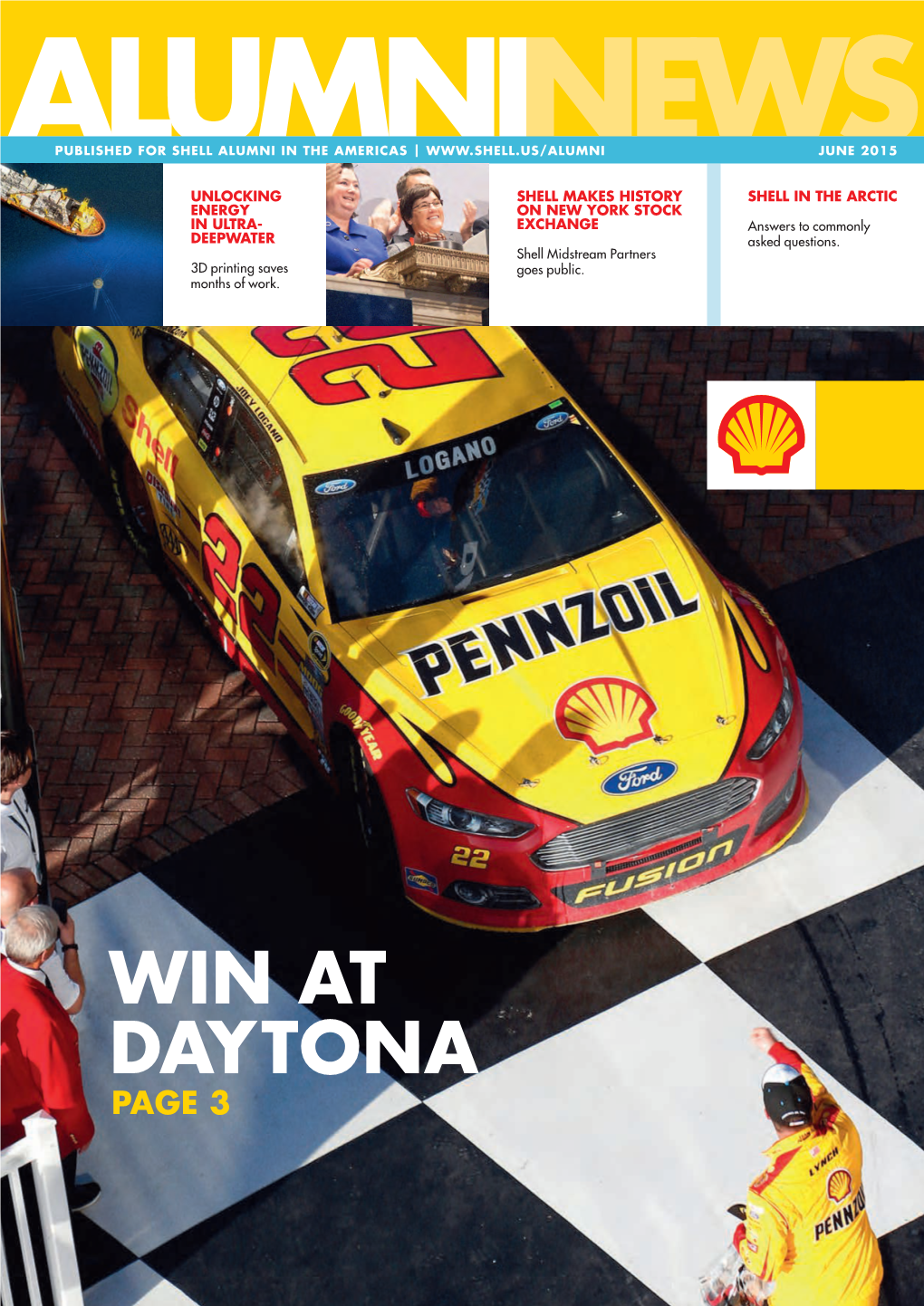

Win at Daytona Page 3

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Shell) Has Applied to the Alberta Energy and Utilities Board (EUB

