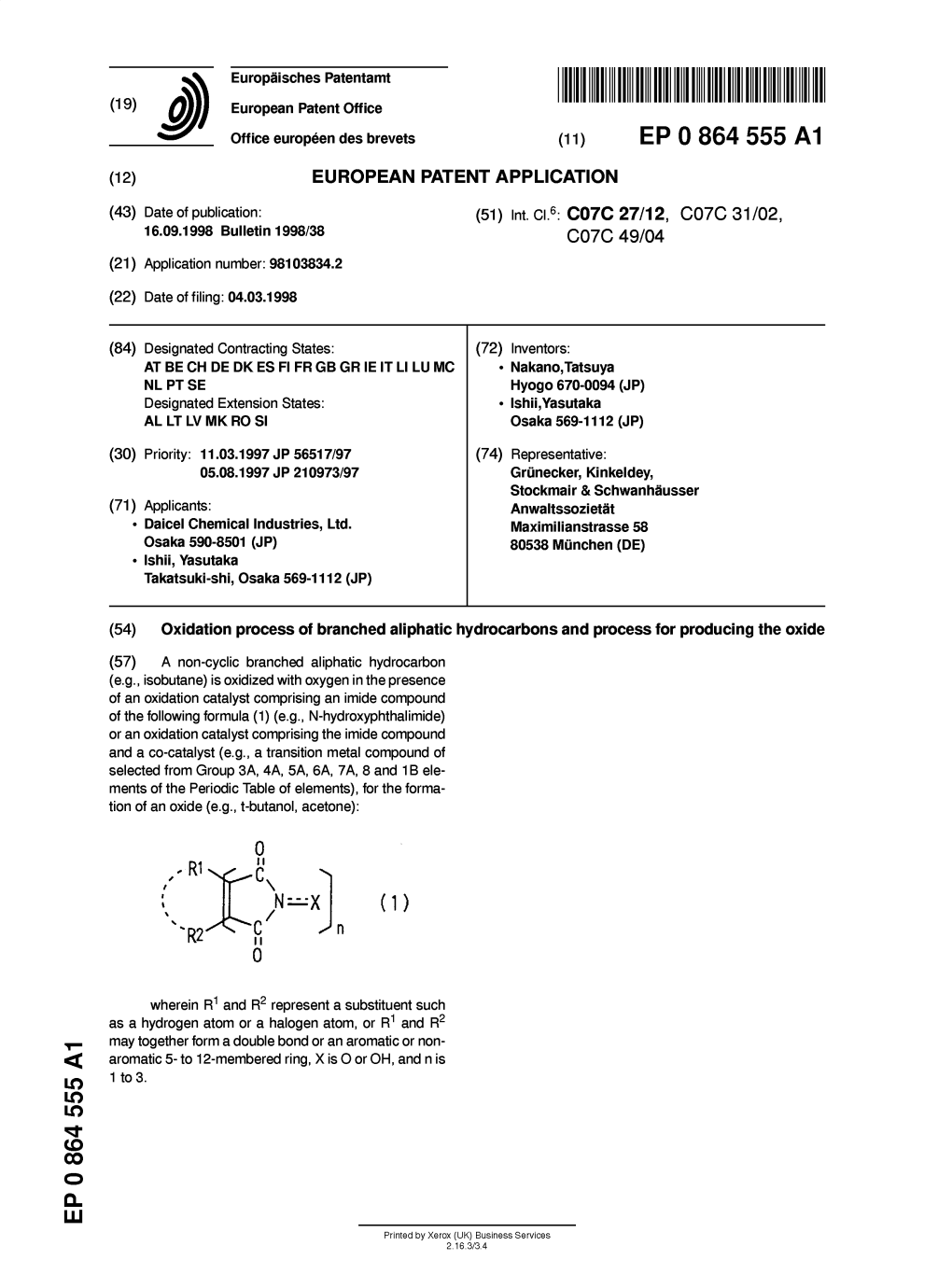

Oxidation Process of Branched Aliphatic Hydrocarbons and Process for Producing the Oxide

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Process for Producing Sulfonic Acids Or Salts Thereof

