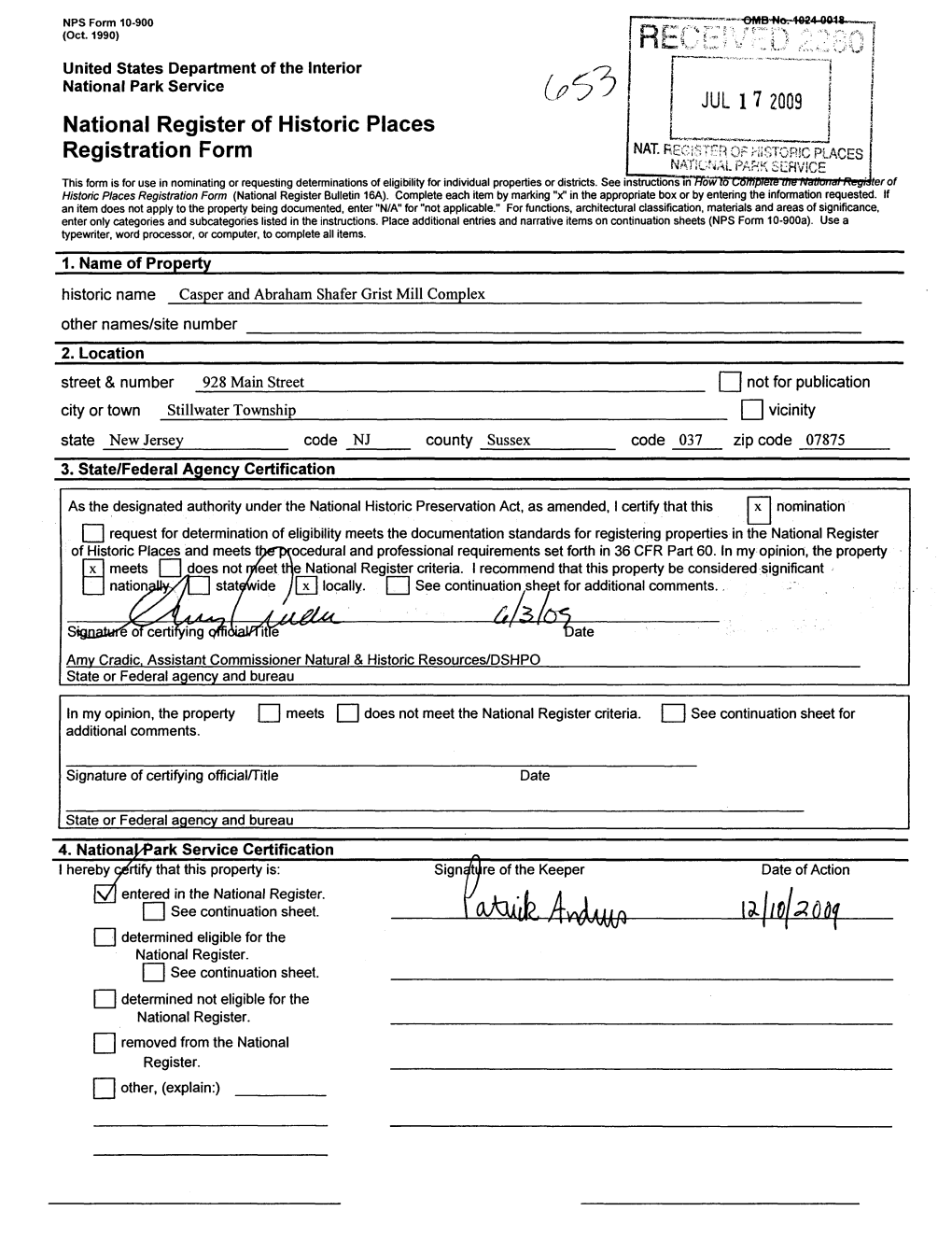

National Register of Historic Places Registration Form

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

2019 Elected Officials Salary Ordinance

TOWN OF MORRISTOWN ORDINANCE O-26-2019 AN ORDINANCE OF THE TOWN OF MORRISTOWN, IN THE COUNTY OF MORRIS, STATE OF NEW JERSEY, FOR COMPENSATION FOR THE ELECTED MAYOR, TOWN COUNCIL MEMBERS AND COUNCIL PRESIDENT IN THE TOWN OF MORRISTOWN, NEW JERSEY AND AMENDING ALL ORDINANCES CONCERNING SUCH COMPENSATION HERETOFORE ADOPTED BE IT ORDAINED, by the Town Council of the Town of Morristown, County of Morris, State of New Jersey, being the governing body thereof as follows that: (1) The Town of Morristown is organized under the “Mayor-Council Plan” form of government as established under the Optional Municipal Charter Act, i.e., The Faulkner Act, at N.J.S.A. 40:69A-31 et seq., which provides for a separately elected Mayor and Council to serve as the elected officials of the said municipality; and (2) The elected Mayor, Town Council Members and Council President of the Town of Morristown shall be compensated within the salary ranges set forth in this Ordinance and shall perform all duties as are prescribed by law. All salary amounts shall be effective as of January 1, 2019; and BE IT FURTHER ORDAINED, that the annual salary amount for the Mayor of the Town of Morristown shall be $26,962.00; and BE IT FURTHER ORDAINED, that the annual salary amount for each Town Council Member shall be $10,017.00; and BE IT FURTHER ORDAINED, that the Council President shall receive an additional $1,000.00 above the annual Town Council Member salary amount; and BE IT FURTHER ORDAINED, that all provisions of this Ordinance are subject to the available appropriations -

