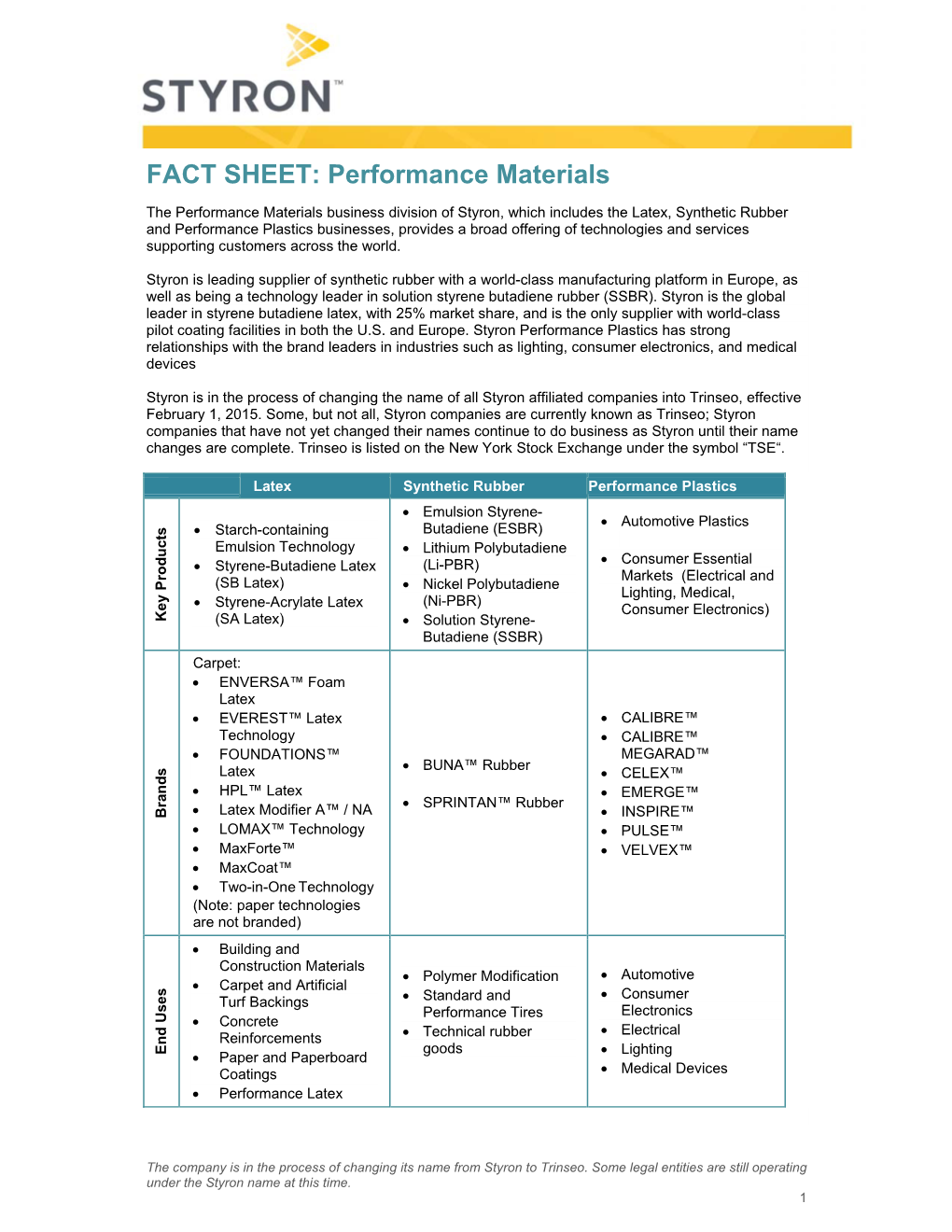

FACT SHEET: Performance Materials

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

The Difference of Butyl Rubber and Butadiene Styrene Rubber? by Butyl Rubber Sheets - [email protected], Date: Sep.18.06