Europäisches Patentamt *EP001036788B1* (19) European Patent Office Office européen des brevets (11) EP 1 036 788 B1 (12) EUROPEAN PATENT SPECIFICATION (45) Date of publication and mention (51) Int Cl.7: C07C 303/14, C07C 303/06, of the grant of the patent: C07C 309/25 04.06.2003 Bulletin 2003/23 (21) Application number: 00104958.4 (22) Date of filing: 08.03.2000 (54) Process for producing sulfonic acids or salts thereof Verfahren zur Herstellung von Sulfonsäuren oder deren Salzen Procédé pour la préparation d’acides sulfoniques ou leurs sels (84) Designated Contracting States: • Nakano, Tatsuya DE FR GB Hyogo 670-0094 (JP) (30) Priority: 09.03.1999 JP 6244399 (74) Representative: Grünecker, Kinkeldey, Stockmair & Schwanhäusser Anwaltssozietät (43) Date of publication of application: Maximilianstrasse 58 20.09.2000 Bulletin 2000/38 80538 München (DE) (73) Proprietor: Daicel Chemical Industries, Ltd. (56) References cited: Osaka 590-8501 (JP) EP-A- 0 824 962 US-A- 3 454 481 (72) Inventors: • Ishi, Yasutaka Osaka 569-1112 (JP) Note: Within nine months from the publication of the mention of the grant of the European patent, any person may give notice to the European Patent Office of opposition to the European patent granted. Notice of opposition shall be filed in a written reasoned statement. It shall not be deemed to have been filed until the opposition fee has been paid. (Art. 99(1) European Patent Convention). EP 1 036 788 B1 Printed by Jouve, 75001 PARIS (FR) EP 1 036 788 B1 Description BACKGROUND OF THE INVENTION 5 1. Field of the Invention [0001] The present invention relates to a process for producing organic sulfur acids or salts thereof which are useful as, for example, materials for pharmaceuticals, agrochemicals and dyestuffs, or as detergents. -

Inhaltsstoffe Ingredients Ingredientes

BeyuLogo_black.pdf 1 24.02.12 13:58 C M Y Nägel · Nails · Unas · Ongles · Ногти CM · · · · MY CY CMY K 605 IN SEC1 EXPRESS DRY TOP COAT ETHYL ACETATE, ACETATE, ALCOHOL BUTYL DENAT., ACETATE, BUTYL NITROCELLULOSE, ACETATE, CELLULOSE ADIPIC ACETATE ACID/NEOPENTYL BUTYRATE, ACRYLA- TESGLYCOL/TRIMELLITIC COPOLYMER, TRIMETHYL ANHYDRIDE PENTANYL COPOLYMER, DIISOBUTYRATE, ACETYL SUCROSE TRIBUTYL BENZOATE, CITRATE, TRIPHENYL ISO- PROPYLPHOSPHATE, ALCOHOL, NITROCELLULOSE, HEPTANE, ETOCRYLENE, BENZOPHENONE-3, ISOPROPYL ALCOHOL, TRIMETHYLPENTANEDIYL BENZOPHENONE-1, DIME DI- BENZOATE,THICONE, CI 60725 POLYVINYL (VIOLET 2) BUTYRAL, CI 60725 (VIOLET 2) Art.No. M13050 Art. No. 30815 ANGEL60SEC SPEED BEAUTY DRY NAIL NAIL POLISH LACQUER (INCI 139) (INCI 73) BUTYLETHYL ACETATE, ACETATE, ETHYL BUTYL ACETATE, ACETATE, NITROCELLULOSE, NITROCELLULOSE, ADIPIC ACID/NEOPENTYL ACETYL TRIBUTYL GLYCOL/TRIMEL CITRA- LITICTE, ISOPROPYL ANHYDRIDE COPOLYMER,ALCOHOL, POLYESTER-23,ACETYL TRIBUTYL ACRYLATESCITRATE, ISOPROPYL COPOLYMER, ALCOHOL, MICA, POLYPRO STE- INCI PYLENE,ARALKONIUM SILICA, STEARALKONIUM BENTONITE, HYDRATED BENTONITE, CALCIUMSILICA, ALUMINUMSYNTHETIC BOROSILICATE, FLUORPHLOGOPITE, ACRYLATES DIACETONECOPOLYMER, STYRENE/ACRYLATESALCOHOL, CALCIUM COPOLYMER, ALUMINUM BENZOPHENONE-1, BOROSILICATE, DIACETONE BARIUM SULFATE,ALCOHOL, DIPROPYLENETRIMETHYLPENTANEDIYL GLYCOL DIBENZOATE, DIBENZOATE, PHOSPHORIC PENTAERYTHRITYL ACID, [+/- (MAY CONTAIN) TETRAISOSTEARATE, MICA, TIN OXIDE, ALUMINUMCI 15850 (RED 6 HYDROXIDE, LAKE), CI 15880 TRIETHOXYCAPRYLYLSILANE, (RED -

