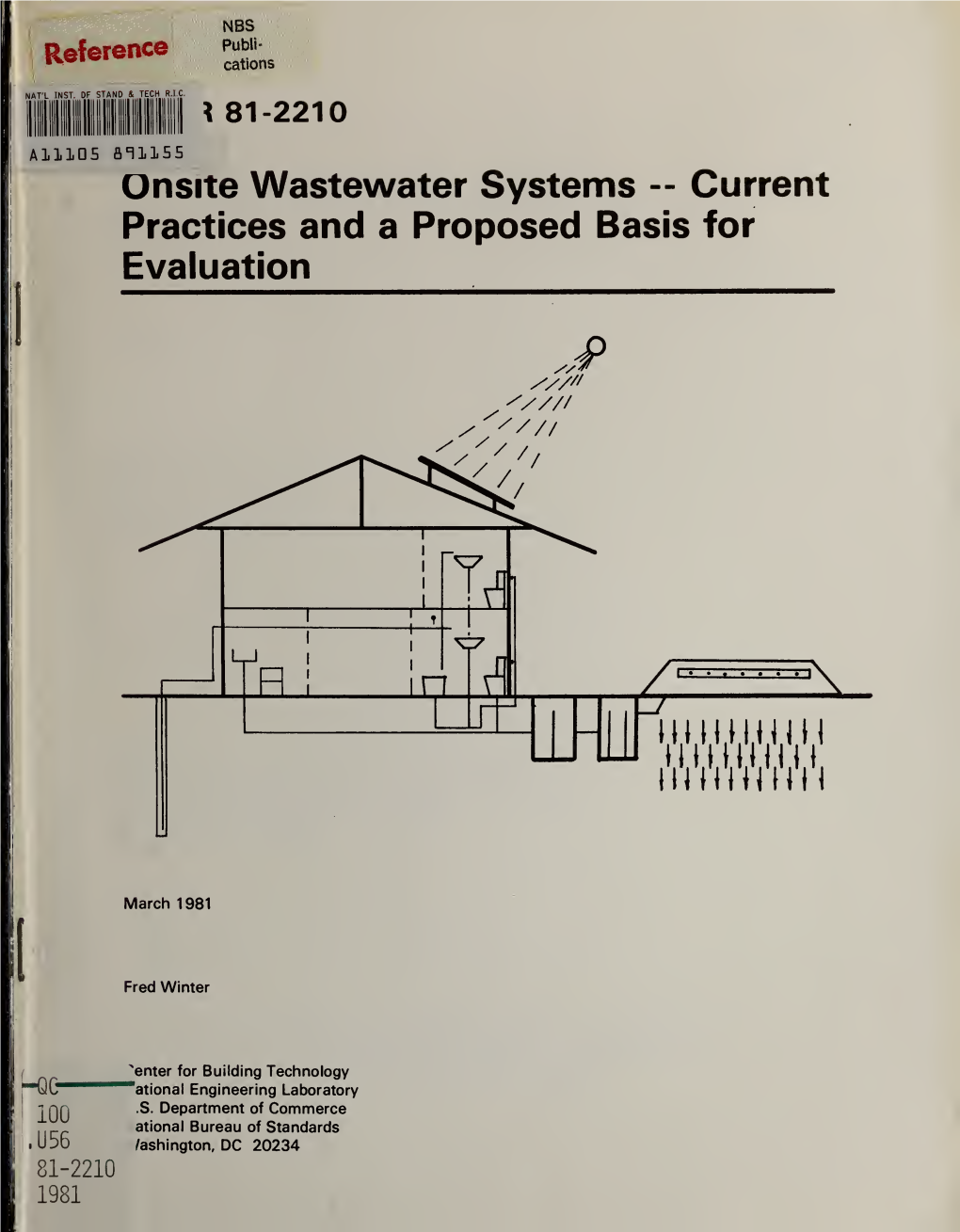

Onsite Wastewater Systems — Current Practices and a Proposed Basis for Evaluation

