1 300 ......................................................................15 AMBASSADOR ..................................................... 1 CONQUEST ........................................................15 CONCORD ...........................................................1 CORDOBA ..........................................................15 EAGLE ..................................................................1 FIFTH AVENUE .................................................. 16 MARLIN ................................................................1 IMPERIAL ...........................................................16 PACER ..................................................................2 LEBARON ...........................................................16 -

Design of Constant Velocity Coupling

Design of Constant Velocity Coupling Prof. A. A. Moghe1, Mr. Yuvraj Patil2, Mr. Mayur Pawar³, Mr. Akshaykumar Thaware4, Mr. Nitin Thorawade5 1Assistant Professor, 2,3,4,5UG Students Department of Mechanical Engineering Sppu, PVPIT, Pune, Mahrashtra, India ABSTRACT: A coupling is mechanical device used to connect two shafts together at their ends for the purpose of transmission of power. The basic role of couplings is to join two parts of rotating elements while permitting some degree of misalignment or end movement or both. Presently Oldham’s coupling and Universal joints are used for parallel offset power transmission and angular offset transmission. These joints have limitations on maximum offset distance, angle, speed and result in vibrations, noise and low efficiency (below 70%). These limitations can be overcome with Thompson constant velocity (CV) coupling which offers features like minimizing side loads, higher misalignment capabilities, more operating speeds, improved efficiency of transmission and many more. The constant velocity joint is an alteration in design that offers up to 18 mm parallel offset and 21-degree angular offset, at high speeds up to 2000 or 2500 rpm at 90% efficiency. This design lowers cost of production, space requirement and simply technology of manufacture as compared too present CVJ in market. This paper presents review on constant velocity joints/couplings design and optimization. Keywords: Thompson constant velocity joint, Optimization & design, Constant velocity couplings, Parallel Offset, Angular Offset, Power Transmission. [I] INTRODUCTION The basic function of a power transmission coupling is to transmit torque from an input/driving shaft to an output/driven shaft at a specified shaft speed. -

Your Steering Column Specialist

Basic Installation Instructions for: ididit’s Universal “Shorty” Columns www.ididitinc.com What’s inside this installation booklet: • U-Joint & Shafting Installation • Shorty Installation • Lever Installation • Wiring your Column • Synchronizing your Column • Additional Notes ididit is... Your Steering Column Specialist For #’s 1011160010, 1011160020, 1011160051, 1010160010, 1010160020, 1010160051, 1020160030, 1020160040, 1160180010, 1160180020, 1160180051, 1120120010, 1520120010, 1120120020, 1520120020, 1120120051, 1520120051, 1120160010, 1520160010, 1120160020, 1520160020, 1120160051, 1520160051, 1030120030, 1030120040, 1030160030, 1030160040, 1130180010, 1530180010, 1130180020, 1530180020, 1130180051, 1530180051, 1050180030, 1050180040, 1180160010, 1180160020, 1180160051, 1040160030, 1040160040, 1190180010, 1190180020, 1190180051, 1590180010, 1590180020, 1590180051 ididit inc. 610 S. Maumee St. Tecumseh, MI 49286 PH: 517-424-0577 FAX: 517-424-7293 Revised 3/5/2012 Instruction # 8000000018 Thank you for purchasing an ididit steering column! We will first give you an overview of mounting the steering column in the most common street rod or hot rod applications. The steering column must be supported at the dash and where it protrudes through the firewall. It is impor- tant that the steering column is tight and secure. There is a shorty application which will use two drops under the dash, with the support bearing through the firewall (since the column ends under the dash). To attach your column to the steering gear box, a u-joint is attached to the column, a shaft is attached to the u-joint, and that shaft will lead down to a u-joint connected to the gear box (or rack). It is highly recommended that you test fit your steering column before painting the column. Test fitting now will save you a headache later on. -

The Structure, Geometry, and Kinematics of a Universal Joint

INDEPENDENT JOURNAL OF MANAGEMENT & PRODUCTION (IJM&P) http://www.ijmp.jor.br v. 10, n. 8, Special Edition Seng 2019 ISSN: 2236-269X DOI: 10.14807/ijmp.v10i8.923 THE STRUCTURE, GEOMETRY, AND KINEMATICS OF A UNIVERSAL JOINT Florian Ion Tiberiu Petrescu IFToMM, Romania E-mail: [email protected] Relly Victoria Virgil Petrescu IFToMM, Romania E-mail: [email protected] Submission: 11/30/2018 Revision: 2/8/2019 Accept: 2/27/2019 ABSTRACT The paper briefly presents the geometry, structure, and kinematics of a universal joint, very commonly used in machine building, especially today for heavy and engine-driven vehicles and transmissions located in different areas as well as for all-wheel-drive vehicles. The universal joint, or the cardan cross, conveys the rotation movement from one bridge to the other (when the rotary shaft suffers both movements, upward and downward). The kinematic scheme of a cardan transmission is composed of two cardan shafts (one input and one output), both of which are equipped with a cardan cross (universal joint or universal joint). Between the two universal couplings, a further (additional) cardan shaft (axle) is mounted. This mechanism is designed to transmit the mechanical movement (within a vehicle) from one bridge to the other. If the vehicle's motor is on the front and with on the rear axle transmission, or vice versa when the vehicle's engine is on the rear and the transmission is on the front axle, or when we have multiple (multi-axle) transmission on heavy vehicles or 4x4 cars. Keywords: Cardan transmission; Universal joint; Heavy vehicles; Angular speed variation; Rotation movement; Geometry; Structure; kinematics. -