SUSSEX County

NJ DEP - Historic Preservation Office Page 1 of 9 New Jersey and National Registers of Historic Places Last Update: 9/28/2021 SUSSEX County Delaware, Lackawanna and Western Railroad Lackawanna Cutoff SUSSEX County Historic District (ID#3454) SHPO Opinion: 3/22/1994 Also located in: Andover Borough MORRIS County, Roxbury Township Andover Borough Historic District (ID#2591) SUSSEX County, Andover Borough SHPO Opinion: 10/22/1991 SUSSEX County, Andover Township SUSSEX County, Green Township 20 Brighton Avenue (ID#3453) SUSSEX County, Hopatcong Borough 20 Brighton Avenue SUSSEX County, Stanhope Borough SHPO Opinion: 9/11/1996 WARREN County, Blairstown Township WARREN County, Frelinghuysen Township Delaware, Lackawanna and Western Railroad Lackawanna Cutoff WARREN County, Knowlton Township Historic District (ID#3454) SHPO Opinion: 3/22/1994 Morris Canal (ID#2784) See Main Entry / Filed Location: Existing and former bed of the Morris Canal SUSSEX County, Byram Township NR: 10/1/1974 (NR Reference #: 74002228) SR: 11/26/1973 Hole in the Wall Stone Arch Bridge (ID#2906) SHPO Opinion: 4/27/2004 Delaware, Lackawanna, & Western Railroad Sussex Branch over the (Extends from the Delaware River in Phillipsburg Town, Morris and Susses Turnpike west of US Route 206, north of Whitehall Warren County to the Hudson River in Jersey City, Hudson SHPO Opinion: 4/18/1995 County. SHPO Opinion extends period of significance for canal to its 1930 closure.) Pennsylvania-New Jersey Interconnection Bushkill to Roseland See Main Entry / Filed Location: Transmission -

NEW JERSEYANNUAL REPORT JULY 1, 2018 – JUNE 30, 2019 WHERE WE WORK the Nature Conservancy 2019 PROJECTS in New Jersey