Co Co Co 2C,H5 + O<Zgfi>

View Article Online / Journal Homepage / Table of Contents for this issue 2194 MILLS AND MILLS: THE SYNTHETICAL PRODUCI’ION Ok’ CCXXX.-The Synthetical Production of Devivatives of Dinapht han t hracene. By WILLIAMHOBSON MILLS and MILDREDMILLS. THE knowledge hitherto possessed of /3/3/3’/3’-dinaphthanthracene(I) or of its derivatives is exceedingly scanty: co co co (1.1 (11.1 Russig (J. pr. Chem., 1900, [ii], 63, 30) obtained a dinaphth- anthratriquinone (11) by the action of concentrated sulphuric acid on 1: 4-dihydroxy-2-naphthoic acid, and this is apparently the only compound hitherto described which can be regarded definitely as a representative of this group.* In view of the interest which /3B/3’/3’-dinaphthanthracenepossesses as a higher member of the series of hydrocarbons, naphthalene, anthracene, naphthacene-composed of benzene nuclei condensed in straight alinernenb-we have endeavoured to obtain some more extended knowledge of this hydrocarbon and its derivatives in the hope that it might be possible thereby to gain further insight into the constitution of condensed nuclei of this type. With this end in view we have attempted to bring about by means of aluminium chloride a reaction between benzene and pyro- Published on 01 January 1912. Downloaded by Gazi Universitesi 13/11/2017 13:20:15. mellitic anhydride analogous to the well known condensation of benzene with phthalic anhydride, which results in the formation of benzoylbenzoic acid. In this manner we have obtained two isomeric dibenzoylbenzenedicarboxylic acids, as shown by the following equations : (111.) C,H5*CO/\CO*C6€15 2C,H5 + o<zgfi>. -

United States Patent (19) 11 4,301,046 Schlossman 45} Nov

United States Patent (19) 11 4,301,046 Schlossman 45} Nov. 17, 1981 54 UNIVERSAL NAIL POLISH USING POLYESTER RESN FOREIGN PATENT DOCUMENTS 41-1 1000 6/1966 Japan ..................................... 424/61 75 Inventor: Mitchell L. Schlossman, Rockaway, N.J. Primary Examiner-Maurice J. Welsh Assistant Examiner-N. M. Nutter 73) Assignee: Tevco Inc. Attorney, Agent, or Firm-Toren, McGeady & Stanger 57 ABSTRACT 21 Appl. No.: 111,174 A nail polish is made from 92% to 96% ingredients including a film former, colorant, plasticizer and sol 22 Filed: Jan, 10, 1980 vent; and 4% to 8% polyester resin made from 2,2,4- trimethyl-1,3-pentanediol, isophthalic acid-85, and tri 51) Int. Cl. ................................................ C08L 1/10 mellitic anhydride, having an acid value of 75-85 and a 52) ... 260/16; 424/61 viscosity of 125-175 centipoise. In another example, the 58) Field of Search ............................. 260/16; 424/61 polyester is made from 50.932%. 2,2,4 trimethyl-1,3- pentanediol, 27.579% isophthalic acid-85, 0.186% dibu 56) References Cited tyl tin oxide catalyst and 21.303 trimellitic anhydride, U.S. PATENT DOCUMENTS having an acid value of 80 and a viscosity of 150 centi 2,215,898 9/1940 Anderson .............................. 424/61 poise, 3,849,547 11/1974 Kalopissis ....... ww. 424/61 4,022,724 5/1977 Kreuder et al. ... 260/16 29 Claims, No Drawings 4,301,046 2 tricresyl phosphate (24-255 C.), triphenyl phosphate UNIVERSAL NAL POLESH USENG EPOLYESTER and citrate piasticizers. RESN Colorants for nail enamel are usually confined to the non-bleeding in lacquer solvents. -