Subject-Automobile Engineering TOPIC

BY-JITENDRA KUMAR Date-25/03/2020 Diploma Mechanical 3rd Year (6th Sem) Subject-Automobile Engineering TOPIC:-PROPELLER SHAFT AND REAR AXLE Propeller shaft: The propeller shaft is a driving shaft which connects the transmission main shaft to the differential of the real axle. It transmits the power from gear box to rear axle with the help of universal joints. ... This changes the angle of drive between the propeller shaft and the transmission shaft. Main components Vehicle components and their functions. the essential vehicle components are: a)engines b)flywheel & clutch c)gearbox d)propeller shafts and universal joints (in RWD) e)drive shafts f)final drive g) steering RWD Engine Power Units engine is a machine that takes in a mixture of combustible air and fuel, burns it and convert heat energy released into mechanical energy which rotates then a crankshaft. Gearbox machine that takes engine power from a crankshaft and through a relay of gearwheels. allowing to change the speed of the vehicle. Flywheel the flywheel attached to the end of the crankshaft performs the task of absorbing excess energy while the crankshaft is accelerating on it’s power stroke and automatically transfer this stored kinetic energy to the crankshaft to overcome the resisting motion of the other cycles of the engine that will be described later. Clutch device that is used to separate the engine power unit while running from the final drive allowing the driver to change gears smoothly and bring the vehicle to standstill without engine stalling. Propeller shaft a hollow shaft that is used to transmit gearbox output to the final drive. -

Universal Joint

Universal Joint High Shock and Overload Capacity Long Life Heat Treated Alloy Steel Components Minimal Lubrication Required Virtually Backlash- Free Quick Delivery Superior Technology www.renold.com Advantages and Design: Typical Applications Advantages and Features Typical Applications • Domestic manufacture Following is a partial list of applications for the Renold Universal Joint. • High torque capacity • Long bearing life Agitators Packaging • High operating angle capability Balancing Machines Paper Mills Table of Contents Page – Calender Drives • One piece yoke and bearing housing construction Blowers and Fans Introduction .............................................................................................................2 – Sizing and Press Compressors Advantages and Features; • Eliminates unnecessary bolted connections and serrations in yokes Rolls Typical Applications ...............................................................................................3 • Heat treated alloy steel components Conveyors – Couch Rolls Construction and Speed Limits ........................................................................... 4-5 • Ideal loading across entire bearing length due to balanced deflection Cooling Tower Fans – Process Pumps Selection Procedure ............................................................................................ 6-7 between yokes and cross Cranes and Hoists Plastic Manufacturing Engineering Data .............................................................................................. -

Analysis of Ball-Type Constant-Velocity Joints Based On

736 Analysis of Ball-Type Constant-Velocity Joints BasedonDynamics∗ Kei KIMATA∗∗, Haruo NAGATANI∗∗∗ and Masayuki IMOTO∗∗∗ Universal joints, which transmit torque through the balls guided in such a manner that they always lie in the plane bisecting the angle between the driving-shaft and driven-shaft, are called ball-type constant-velocity joints. The authors presented papers on the analysis of this type of universal joint based on statics neglecting the friction force between their compo- nents. To obtain more precise estimations of the internal forces and the moments, it appears to be important to evaluate the effect of the friction between the parts. Furthermore, grasping the relative motions of the parts, such as rolling of the balls on the tracks, is beyond the scope of static analysis. In this study, the authors analyze the motions of each part based on dy- namics, taking account of the friction between the parts. The analysis results in simultaneous differential equations, which can be solved numerically using an electronic computer. Key Words: Machine Element, Universal Joints, Constant Velocity Joints, Ball-Type, An- gular Contact, Contact Force, Friction, Dynamics, Analysis In order to grasp more accurately the characteristics 1. Introduction of ball-type constant-velocity joints, the forces acting on Universal joints which transmit torque and rotational the inside, and the relative motion of the parts, it is consid- motion of the shaft through the balls whose center is con- ered necessary to carry out the analysis based on dynam- strained on the plane bisecting the crossed axes angle ics taking the frictional forces into considerations. -

