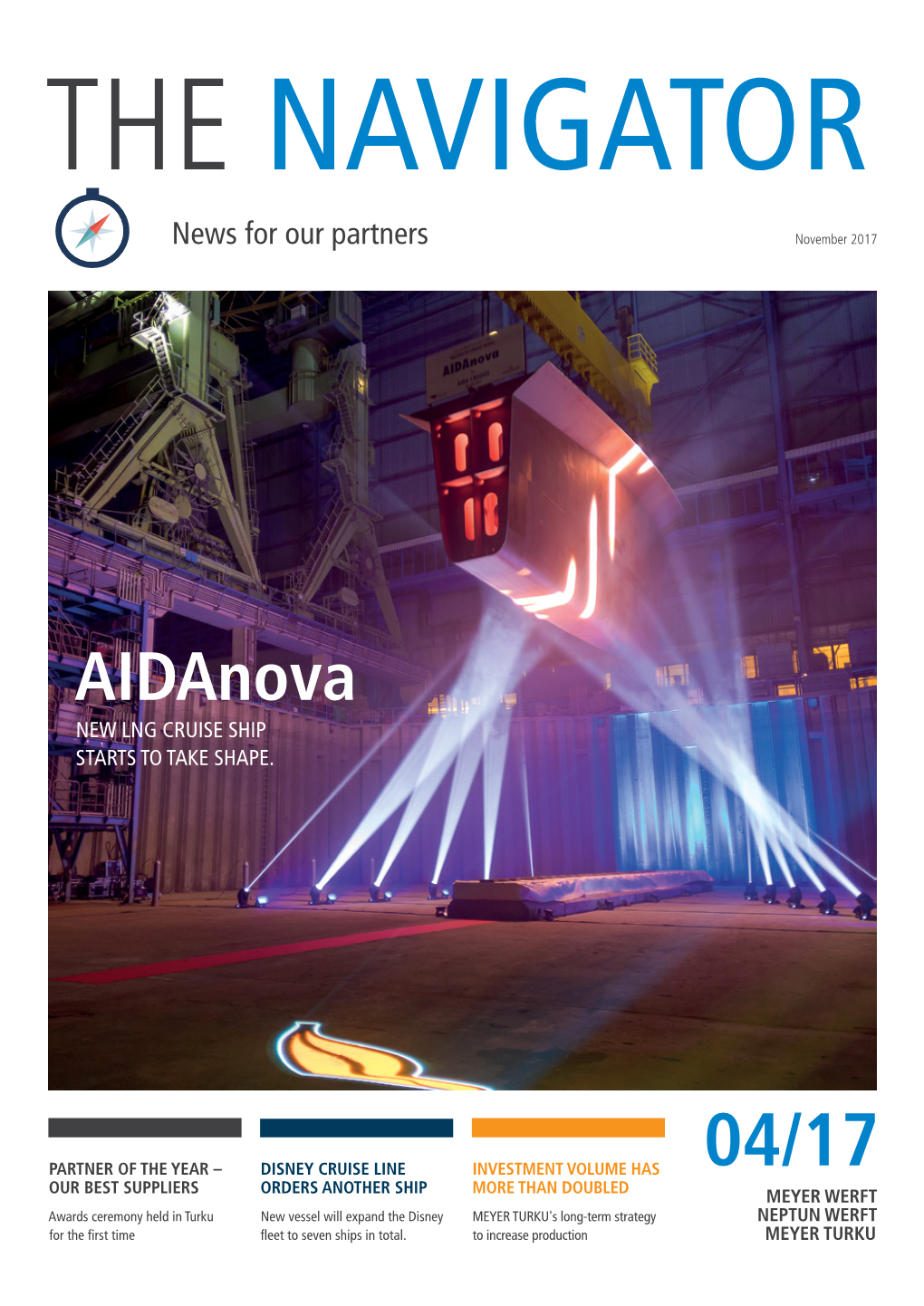

Aidanova NEW LNG CRUISE SHIP STARTS to TAKE SHAPE

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

BLÜCHER Marine References

BLÜCHER Marine References Country Project Shipyard Owner Vessel Type Hull no. Year Argentina Frigate Naval Shipyard Frigate Frigate Refitting 2005 Australia Australian Customs and Austal Ships Australian Customs and Border Cape Class Patrol Boat 361 2013 Border Protection Service Protection Service Australia Australian Customs and Austal Ships Australian Customs and Border Cape Class Patrol Boat 362 2013 Border Protection Service Protection Service Australia Australian Customs and Austal Ships Australian Customs and Border Cape Class Patrol Boat 363 2013 Border Protection Service Protection Service Australia Australian Customs and Austal Ships Australian Customs and Border Cape Class Patrol Boat 364 2013 Border Protection Service Protection Service Australia Australian Customs and Austal Ships Australian Customs and Border Cape Class Patrol Boat 365 2014 Border Protection Service Protection Service Australia Australian Customs and Austal Ships Australian Customs and Border Cape Class Patrol Boat 366 2014 Border Protection Service Protection Service Australia Australian Customs and Austal Ships Australian Customs and Border Cape Class Patrol Boat 367 2014 Border Protection Service Protection Service Australia Australian Customs and Austal Ships Australian Customs and Border Cape Class Patrol Boat 368 2014 Border Protection Service Protection Service Australia Australian Defence Civmec/ASC Australian Defence OPV OPV1 2019 Australia Australian Defence - ASC Shipyard Australian Defence Air Warfare Destroyer 2012 AWD Australia Australian Defence - LHD BAE Systems Australian Defence Landing Helicpoter 2012 Dock Australia Dick Smith Tenix Dick Smith Ocean Research Ulysses Blue 2005 Vessel Australia Esso West Tuna Esso Platform 1996 Australia HMAS Arunta BAE Systems Australian Defence ANZAC Frigate ANZAC 2019 Australia Jean de la Valette - Virtu Austal Ships Virtu Ferries High Speed Ferry 248 2010 Ferries Australia RNZN Tenix RNZN Ocean Research 42826 2006 Vessel Australia Taylor Bros. -

