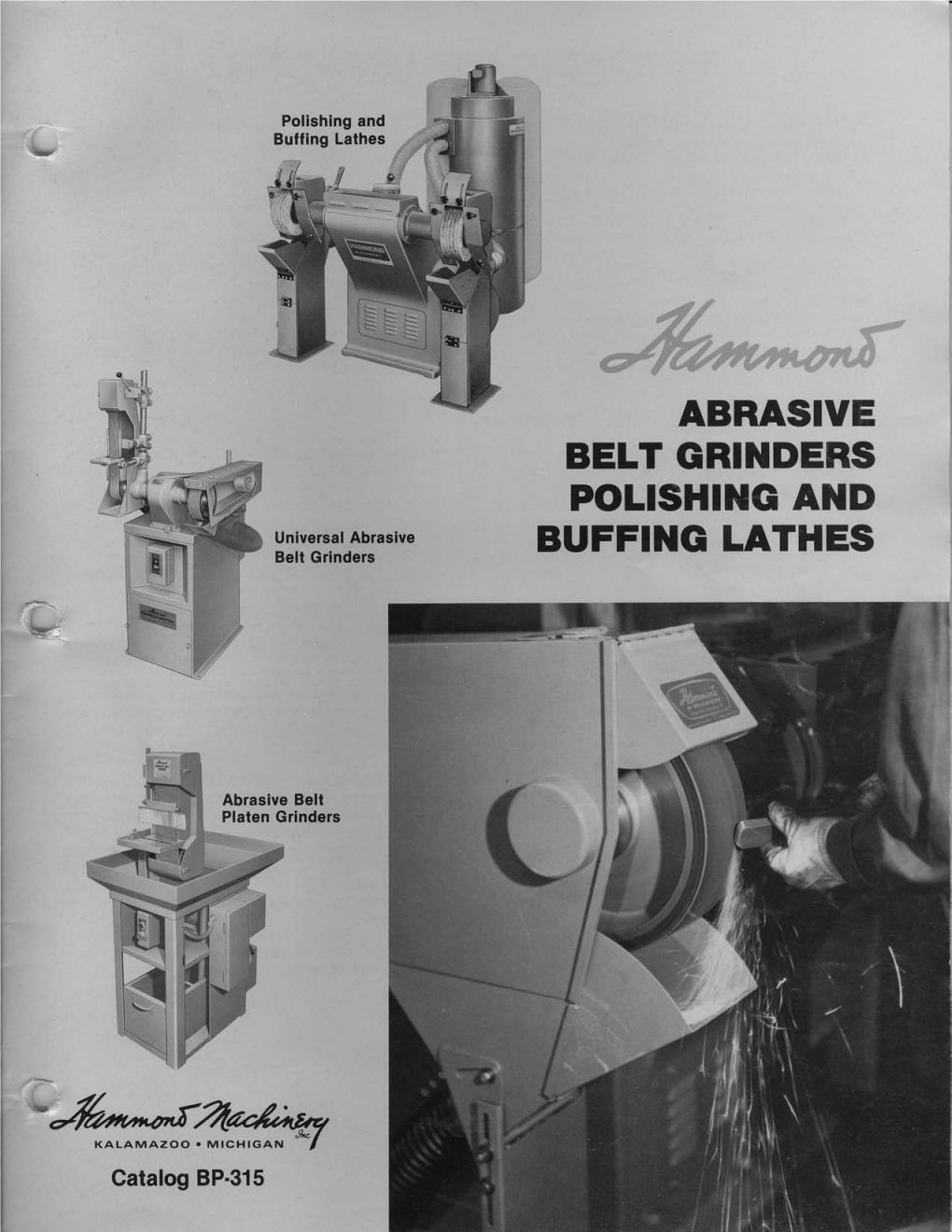

Abrasive Belt Grinders Polishing and Buffing Lathes

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Troubleshooting Decorative Electroplating Installations, Part 5