2007 NOTICE OF APPLICATION SHELL CANADA LIMITED SCOTFORD UPGRADER 2 PROJECT ALBERTA ENERGY AND UTILITIES BOARD APPLICATION NO. 1520445 ALBERTA ENVIRONMENT ENVIRONMENTAL PROTECTION AND ENHANCEMENT ACT APPLICATION NO. 001-240711 WATER ACT FILE NO. 60411 Take Notice that Shell Canada Limited (Shell) has applied to the Alberta Energy and Utilities Board (EUB) and Alberta Environment (AENV) for approval to construct, operate, and reclaim a 63,600 cubic metres per day bitumen upgrader, the Shell Scotford Upgrader 2 project. The proposed project will be located on portions of Sections 4, 5, 8, 9, and 16, Township 56, Range 21 West of the 4th Meridian and portions of Section 28, 30 and 33, Township 55, Range 21 West of the 4th Meridian. The proposed project will be located within the Scotford Complex near Fort Saskatchewan, Alberta, and will be adjacent to, but separate from, the existing Scotford upgrader. The proposed project will be developed in four phases, each processing 15,900 cubic metres per day of bitumen. This Notice of Application is being distributed to advise interested persons that the applications are available, and that the EUB, AENV and other government departments are now undertaking a review of the applications. Nature of the Application In support of their proposal, Shell has prepared and submitted the following documents: z Application No.1520445 to the EUB, pursuant to Section 11 of the Oil Sands Conservation Act. In support of its proposal Shell has also submitted an Environmental Impact Assessment (EIA) report to AENV. The EIA report forms part of the application to the EUB. -

Update on Waterton Development Plans

CHINOOK NEWS THE NEWSLETTER FOR THE SHELL WATERTON REGION FALL 2015 FACILITY UPDATE PETER ARGUMENT, OPERATIONS MANAGER FOR SHELL’S WATERTON COMPLEX IT’S BEEN ALMOST 18 MONTHS SINCE I STEPPED INTO THE ROLE OF OPERATIONS MANAGER AT WATERTON, TAKING OVER FOR JIM LITTLE. WHAT A WONDERFUL AND CHALLENGING 18 MONTHS IT’S BEEN. First, to be able to live in the grandeur that is southern And we’ve done it while maintaining our gas Alberta is a gift for me and my family. I’ve been with production and reducing our unplanned deferment. Shell for over 15 years – before my assignment in Through these innovative efforts, we have improved Pincher Creek I worked on the front-end of several our competitiveness and saved many hundreds of sour gas projects at Shell’s joint venture in Oman, thousands of dollars through improved efficiency was Maintenance Superintendent at Shell’s Jumping and reduced waste. Pound facility and was Operations Engineer at the We continue to look for ways to be better at what Scotford Refinery. While international experiences we do in this continuingly challenging environment are amazing, Canada is home for the family so it’s – it’s simply called continuous process improvement. nice to be back in Canada in the spectacular setting Our improvement efforts have been recognized by at Waterton. our parent company Royal Dutch Shell as well: the Foothills asset, of which Waterton is a part – recently doing the right thing here at the Complex as they The Waterton plant is doing well, thanks to the was a runner up in a Shell global competition which are in the community. -

Shell" Transport and Trading Company, Ltd

THE ECONOMIC WEEKLY May 21, 1955 The "Shell" Transport and Trading Company, Ltd. Greater Operational Activity Results in Increased Sales Volume Heavy Capital Expenditure Inescapable Substantially Enlarged World Consumption Sir Frederick Godber's views on Oil Prices HE Annual General Meeting of through the capitalization of part of ber, was widely appreciated and T The " Shell " Transport and the company's share premiums re favourably commented upon, as Trading Company, Limited, will be serve. affording an opportunity of following held on June 1 at The Chartered In more closely the current trading When commenting on this issue surance Institute, 20, Aldermanbury, results of the group. I am glad to in my statement last year, I said that say that this year we propose to London, E.C. one of its objects was to broaden the publish similar results on a quarterly The following is the statement by basis of the ownership of the com basis, and that figures for the first the Chairman, Sir Frederick Godber, pany. You may, therefore, be inter quarter will be available within a few which has been circulated with the ested to learn that during 1954 re weeks. report and accounts for the year end gistered Ordinary stockholders in ed December 31, 1954: — creased by approximately 10,000, and I will now proceed to the report in December numbered over 142,000. on the group financial results for The Board of Directors You will appreciate, of course, that 1954. Little more than a year after his the number of individuals who own THE ROYAL DUTCH/SHELL resignation from the board owing to the equity of the company must ill health, Sir Andrew Agnew, our exceed this figure by a substantial GROUP REPORT ON THE colleague for so many years, has margin, there being no record of those YEAR 1934 passed away. -