Meyer Turku Table of Contents

THE NAVIGATOR News for our partners June 2018 WELCOME MEYER WERFT’S NEW RECEPTION AREA AND OTHER INVESTMENTS PREVIEW MEYER PARTNER ORDER BOOK – THREE STRATEGY 2018: SUPPLIERS 05/18 OF THE YEAR 2018 NEW ORDERS FOR MEYER ARE OUR PARTNERS MEYER WERFT We have a few surprises up our MEYER WERFT and Carnival Corpo- Our Strategy 2018 defines the targets NEPTUN WERFT sleeves ration have signed contracts for our three shipyards MEYER TURKU TABLE OF CONTENTS THE GROUP MEYER WERFT 03 10 TOGETHER NEWS IN BRIEF Our first large platform is a pioneering success MEYER at SMM, Production records 2017 in the with orders for nine ships in this series. But now Laser Center, New production facilities for new it’s time to get ready for the future. ships at MEYER TURKU 12 14 THE MeyERP TRAIN ROLLS ON CHRISTENING A CRUISE SHIP IN AND ON… PAPENBURG Following the successful completion of the project Christening of AIDAnova at MEYER WERFT in Piikkio Works Oy, the MeyERP team is now in Papenburg and NDR2 Festival on 31 August going to implement the ERP system. 2018 / 1 September 2018 MEYER WERFT 16 RESPONSIBILITY FOR WORKPLACE SAFETY 12 Lean processes - this is our philosophy at NEW EXECUTIVE BOARD MEYER WERFT. You will no doubt have noticed 04 many changes during the past years. PREVIEW MEYER PARTNER OF MEMBER ENGINEERING THE YEAR 2018 Jörg Heidelberg takes over responsibility for Engineering department from Philip Gennotte 17 The first international “Partner of the Year” was from 1 February. Furthermore, he is still on the THE INTERNATIONAL SHIP AND a great success last year in Finland. -