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Onsite Wastewater Treatment System Regulations, and Any Board Policies in Effect at the Time Application Is Made for the Permit

Onsite Wastewater Regulations Effective May 4, 2018 Elk Falls Staunton State Park ONSITE WASTEWATER REGULATIONS This Regulation was originally adopted by the Jefferson County Board of Health on April 1, 1967 and subsequently amended (effective dates) on: November 10, 1973 December 6, 1974, December 5, 1977, June 20, 1980, July 1, 1986, August 1, 1995, November 17, 1998, July 4, 2003, August 4, 2007 May 30, 2014, and May 4, 2018 Jefferson County Board of Health Bonnie McNulty, President Kimberley Krapek Greg Deranleau Dr. R. Dawn Comstock Lane Drager Lindsey Gonzales, Clerk to the Board Amanda B. Cruser, Esq., Counsel for the Board * * * * * * * Jefferson County Public Health 645 Parfet Street, Lakewood CO 80215 https://www.jeffco.us/public-health Mark B. Johnson, MD, MPH Executive Director James Rada, REHS Director, Environmental Health Services Division * * * * * * * Mission: To promote and protect health across the lifespan through prevention, education and partnerships. Vision: Healthy People, Healthy Places T A B L E O F C O N T E N T S Section 1 – AUTHORITY 1.0 Onsite Wastewater Treatment System Act ............................................................................ 1 1.1 Division Authority to Administer and Enforce ......................................................................... 1 Section 2 – DECLARATION, APPLICABILITY, PURPOSE AND SCOPE 2.0 Declaration ............................................................................................................................... 1 2.1 Applicability ............................................................................................................................. -

A Sewer Catastrophe Companion

A SEWER CATASTROPHE COMPANION Dry Toilets for Wet Disasters EMERGENCY The year is 20__. The Juan de Fuca tectonic plate has shifted, causing an earthquake with a magnitude of 9.0, devastating the Pacific Northwest. Underground infrastructure has shaken. Sewers are broken and leaking into waterways. You have food and water, your house is still habitable, and your friends and fam- ily are all accounted for. Finally, you can slow down and take stock. You need to poop. Where will you go? RESPONSE This guide presents a toilet system that you can do yourself without relying on a co- ordinated and timely response by someone else. This system served after earthquakes destroyed sanitation systems in Haiti and New Zealand. This guide is for planning ahead and preparing kits, whether for yourself, your household, your apartment building, or your block. This flexible system is built around ubiquitous and freely available 5-gallon buckets. A solution for today that’s Urine itself is sterile, it can be applied to not a problem for tomor- land, dramatically reducing the amount of row. 1. Pee in Bucket material handling. After the earthquake in New Zealand, 2. Poop in Bucket people used separate toilets for poop and pee to reduces material handling, disease risks, and work. Washing hands is fundamental. We de- 3. Wash Hands signed a simple, efficient, and ergonomic portable sink using buckets. A solution for managing Store materials until they can be properly excreta that’s not excreting 1. Cap and processed and treated. This allows time for problems later. an official response and pickup, or to build Store your own compost processing area. -

The Utilization of Human Excreta and Human Urine in the Agriculture As a Fertilizer

View metadata, citation and similar papers at core.ac.uk brought to you by CORE provided by Repository of the Academy's Library Proceedings of Architecture, Engineering and Technologies (AET), 3rd Edition Cairo, Egypt, 2019 Editors: Mona El Basyouni, Osama Al-Gayar, Reham I. Momtaz, Indjy M. Shawket The utilization of human excreta and human urine in the agriculture as a fertilizer J. Nagy1, A. Zseni2, A.J. Tóth3 1Budapest University of Technology and Economics, Department of Building Service Engineering and Process Engineering, Budapest, Hungary, [email protected] 2Széchenyi István University, Department of Environmental Engineering, Győr, Hungary, [email protected] 3Budapest University of Technology and Economics, Department of Chemical and Environmental Process Engineering, Budapest, Hungary, [email protected] Keywords Abstract human excreta; composting Human excreta contains all the macroelements which are important for the soil, for toilet; urine-diversion toilet; natural fertilizer; nutrient cycle example nitrogen, phosphorus and potassium. Although there are many ways of treating human excreta, composting is often regarded as the best solution because the final result of this treatment is valuable humus. However, human urine contains the most of the nutrients, so it may be more reasonable to apply human urine alone as a fertilizer. Direct utilization of urine emerges a lot of problems, but there are several existing technologies which are able to recover the nutrients from urine. These technologies (stripping, absorption, struvite precipitation and membrane technologies) also capable to recover nutrients from wastewater. Our paper are focusing on the comparison of composting toilet and urine-diversion toilet by analysing the advantages and disadvantages of the two methods. -