7-Eleven & Shell

MARCUS & MILLICHAP OFFERING MEMORANDUM Activity#Z0380619 7 - ELEVEN & SHELL 8541 WEST FREEWAY FORT WORTH, TEXAS 76116 OFFERING MEMORANDUM | 7 - ELEVEN & SHELL 8541 WEST FREEWAY, FORT WORTH, TEXAS 76116 INVESTMENT OVERVIEW INVESTMENT HIGHLIGHTS • Irreplaceable Off-Ramp Location • Absolute NNN Lease with Zero Landlord Responsibilities • Income Tax Free State • Corner Location with Dedicated Turn Lane • Large Pylon Sign with Freeway Visibility • 80,523 People in Three Mile Radius • 106,194 Vehicles Per Day on Interstate 30 • 7-Eleven is the World’s Largest Operator, Franchisor & Licensor of INVESTMENT SUMMARY Convenient Stores The Conway Group at Marcus & Millichap is pleased to present th • Fort Worth is the 4 Most Populous Metropolitan Area in the the sale of this 3,042 square foot 7-Eleven and Shell property in United States Fort Worth, Texas. The subject property operates as a NNN Lease, with zero landlord responsibilities. This convenient store sits on 0.74 acres of and, with filling stations present. Situated on a signalized OFFERING SUMMARY corner, with a dedicated turn lane and pylon signage, the subject property sees over 106,194 Vehicles Per Day on Interstate PRICE $1,974,000 30. Located in a Tax Free State, this 7-Eleven offers great visibility and easy access. NOI $101,640 th C A P R A T E 5.15 % Fort Worth is the 15 -Largest City in the United States, with a population of 875,000 people. Population growth is up 8.50 PRICE/SF $648.92 percent in a one mile radius from the property. RENT/SF $33.41 7-Eleven was founded in 1927 and has now grown and evolved L E A S E T Y P E NNN into an international chain of convenience stores, operating nearly 7,800 company-owned and franchised stores in North GROSS LEASABLE AREA 3,042 SF America. -

COGENERATION PLANT and HYDROGEN PIPELINE Addendum to Decision 2000-30 FORT SASKATCHEWAN AREA Applications No.990464 and 1051618

ALBERTA ENERGY AND UTILITIES BOARD Calgary Alberta SHELL CANADA LIMITED COGENERATION PLANT AND HYDROGEN PIPELINE Addendum to Decision 2000-30 FORT SASKATCHEWAN AREA Applications No.990464 and 1051618 DECISION 2000-30 The Alberta Energy and Utilities Board (Board/EUB) issued Decision 2000-30 (attached) on May 30, 2000, approving the applications. This addendum provides the reasons for the Board’s decisions. 1 INTRODUCTION 1.1 Application 990464 Shell Canada Limited (Shell) applied to the Board, pursuant to Section 9 of the Hydro and Electric Energy Act, for approval to construct and operate a 150 megawatt (MW) natural-gas- fired cogeneration plant on its approved Scotford Upgrader site. This site is adjacent to the Scotford Refinery in Strathcona County, about 14 km north of Fort Saskatchewan, Alberta. The cogeneration plant would include • a natural-gas-fired combustion gas turbine, which would generate 80 MW of electric power, • a heat recovery steam generator (HRSG), and • a steam turbine, which would generate about 70 MW of electric power. The applicant described the cogeneration process as follows: • Natural gas would be fired in the combustion turbine to generate about 80 MW of electricity. • Heat would be recovered from the hot combustion turbine exhaust gases in the HRSG, which would produce steam. • The steam would be delivered to the upgrader to help meet its steam requirements. • High-pressure HRSG steam and the excess high-pressure steam from the upgrader process units would be delivered to the steam turbine to produce an additional 70 MW of electricity. 1.2 Application 1051618 Shell also applied, pursuant to Part 4 of the Pipeline Act, for approval to construct and operate approximately 8.7 km of 762 mm outside diameter pipeline to transport hydrogen gas from the existing Dow Chemical Canada Inc. -