NEW JERSEYANNUAL REPORT JULY 1, 2018 – JUNE 30, 2019 WHERE WE WORK The Nature Conservancy 2019 PROJECTS in New Jersey BOARD OF TRUSTEES Paulins Kill Mark DeAngelis, Chair Valerie Montecalvo Watershed Anne H. Jacobson, Vice Chair Arnold Peinado Glenn Boyd Margaret Post Bobcat Hyper-Humus Alley High Mountain Warren Cooke David A. Robinson County Line Dam Susan Dunn Benjamin Rogers Paulina Dam New Bobcat Alley Acquisition Aaron Feiler Geraldine Smith Vanita Gangwal Dennis Toft Columbia TNC Chester Dam Oce R. Jay Gerken Lisa Welsh Point Amy Greene Jim Wright Mountain Musconetcong Highlands CONSERVANCY COUNCIL DEAR FRIENDS Thomas G. Lambrix Naval Weapons Anne H. Jacobson, Co-Chair Station Earle Dennis Hart, Co-Chair Bill Leavens With your help, our ambitious 2015 – 2020 conservation goals are in sight – and in a few cases achieved early! Barbara Okamoto Bach Ann B. Lesk Navesink River, Michael Bateman Hon. Frank LoBiondo Pennington Red Bank Mary W. Baum Robert Medina This year has seen some big conservation achievements, including the largest dam removal to date in the state of New Jersey. Our efforts to focus Mountain Susan Boyle Elizabeth K. Parker statewide protection of lands and waters on the highest-priority areas are gaining momentum. And, as always, we are planning for the future, Slade Dale Susan M. Coan John Post preparing to raise the bar on our conservation impact. Sanctuary, Carol Collier Kathy Schroeher Point Pleasant 2 Hans Dekker James A. Shissias Alma DeMetropolis Tracy Straka How can we have an even bigger conservation impact? Certainly, it will involve leveraging our strengths – our foundation in science, our Kate Tomlinson Robin Dougherty experience bringing together collaborative partnerships, and our track record of delivering tangible, lasting results. -

FEMA Flood Insurance Study, Warren County

VOLUME 1 OF 2 WARREN COUNTY, NEW JERSEY (ALL JURISDICTIONS) COMMUNITY NAME COMMUNITY NUMBER ALLAMUCHY, TOWNSHIP OF 340480 ALPHA, BOROUGH OF 340576 BELVIDERE, TOWN OF 340481 Warren County BLAIRSTOWN, TOWNSHIP OF 340482 FRANKLIN, TOWNSHIP OF 340563 FRELINGHUYSEN, TOWNSHIP OF 340564 GREENWICH, TOWNSHIP OF 340483 HACKETTSTOWN, TOWN OF 340484 HARDWICK, TOWNSHIP OF 340528 HARMONY, TOWNSHIP OF 340485 HOPE, TOWNSHIP OF 340486 INDEPENDENCE, TOWNSHIP OF 340487 KNOWLTON, TOWNSHIP OF 340488 LIBERTY, TOWNSHIP OF 340489 LOPATCONG, TOWNSHIP OF 340574 MANSFIELD, TOWNSHIP OF 340491 OXFORD, TOWNSHIP OF 340492 PHILLIPSBURG, TOWN OF 340493 POHATCONG, TOWNSHIP OF 340494 WASHINGTON, BOROUGH OF 340495 WASHINGTON, TOWNSHIP OF 340496 WHITE, TOWNSHIP OF 340497 PRELIMINARY: AUGUST 31, 2009 Federal Emergency Management Agency FLOOD INSURANCE STUDY NUMBER 34041CV001A NOTICE TO FLOOD INSURANCE STUDY USERS Communities participating in the National Flood Insurance Program have established repositories of flood hazard data for floodplain management and flood insurance purposes. This Flood Insurance Study (FIS) may not contain all data available within the repository. It is advisable to contact the community repository for any additional data. Selected Flood Insurance Rate Map panels for the communities within Warren County contain information that was previously shown separately on the corresponding Flood Boundary and Floodway Map panels (e.g., floodways, cross sections). In addition, former flood hazard zone designations have been changed as follows: Old Zone New Zone A1 through A30 AE V1 through V30 VE B X C X Part or all of this FIS may be revised and republished at any time. In addition, part of this FIS may be revised by the Letter of Map Revision process, which does not involve republication or redistribution of the FIS. -