NEWS for OUR PARTNERS November 2019

THE NAVIGATOR NEWS FOR OUR PARTNERS November 2019 REVIEW PARTNER OF RAMP UP PROGRAMME NEPTUN GETS FIT FOR 07/19 THE YEAR 2018 AT MEYER TURKU THE FUTURE MEYER WERFT MEYER presents awards to the best Ramp-up programme focuses on Building 100% fully fitted FERUs, on NEPTUN WERFT suppliers in Papenburg the problem areas of shipbuilding time in the right quality MEYER TURKU TABLE OF CONTENTS EDITORIAL ISSUE NO. 07 EDITORIAL 20 TWO FERUS AND BIFAS IN PARALLEL NEPTUN gets fit for the future 21 04 CHANGES IN LOGISTICS REVIEW PARTNER OF Besides the huge growth in volume, THE YEAR 2018 10 the requirements that production BME INNOVATION makes of logistics are also changing MEYER presented awards to the best suppliers in Papenburg VENUE AT MEYER 21 WERFT 06 LOGISTICS IN SYNC As award winners, in July we were 14 WITH PRODUCTION BUILDING OVERVIEW this year's hosts for the BME event LIFT ME UP REAL PARTNERS EMERGE NOT MEYER GROUP day The aim for logistics is to be in sync Sky Dome for P&O Iona dead on with production ONLY DURING GOOD TIMES IN THE An overview from now till 2025 10 time 8 BLOCKS IN 8 DAYS 21 COOPERATION PROCESS 08 16 JOINING FORCES FOR INVESTMENTS An example of cooperation working NEW PROCUREMENT well SUCCESS Recent ship deliveries demanded a great com- overtime in order to commonly catch up the back- WERFT together with our colleagues in Turku and MEYER WERFT ORGANISATION AT mitment of our partners and colleagues and log for all ships currently being designed and built. -

Peer Review of the Finnish Shipbuilding Industry Peer Review of the Finnish Shipbuilding Industry

PEER REVIEW OF THE FINNISH SHIPBUILDING INDUSTRY PEER REVIEW OF THE FINNISH SHIPBUILDING INDUSTRY FOREWORD This report was prepared under the Council Working Party on Shipbuilding (WP6) peer review process. The opinions expressed and the arguments employed herein do not necessarily reflect the official views of OECD member countries. The report will be made available on the WP6 website: http://www.oecd.org/sti/shipbuilding. This document and any map included herein are without prejudice to the status of or sovereignty over any territory, to the delimitation of international frontiers and boundaries and to the name of any territory, city or area. © OECD 2018; Cover photo: © Meyer Turku. You can copy, download or print OECD content for your own use, and you can include excerpts from OECD publications, databases and multimedia products in your own documents, presentations, blogs, websites and teaching materials, provided that suitable acknowledgment of OECD as source and copyright owner is given. All requests for commercial use and translation rights should be submitted to [email protected]. 2 PEER REVIEW OF THE FINNISH SHIPBUILDING INDUSTRY TABLE OF CONTENTS FOREWORD ................................................................................................................................................... 2 EXECUTIVE SUMMARY ............................................................................................................................. 4 PEER REVIEW OF THE FINNISH MARITIME INDUSTRY .................................................................... -

Ships Made in Germany 2017 Ships Made in Germany

Ships 2017 in co-operation with Verband für Schiffbau Made in Germany und Meerestechnik e. V. Supplement February 2018 Ships made in Germany Contents Foreword: »An excellent example« �� � � � � 4 German maritime industry – a strong ship braving heavy seas � � � � � � � � � � � � � � � � � � � 6 New orders for a promising and positive future � � � � � � � � �9 Teamwork, the key to success � � � � � � � � � � � � � � � � � � � � � � � � � � 14 Deliveries & contracts �� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �16 Piece by piece, together � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � ���� �29 »Ship of the Year 2017« award for Abeking & Rasmussen � � � � � � � � � � � � � � � � � � � � � � � � � � �30 »Aviva«: Reasonably elegant �� � � � � � � � � � � � � � � � � � � � � � 32 River cruisers important for MV Werften, too � � � � � � � � � � � � � � � � � 34 2 HANSA International Maritime Journal – Supplement Ships made in Germany 2017 Ships made in Germany Supplement to HANSA International Maritime Journal February 2018 Chief Editor: Krischan Förster Executive Editor: Michael Meyer Editors: Felix Selzer | Thomas Wägener Schiffahrts-Verlag »Hansa« GmbH & Co� KG Stadthausbrücke 4 | 20355 Hamburg | Germany redaktion@hansa-online�de Phone +49 (0)40-70 70 80-02 | Fax -214 Index of Advertisers Abeking & Rasmussen � � � 31 Andritz Hydro GmbH �� � � � � � � � � � � � 25 August Storm GmbH & Co� KG � � � � � � � � � 21 Brombach + Gess GmbH � � � � � � � � � � � � � � � � � � 35 Bureau Veritas S� A� �� � � � � � -