Valid Operating Permits

Valid Petroleum Storage Permits (as of September 15, 2021) Permit Type of Business Name City/Municipality Region Number Facility 20525 WOODLANDS SHELL UST Woodlands Interlake 20532 TRAPPERS DOMO UST Alexander Eastern 55141 TRAPPERS DOMO AST Alexander Eastern 20534 LE DEPANNEUR UST La Broquerie Eastern 63370 LE DEPANNEUR AST La Broquerie Eastern 20539 ESSO - THE PAS UST The Pas Northwest 20540 VALLEYVIEW CO-OP - VIRDEN UST Virden Western 20542 VALLEYVIEW CO-OP - VIRDEN AST Virden Western 20545 RAMERS CARWASH AND GAS UST Beausejour Eastern 20547 CLEARVIEW CO-OP - LA BROQUERIE GAS BAR UST La Broquerie Red River 20551 FEHRWAY FEEDS AST Ridgeville Red River 20554 DOAK'S PETROLEUM - The Pas AST Gillam Northeast 20556 NINETTE GAS SERVICE UST Ninette Western 20561 RW CONSUMER PRODUCTS AST Winnipeg Red River 20562 BORLAND CONSTRUCTION INC AST Winnipeg Red River 29143 BORLAND CONSTRUCTION INC AST Winnipeg Red River 42388 BORLAND CONSTRUCTION INC JST Winnipeg Red River 42390 BORLAND CONSTRUCTION INC JST Winnipeg Red River 20563 MISERICORDIA HEALTH CENTRE AST Winnipeg Red River 20564 SUN VALLEY CO-OP - 179 CARON ST UST St. Jean Baptiste Red River 20566 BOUNDARY CONSUMERS CO-OP - DELORAINE AST Deloraine Western 20570 LUNDAR CHICKEN CHEF & ESSO UST Lundar Interlake 20571 HIGHWAY 17 SERVICE UST Armstrong Interlake 20573 HILL-TOP GROCETERIA & GAS UST Elphinstone Western 20584 VIKING LODGE AST Cranberry Portage Northwest 20589 CITY OF BRANDON AST Brandon Western 1 Valid Petroleum Storage Permits (as of September 15, 2021) Permit Type of Business Name City/Municipality -

NACE Tour and Dinner Meeting Shell Scotford Upgrader Shell Scotford Upgrader

NACE Tour and Dinner Meeting Tuesday, May 20, 2008 Shell Scotford Upgrader Dow Center, Fort Saskatchewan, AB TTTOOOPPPIIIICCC Shell Scotford Upgrader Plant Tour SSSPPPEEEAAAKKKEEERRR Harm de Groot P.Eng. Engineering Services Coordinator Shell Canada Scotford Upgrader It has been a while since NACE Edmonton has organized a plant tour so we are happy to announce that Shell has offered to organize a plant tour of their Upgrader plant for NACE Edmonton, ASM and AWS members. For now the tour is limited to 40 people so please make sure that if you are interested sign up in time. After the tour there will be a dinner and a presentation on materials and corrosion issues in Upgraders by Harm de Groot. The Scotford Upgrader is located next to Shell Canada's Scotford Refinery near Fort Saskatchewan, Alberta. The Scotford Upgrader uses hydrogen-addition technology to upgrade the high viscosity "extra heavy" crude oil (called bitumen) from the Muskeg River Mine into a wide range of synthetic crude oils. A significant portion of the output of the Scotford Upgrader is sold to the Scotford Refinery. Both light and heavy crudes are also sold to Shell's Sarnia Refinery in Ontario. The balance of the synthetic crude is sold to the general marketplace. The Scotford Upgrader - which is part of the joint venture project between Shell Canada, Chevron Canada (a wholly owned subsidiary of Chevron Corporation) and Western Oil Sands – is operated by Shell Canada. UUUpppgggrrraaadddiiiiiinnnggg Upgrading is the process of breaking large hydrocarbon molecules (such as bitumen) into smaller ones by increasing the hydrogen to carbon ratio. -