Onsite Sewage Treatment and Disposal

RULES OF STATE BOARD OF HEALTH BUREAU OF ENVIRONMENTAL SERVICES DIVISION OF COMMUNITY ENVIRONMENTAL PROTECTION CHAPTER 420-3-1 ONSITE SEWAGE TREATMENT AND DISPOSAL ADOPTED BY THE STATE BOARD OF HEALTH _______ EFFECTIVE DATE MARCH 6, 2017 ALABAMA STATE BOARD OF HEALTH ALABAMA DEPARTMENT OF PUBLIC HEALTH BUREAU OF ENVIRONMENTAL SERVICES DIVISION OF COMMUNITY ENVIRONMENTAL PROTECTION ONSITE SEWAGE TREATMENT AND DISPOSAL ADMINISTRATIVE CODE CHAPTER 420-3-1 TABLE OF CONTENTS 420-3-1-.01 Definitions .................................................................................................................................... 1 420-3-1-.02 Use of an Onsite Sewage Treatment and Disposal System (OSS) ............................................. 14 420-3-1-.03 General Requirements for an OSS ............................................................................................. 14 420-3-1-.04 OSS Type, Site Classification, and Development ...................................................................... 15 420-3-1-.05 Permits Required for an OSS ..................................................................................................... 16 420-3-1-.06 Proprietary and Non-Proprietary Product Permits...................................................................... 17 420-3-1-.07 OSS Installation ......................................................................................................................... 18 420-3-1-.08 Engineer Design Required......................................................................................................... -

We Need to Talk About Alternative Toilets

IT ADDS UP TO about a quarter-kilogram a day, this package that everyone delivers, but no one wants to receive. In the city, it disappears with the pull of a lever and a watery flourish. At the lake, well, human waste is another element We need cottagers must come to grips with. (Figuratively, folks.) When conventional septic solutions won’t fit the lot or the to talk about budget, or your heart quails at another cheek-chilling stum- ble to the outhouse, a composting or an incinerating toilet alternative seems increasingly attractive. Maybe your septic can’t han- ARE toilets dle another flush toilet, or you want to add facilities to a far- flung bunkie. Let’s see: Pay $15,000-plus for a new septic system, or shell out two to three grand for a box that turns poop into fertilizer or dispatches it in a blaze of glory? As a bonus, self-contained composting toilets, like incinerating ones, require no permit. Bye-bye, Mr. Septic Cop. YOU But wait: Maybe saving money and avoiding permits isn’t a basis for a good long-term relationship, considering you’ll spend years in, around, and—by some estimates—on the throne during your lifetime. Without the option of test drives, dating, or living together, how can you really know if an alterna-john is right—or wrong—for you? Rob Davis, SITTING president of EcoEthic, the distributor of the MullToa com- posting toilet, has an easy personality test. “If you’re will- ing to squat on the ground or take a leak on a tree, you’ll be much more in tune with composting than if you need a $1,400 Kohler with a pristine porcelain bowl.” On the other hand, maybe you’re already scribbling an DOWN? angry letter to the editor about Cottage Life’s sick toilet By Ray Ford Illustration Allie Smith obsession. -

