Grasberg Copper-Gold Mine, Indonesia / 10.2015 / Id: 60880

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Scope Key Findings Methodology

CORPORATE INTEGRITY The Freeport-McMoRan Inc. (Freeport-McMoRan) 2018 Working Toward Sustainable Development (WTSD) report, including information referenced by the Global Reporting Initiative (GRI) Sustainability Reporting Standards published on the Freeport-McMoRan web site, has been prepared by the management of Freeport-McMoRan who are responsible for the collection and presentation of this information. SCOPE Corporate Integrity Ltd., in accordance with Freeport-McMoRan management’s instructions, was asked to perform: 1. A review of policies and systems in place in relation to the International Council on Mining & Metals (ICMM) Sustainable Development (SD) Framework – using as a basis the ICMM Sustainable Development Framework: Assurance Procedure and the core option of the GRI Sustainability Reporting Standards. 2. A review of statements made in the 2018 WTSD report and information referenced by the GRI Content Index. Our assurance work covered Subject Matters 1 to 5 referred to in the ICMM SD Framework: Assurance Procedure. Our assurance work scope covered all the Freeport-McMoRan mining and metals processing operations defined by the reporting boundaries of the 2018 WTSD report. The work involved selective reviews of documents, interviews and site visits to: • Cerro Verde Mine, Peru; • El Abra Mine, Chile; • Atlantic Copper Refinery, Spain; • PT Freeport Indonesia (PTFI)- Grasberg Mine, Indonesia; • Morenci Mine, USA • Safford Mine, USA • Sierrita Mine, USA; and • Head Office, Phoenix, USA. The review also involved a desktop review and telephone interview with management of: • Stowmarket Chemical Conversion Plant, UK; • Rotterdam Chemical Conversion Plant, Netherlands; • Bayway Copper Product Manufacturing Plant, USA; • Norwich Copper Rod Plant, USA Freeport-McMoRan’s site visit programme is part of an ongoing process to conduct this assurance scope of work at all major Freeport-McMoRan mining and processing sites at least one time every three years. -

Freeport-Mcmoran Copper & Gold Inc. Announces Revised Operating

Financial Contacts: Media Contact: One North Central Avenue Phoenix, AZ 85004 Kathleen L. Quirk David P. Joint William L. Collier (602) 366-8016 (504) 582-4203 (504) 582-1750 Freeport-McMoRan Copper & Gold Inc. Announces Revised Operating Plans in Response to Weak Market Conditions • Reduction in Copper Production and Sales of 200 million pounds (5%) in 2009e and 500 million pounds (11%) in 2010e Compared with Previous Estimates • 18% Reduction in Estimated 2009 Unit Site Production and Delivery Costs Compared with 2008e • $1.2 billion Reduction (50%) in Estimated 2009 Capital Expenditures Compared with Previous Estimates • Suspension of Common Stock Dividend PHOENIX, AZ, December 3, 2008 – Freeport-McMoRan Copper & Gold Inc. (NYSE: FCX) announced today revised operating plans in response to the recent sharp decline in copper and molybdenum prices to incorporate reduced production levels, operating and administrative costs, exploration costs and capital expenditures. Since completion of the Phelps Dodge acquisition in March 2007, FCX’s business strategy has been focused on defining the potential of its resources and developing expansion and growth plans to deliver additional volumes to a growing marketplace. Following the more than $10 billion in debt reduction during 2007, FCX’s financial policy was designed to use its cash flows to invest in growth projects with high rates of return and return excess cash flows to shareholders in the form of dividends and share purchases. In response to the dramatic recent shift in global economic conditions, FCX has revised its near-term business strategy. LME copper prices averaged $3.61 per pound in the nine-month period ending September 30, 2008, $2.23 per pound in October 2008 and declined further to average $1.69 per pound in November 2008. -