The difference of butyl rubber and butadiene styrene rubber? By Butyl Rubber Sheets - www.dongrubber.com, [email protected], Date: Sep.18.06 Butyl rubber sheets is a kind of synthetic rubber which is a copolymer of Isobutylene and a small amount of isoprene copolymer, short for IIR. Butyl rubber sheeting has good chemical stability and thermal stability, the most prominent character is the air tightness and water tightness. Its air transmittance is only about 1/7 of the natural rubber, 1/5 of the styrene-butadiene rubber. Meanwhile its transmittance of steam is 1/200 of the natural rubber, and 1/140 of the styrene-butadiene rubber. Thus IIR is mainly used in the manufacture of tires, inner tubes, steam pipe, water dam and bottom gasket and other rubber products. Styrene-butadiene rubber (SBR) is one of the biggest general synthetic rubber varieties, and is also among the first rubber to realize industrialization production. Styrene butadiene rubber sheet is a random copolymer of butadiene and styrene. Its physical performance, processing performance and product performance is close to those of natural rubber sheets, and some properties such as wear resistance, heat resistance, ageing resistance and curing rate are more excellent than natural rubber sheeting, SBR can be used with a variety of natural rubber sheets and synthetic rubbers, widely applied to tires, tape, rubber hose, wire and cable, medical instruments and various kinds of rubber products production and other fields. Author: Butyl Rubber Sheets copyright reserved. Original URL should be kept in reproduction. . -

Vulcanization & Accelerators

Vulcanization & Accelerators Vulcanization is a cross linking process in which individual molecules of rubber (polymer) are converted into a three dimensional network of interconnected (polymer) chains through chemical cross links(of sulfur). The vulcanization process was discovered in 1839 and the individuals responsible for this discovery were Charles Goodyear in USA and Thomas Hancock in England. Both discovered the use of Sulfur and White Lead as a vulcanization system for Natural Rubber. This discovery was a major technological breakthrough for the advancement of the world economy. Vulcanization of rubbers by sulfur alone is an extremely slow and inefficient process. The chemical reaction between sulfur and the Rubber Hydrocarbon occurs mainly at the C = C (double bonds) and each crosslink requires 40 to 55 sulphur atoms (in the absence of accelerator). The process takes around 6 hours at 140°C for completion, which is uneconomical by any production standards. The vulcanizates thus produced are extremely prone to oxidative degradation and do not possess adequate mechanical properties for practical rubber applications. These limitations were overcome through inventions of accelerators which subsequently became a part of rubber compounding formulations as well as subjects of further R&D. Following is the summary of events which led to the progress of ‘Accelerated Sulfur Vulcanization'. Event Year Progress - Discovery of Sulfur Vulcanization: Charles Goodyear. 1839 Vulcanizing Agent - Use of ammonia & aliphatic ammonium derivatives: Rowley. 1881 Acceleration need - Use of aniline as accelerator in USA & Germany: Oenslager. 1906 Accelerated Cure - Use of Piperidine accelerator- Germany. 1911 New Molecules - Use of aldehyde-amine & HMT as accelerators in USA & UK 1914-15 Amine Accelerators - Use of Zn-Alkyl Xanthates accelerators in Russia. -

SAFETY DATA SHEET for Mission Rubber Neoprene Gaskets

SAFETY DATA SHEET for Mission Rubber Neoprene Gaskets SECTION TOPIC PG 1 Identification 1 2 Hazard Identification 1-2 3 Composition/Information On Ingredients 2 4 First Aid Measures 2 5 Firefighting Measures 2 6 Accidental Release Measures 3 7 Handling and Storage 3 8 Exposure Controls/Personal Protection 3 9 Physical and Chemical Properties 4 10 Stability and Reactivity 4 11 Toxicological Information 4 12 Ecological Information 5 13 Disposal Considerations 5 14 Exposure Controls/Personal Protection 5 15 Regulatory Information 5-6 16 Other Information 6 missionrubber.com (800) 854-9991 SAFETY DATA SHEET NEOPRENE GASKETS Section 1: IDENTIFICATION 1.1 Product identifier Product name: Neoprene Product part number: DPESISGRP251 CAS number: Ingredients: 184963-09-1. Synonyms: Neoprene. Product description: Neoprene Synthetic Rubber Gasket is a black color rubber with a mild characteristic odor. Product type: Solid 1.2 Relevant identified uses of the substance or mixture and uses advised against Product use: For use only as specified in product literature 1.3 Details of the supplier of the safety data sheet Mission Rubber Company, LLC 1660 Lesson Lane Corona, CA 92879 1.4 Telephone number: 800-854-9991 Section 2: HAZARD IDENTIFICATION 2.1 Classification of Substance or Mixture Potential Health Effects Before using Neoprene Synthetic Rubbers, read Bulletin "Guide for Safety in Handling and FDA Status of Neoprene Solid Polymers". ADDITIONAL HEALTH EFFECTS POLYCHLOROPRENE BLEND ACUTE OR IMMEDIATE EFFECTS: ROUTES OF ENTRY AND SYMPTOMS Ingestion One type of Neoprene was tested for oral toxicity in rats. The LD-50 is in excess of 20,000 milligrams per kilogram body weight which is low toxicity. -