Troubleshooting Decorative Electroplating Installations, Part 5: Plating Problems Caused Article By Heat & Bath Temperature Fluctuations by N.V. Mandich, CEF, AESF Fellow Technical Technical In previous parts of this series, emphasis was given The fast-machining steels must then be carburized to troubleshooting of the sequences for pre-plating or case-hardened to obtain a surface with the hardness and electroplating over metals, Parts 1 and 2;1 required to support the top chromium electroplate. the causes, symptoms and troubleshooting for Case hardening is the generic term covering several pores, pits, stains, blistering and “spotting-out” processes applicable to steel or ferrous alloys. It changes phenomena, Part 3;2 and troubleshooting plating on the surface composition of the top layer, or case, by plastic systems, Part 4.3 Here in Part 5, causes and adsorption of carbon, nitrogen or a mixture of the two. some typical examples of problems that occur in By diffusion, a concentration gradient is created. The electroplating as a result of a) thermal, mechanical heat-treatments and the composition of the steel are surface treatments, b) the metallurgy of the part to additional variables that should be addressed and taken be plated or c) effects of plating bath temperature into account in the electroplating procedure. on plating variables and quality of the deposits When discussing the effect of heat-treatment on are discussed. subsequent electroplating processes it is necessary to zero in on the type of heat-treatment involved. We Nearly every plater has at one time or another had the can defi ne the heat-treatment process as changing the experience of trying to plate parts that simply would characteristics of the parts by heating above a certain not plate. -

UDDEHOLM STAVAX® ESR © UDDEHOLMS AB No Part of This Publication May Be Reproduced Or Transmitted for Commercial Purposes Without Permission of the Copyright Holder

UDDEHOLM STAVAX® ESR © UDDEHOLMS AB No part of this publication may be reproduced or transmitted for commercial purposes without permission of the copyright holder. This information is based on our present state of knowledge and is intended to provide general notes on our products and their uses. It should not therefore be construed as a warranty of specific properties of the products described or a warranty for fitness for a particular purpose. Classified according to EU Directive 1999/45/EC For further information see our “Material Safety Data Sheets”. Edition 11, 05.2013 The latest revised edition of this brochure is the English version, SS-EN ISO 9001 which is always published on our web site www.uddeholm.com SS-EN ISO 14001 UDDEHOLM STAVAX ESR UDDEHOLM STAVAX ESR Uddeholm Stavax ESR is a premium stainless mould steel for small and medium inserts and cores. Uddeholm Stavax ESR combines corrosion and wear resistance with excellent polishability, good machinability and stability in hardening. Mould maintenance requirement is reduced by assuring that core and cavity surfaces retain their original finish over extended operating periods. When compared with non stainless mould steel, Uddeholm Stavax ESR offers lower production costs by maintaining rust free cooling channels, assuring consistent cooling and cycle time. This classic stainless tool steel is the right choice when rust in production is unacceptable and where requirements for good hygiene are high, as within the medical industry, optical industry and for other high quality transparent parts. Uddeholm Stavax ESR is a part of the Uddeholm Stainless Concept 3 UDDEHOLM STAVAX ESR General Applications Uddeholm Stavax ESR is a premium grade Uddeholm Stavax ESR is recommended for all stainless tool steel with the following proper- types of moulding tools and its special proper- ties: ties make it particularly suitable for moulds •good corrosion resistance with the following demands: •excellent polishability • Corrosion/staining resistance, i.e. -