Golden Rules Making the Case for Responsible Mining

GOLDEN RULES Making the case for responsible mining A REPORT BY EARTHWORKS AND OXFAM AMERICA Contents Introduction: The Golden Rules 2 Grasberg Mine, Indonesia 5 Yanacocha Mine, Peru, and Cortez Mine, Nevada 7 BHP Billiton Iron Ore Mines, Australia 9 Hemlo Camp Mines, Canada 10 Mongbwalu Mine, the Democratic Republic of Congo 13 Rosia Montana Mine, Romania 15 Marcopper Mine, the Philippines, and Minahasa Raya and Batu Hijau Mines, Indonesia 17 Porgera Gold Mine, Papua New Guinea 18 Junín Mine, Ecuador 21 Akyem Mine, Ghana 22 Pebble Mine, Alaska 23 Zortman-Landusky Mine, Montana 25 Bogoso/Prestea Mine, Ghana 26 Jerritt Canyon Mine, Nevada 27 Summitville Mine, Colorado 29 Following the rules: An agenda for action 30 Notes 31 Cover: Sadiola Gold Mine, Mali | Brett Eloff/Oxfam America Copyright © EARTHWORKS, Oxfam America, 2007. Reproduction is permitted for educational or noncommercial purposes, provided credit is given to EARTHWORKS and Oxfam America. Around the world, large-scale metals mining takes an enormous toll on the health of the environment and communities. Gold mining, in particular, is one of the dirtiest industries in the world. Massive open-pit mines, some measuring as much as two miles (3.2 kilometers) across, generate staggering quantities of waste—an average of 76 tons for every ounce of gold.1 In the US, metals mining is the leading contributor of toxic emissions to the environment.2 And in countries such as Ghana, Romania, and the Philippines, mining has also been associated with human rights violations, the displacement of people from their homes, and the disruption of traditional livelihoods. -

BUILDING on STRENGTH Annual Report on Sustainability

BUILDING ON STRENGTH Annual Report on Sustainability 2019 Sustainability Report | 1 Cover Photo: Remote underground equipment operators at the Grasberg Block Cave, Indonesia. About Freeport-McMoRan Freeport-McMoRan Inc. (Freeport-McMoRan, FCX or the company) is a leading international mining company with headquarters in Phoenix, Arizona. FCX operates large, long-lived, geographically diverse assets with significant proven and probable reserves of copper, gold and molybdenum. FCX is one of the world’s largest publicly traded copper producers. Our portfolio of assets includes the Grasberg minerals district in Indonesia (PT Freeport Indonesia or PT-FI), one of the world’s largest copper and gold deposits; and significant mining operations in North America and South America (Freeport Minerals Corporation or FMC), including the large-scale Morenci minerals district in Arizona and the Cerro Verde operation in Peru. RECENT AWARDS & RECOGNITION Freeport-McMoRan was named to Forbes Magazine’s JUST 100 as one of America’s most JUST Companies for the 4th consecutive year (ranked 43rd nationally and 1st in Basic Resources). Freeport-McMoRan ranked 6th among 200 of the largest publicly traded companies in the world assessed by the Corporate Human Rights Benchmark (ranked 1st in North America and 3rd among 56 global extractive companies evaluated). Forbes Magazine ranked Freeport-McMoRan on its 2019 Best Employers List (2nd best employer in Arizona and 143rd nationally). Newsweek ranked Freeport-McMoRan as one of America’s 300 Most Responsible Companies (ranked 138th). 100 BEST Corporate Responsibility Magazine listed Freeport-McMoRan as one of the CORPORATE 100 Best Corporate Citizens for the 8th year for outstanding environmental, CITIZENS social and governance (ESG) transparency and performance. -