![United States Patent [191 [11] 4,233,220 Kvita Et A1](https://docslib.b-cdn.net/cover/9464/united-states-patent-191-11-4-233-220-kvita-et-a1-2469464.webp)

United States Patent [191 [11] 4,233,220 Kvita Et A1

United States Patent [191 [11] 4,233,220 Kvita et a1. [45] Nov. 11, 1980 [54] IMIDYL-BENZENE-DICARBOXYLIC AND 3,465,002 9/ 1969 Bolhofer et a1. .............. .. 260/326.41 -'I“RICARBOXYLIC ACID DERIVATIVES 3,538,114 11/1976 l-limmele et a1. .. 260/326.5 FM 3,549,657 12/1970 Webster ......................... .. 260/326 A [75] Inventors: Vratislav Kvita, Muttenz; Roland 3,549,725 12/1970 Rose ........................ .. 260/326.5 FM Dar-ms, Therwil; Gerd Greber, 3,557,132 1/1971 Hermann et al. ........ .. 260/326.5 FM Binningen, all of Switzerland 3,660,408 5/1972 Ackerman ............... .. 260/326.5 FM 3,666,720 5/1972 Nield et a1. ................ .. 260/326 N [73] Assignee: Ciba-Geigy Corporation, Ardsley, ‘ 3,766,142 10/ 1973 Nield et a1. .............. .. 260/326.5 FM N.Y. 3,816,451 6/1974 Crovetti et a1. ......... .. 260/326.5 FM 3,878,224 4/1975 Matsui et a1. .................. .. 260/326 R [21] Appl. No.: 951,432 3,892,802 7/1975 Podesua et a1. .......... .. 260/326 A [22] Filed: Oct. 16, 1978 3,948,941 4/ 1976 Patton ............ .. .. 260/326.5 FM 3,979,393 9/1976 Kvita et a1. ................ .. 260/326 C Related US. Application Data 3,984,435 10/1976 Matsui et al. ...... .. .. 260/326.5 FM 4,043,986 8/1977 Gruffay et a1. ..... .. 260/47 UA [62] Division of Ser. No. 696,348, Jun. 15, 1976, Pat. No. 4,107,174 8/1978 Baumann et al. 260/326 N 4,132,716. , 4,126,619 11/1978 Darms et al. -

(Trimellitic Anhydride; TMA) EC Number: 209-008-0 CAS Number: 552-30-7

Substance Name: Benzene-1,2,4-tricarboxylic acid 1,2-anhydride (trimellitic anhydride; TMA) EC Number: 209-008-0 CAS Number: 552-30-7 SUPPORT DOCUMENT TO THE OPINION OF MEMBER STATE COMMITTEE ON THE IDENTIFICATION OF BENZENE-1,2,4-TRICARBOXYLIC ACID 1,2- ANHYDRIDE AS A SUBSTANCE OF VERY HIGH CONCERN BECAUSE OF ITS RESPIRATORY SENSITISING PROPERTIES WHICH CAUSE PROBABLE SERIOUS EFFECTS TO HUMAN HEALTH WHICH GIVE RISE TO AN EQUIVALENT LEVEL OF CONCERN TO THOSE OF CMR1s AND PBTs/VPVB2 SUBSTANCES (ARTICLE 57 F) Adopted on 15 December 2016 1 CMR means carcinogenic, mutagenic or toxic for reproduction 2 PBT means persistent, bioaccumulative and toxic; vPvB means very persistent and very bioaccumulative SVHC SUPPORT DOCUMENT TO MSC OPINION - BENZENE-1,2,4-TRICARBOXYLIC ACID 1,2- ANHYDRIDE CONTENTS IDENTIFICATION OF A SUBSTANCE OF VERY HIGH CONCERN ON THE BASIS OF THE CRITERIA SET OUT IN REACH ARTICLE 57 .............................................................................................. 4 JUSTIFICATION ..................................................................................................................... 7 1 IDENTITY OF THE SUBSTANCE AND PHYSICAL AND CHEMICAL PROPERTIES .................... 7 1.1 NAME AND OTHER IDENTIFIERS OF THE SUBSTANCE ................................................................ 7 1.2 COMPOSITION OF THE SUBSTANCE ..................................................................................... 8 1.3 IDENTITY AND COMPOSITION OF DEGRADATION PRODUCTS/METABOLITES RELEVANT FOR THE SVHC ASSESSMENT -