Together for Waterless Toilets

Together for waterless toilets This years biggest news, though the smallest toilet. You can read all about our tiny master on page 12 and 13. Separett 2021 Intro ”Our vision is to contribute to a higher quality of life for the many” This broschure has been created with accuracy. Products may differ slightly from image and reality. We reserve the right to make any product changes regarding appearance and content as well as errors in text and images 2 3 Intro Separett 2021 The journey towards hygenic toilet solutions Over 2,4 million people are at the moment not having www.separett.com access to a toilet. The result of this is the every year death of Look in to our blogg for thousands of adults and children. The contribution of interesting articles and Separett being able to provide toilet solutions that can give other fun reading people a higher quality of life all over the world is very important. We want to accelerate the development of hygenic toilet solutions for the population of the world. That is the mission of Separett. And we do it by developing sewage- and waterless toilets. It is a long journey I want to improve that is being guided by our Separett AB hearts more than our economical goals. It is only together that we can at Youtube. reach the goals being set by United nations regarding the security for Follow our Youtube channel for inspiration and advices safe water and sanitation around the world. As a part of the humanity and its progress towards sanitary toilet solutions are we at Separett together with a non-profit organisation sending toilets to areas in Peru where the need of toilet solutions are great. -

Draft High Efficiency Toilet Specification

Version 1.0 EPA Water Efficiency Program 7 April 2006 Draft High Efficiency Toilet Specification 1.0 SCOPE AND OBJECTIVE This specification establishes the criteria to qualify a high efficiency toilet (HET) under the United States EPA Water Efficiency Program. It is applicable to: y single-flush, tank-type gravity toilets; y dual-flush, tank-type gravity toilets; y dual-flush, tank-type flushometer tank (pressure-assist) toilets, y tank-type, flushometer tank (pressure-assist) toilets, and y tank-type electrohydraulic toilets. The specification is designed to ensure both sustainable, efficient water use and a high level of user satisfaction with flushing performance. 2.0 SUMMARY OF CRITERIA To qualify under the program, toilets must meet criteria in three areas: y Effective flush volume shall not exceed 1.28 gallons1 (4.8 liters), as specified in Section 3.0; y Solid waste removal must be 350 grams2 or greater, as specified in Section 4.0; and y The toilet must conform to the adjustability and other supplementary requirements specified in Section 5.0. Conformance with these criteria must be established through independent laboratory testing, as specified in Section 6.0. 3.0 WATER EFFICIENCY CRITERIA 3.1 Single Flush Toilets - The effective flush volume shall not exceed 1.28 gallons (4.8 liters). The effective flush volume is the average flush volume when tested in accordance with ASME A112.19.2-2003. 3.2 Dual Flush Toilets - The effective flush volume shall not exceed 1.28 gallons (4.8 liters). The effective flush volume is defined as the composite, average flush volume of two reduced flushes and one full flush. -

Council Meeting 9:00 AM - Wednesday, April 7, 2021 Electronic

AGENDA Council Meeting 9:00 AM - Wednesday, April 7, 2021 Electronic Page A. Call to Order B. Moment of Reflection / O Canada C. Disclosure of Pecuniary Interest D. Public Meetings / Hearings E. Presentations / Delegations F. Consent Agenda F.1. Adoption of Council & Committee Minutes F.1.1. Council Meeting Minutes - March 3, 2021 4 - 8 Council Minutes - March 3, 2021 F.1.2. Planning & Development Committee Meeting Minutes - March 17, 9 - 24 2021 Planning and Development Committee Minutes - March 17, 2021 F.1.3. Special Council Meeting Minutes - March 17, 2021 25 - 30 Special Council Minutes - March 17, 2021 F.1.4. Special Planning & Development Committee Meeting Minutes - 31 - 39 March 18, 2021 Special Planning and Development Committee Minutes - March 18, 2021 F.1.5. Corporate Services Committee Meeting Minutes - March 24, 40 - 49 2021 Corporate Services Committee Minutes - March 24, 2021 F.1.6. Coldwater BIA Meeting Minutes - March 22, 2021 50 - 52 Coldwater BIA Minutes - March 22, 2021 F.1.7. Villages & Hamlets Committee Meeting Minutes - March 2, 2021 53 - 55 Villages & Hamlets Minutes - March 2, 2021 F.2. Correspondence F.2.1. Correspondence from 1885 Providence Lane re Z-21-03 56 (Paczay) Z-21-03 F.3. Reports from Officials (for information) F.3.1. Statement from the Treasurer re 2020 Council Remuneration & 57 - 58 Expenses Council Remuneration & Expenses 2020 Page 1 of 157 G. Adoption of Regular Agenda H. Reports from Officials (for direction) H.1. Planning & Development H.1.1. Planning Report No. P21-017 re Mandatory & Discretionary On- 59 - 70 Site Sewage System Maintenance Inspection – 2020 Year Review / 2021 Inspections P21-017 H.1.2. -