Human Rights and the Mining Sector in Indonesia: a Baseline Study

Mining, Minerals and Sustainable Development October 2001 No. 182 Human Rights and the Mining Sector in Indonesia: A Baseline Study Dr Chris Ballard The Australian National University Canberra, Australia This report was commissioned by the MMSD project of IIED. It remains the sole Copyright © 2002 IIED and WBCSD. All rights reserved responsibility of the author(s) and does not necessarily reflect the views of the Mining, Minerals and MMSD project, Assurance Group or Sponsors Group, or those of IIED or WBCSD. Sustainable Development is a project of the International Institute for Environment and Development (IIED). The project was made possible by the support of the World Business Council for Sustainable Development (WBCSD). IIED is a company limited by guarantee and incorporated in England. Reg. No. 2188452. VAT Reg. No. GB 440 4948 50. Registered Charity No. 800066 Contents Notes To This Report 3 1 Introduction 4 1.1 Terms of Reference 4 1.2 Research Aims and Methods 4 1.3 Report Outline 6 1.4 Acknowledgments 6 2 Human Rights and the Mining Sector in Indonesia 7 – Contextual Issues 7 2.1 Human Rights and the Mining Industry 7 2.2 Human Rights in Indonesia 9 2.3 The Mining Industry in Indonesia 12 3 Human Rights and the Mining Sector in Indonesia 17 – Case Studies 17 3.1 Introduction 17 3.2 Case Study 1 – Ombilin (West Sumatra) 18 3.3 Case Study 2 – PT Inco at Soroako (South Sulawesi) 20 3.4 Case Study 3 – Freeport at Grasberg (Irian Jaya) 22 3.5 Case Study 4 – Rio Tinto at Kelian (East Kalimantan) 32 3.6 Case Study 5 – Newmont at Batu Hijau (Sumbawa, Nusa Tenggara Barat) 36 4 Human Rights and the Mining Sector in Indonesia 39 – Industry Performance 39 4.1 Industry Performance on Human Rights in Indonesia 39 4.2 Gap Analysis 42 4.3 Beyond Compliance: Improving Industry Performance on Human Rights in Indonesia 43 Recommendations 45 5. -

TROUBLED WATERS How Mine Waste Dumping Is Poisoning Our Oceans, Rivers, and Lakes

TROUBLED WATERS HOW MINE WASTE DUMPING IS POISONING OUR OCEANS, RIVERS, AND LAKES Earthworks and MiningWatch Canada, February 2012 TABLE OF CONTENTS EXECUTIVE SUMMARY .......................................................................................................1 TABLE 1. WATER BODIES IMPERILED BY CURRENT OR PROPOSED TAILINGS DUMPING ................................. 2 TABLE 2. MINING CORPORATIONS THAT DUMP TAILINGS INTO NATURAL WATER BODIES .......................... 4 TAILINGS DUMPING 101....................................................................................................5 OCEAN DUMPING ....................................................................................................................................... 7 RIVER DUMPING........................................................................................................................................... 8 TABLE 3. TAILINGS AND WASTE ROCK DUMPED BY EXISTING MINES EVERY YEAR ......................................... 8 LAKE DUMPING ......................................................................................................................................... 10 CAN WASTES DUMPED IN BODIES OF WATER BE CLEANED UP? ................................................................ 10 CASE STUDIES: BODIES OF WATER MOST THREATENED BY DUMPING .................................11 LOWER SLATE LAKE, FRYING PAN LAKE ALASKA, USA .................................................................................. 12 NORWEGIAN FJORDS ............................................................................................................................... -

Grasberg Gold and Copper Mine Indonesia

Grasberg gold and copper mine Indonesia Sectors: Mining On record This profile is no longer actively maintained, with the information now possibly out of date Send feedback on this profile By: BankTrack Created before Nov 2016 Last update: Nov 1 2015 Contact: Leen Schmücker FairFin, Belgium Project website Sectors Mining Location About Grasberg gold and copper mine The Grasberg mine, located in the indonesian province of Papua, on the island New Guinea, just north of Australia, is being run by the mining company Freeport McMoran. The Grasberg mine is the biggest goldmine and the third biggest coppermine in the world. New Guinea is known for its biologically diverse ecosystems and endemic species but it also has great cultural value. In the western part of the island, in the Indonesian province Papua, 1.5 million of the 2.5 million people are indigenous peoples speaking more than 250 different languages. But the area is not only known for its cultural and natural wonders. It is also one of the last places on earth where companies still use a very controversial mining technique; the 'riverine tailings disposal'. This technique, which involves dumping toxic rubble in riversystems, is used by Freeport McMoran at the Grasberg mine. Latest developments May 22 2008 What must happen Friends of the earth Indonesia (Wahli) recommends in its latest report 'The environmental impacts of Freeport-Rio Tinto's Copper and Gold Mining Operation in Papua' the following to the Indonesian government: "Immediately enforce national environmental law. This should be done by halting Freeport-Rio Tinto operations until breaches are remedied, and prosecuting legal breaches which continue today despite warnings in the early 2000s. -