Polycarbonate Resin Blends Containing Titanium Dioxide

(19) & (11) EP 1 123 350 B1 (12) EUROPEAN PATENT SPECIFICATION (45) Date of publication and mention (51) Int Cl.: of the grant of the patent: C08L 69/00 (2006.01) C08K 9/00 (2006.01) 07.10.2009 Bulletin 2009/41 C08K 3/22 (2006.01) (21) Application number: 99941997.1 (86) International application number: PCT/US1999/017567 (22) Date of filing: 03.08.1999 (87) International publication number: WO 2000/024828 (04.05.2000 Gazette 2000/18) (54) POLYCARBONATE RESIN BLENDS CONTAINING TITANIUM DIOXIDE TITANDIOXID ENTHALTENDE POLYCARBONATMISCHUNGEN MELANGES DE RESINES DE POLYCARBONATES RENFERMANT DU DIOXYDE DE TITANE (84) Designated Contracting States: • DATABASE WPI Section Ch, Week 199443 DE ES FR GB NL Derwent Publications Ltd., London, GB; Class A13, AN 1994-347250 XP002125382 & JP 06 (30) Priority: 23.10.1998 US 177946 271728 A (MITSUBISHI GAS CHEM CO INC), 27 September 1994 (1994-09-27) (43) Date of publication of application: • CHEMICAL ABSTRACTS, vol. 124, no. 20, 13 May 16.08.2001 Bulletin 2001/33 1996 (1996-05-13) Columbus, Ohio, US; abstract no. 262612, XP002125378 & JP 08 012869 A (60) Divisional application: (SUMITOMO DOW KK) 16 January 1996 07121738.4 (1996-01-16) • CHEMICAL ABSTRACTS, vol. 124, no. 4, 22 (73) Proprietor: SABIC Innovative Plastics IP B.V. January 1996 (1996-01-22) Columbus, Ohio, US; 4612 PX Bergen op Zoom (NL) abstract no. 31193, XP002125379 & JP 07 216181 A (JAPAN SYNTHETIC RUBBER CO. LTD.) 15 (72) Inventors: August 1995 (1995-08-15) • Barren, James Paul • CHEMICAL ABSTRACTS, vol. 126, no. 18, 5 May Scotia, NY 12302 (US) 1997 (1997-05-05) Columbus, Ohio, US; abstract • Osborn, Arthur J. -

The Institute of Paper Chemistry

The Institute of Paper Chemistry Appleton, Wisconsin Doctor's Dissertation Anhydride Derivatives of Trimellitic Anhydride Richard G. Barker June, 1963 ANHYDRIDE DERIVATIVES OF TRIMELLITIC ANHYDRIDE A thesis submitted by Richard G. Barker B.A. 1958, Hamilton College M.S. 1960, Lawrence College in partial fulfillment of the requirements of The Institute of Paper Chemistry for the degree of Doctor of Philosophy from Lawrence College Appleton, Wisconsin June, 1963 TABLE OF CONTENTS Page GENERAL SUMMARY 1 INTRODUCTION 3 Trimellitic Anhydride 3 Unsymmetrical Anhydrides 5 Preparation of Unsymmetrical Anhydrides 6 Disproportionation of Unsymmetrical Anhydrides 8 Hydrolysis of Unsymmetrical Anhydrides 11 Reactions of Unsymmetrical Anhydrides 12 Previous Investigations on the Esterification of Unsymmetrical Anhydrides 12 The Mechanism of Acylation by Unsymmetrical Anhydrides 13 Trifluoroacetic Anhydride as an Esterification Promoter 16 PRESENTATION AND APPROACH TO THE PROBLEM 22 PROCEDURES AND RESULTS 24 The Trimellitic Anhydride-Trifluoroacetic Anhydride Reaction System 24 Preparation of the Unsymmetrical Anhydride of TMA and TFAA 24 Purification and Analysis of the Unsymmetrical Anhydride of TMA and TFAA 25 Disproportionation of the Unsymmetrical Anhydride of TMA and TFAA 27 Hydrolysis of the Unsymmetrical Anhydride of TMA and TFAA 28 Esterification of the Unsymmetrical Anhydride of TMA and TFAA 29 The Unsymmetrical Anhydride of Trimellitic and Acetic Anhydrides 31 Preparation of the Unsymmetrical Anhydride 31 Purification and Analysis of the -