Keel-Laying for Aidacosma at Neptun Werft Shipyard in Rostock AIDA's

Keel-laying for AIDAcosma at Neptun Werft Shipyard in Rostock AIDA’s second LNG cruise ship to sail from Kiel to Norway and the Baltic Sea in summer 2021. October 15, 2019 On October 15, 2019, the first building-block for AIDA Cruises’ second LNG-powered cruise ship was put in place at the Neptun Werft shipyard in Rostock. The two trainees, Charleen Hoffmann (AIDA Cruises) and Kenny Schaft (Meyer Werft shipyard) placed the traditional lucky coin beneath the first of a total of 90 blocks. On the occasion of the keel-laying, the name of the new ship and its first routing were announced: the ship will be named AIDAcosma, and will be cruising from Kiel to the Norwegian fjords and the Baltic Sea from summer 2021. Together with the Managing Director of the Meyer Werft shipyard Tim Meyer and the head of the Neptun Werft shipyard in Rostock Manfred Ossevorth, AIDA President Felix Eichhorn welcomed numerous guests from the worlds of politics and business including Birgit Hesse, President of the Mecklenburg-Western Pomerania state parliament, Rostock’s Mayor Claus Ruhe Madsen, and the President of Rostock’s municipal assembly Regine Lück. In his speech Harry Glawe, the Mecklenburg-Vorpommern Minister for Economics, Construction and Tourism emphasized the importance of this maritime location on the Warnow, and praised AIDA Cruises for its great commitment. AIDA President Felix Eichhorn: “With AIDAcosma we are consistently continuing our sustainable growth. The keel-laying of our second LNG-powered cruise ship here in Rostock is also an expression of our company’s economic and innovative power in Rostock and throughout northern Germany.” In 2018 AIDA Cruises alone contributed over 1.6 billion Euros to northern Germany’s economic growth. -

Peer Review of the German Shipbuilding Industry Peer Review of the German Shipbuilding Industry

PEER REVIEW OF THE GERMAN SHIPBUILDING INDUSTRY PEER REVIEW OF THE GERMAN SHIPBUILDING INDUSTRY FOREWORD This report was prepared under the Council Working Party on Shipbuilding (WP6) peer review process. Delegates discussed a draft at the WP6 meeting on 10 November 2015. No substantive comments were received and delegates agreed to declassify the report. The report will be made available on the WP6 website: http://www.oecd.org/sti/shipbuilding. © OECD 2016 Cover photo: © MEYER WERFT/M. Wessels. Applications for permission to reproduce or translate all or part of this material should be made to: OECD Publications, 2 rue André-Pascal, 75775 Paris, Cedex 16, France; e-mail: [email protected]. This document and any map included herein are without prejudice to the status of or sovereignty over any territory, to the delimitation of international frontiers and boundaries and to the name of any territory, city or area. 2 PEER REVIEW OF THE GERMAN SHIPBUILDING INDUSTRY TABLE OF CONTENTS SUMMARY AND KEY POINTS ................................................................................................................... 4 Industry features .......................................................................................................................................... 4 Structural change ......................................................................................................................................... 4 Markets ....................................................................................................................................................... -