Charging Ahead Responsibly

2020 ANNUAL REPORT ON SUSTAINABILITY / 3 CHARGING AHEAD RESPONSIBLY. RELIABLY. RELENTLESSLY. 2020 ANNUAL REPORT ON SUSTAINABILITY ABOUT FREEPORT-MCMORAN Freeport-McMoRan Inc. (Freeport-McMoRan, Freeport or FCX) is a leading international mining company with headquarters in Phoenix, Arizona. FCX operates large, long-lived, geographically diverse assets with significant proven and probable reserves of copper, gold and molybdenum. FCX’s portfolio of assets includes the Grasberg minerals district in Indonesia (PT Freeport Indonesia or PT-FI), one of the world’s largest copper and gold deposits; and significant mining operations in North America and South America (Freeport Minerals Corporation or FMC), including the large-scale Morenci minerals district in Arizona and the Cerro Verde operation in Peru. RECENT AWARDS & RECOGNITION Freeport was named to Fortune magazine’s 2021 World’s Most Admired Companies list and ranked No. 6 in its industry category. Forbes magazine ranked Freeport on its 2020 World’s Best Employers List (No. 338), 2020 America’s Best Employer by State (No. 16) and 2020 Best Employers for Diversity (No. 458). Newsweek named Freeport as one of America’s 300 Most Responsible Companies. Points of Light named Freeport to the 2020 The Civic 50 list, recognizing the 50 most community-minded companies in the U.S. for the eighth year in a row and was selected as the Materials Sector Leader. Freeport was named to Forbes magazine’s 2020 JUST 100 as one of America’s most JUST Companies (first in Basic Resources and No. 43 nationally). Cover Photo: Our El Abra operations in Chile implemented Chile's voluntary gender equality ordinance to support increased representation in the workforce. -

Mining in Conflicted Lands

Lessons learned from Case Studies of InternationalInternational Investment Financial in Extractive Flows and Land-use Industries and the Environment Best Practices for Transnational Investment in Extractive and Land Use Sectors School of International Service American University Foreword With the wave of globalization and the empowerment of civil societies around the world, foreign investment has become an increasingly important issue due to the inherent social and environmental impacts that foreign companies inflict upon the local communities in which they operate. The results of foreign investment are complicated: some investment improves local economic, environmental, and social conditions, while other investment leads to tensions between transnational companies and local communities. There are currently few broadly agreed-upon standards that guide how foreign companies should invest and behave in host countries in order to achieve not only business benefits, but also social responsibility and environmental sustainability. This portfolio of best and worst practices of foreign investment exhibits both positive and negative cases of foreign investment. This document is the cooperative product of the World Resources Institute (WRI) and the American University (AU) practicum team. IFFE’s Senior Associate, Mr. Hu Tao, and Research Analyst, Denise Leung, worked closely with the practicum team to develop the project. The AU practicum team consisted of professors Dr. Ken Conca and Dr. Judy Shapiro and eleven graduate students: Stephanie DaCosta, Kristin DeValue, Hilary Kirwan, Lauren Lane, John Noel, Sebastian O’Connor, Schuyler Olsson, Jen Richmond, Natnari Sihawong, Toussaint Webster, and Yuxi Zhao. In March 2013, the AU practicum team travelled to Beijing, China, to present their initial research and coordinate with a WRI partner research team from Beijing Normal University. -