Crystalite®Lapidary & Glass Products

CRYSTALITE CORPORATION CRYSTALITE® LAPIDARY & GLASS PRODUCTS An Abrasive Technology Company WARNING: Cancer DIAMOND WHEELS www.PWarnings.ca.gov Crystalring® This efficient, lightweight wheel features a uniform, continuous diamond coating. No voids exist in the seamless steel rim of this electroplated wheel. Crystalring® wheels are designed to run on conventional cabochon units operating at 1725 rpm. The 1” arbor hole is bushed to 3/4”, 5/8”, and 1/2”. WARNING Mesh : Cancer4” x 1-1/2” 6” x 1” 6” x 1-1/2” 8” x 1-1/2” www.PWarnings.ca.gov 60 C5321290 C5322010 C5323210 80 C5322030 C5323230 100 C5320150 C5321310 C5322050 C5323250 180 C5321330 C5322070 C5323270 220 C5320170 C5321350 C5322090 C5323290 360 C5320190 C5321370 C5322110 C5323310 600 C5320210 C5321390 C5322130 C5323330 1200 C5320230 Turbine Wheel® This diamond wheel has a unique, sawtoothed profile. As the crests wear, sharp fresh diamond is exposed, making it one of the fastest roughing wheels ever built Diamondback™ for preforming agate, jasper, and other hard stones. This aggressive diamond wheel is uniquely designed with an The 1” arbor hole is bushed to 3/4”, 5/8”, and 1/2”. interrupted cutting surface which delivers a definite metallic uplift. Recommended operating speed is 1500 to 2000 rpm. It contains one-third more diamond than our regular Crystalring® wheel, producing a longer lasting wheel with a higher cutting rate. WARNINGMesh : 6”Cancer x 1-1/2” 8” x 1-1/2” The 360 mesh wheel is capable of roughing stones while yielding a www.PWarnings.ca.gov gentle finish. The 1” arbor hole is bushed to 3/4”, 5/8”, and 1/2”. -

Investigating the Effect of Post Processing Procedures On

Investigating the Effect of Post Processing Procedures on Corrosion Resistance of Additively Manufactured 316L Stainless Steel Science and Technology Program Research and Development Office Final Report No. ST-2020-20035 Technical Memorandum No. 8540-2020-20035 50 microns U.S. Department of the Interior September 2020 Form Approved REPORT DOCUMENTATION PAGE OMB No. 0704-0188 The public reporting burden for this collection of information is estimated to average 1 hour per response, including the time for reviewing instructions, searching existing data sources, gathering and maintaining the data needed, and completing and reviewing the collection of information. Send comments regarding this burden estimate or any other aspect of this collection of information, including suggestions for reducing the burden, to Department of Defense, Washington Headquarters Services, Directorate for Information Operations and Reports (0704-0188), 1215 Jefferson Davis Highway, Suite 1204, Arlington, VA 22202-4302. Respondents should be aware that notwithstanding any other provision of law, no person shall be subject to any penalty for failing to comply with a collection of information if it does not display a currently valid OMB control number. PLEASE DO NOT RETURN YOUR FORM TO THE ABOVE ADDRESS. 1. REPORT DATE (DD-MM-YYYY) 2. REPORT TYPE 3. DATES COVERED (From - To) 09-30-2020 Research FY20 – FY20 4. TITLE AND SUBTITLE 5a. CONTRACT NUMBER Investigating the Effect of Post Processing Procedures on Corrosion 20XR0680A1-RY15412020PE20035/X0035 Resistance of Additively Manufactured 316L Stainless Steel 5b. GRANT NUMBER 5c. PROGRAM ELEMENT NUMBER 1541 (S&T) 6. AUTHOR(S) 5d. PROJECT NUMBER Stephanie Prochaska, M.S., Materials Engineer ST-2020-20035 8540-2020-45 5e. -

An Introduction to Buffing and Polishing

AN INTRODUCTION TO BUFFING AND POLISHING 7696 Route 31, Lyons NY 14489 http://www.caswellplating.com (315) 946-1213 Page 1 To Order Call: 315-946-1213 AN INTRODUCTION TO BUFFING & POLISHING Buffing and polishing using wheels and ‘compounds’ is somewhat like using wet and dry sanding paper, only much faster. Instead of using ‘elbow grease’ you will be using the power and speed of an electric motor. The edge, or face, of the wheel is the ‘sanding block’, which carries a thin layer of compound’ which is the sandpaper. Varying types of wheel are available, and the different grades of com- pound are scaled similar to sandpaper. The compounds are made from a wax substance which has the different abrasive powders added to it. When this hard block is applied to the edge of a spinning buffing wheel, the heat from the friction melts the wax, and both wax and abrasive are applied in a thin slick to the face of the wheel. The objective of buffing and polishing is to make a rough surface into a smooth one and, of course, each work piece will be in a different condition, so will need different procedures. Imagine the surface magnified thousands of times, it will look like jag- ged mountains and valleys. By repeated abrasion, you are going to wear down those mountains until they are old, soft, rolling hills! Then they will not dissipate the light, but reflect it. It is the reflection that makes the buffed part appear shiny. TRICKS OF THE TRADE Repairing small dents. Sand the inside of the part with emery paper. -