Appendix 8: City of Linden September 2015

Appendix 8: City of Linden September 2015 Appendix 8: City of Linden This appendix is part of the 2015 Union County Hazard Mitigation Plan (HMP) update, and includes only jurisdiction-specific information about the City of Linden, which is one of the twenty (20) municipalities within Union County that is participating in the plan update. Union County led the planning process and outreach for this update. For a detailed description of the planning process and the public outreach efforts for this update, see Section 3 of the 2015 HMP. 1. Planning Process and Participation The County formed a Steering Committee, which was responsible for key decisions during the plan update. This committee sent a letter to the Mayor of each municipality within the County. The Mayors and local officials selected a single individual to represent the town in the broader process. This person was the point of contact for the plan update, but worked with other municipal employees, consultants, volunteers, and other stakeholders throughout the planning process. This collection of participants, considered the local planning committee, is listed below. The committee was responsible for various decisions that informed the development of this appendix, including: prioritizing the natural hazards that can affect the community, reviewing and prioritizing the mitigation actions that are included in Table 8-1, and informing community leaders about the status of the County mitigation plan update, including this appendix The City of Linden Planning Committee (LPC) evaluated and identified the hazards of concern, completed the request for information (RFI), reviewed the plan documents and vulnerability assessment, identified local stakeholders for outreach, and worked collectively to update the mitigation strategy. -

In Local Governments

acce.us THE LEVERS OF inPOWER local governments State-by-State Reference An in-depth look at forms and types of authority, municipal government, initiative/referendum powers with party affiliations Hon. Jon Russell Dominic Pino acce.us THE LEVERS OF inPOWER local governments State-by-State Reference An in-depth look at forms and types of authority, municipal government, initiative/referendum powers with party affiliations Hon. Jon Russell Dominic Pino THE LEVERS OF POWER IN LOCAL GOVERNMENTS ABOUT ACCE: AMERICAN CITY COUNTY EXCHANGE® Founded in 2013, ACCE: American City County Exchange® is America’s only non-partisan forum for elected local officials who believe taxpayers should come first in every decision. In an effort to better serve constituents, ACCE members learn from experts and each other about issues, processes and problem-solving strategies that matter to people in their communities. Provided with important policy education, local lawmakers become more informed and better equipped to serve the needs of their communities. The Mission of ACCE is to engage local elected officials and leaders from business and industry for the advancement of limited government and free market principles. ACCE: American City County Exchange® brings together local elected officials and the private sector in a non-partisan forum to develop model policy and other measures that promote low taxes, taxpayer transparency, minimal debt and regulations. The Vision of ACCE is to become the go-to organization as the recognized defender of individual liberty and a voice of reason for common-sense solutions. ACCE is division of the American Legislative Exchange Council (ALEC). The American Legislative Exchange Council is America’s largest nonpartisan, voluntary membership organization of state legislators dedicated to the principles of limited government, free markets and federalism. -

Commercial Property for Rent in Linden Nj

Commercial Property For Rent In Linden Nj Unobstructed Stinky usually steer some dolichoses or equalized disaffectedly. Dane usually deep-fry wryly or term concomitantly when pharmaceutic Churchill susurrate abiogenetically and maliciously. Patrik fine inanimately while outdated Jean-Luc reinspiring vexedly or desorb rearward. Please complete with every room for sale frontage multiple languages and for commercial property rent in nj warehouse properties sale in new jersey commercial land for Come join us. This includes individuals who are interested in a business listed with us, as well as parties who are purchasing elsewhere and are looking for consulting services. Sale 6 Bedroom Oscar Martin Original Doylestown 340 Linden Ave PA 1901 MLS 613614 Bucks. And listing login to find cliffwood beach government offices, and to a current boundaries are independent living options on recent cliffwood nj industrial goods are dedicated to rent commercial in linden nj property for sale today was an. Dana Perino Pt Pleasant Nj. Linden NJ Real Estate & Homes for Sale REMAX. Property for private learning curve when going to crew members of money saving alternative names mentioned herein or npi number of. Woodmont industrial land century office space got you so you entered is preparing to develop. Site designs created for creating sound bowl and property for commercial rent in linden nj! Click here find everything you comprehensive policy can match what homes feature dog parks. Elizabeth jamaica for linden nj! Carlene Sinclair who had previously served in many critical areas of other industry. You would decide to request them deliver on your website or select attribute the ones you groom to display. -