Guide to Sanitation Resource Recovery Products & Technologies

Guide to Sanitation Resource Recovery Products & Technologies A supplement to the Compendium of Sanitation Systems and Technologies 1st Edition Guide to Sanitation Resource Recovery Products & Technologies A supplement to the Compendium of Sanitation Systems and Technologies Jennifer McConville, Charles Niwagaba, Annika Nordin, Marcus Ahlström, Vivian Namboozo and Mark Kiffe We would like to thank the following individuals and their organisations/ institutions for their invaluable contributions to this publication: Allan Komakech (Makerere University), Åke Nordberg (SLU), Amadou Gueye (Delvic Sanitation Initiatives), Arne Panesar (GIZ), Barbara Jeanne Ward (Eawag), Bastian Etter (VUNA), Björn Vinnerås (SLU), Christian Zurbrügg (Eawag/SLU), Christoph Lüthi (Eawag), Cecilia Lalander (SLU), Daniel Ddiba (SEI), Dorothee Sphuler (Eawag), Ebenezer Soh Kengne (University of Bamenda), Elhadji Mamadou Sonko (Cheikh Anta Diop University), Elisabeth Kvarnström (RISE), Ershad Ulla Khan (SLU), Eva Thorin (Mälardalen University), Grietje Zeeman (Wageningen University & Research), Håkan Jönsson (SLU), Jenna Senecal (SLU), Kim Andersson (SEI), Linda Strande (Eawag), Linus Dagerskog (SEI), Luis Perez Mercado (SLU), Lukas Ulrich (Eawag), Madeleine Fogde (SEI), Melissa A. Barton, Naomi Korir (Sanivation), Peter Morgan, Priscila de Morais Lima (SLU), Prithvi Simha (SLU), Robert Gensch (German Toilet Organisation), and Sahar Dalahmeh (Uppsala University). We would like to acknowledge support from: The Swedish Research Council (grant number: 2016-06297) and -

Water Efficiency Standards We 1: Enhance Water Efficiency Standards

WE 1: ENHANCE WATER EFFICIENCY STANDARDS WE 1: ENHANCE WATER EFFICIENCY STANDARDS New York City Plumbing Code and Administrative Code Proposal developed by the Water Efficiency & Building Stormwater Committee Summary Issue: Although New York City receives substantial rainfall, the city is still vulnerable in dry years and has experienced seven droughts in the last 45 years. Fortunately, the need for water can be easily reduced with more-efficient plumbing fixtures. Recommendation: Enhance water efficiency standards for plumbing fixtures. Proposed Legislation, Rule or Study Amendments to the New York City Plumbing Code: 1. Add the following definitions to Section 202: DUAL-FLUSH TOILET. A toilet that enables the user to select a high flush for solid waste or a reduced volume, low flush for liquid waste. HIGH-EFFICIENCY TOILET (HET). A toilet that is authorized by the WaterSense Program of the United States Environmental Protection Agency to bear the WaterSense label. NON-WATER URINAL. A urinal that discharges into the sanitary drainage system but is not supplied by a water distribution system. WATERSENSE-LABELED FIXTURE. A plumbing fixture that has been tested by a third-party laboratory in accordance with the WaterSense Program of the United States Environmental Protection Agency, has been certified by such laboratory as meeting the performance and efficiency requirements of the program and has been authorized by the program to use its label. 2. Add a new Section 417.4.2 as follows: 417.4.2 Limitation on showerheads. The aggregate allowable flow rate from all shower head fixtures (including rain systems, waterfalls, bodysprays, and jets) that can operate simultaneously in a single shower compartment shall be limited to the flow rate in Table 604.4 for a single shower head. -