Celebrate Success

Community: Strathcona county Economic DEvElopmEnt & touriSm ProjeCt: ShEll ScotforD upgraDEr ExpanSion onE Celebrate Success entry for the 2011 Alex metcalfe AwArds Strathcona County Economic Development and Tourism Shell Scotford Upgrader Expansion One Entry for Alex Metcalfe Award (Large Population 50,001) Executive Summary Shell Canada - Scotford Upgrader Expansion One The Scotford Upgrader is located next to Shell Canada’s Scotford Refinery in Strathcona County, Alberta. The Scotford Upgrader uses hydrogen-addition technology to upgrade the high viscosity “extra heavy” crude oil (called bitumen) from the Muskeg River Mine into a wide range of synthetic crude oils. A significant portion of the output of the Scotford Upgrader is sold to the Scotford Refinery. Both light and heavy crudes are also sold to Shell’s Sarnia Refinery in Ontario. The balance of the synthetic crude is sold to the general Shell Scotford Upgrader marketplace. Expansion One increased production by 100,000 What is Upgrading? barrels per day. Upgrading is the process of breaking large hydrocarbon molecules (such as bitumen) into smaller ones by increasing the hydrogen to carbon ratio. These upgraded crude oils are suitable feedstocks for refineries, which will process them into refined products like gasoline. Scotford’s upgrading process adds hydrogen to the bitumen, breaking up the large hydrocarbon molecules - this process is called hydrogen-addition or hydrogen-conversion. The original Upgrader completed in 2003 had a capacity of 155,000 barrels per day (bpd). Shell Expansion One will add 100,000 bpd. This project will start production in 2011. Most of the construction was completed in 2010. Economic Impact • Construction jobs: Peaked in 2010 at 12,000 workers on site. -

Halronmicreditapplication.Pdf

CONTINUING GUARANTY FOR VALUE RECEIVED, and to induce HALRON LUBRICANTS INC. of Green Bay, Wisconsin (“Halron”) to extend credit to (“Debtor”), the Insert Company Name Here undersigned (“Guarantor”, whether one or more) jointly and severally guarantee payment to Halron when due or, to the extent not prohibited by law, at the time Debtor becomes the subject of bankruptcy or other insolvency proceedings, all debts, obligations and liabilities of every kind and description, arising out of the credit granted by Halron to Debtor (the “Obligations”), and to the extent not prohibited by law, all costs, expenses and fees at any time paid or incurred in endeavoring to collect all or part of the Obligations or to realize upon this Guaranty. This includes, but is not limited to any collection fee, legal proceeding and/or reasonable attorney’s fees. No claim which Guarantor may have against a co-guarantor of any of the Obligations or against Debtor shall be enforced nor any payment accepted until the Obligations are finally paid in full. To the extent not prohibited by law, this Guaranty is valid and enforceable against Guarantor even though any Obligation is invalid and unenforceable against Debtor. To the extent not prohibited by law, Guarantor expressly waives notice of the acceptance, the creation of any present or future Obligation, default under any Obligation, proceedings to collect from Debtor or anyone else, and all diligence of collection and presentment, demand, notice and protest. This is a continuing Guaranty and shall remain in full force and effect until Halron receives written notice of its revocation signed by Guarantor or actual notice of the death of Guarantor. -