Freeport-Mcmoran Copper & Gold Inc

UNITED STATES SECURITIES AND EXCHANGE COMMISSION Washington, D.C. 20549 FORM 10-K (Mark One) [X] ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 For the fiscal year ended December 31, 2010 OR [ ] TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 For the transition period from to Commission File Number: 001-11307-01 Freeport-McMoRan Copper & Gold Inc. (Exact name of registrant as specified in its charter) Delaware 74-2480931 (State or other jurisdiction of (I.R.S. Employer Identification No.) incorporation or organization) 333 North Central Avenue Phoenix, Arizona 85004-2189 (Address of principal executive offices) (Zip Code) (602) 366-8100 (Registrant's telephone number, including area code) Securities registered pursuant to Section 12(b) of the Act: Title of each class Name of each exchange on which registered Common Stock, par value $0.10 per share New York Stock Exchange Securities registered pursuant to Section 12(g) of the Act: None Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act 5 Yes No Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or Section 15(d) of the Act. Yes 5 No Indicate by check mark whether the registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. -

2013 Working Toward Sustainable Development Report

STRENGTH IN RESOURCES 2013 Working Toward Sustainable Development Report Freeport-McMoRan (the Company) is a premier United States-based natural resources company with an industry-leading global portfolio of mineral assets, significant oil and gas resources and a growing production profile. Freeport-McMoRan is the world’s largest publicly traded copper producer. Freeport-McMoRan’s portfolio of assets includes the Grasberg minerals district in Indonesia, one of the world’s largest copper and gold deposits; significant mining operations in the Americas, including the large-scale Morenci minerals district in North America and the Cerro Verde operation in South America; the Tenke Fungurume minerals district in the Democratic Republic of Congo (DRC); and significant oil and natural gas assets in North America, including reserves in the Deepwater Gulf of Mexico (GOM), onshore and offshore California, in the Eagle Ford shale play in Texas, in the Haynesville shale plays in Louisiana, in the Madden area in Central Wyoming, and an industry-leading position in the emerging Inboard Lower Tertiary/Cretaceous natural gas trend in the shallow waters of the GOM and onshore in South Louisiana. ABOUT THIS REPORT EXTERNAL ASSURANCE This 2013 Working Toward Sustainable Development (WTSD) Since 2005, Freeport-McMoRan has sought independent report is meant to provide stakeholders with summary information verification of its annual sustainability reports. We are on our sustainability programs, including policies, systems and implementing the International Council performance data. Additional information is located on our website on Mining & Metals (ICMM) Sustainable at www.fcx.com, and a 5-year trend of performance metrics is Development Framework, including presented on page 33. -