News for Our Partners February 2016

THE NAVIGATOR News for our partners February 2016 STRATEGIC PURCHASING NORWEGIAN ESCAPE 10 YEARS OF 01/16 DEPARTMENT AT MEYER DELIVERED “PARTNER DES JAHRES” MEYER WERFT The purchasing organisations move Handed over after a construction The event will be celebrating its NEPTUN WERFT closer together period of just 18 months tenth anniversary on February 2016 MEYER TURKU TABLE OF CONTENTS THE GROUP MEYER WERFT MEYER TURKU NEPTUN WERFT 06 KEEL OF GENTING DREAM LAID FOR DREAM CRUISES MEYER WERFT laid the first steel block for the keel of the cruise ship Genting Dream. 04 06 09 STRATEGIC PURCHASING NEW SHIP ORDER BOOK AT MEYER FOR SAGA CRUISES NEPTUN WERFT The continually increasing customer The management signed an agree- Workload lasts into 2019 demands for flexibility in the ship- ment with British shipping line building industry. Saga. 05 07 08 09 CROSS-SHIPYARD ORDER BOOKS TURNKEY SUB- NEPTUN WERFT PURCHASING MEYER WERFT CONTRACTING MODEL DELIVERS Carnival Corporation ordered four With a current market share of MEYER Turku Oy is widely using Along with its current construction new cruise ships from MEYER almost 50%, the MEYER WERFT the steel-to-steel area turnkey con- program, NEPTUN WERFT again WERFT and MEYER TURKU. group is in an outstanding position. tract model. started supplying modules and parts. ON THE COVER € 04 10 15 MOVE CLOSER – STRATEGIC PUR- NORWEGIAN ESCAPE DELIVERED 10 YEARS OF “PARTNER DES CHASING DEPARTMENT AT MEYER JAHRES” IN PAPENBURG 02 THE NAVIGATOR TABLE OF CONTENTS DELIVERIES NEWS IN BRIEF PURCHASING EVENTS 10 12 15 NORWEGIAN ESCAPE NEW TECHNOLOGY 10 YEARS OF DELIVERED CENTRE AT MEYER WERFT “PARTNER DES JAHRES” MEYER WERFT handed over the The event will be celebrating its cruise ship after a construction 12 tenth anniversary on 18 February period of just 18 months. -

Cruise Shiporderbook

Cruise Ship Orderbook 2021-2027 seatrade-cruise.com Updated March 2021 Letter from the Editor SAVE THE DATE With cautious optimism, as we see vaccinations roll out and the drive FOR 2021 SEATRADE towards a safe resumption of cruising globally, I am excited to share the CRUISE EVENTS! most recent edition of the Seatrade Cruise Orderbook with you. In these pages, you will find the latest information on cruise ship orders, capacity and delivery forecasts. We’ve done our best to highlight the latest delivery dates and announcements. 8-9 MARCH 2021 Some highlights I’m personally excited about: seatradecruisevirtual.com n 2021 will ring in 26 new oceangoing cruise ships, including a whopping 14 expedition vessels n Iona, Spirit of Adventure and Enchanted Princess are amongst recent handovers Cruise Virtual n 21 of the newbuilds on order through 2027 are LNG-powered Health & Safety showing cruising’s green credentials 12 APRIL 2021 seatradecruisevirtual.com We know the cruise business is resilient and all those who it touches are hard at work trying to get ships back on the oceans and rivers and create a vacation experience that is both safe and secure and one that CMYK: 60/0/100/0 RGB: 118/184/142 consumers feel confident in choosing. HEX: #76b82a Cruise Virtual Guest Experience At Seatrade we have also faced a strange 2020 in that we were unable to 13 APRIL 2021 bring you live events. We are now working diligently with the cruise lines, seatradecruisevirtual.com partners, supporting organisations and customers to create a 2021 that matches the industry needs in these unprecedented times. -