DRIVELINE CATALOGUE 2009 How to Use This Catalogue

DRIVELINE CATALOGUE 2009 How to use this Catalogue This catalogue contains part breakdowns for most popular driveline parts & components. It was designed to provide consumers of Quality Gear products easy access to information and the ability to order by part number. Every effort has been made to ensure the accuracy of this catalogue. We use factory sources of information to maintain accuracy. We cannot assume responsibility for possible omissions or errors. Contradictions may exist based on manufacturing tolerances and procedures. Please consult an authorized Quality Gear Parts distributor for final verification. If you require driveline, differential, transmission, steering or transfer case parts for automotive, medium and heavy duty applications, call an authorized Quality Gear distributor near you today. It’s easy to order! Call one of our authorized Quality Gear distributors to order anywhere in Canada or the USA. To locate a distributor near you call 1-888-452-7979 or visit wwww.qualitygear.com Payment and Shipping Options Most Quality Gear distributors accept cash, cheque or credit card as payment. Let your nearest Quality Gear distributor know your shipping requirements and they can ship it to you by courier, truck, bus or air. Shipping costs will apply. Please note: Quality Gear distributors may not stock all items listed in this catalogue. Parts listed are not necessarily manufactured by the original equipment manufacturer and any reference to the trademarks or part numbers of others are for cross reference informational purposes only. Reader Reply Card To receive a free copy of a Quality Gear Catalogue, please fill out the form below Catalogue Requested.................. -

Owner's Manual

OWNER’S MANUAL Shuttle 4 EFI 666011 - A ISSUED DECEMBER 2018 Read and comply with all of the instructions and safety precautions in this manual and on all product labels. Failure to follow the safety precautions could result in serious injury or death. California Proposition 65 WARNING The Engine Exhaust from this product contains chemicals known to the State of California to cause cancer, birth defects or other reproductive harm. Never modify the vehicle in any way that will alter the weight distribution of the vehicle, decrease its sta- bility or increase the speed beyond the factory specifications. Such modifications can cause serious per- sonal injury or death. The manufacturer, TEXTRON SPECIALIZED VEHICLES (TSV Augusta), prohibits and disclaims responsibility for any such modifications or any other alteration which would adversely affect the safety of the vehicle. OWNER’S MANUAL GASOLINE Shuttle 4 EFI Starting MODEL YEAR 2019 CONTACT INFORMATION Textron Specialized Vehicles, Inc. 1451 Marvin Griffin Road. Augusta, Georgia, USA 30906-3852 1-800-774-3946 Technical Assistance & Warranty 1-888-438-3946 Service Parts 001-706-798-4311 International www.cushman.com 1 WELCOME Thank you for purchasing this vehicle. Before driving your new vehicle, read this owner’s manual to familiarize your- self with safe driving practices, operation, features and controls. This manual contains instructions for minor maintenance only. Information about major repairs can be found in the repair manual. Your dealer has thorough knowledge of your vehicle and wants your total satisfaction with your pur- chase. We recommend you return to your dealership for all of your service needs during, and after the warranty period. -

HIGHLANDER Hybrid Gasoline-Electric Hybrid Vehicles

HIGHLANDER Hybrid Gasoline-Electric Hybrid Synergy Drive GVU58 Series Foreword This guide was developed to educate and assist dismantlers in the safe handling of Toyota HIGHLANDER Hybrid gasoline-electric hybrid vehicles. HIGHLANDER Hybrid dismantling procedures are similar to other non-hybrid Toyota vehicles with the exception of the high voltage electrical system. It is important to recognize and understand the high voltage electrical system features and specifications of the Toyota HIGHLANDER Hybrid, as they may not be familiar to dismantlers. High voltage electricity powers the electric motors, generator, air conditioning (A/C) compressor and inverter/converter. All other automotive electrical devices such as the headlights, radio and gauges are powered from a separate 12 Volts auxiliary battery. Numerous safeguards have been designed into the HIGHLANDER Hybrid to help ensure the high voltage, approximately 288 Volts, Nickel Metal Hydride (NiMH) Hybrid Vehicle (HV) battery pack is kept safe and secure in an accident. The NiMH HV battery pack contains sealed batteries that are similar to rechargeable batteries used in some battery operated power tools and other consumer products. The electrolyte is absorbed in the cell plates and will not normally leak out even if the battery is cracked. In the unlikely event the electrolyte does leak, it can be easily neutralized with a dilute boric acid solution or vinegar. High voltage cables, identifiable by orange insulation and connectors, are isolated from the metal chassis of the vehicle. Additional topics contained in the guide include: • Toyota HIGHLANDER Hybrid identification. • Major hybrid component locations and descriptions. By following the information in this guide, dismantlers will be able to handle HIGHLANDER Hybrid hybrid-electric vehicles as safely as the dismantling of a conventional non-hybrid automobile.