The Dynisco Extrusion Processors Handbook 2Nd Edition

The Dynisco Extrusion Processors Handbook 2nd edition Written by: John Goff and Tony Whelan Edited by: Don DeLaney Acknowledgements We would like to thank the following people for their contributions to this latest edition of the DYNISCO Extrusion Processors Handbook. First of all, we would like to thank John Goff and Tony Whelan who have contributed new material that has been included in this new addition of their original book. In addition, we would like to thank John Herrmann, Jim Reilly, and Joan DeCoste of the DYNISCO Companies and Christine Ronaghan and Gabor Nagy of Davis-Standard for their assistance in editing and publication. For the fig- ures included in this edition, we would like to acknowledge the contributions of Davis- Standard, Inc., Krupp Werner and Pfleiderer, Inc., The DYNISCO Companies, Dr. Harold Giles and Eileen Reilly. CONTENTS SECTION 1: INTRODUCTION TO EXTRUSION Single-Screw Extrusion . .1 Twin-Screw Extrusion . .3 Extrusion Processes . .6 Safety . .11 SECTION 2: MATERIALS AND THEIR FLOW PROPERTIES Polymers and Plastics . .15 Thermoplastic Materials . .19 Viscosity and Viscosity Terms . .25 Flow Properties Measurement . .28 Elastic Effects in Polymer Melts . .30 Die Swell . .30 Melt Fracture . .32 Sharkskin . .34 Frozen-In Orientation . .35 Draw Down . .36 SECTION 3: TESTING Testing and Standards . .37 Material Inspection . .40 Density and Dimensions . .42 Tensile Strength . .44 Flexural Properties . .46 Impact Strength . .47 Hardness and Softness . .48 Thermal Properties . .49 Flammability Testing . .57 Melt Flow Rate . .59 Melt Viscosity . .62 Measurement of Elastic Effects . .64 Chemical Resistance . .66 Electrical Properties . .66 Optical Properties . .68 Material Identification . .70 SECTION 4: THE SCREW AND BARREL SYSTEM Materials Handling . -

Electrode Polishing and Care

LCEC and EC Accessories January 2001 A-1302 ELECTRODE POLISHING AND CARE Cross-Flow Cell Package UniJet Cell Package C3 Voltammetry Cell Stand Rotating Disk Electrode Low Current Module Calomel Reference Electrode Bioanalytical www.bioanalytical.com Systems, Inc 2701 Kent Avenue West Lafayette Indiana 47906 Thank you for your recent purchase from BAS. This manual includes instructions for several different products, and should be used as a supplement to various BAS instrument manuals. Due to continuing development of our line, some products may be slightly different in appearance from the drawings depicted here. These changes should not affect performance or the relevant use and maintenance instructions. Check the inserts that may be provided with individual electrodes for additional notes or revisions. Working electrodes are warranted for 60 days from date of shipment. Reference electrodes are considered consumable items and are not covered by a timed warranty period. We warrant only that they are viable as shipped. Their lifetime after purchase will depend solely on usage and storage conditions. Copyright May 1998, January 2001 Bioanalytical Systems, Inc. 2701 Kent Avenue West Lafayette, IN 47906 USA www.bioanalytical.com ALL RIGHTS RESERVED UniJet, UniStand, and SepStik are trademarks of Bioanalytical Systems, Inc. Vycor is a registered trademark of Corning Glass. Kel-F is a registered trademark of 3M Corporation. Table of Contents Table of Contents Section 1. Thin-Layer Cells........................................................................................ -