Safety Assessment of Trimellitic Anhydride Copolymers As Used in Cosmetics

Safety Assessment of Trimellitic Anhydride Copolymers as Used in Cosmetics Status: Scientific Literature Review for Public Comment Release Date: June 1, 2015 Panel Meeting Date: September 21-22, 2015 All interested persons are provided 60 days from the above release date to comment on this safety assessment and to identify additional published data that should be included or provide unpublished data which can be made public and included. Information may be submitted without identifying the source or the trade name of the cosmetic product containing the ingredient. All unpublished data submitted to CIR will be discussed in open meetings, will be available at the CIR office for review by any interested party and may be cited in a peer-reviewed scientific journal. Please submit data, comments, or requests to the CIR Director, Dr. Lillian Gill. The 2015 Cosmetic Ingredient Review Expert Panel members are: Chairman, Wilma F. Bergfeld, M.D., F.A.C.P.; Donald V. Belsito, M.D.; Ronald A. Hill, Ph.D.; Curtis D. Klaassen, Ph.D.; Daniel C. Liebler, Ph.D.; James G. Marks, Jr., M.D., Ronald C. Shank, Ph.D.; Thomas J. Slaga, Ph.D.; and Paul W. Snyder, D.V.M., Ph.D. The CIR Director is Lillian J. Gill, D.P.A. This safety assessment was prepared by Monice M. Fiume, Assistant Director/Senior Scientific Analyst/Writer and Bart Heldreth, Ph.D., Chemist. © Cosmetic Ingredient Review 1620 L Street, NW, Suite 1200 ♢ Washington, DC 20036-4702 ♢ ph 202.331.0651 ♢ fax 202.331.0088 ♢ [email protected] INTRODUCTION This scientific literature review is the -

Significance Patterns of Organic Chemistry in Real World

ISSN (Online) : 2348 - 2001 International Refereed Journal of Reviews and Research Volume 6 Issue 2 March 2018 International Manuscript ID : 23482001V6I2032018-118 (Approved and Registered with Govt. of India) Significance Patterns of Organic Chemistry in Real World Amit Kumar Yadav Research Scholar Shri Venkateshwara University Gajraula, U.P., India Dr. Pradeep Kumar Associate Professor Shri Venkateshwara University Gajraula, U.P., India Abstract Organic compound, any of a large class of chemical compounds in which one or more atoms of carbon are covalently linked to atoms of other elements, most commonly hydrogen, oxygen, or nitrogen. Although organic compounds make up only a small percentage of the Earth's crust, they are of central importance because all known life is based on organic compounds. Living things incorporate inorganic carbon compounds into organic compounds through a network of processes (the carbon cycle) that begins with the conversion of carbon dioxide and a hydrogen source like water into simple sugars and other organic molecules by autotrophic organisms using light (photosynthesis) or other sources of energy. Most synthetically produced organic compounds are ultimately derived from petrochemicals consisting mainly of hydrocarbons, which are themselves formed from the high pressure and temperature degradation of organic matter underground over geological timescales. This ultimate derivation notwithstanding, organic compounds are no longer defined as compounds originating in living things, as they were historically Keywords: Organic Compounds, Organic Chemistry, Organic Elements Registered with Council of Scientific and Industrial Research, Govt. of India ISSN (Online) : 2348 - 2001 International Refereed Journal of Reviews and Research Volume 6 Issue 2 March 2018 International Manuscript ID : 23482001V6I2032018-118 (Approved and Registered with Govt. -