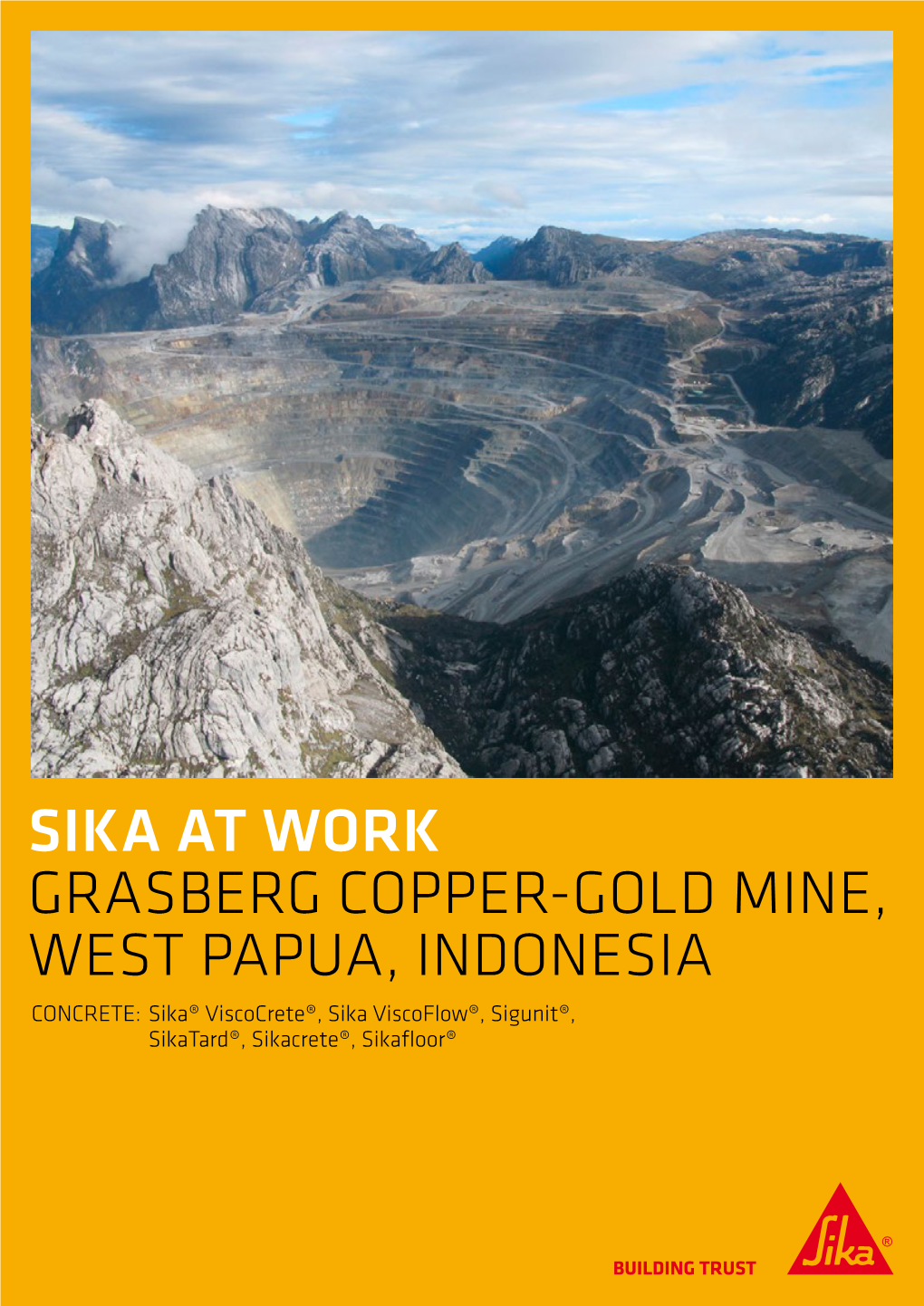

Environmental Geography of Southeast Asia Case Study: Grasberg Mineral District by Michelle Crane Teacher Consultant for the Texas Alliance for Geographic Education

Environmental Geography of Southeast Asia Case Study: Grasberg Mineral District by Michelle Crane Teacher Consultant for the Texas Alliance for Geographic Education Texas Alliance for Geographic Education; http://www.geo.txstate.edu/tage/ September 2013 Grasberg Mineral District . Located on New Guinea in Indonesia . Single largest reserve of gold in the world . Second largest reserve of copper . The mine is owned by Freeport McMoRan Copper and Gold, which has a controlling interest, the Government of Indonesia and 2 other companies. The mine is operated by PT Freeport Indonesia and employs 18,000 people. Texas Alliance for Geographic Education; http://www.geo.txstate.edu/tage/ September 2013 Freeport-McMoRan . Freeport-McMoRan is a global mineral mining company. Copper, gold, molybdenum, and cobalt are the primary minerals they mine. Freeport-McMoRan began mining in Grasberg in the early 1970’s. One billion pounds of copper and 1 – 2 ½ million ounces of gold per year are produced. Watch a video produced by Freeport-McMoRan about their global operations. http://www.fcx.com/videos/Connect_English.htm Texas Alliance for Geographic Education; http://www.geo.txstate.edu/tage/ September 2013 Open Pit Mine . Mine was originally a mountain over 4000 meters high. The mine is 3000 meters deep at present. Open pit will be exhausted around 2015 Texas Alliance for Geographic Education; http://www.geo.txstate.edu/tage/ September 2013 Satellite view of the mine Texas Alliance for Geographic Education; http://www.geo.txstate.edu/tage/ September 2013 A Perspective of how large the mine really is Texas Alliance for Geographic Education; http://www.geo.txstate.edu/tage/ September 2013 Environmental Impact .