Metallographic Preparation of Stainless Steel Application Notes

Metallographic preparation of stainless steel Application Notes Corrosion resistant steels contain at least 11% chromium and are collectively known as “stainless steels“. Within this group of high alloy steels four categories can be identified: ferritic, martensitic, austenitic, and austenitic-ferritic (duplex) stainless steels. These categories de- scribe the alloy’s microstructure at room temperature, which is largely influenced by the alloy composition. The main characteristic of stainless steels is their corrosion resistance. This prop- High performance stainless steel parts for the erty can be enhanced by the addition of aircraft industry specific alloying elements, which have a further beneficial effect on other charac- chemical, medical and food industries, teristics such as toughness and oxidation in professional kitchens, architecture and resistance. even jewelry. For instance, niobium and titanium in- Metallography of stainless steels is an crease resistance against intergranular important part of the overall quality corrosion as they absorb the carbon to control of the production process. The form carbides; nitrogen increases strength main metallographic tests are grain size and sulphur increases machinability, measurement, identification of delta because it forms small manganese sul- ferrite and sigma phase and the evalu- phides which result in short machining ation and distribution of carbides. In chips. Due to their corrosion resistance addition, metallography is used in failure and superior surface finishes stainless analysis investigating corrosion/oxida- steels play a major part in the aircraft, tion mechanisms. Fig.1: Duplex steel etched electrolytically with 150x 40% aqueous sodium hydroxide solution, showing blue austenite and yellow ferrite Difficulties during metallographic preparation Solution: Grinding and polishing: Deformation and scratching in ferritic and austenitic stain- Thorough diamond polishing and final less steels. -

Improvement of Punch and Die Life and Part Quality in Blanking of Miniature Parts

Improvement of Punch and Die Life and Part Quality in Blanking of Miniature Parts DISSERTATION Presented in Partial Fulfillment of the Requirements for the Degree Doctor of Philosophy in the Graduate School of The Ohio State University By Soumya Subramonian Graduate Program in Mechanical Engineering The Ohio State University 2013 Dissertation Committee: Dr.Taylan Altan, Advisor Dr.Blaine Lilly, Advisor Dr.Gary L.Kinzel Dr.Jerald Brevick Abstract Blanking or piercing is one of the most commonly used sheet metal manufacturing processes in the industry. Having a good understanding of the fundamentals and science behind this high deformation shearing process can help to improve the tool life and blanked edge quality in various ways. Finite Element Modeling of the blanking process along with experimental testing is used in this study to study the influence of various process parameters on punch and die life and blanked edge quality. In high volume blanking and blanking of high strength materials, improving the tool life can save not only tool material but also change over time which can take up to a few hours for every change over. The interaction between punch, stripper plate and sheet material is first studied experimentally since a fundamental understanding of the behavior of these components at different blanking speeds is very essential to design robust tooling for high speeds. A methodology is developed using the experimentally obtained blanking load and FEM of blanking to obtain flow stress data of the sheet material at high strains and strain rates. This flow stress data is used to investigate the effects of various process parameters on tool stress and blanked edge quality. -

Chapter 2 the Preparation of Samples for Ore Microscopy

CHAPTER 2 THE PREPARATION OF SAMPLES FOR ORE MICROSCOPY 2.1 INTRODUCTION Th e preparation of polished surfaces free from scratches, from thermal and mechanical modification of the sample surface, and from relief is essential forthe examination, identification, and textural interpretation of ore minerals using the reflected-light microscope. Adequate polished surfaces can be pre pared on many types of materials with relatively little effort using a wide variety of mechanical and manual procedures. However, ore samples often present problems because they may consist ofsoft, malleable sulfides or even nati ve metal s intimately intergrown with hard, and som etimes brittle, sili cates, carbonates, oxides, or other sulfides. Weathering may complicate the problem by removing cements and interstitial minerals and by leaving sam ples that are friable or porous. Delicate vug fillings also cau se problems with theiropen void spaces and poorly supported crystals.Alloys and ben eficiation products present their own difficulties because of the presence of admixed ph ases ofvariable properties and fine grain sizes. In this chapter, the general procedures ofsample selection and trimming, casting, grinding, and polish ing (and, in special cases, etching) required to prepare solid or particulate samples for examination with the ore microscope are discussed. The prepara tion ofthese polishedsections, and also polished and doubly polished thin sec tions, which are useful in the study of translucent or coexisting opaque and translucent specimens, is described. These are matters about which all stu dents of reflected-light microscopy should be aware, ideally through per sonal experience. lReliej is the un even surface of a section resulting from so ft ph ases being worn away mor e than hard ph ases during polish ing. -