Kentucky State Plumbing Law, Regulations and Code Book

Kentucky State Plumbing Law, Regulations and Code Book Revised 2-28-2017 DEPARTMENT OF HOUSING, BUILDINGS & CONSTRUCTION DIVISION OF PLUMBING 101 SEA HERO RD., STE 100 FRANKFORT KY 40601 Phone: 502-573-0397 Website Address: dhbc.ky.gov/plb E-mail Address: [email protected] UNOFFICAL TEXT OF STATUTES AND ADMINISTATIVE REGULATIONS FOR INFORMATIONAL ONLY Mathew G. Bevin, Governor 1 DEPARTMENT OF HOUSING, BUILDINGS AND CONSTRUCTION Steven A. Milby, Commissioner Timothy R. House, Deputy Commissioner DIVISION OF PLUMBING David J. Moore, Director VACANT, Assistant Director Dennis J. Rodgers, Field Operations Jeffrey Hardin, Field Operations Floyd Schanz, Field Operations Plan Reviewers Geno Washington, Frankfort Office Gloria Wetzel Frankfort Office Frank Blevins, Lexington Office Chris Quire, Louisville Office Chris Stein, Edgewood Office Mike McPherson, Bowling Green Office AREA PLUMBING CONSULTANTS Area Supervisor Area Phone number David Beaven A 270-314-0563 Alan Lush B 502-262-9271 Mark Curry C 270-589-1848 George Kelley D Connell Powell E 502-271-8601 Pat Quisenberry F 859-595-7090 Keith Centers G 859-229-3300 Rodney Adams H 606-359-3851 Vacant I AREA COMPLIANCE Mark Hayden West 270-339-0867 Doug King South 859-339-9152 Jeff Phelps East 606-224-9188 Vacant North 2 Area Plumbing Inspectors Area A Lynn Bundy 270-210-6293 Roy McGregor 270-339-8539 Raymond Dawes 207-505-2166 Mike Shocklee 270-977-2575 Jerry Dorris 270-577-5350 Mark Thomas 270-314-9933 Area B John Baird 502-234-8844 Bob Maeser 270-331-9974 Jason Collins 270-307-7580 Gloria Wetzel -

Part 3: Toilet Design Considerations: Micro Level

PLANNING FOR PUBLIC TOILETS PART 3: MICRO LEVEL: TOILET DESIGN CONSIDERATIONS: Inclusive Design for Different Types of User Groups ' To a good doctor there is no physical or mental aspect of his patient which should embarrass him. He may be worried or shocked by what his diagnosis reveals, but if he's any good, he is not embarrassed. Correspondingly, therefore, there should be no type of building, and no human function related to it which should embarrass the architect!' (Architects Journal, 1953, No.117). This section looks at the 'micro' level of detailed toilet design. However, the emphasis is upon principles, and upon 'seeing' how the different components of the toilet cubicle 'work' together, because, as they say, 'the devil is in the detail'. The emphasis is again upon the user, the range of user types, and the social and qualitative factors involved, rather than upon the technical plumbing and engineering aspects dealt with elsewhere in this course programme. There is also a longer optional explanation of the issues in the second part of the paper. A PowerPoint accompanies and illustrates Part 3. Part 3 is longer because detailed issues are so important. A fuller bibliography, list of references is given at the end. In fact Part 3 may be used as a module in its own right on inclusive design. People are Important There are many detailed design guides on the precise dimensions and locations of rails, toilet pans, washbasins, mirrors etc and so it is not the purpose of this chapter to give precise guidance on these. 'The problem' is that some toilet manuals deal with each component without seeing how they inter-relate with each other spatially.