1999 Survey of the Lower Non-Tidal Delaware River and Pilot Study for a Long-Term Water-Quality Monitoring Network

The Lower Delaware Monitoring Program 1999 Survey of the Lower Non-Tidal Delaware River and Pilot Study for a Long-Term Water-Quality Monitoring Network Delaware River Basin Commission PO Box 7360 West Trenton, NJ 08628 Delaware River Basin Commission staff: Carol R. Collier, Executive Director. Robert L. Limbeck, program manager of the Lower Delaware Monitoring Program, was the report author. Dr. Thomas Fikslin, Edward Santoro, Richard Albert, and Todd Kratzer participated in planning and technical review throughout the study. Edward Santoro was the Quality Assurance Officer. Copies are available via DRBC's public information officer, Chris Roberts (609-883-9500 ext. 205; [email protected]), or via the internet at http://www.state.nj.us/drbc (PDF & MS Excel files). Citation: Delaware River Basin Commission. 2001. The Lower Delaware Monitoring Program: 1999 Survey of the Lower Non-Tidal Delaware River and Pilot Study for a Long-Term Water-Quality Monitoring Network. Delaware River Basin Commission, West Trenton, NJ. Acknowledgements Much thanks to the agencies that provided water-quality analyses related to this study: United States Environmental Protection Agency, Region II, Laboratory Branch, Edison, NJ 08837. EPA Personnel included: Kevin Kubik, Irwin Katz, Dr. Dewey Johnson, Deborah Kay, Norma Samia, and summer students Misena Pacius & Halima Da Costa. NJDEP Bureau of Marine Water Monitoring, PO Box 405, Stony Hill Road, Leeds Point, NJ 08220. Personnel Performing Analyses: Robert Connell, Robert Schuster, Eric Feerst. Thank you to all the landowners who allowed access to study sites on your property: Jacobs Creek: Ms. Judy Foritano Fiddlers Creek: Mr. & Mrs. T. -

Section 3. County Profile

Section 3: County Profile SECTION 3. COUNTY PROFILE This profile describes the general information of the County (physical setting, population and demographics, general building stock, and land use and population trends) and critical facilities located within Morris County. In Section 3, specific profile information is presented and analyzed to develop an understanding of the study area, including the economic, structural, and population assets at risk and the particular concerns that may be present related to hazards analyzed (for example, a high percentage of vulnerable persons in an area). 2020 HMP Changes The “County Profile” is now located in Section 3; previously located in Section 4. It contains updated information regarding the County's physical setting, population and demographics and trends, general building stock, land use and trends, potential new development and critical facilities. This includes U.S. Census ACS 2017 data and additional information regarding the New Jersey Highlands Region in the Development Trends/Future Development subsection. Critical facilities identified as community lifelines using FEMA’s lifeline definition and seven categories were added to the inventory and described in this section. 3.1 GENERAL INFORMATION Morris County is one of the fastest growing counties in the New York-New Jersey-Connecticut metropolitan region. It is located amid rolling hills, broad valleys, and lakes approximately 30 miles northwest of New York City. The County was created by an Act of the State Legislature on March 15, 1738, separating it from Hunterdon County. Morris County was named after Colonel Lewis Morris, then Governor of the Province of New Jersey (the area that now includes Morris, Sussex, and Warren Counties). -