Welding ABSTRACT Units Are General Safety, Basic Metalworking Tools, Layout, Bench Metal Casting, Welding, Metal Finishing, Plan

DOCUMENT RESUME ED 223 837 CE 034 374 TITLE lndustrial Arts Curriculum Guide in Basic Metals. Bulletin No. 1685. INSTITUTION Louisiana State Dept. of Education, Baton Rouge. Div. of Vocational Education. PUB DATE Sep 82 NOTE 127p.; For related documents, see CE 034 372-375. PUB TYPE Guides Classroom Use Guides (For Teachers) (052) EDRS PRICE MF01/PC06 Plus Postage. DESCRIPTORS Behavioral Objectives; *Course Content; Curriculum Guides; Equipment Utilization; Hand Tools; *Industrial Arts; Instructional Materials; Learning Activities; Machine Tools; Metal Industry; *Metals; *Metal Working; Planning; *Program Implementation; Safety; Secondary Education; Sheet Metal Wolk; *Trade and Industrial Education; Vocational Education; Welding IDENTIFIERS *Louisiana ABSTRACT This curriculum guide contains operational guidelines to help local-administrators, teacher educators, and industrial arts teachers in the State of Louisiana determine the extent to which their basic metals courses are meeting the needs of the youth they serve. It consists of a discussion of course prerequisites, goals, content, and implementation as well as 16 units devoted to various subject areas addressed in a basic metals course. Covered in the units are general safety, basic metalworking tools, layout, bench metalwork, sheet metal, art metal, ornamental metalwork, forging, metal casting, welding, metal finishing, planning, careers in metalworking, and basic metals projects. Each unit contains some or all of the following: objectives, time allotments, suggested topics, student activities, teacher activities, resources, and a unit inventory listing necessary tools and equipment. Among those items appended to the guide are safety rules, steps in making a layout, samples of basic metals projects, a sample student-planning sheet, suggestions for measuring achievement, sample test questions, techniques for conducting classes and for motivating students, and a list of resource materials. -

Metalworking Tools, Equipment & Supplies

Since 1914 Metalworking Tools, Equipment & Supplies Solutions to Unique & Common Challenges www.gesswein.com For Our Valued Customers The Paul H. Gesswein Company is proud to bring to you our latest brochure featuring exciting new products for finishing and deburring: • Ultramax MF multi-function ultrasonic polisher • Dynabrade air powered tools • Expanded line of Ushio air tools • Shaviv deburring tools • Our popular GMX & G-Flex cotton fiber mounted points in new shapes & sizes • New "Hybrid" Shaped Finishing Stones • Portable Dino-Lite analog and digital microscope systems for inspection, measurement, and documentation Be sure to visit www.gesswein.com for all of the latest products, specials, and technical information. Our "Quick Order" form on the homepage makes ordering fast! Please do not hesitate to give us a phone call to speak with one of our technical specialists should you have any questions: 1-800-544-2043. Thank you for your business and consideration. Table of Contents Page Ultrasonic Finishing 4-5 Finishing Stones 6-7 Power Tools 8-13 Air Tools 14-17 Mounted Stones 18-20 Diamond Tools 21-23 Deburring 24-26 Deburring & Deflashing 27 Deburring & Finishing 28-33 Polishing 34-38 Welding 39 Cleaning 40-41 Magnification & Inspection 42-43 3 ULTRASONIC FINISHING ULTRAMAX® MF (Multi-Function) Polishing & Deburring System New! Reduce finishing time dramatically! The first multi-function system for polishing, deburring, and metal removal. ULTRAMAX MF is supplied with an ultrasonic handpiece, and will power optional mechanical rotary and reciprocating handpieces. Has receptacles for both brush- type and brushless handpieces-the full range of Gesswein Power Hand Handpieces (p.10-13).