Shell QRA Q2 2021

ROYAL DUTCH SHELL PLC 2ND QUARTER 2021 AND HALF YEAR UNAUDITED RESULTS SUMMARY OF UNAUDITED RESULTS Quarters $ million Half year Q2 2021 Q1 2021 Q2 2020 %¹ Reference 2021 2020 % 3,428 5,660 (18,131) -39 Income/(loss) attributable to shareholders 9,087 (18,155) +150 2,634 4,345 (18,377) -39 CCS earnings attributable to shareholders Note 2 6,980 (15,620) +145 5,534 3,234 638 +71 Adjusted Earnings² A 8,768 3,498 +151 13,507 11,490 8,491 Adjusted EBITDA (CCS basis) A 24,997 20,031 12,617 8,294 2,563 +52 Cash flow from operating activities 20,910 17,415 +20 (2,946) (590) (2,320) Cash flow from investing activities (3,535) (5,039) 9,671 7,704 243 Free cash flow G 17,375 12,376 4,383 3,974 3,617 Cash capital expenditure C 8,357 8,587 8,470 9,436 8,423 -10 Operating expenses F 17,905 17,042 +5 8,505 8,724 7,504 -3 Underlying operating expenses F 17,228 16,105 +7 3.2% (4.7)% (2.9)% ROACE (Net income basis) D 3.2% (2.9)% ROACE on an Adjusted Earnings plus Non- 4.9% 3.0% 5.3% controlling interest (NCI) basis D 4.9% 5.3% 65,735 71,252 77,843 Net debt E 65,735 77,843 27.7% 29.9% 32.7% Gearing E 27.7% 32.7% Total production available for sale (thousand 3,254 3,489 3,379 -7 boe/d) 3,371 3,549 -5 0.44 0.73 (2.33) -40 Basic earnings per share ($) 1.17 (2.33) +150 0.71 0.42 0.08 +69 Adjusted Earnings per share ($) B 1.13 0.45 +151 0.24 0.1735 0.16 +38 Dividend per share ($) 0.4135 0.32 +29 1. -

Rouseville Refinery Plant 1

Environmental Covenant When recorded, return to: GOC Property Holdings, LLC, 175 Main Street, Oil City, PA 16301 GRANTOR: GOC Property Holdings, LLC PROPERTY ADDRESS: 55 Main Street, Rouseville, PA 16344 ENVIRONMENTAL COVENANT This Environmental Covenant is executed pursuant to the Pennsylvania Uniform Environmental Covenants Act, Act No. 68 of2007, 27 Pa. C.S. §§ 6501-6517 (UECA). This Environmental Covenant subjects the Property identified in Paragraph 1 to the activity and/or use limitations in this document. As indicated later in this document, this Environmental Covenant has been approved by the Pennsylvania Department of Environmental Protection (Department). 1. Property affected. The property affected (Property) by this Environmental Covenant is located in the Borough ofRouseville, Venango County. The postal street address of the Property is: 55 Main Street, Rouseville, PA. The County Parcel Identification No. of the Property is: 25-03-01 C and 25-03-01D. The latitude and longitude of the center of the Property affected by this Environmental Covenant is: 41 degrees - 28 minutes - 0.69 seconds (north) and 79 degrees - 41 minutes - 31.45 seconds (west). The property has been known by the following name: Rouseville Refinery Plant 1. The Primary Facility (PF) No. of the Rouseville Refinery Plant 1 is: 612975. The Tank Facility ID No. ofthe Rouseville Refinery Plant 1 is: 61-91604. A complete description of the Property is attached to this Environmental Covenant as Exhibit. A. A map of the Property is attached to this Environmental Covenant as Exhibit B. 2. Property Owner I GRANTOR. GOC Property Holdings, LLC, ("GOC") is the Owner of the Property and "GRANTOR" of this Environmental Covenant. -

GOVERNMENT Steps up Fight to Curb Global Warming

THE NETL CARBON SEQUESTRATION NEWSLETTER: ANNUAL INDEX SEPTEMBER 2008 – AUGUST 2009 This is a compilation of the past year’s monthly National Energy Technology Laboratory Carbon Sequestration Newsletter. The newsletter is produced by the NETL to provide information on activities and publications related to carbon sequestration. It covers domestic, international, public sector, and private sector news. This compilation covers newsletters issued between September 2008 and August 2009. It highlights the primary news and events that have taken place in the carbon sequestration arena over the past year. Information that has become outdated (e.g. conference dates, paper submittals, etc.) was removed. To navigate this document please use the Bookmarks tab or the Acrobat search tool (Ctrl+F). To subscribe to this newsletter, please visit: http://www.netl.doe.gov/technologies/carbon_seq/refshelf/subscribe.html. HIGHLIGHTS ............................................................................................................................................ 1 SEQUESTRATION IN THE NEWS .............................................................................................................. 9 SCIENCE................................................................................................................................................. 22 POLICY .................................................................................................................................................. 31 GEOLOGY .............................................................................................................................................