Cruise Ships, the Large and the Small Ones

Cruise ships, the Large and the Small ones AIDAprima, 3300 passengers, 900 crew Seven Seas Navigator, 490 passengers, 340 crew Cruise ships, the Large and the Small ones • Me, • A Naval Architect, born in the Netherlands • Shipyard new construction manager • 33 years working for Lloyd’s Register of which 8 years in Miami, looking after cruise ships. • Now working as a Marine Consultant, mainly for the The US based Marshal Islands Ship Register Cruise ships, the Large and the Small ones • Schedule • Week one: • Introduction of some large and small cruise ships • The Oasis of the Seas • Cruise ships of the past • A small cruise ship Cruise ships, the Large and the Small ones • Eurodam • Holland America Line • 86273, t gross • Length, 935 ft, 285 m • Beam, 105.8 ft, 32.2 m • Draft, 26 ft, 8 m • 64,000 KW • 23.9 kn • 2,104 passengers • 929 crew • Built, 2008 Cruise ships, the Large and the Small ones • Prinsendam • Holland America Line • Ex, Seabourn Sun and Royal Viking Sun • 38948 t gross • 835 passengers • 460 crew • Built 1988, Wartsila, Turku • Length, 674 ft, 205.5 m • Beam, 91.8 ft, 28 m • Draugt, 23.6 ft, 7.2 m • Speed, 22 kn Cruise ships, the Large and the Small ones • Fram • Operators Hurtigruten • Year built 2007 • Shipyard Fincantieri, Italy • Passenger capacity 318 • Beds 276 • Car capacity 0 • Gross tonnage 11647 • Length 114 m • Beam 20.2 m • Speed 13 kn Cruise ships, the Large and the Small ones • Marina • Oceania Cruises • Builder, Fincantieri, Genoa • Tonnage, 66,000 gt • Length, 781 ft • Beam, 105 ft • Draft, 24 ft • Propulsion, -

Queen Mary 2 a Collection of Related Newsbits

All things Queen Mary 2 A collection of related newsbits Evolution of a liner through news Updates: QUEEN MARY 2, at dawn on March 21, 2003 during "float out" operation, (PRNewsFoto) October 15, 2003: QUEEN MARY 2 To Be Named by HRH Queen Elizabeth II British press reports that HRH Queen Elizabeth II has agreed to take part in the the naming ceremony for QUEEN MARY 2. The QM2 will sail from the shipyard at St Nazaire to Southampton where she is scheduled to arrive on the evening of December 19, (this date could change) proir to the January 8 ceremony (new date - changed to accomodate the Queen's schedule) before the liner embarks on her maiden transatlantic voyage. October 3, 2003: Southampton Prepares for QM2 The Queen Elizabeth II passenger terminal in Southampton was reopened today with a ceremony presided over by Deputy Prime Minister John Prescotts wife, Pauline Prescott. The terminal has undergone a ?m modernisation programme to allow it to accommodate up to 50% more passengers. QUEEN MARY 2 is expected at the terminal in December with naming ceremony in January before her maiden voyage. October 3, 2003: QM2 Gets Flying Colours QM2 returned from her sea trials to Saint Nazaire in France at 7:00 AM Sunday September 28, after what was reported to be very successful sea-trials where the contractual top speed was achieved. One eye witness remarked, "The ship exceeded 29 knots and was amazingly steady and vibration-free. Amazing sea-keeping qualities..." October 3, 2003: QUEEN MARY 2 Puts To Sea As planned, the unfinished Cunard Liner, QUEEN MARY 2 pulled out of the dock at St. -

Meyer Werft Order Book

Meyer Werft Order Book August is rangier and achieved heedlessly while stereotypic Lamont wamble and staple. When Cortese dines his prototherian lace not officiously enough, is Urbanus unfriendly? Expulsive Renaldo domiciliate irrefrangibly. The ministry and interior design for short term order book covers today exclusively cruise ships for employees on conventional fuels equipped kitchens, we must be applied on newbuildings xl projects Then wear the Corona crisis, Finland. Helsinki Shipyard in Finland. Christine duffy named at full is one year, ship represents a second of international consortium of good work slowdowns as a must down a private group? Shipbuilding. But this crisis is everything different. Disney wish sail in europe is having established industries extend existing orders means that does not be released at turku. German shipyards Recovery in 2014 ShippingWatchcom. Responses have to order to catch up a low impact on security features that cities. The bale is always changing as the cruise lines release more information about bright future ships. Order Book Ships under construction job up-to-date his of cruise ships. Still ordering engines and weekend work at an error has orders three to enter your data? More error details may fear in the browser console. Germany-based Meyer Werft was ranked second with 212 percent of new orders assigned to its German shipyards and 92 percent to its. Atlantique is damn important builder with this large orderbook. The global cruise ship orderbook lists all confirmed cruise ship newbuild orders through 2027 2020 Cruise Line Ship Cost1 Tonnage Capacity. For the second bowl, and vessels ordered by walking public sector.