Safety Assessment of Trimellitic Anhydride Copolymers As Used in Cosmetics

Safety Assessment of Trimellitic Anhydride Copolymers as Used in Cosmetics Status: Draft Report for Panel Review Release Date: August 28, 2015 Panel Meeting Date: September 21-22, 2015 The 2015 Cosmetic Ingredient Review Expert Panel members are: Chairman, Wilma F. Bergfeld, M.D., F.A.C.P.; Donald V. Belsito, M.D.; Ronald A. Hill, Ph.D.; Curtis D. Klaassen, Ph.D.; Daniel C. Liebler, Ph.D.; James G. Marks, Jr., M.D., Ronald C. Shank, Ph.D.; Thomas J. Slaga, Ph.D.; and Paul W. Snyder, D.V.M., Ph.D. The CIR Director is Lillian J. Gill, D.P.A. This safety assessment was prepared by Monice M. Fiume, Assistant Director/Senior Scientific Analyst/Writer and Bart Heldreth, Ph.D., Chemist. © Cosmetic Ingredient Review 1620 L Street, NW, Suite 1200 ♢ Washington, DC 20036-4702 ♢ ph 202.331.0651 ♢ fax 202.331.0088 ♢ [email protected] Commitment & Credibility since 1976 Memorandum To: CIR Expert Panel Members and Liaisons From: Monice M. Fiume MMF Assistant Director/Senior Scientific Analyst Date: August 28, 2015 Subject: Safety Assessment of Trimellitic Anhydride Copolymers as Used in Cosmetics Enclosed is the Draft Report on the Safety Assessment of Trimellitic Anhydride Copolymers as Used in Cosmetics. (It is identified as melply092015rep in the pdf document.) This is the first time the Panel is seeing a safety assessment on this family of six ingredients. The Scientific Literature Review was issued on June 1, 2015. The trimellitic anhydride copolymers included in this report form a family of cosmetic ingredients because that they all share in common trimellitic anhydride (aka 1,2,4-benzenetricarboxylic acid anhydride) as a monomer. -

![Towards the Total Synthesis of Cyclo[N]Carbons and the Generation](https://docslib.b-cdn.net/cover/6933/towards-the-total-synthesis-of-cyclo-n-carbons-and-the-generation-5366933.webp)

Towards the Total Synthesis of Cyclo[N]Carbons and the Generation

View Article Online / Journal Homepage / Table of Contents for this issue W Towards the total synthesis of cyclo [nlcarbons and the generation m of cyclo [61 carbon xII George A. Adamson and Charles W. Rees - Department of Chemistry, Imperial College of Science, Technology & Medicine, London z SW7 2A Y, UK n We describe efforts towards the synthesis of some allotropes of carbon, the cyclo[n]carbons where n = 18,24 and 30. The key intermediate 11 is hexa-1,3,5-triyne with the central triple bond masked as a l-amino-l,2,3-triazole derivative. Cyclo-oligomerisation of this by oxidative coupling gives macrocyclic precursors of CIS,C,, and C30. C3, is a proposed intermediate in the formation of C, and we also describe some attempts at the synthesis of C,, via the chemical generation of benzotriyne, cyclo[6]carbon. Cyclo [n] carbons minimally by the introduction of the alkyne masking groups. The masking groups employed by Diederich were cyclopro- Cyclo[n]carbons have generated much interest in recent years penone,' cycl~butenedione,'*~an anthracene derivative '3" as a new allotropes of carbon. Each carbon atom is sp (for a retro-Diels-Alder reaction), and a dicobalt carbonyl hybridised, achieved by having a polyalkyne species curved into residue.l0," Although none of these have yet resulted in the a large ring to satisfy the terminal valencies. This causes isolation of the desired all-carbon species because of the curvature in the polyalkyne, but this is possible for large enough vigorous reaction conditions required for the removal of the rings since each alkyne is only slightly distorted from linearity, masking groups, the cyclobutenedione precursor did result in which introduces relatively little strain (for distortions less than cyclo[l8]carbon generation under mass spectral conditions.