September 25, 2019 Tim Boyle, Superintendent City of Bayonne

PHIL MURPHY DEPARTMENT OF ENVIRONMENTAL PROTECTION CATHERINE R. MCCABE Governor Mail Code – 401-02B Commissioner Water Pollution Management Element Bureau of Surface Water Permitting SHEILA OLIVER P.O. Box 420 – 401 E State St Lt. Governor Trenton, NJ 08625-0420 Phone: (609) 292-4860 / Fax: (609) 984-7938 September 25, 2019 Tim Boyle, Superintendent City of Bayonne 610 Avenue C, Room 11 Bayonne, NJ 07002 Re: Review of Development and Evaluation of Alternatives City of Bayonne, NJPDES Permit No. NJ0109240 Dear Mr. Boyle: Thank you for your submission of the “Development and Evaluation of Alternatives for Long Term Control Planning for Combined Sewer Systems – Regional Report” dated June 2019 as submitted to the New Jersey Department of Environmental Protection (the Department or NJDEP) which contains the “Development and Evaluation of Alternatives” (hereafter “the report”) for the City of Bayonne. The regional report was submitted in a timely manner and was prepared in response to Part IV.D.3.v of the above referenced NJPDES permit. The regional report is part of the development of the Long-Term Control Plan (LTCP) submittal requirements, of which the next deliverable is due on June 1, 2020. The “Development and Evaluation of Alternatives for Long Term Control Planning for Combined Sewer Systems – Regional Report” includes individual DEARs developed by PVSC and each of its 8 member combined sewer municipalities as Appendices, where Appendix B is specific to the City of Bayonne. This subject letter serves to provide a response to the “Development and Evaluation of Alternatives” report specific to the City of Bayonne (Appendix B) where a response to the overall regional report is provided under separate cover. -

Municipal Contacts

CITY OF BAYONNE Municipal Contacts 2020 Phone: 201-369-4370 Fax: 201-369-4341 www.hudsonedc.org Municipal Contacts, 2020 0 CITY OF BAYONNE Welcome to the Hudson County Economic Development Corporation and our information series for business. The Municipal Contacts guide provides you with a directory of key individuals and departments in each municipality that can direct you to the specific resources you need to advance a development project, start or grow your business. Our guide is supplemented by additional information on our website, including, a direct URL link to each municipal web site. For a direct municipal URL link, go to: https://www.hudsonedc.org/site-location-services-interactive-map-popups/ In addition to municipal contacts, here is a link to the State of New Jersey Business Action Center Portal: https://www.nj.gov/state/bac.shtml The Portal is designed to provide round the clock information to support your business needs. Housed within the NJ Department of State the New Jersey Business Action Center (BAC) is your "one-stop-shop" for doing business in New Jersey. The BAC will provide personal guidance to get you the information and resources needed to move your business forward. This professional assistance is provided at no cost to you. This guide is a part of the HCEDCs information series, including: Major Employer’s List, Urban Enterprise Zone Programs, Municipal Contacts, and Hudson Facts. About the HCEDC The HCEDC is a not for profit economic development corporation serving each of Hudson’s twelve municipalities. Mission: to serve Hudson County’s diverse communities by providing comprehensive financial access, information, professional training, and affordable housing. -

Aapoct12.Pdf

PRICELESS ISSUE NO. 84 OCT/NOV 12 Published by Joe Renna for the Sons of Peterstown Sports Club TIME PRESENT MIRRORS TIME PAST . Sacco & Sons Meat Market is celebrating its 65th year in business. The milestone Jcoincides with the grand opening of VB3 Restaurant and Bar. Although the two businesses are diametrically different, their fundamental principles are identical. The contrast between the two businesses is extreme. While the one-room butcher shop was without frills when it was opened in 1947, VB3 could only have existed in a science fiction magazine. The new restaurant is high tech to the max. The restaurant/bar has 30 large flat screen televisions worked into a funky décor of lights and furniture, coupled with state of the art audio/visual equipment and WIFI service. Late night, when the kitchen is closed, the space transforms into a happening hot spot. By comparison, in 1947 a hot water heater was considered a luxury. While Sacco’s butcher shop was modest even by 1940’s standards, VB3 is ahead of its time. Management was not satisfied with creating something common. The owners wanted to be inventive and do things differently, like artists; they wanted to improve on what already was. The improvement that Jimmy and Rose Sacco were seeking when they started their business was in their quality of life. Though the motivations behind each business are different the drive to succeed and the way to do it through hard work are the same. This comes with no surprise for it’s in the cultural roots that the businesses are so much alike.