Mechanical Study Guide.Pdf

MECHANICAL CONCEPTS Turn on bookmarks to navigate this document . PURPOSE OF THIS GUIDE . BEARINGS . Michelin North America, Inc. Copyright © 2012 Michelin North America, Inc All rights reserved. The Michelin Man is a registered trademark of Michelin North America, Inc. www.michelin.com BEARINGS AND THEIR CATEGORIES Generalities A bearing is a mechanical device and it is important to know its various components. 1 2 Figure 1-1 . Michelin North America, Inc. Copyright © 2012 Michelin North America, Inc All rights reserved. The Michelin Man is a registered trademark of Michelin North America, Inc. www.michelin.com Categories of bearings Figure 1-2 . Michelin North America, Inc. Copyright © 2012 Michelin North America, Inc All rights reserved. The Michelin Man is a registered trademark of Michelin North America, Inc. www.michelin.com Radial bearings Radial bearings are made with balls or rollers, depending on the how the bearings are used. They are designed to withstand forces that are perpendicular to the axis of the shaft. Figure 1-3 Axial bearings Axial bearings, also known as thrust bearings, have either balls or rollers, but both are designed to withstand axial forces, which push or pull along the axis. Figure 1-4 . Michelin North America, Inc. Copyright © 2012 Michelin North America, Inc All rights reserved. The Michelin Man is a registered trademark of Michelin North America, Inc. www.michelin.com Radial bearings and their functions Ball bearings Name Function Rigid, with balls and Designed mainly to support deep track. radial loads, but can also take a bit of axial load. Name Function With filling notch. -

BIOMIMETIC SYNTHETIC RUBBER Better Than Natural Rubber

Better than natural rubber BISYKA BIOMIMETIC SYNTHETIC RUBBER 30 % less FRAUNHOFER abrasion EXPERTISE Elastomers Superior Life sciences roll resistance Silica fillers Scale up Can be produced in existing plants THE FRAUNHOFER-GESELLSCHAFT ABOUT THE FRAUNHOFER-GESELLSCHAFT The Fraunhofer-Gesellschaft is contract research, 70 percent of Europe’s leading organization which is through contracts with in applied research. It is made up of industry and with publicly financed 72 institutes and research facilities research projects. International collab- located throughout Germany. More oration with outstanding research than 26,600 employees generate partners and innovative companies an annual research volume of more worldwide provides direct access than 2.5 billion euros. Of this, more to major scientific and economic than 2.1 billion euros come from regions now and into the future. www.fraunhofer.de/en 2 CONTENT On behalf of the Fraunhofer-Gesellschaft, 4 Why is rubber so important for the auto- I would like to congratulate the BISYKA motive industry? Fraunhofer’s project on consortium on its excellent outcomes in the field biomimetic synthetic rubber of biomimetic synthetic rubber. “BISYKA” 6 What makes natural rubber so unique? Within the framework of MAVO, 8 Understanding Fraunhofer’s internal research program for dandelion rubber market-oriented preliminary research, Biocomponents enable innovative elastomers the Fraunhofer-Gesellschaft bundles the 12 From natural rubber expertise of various institutes into original to biomimetic preliminary research projects. synthetic rubber Synthesis of BISYKA rubber BISYKA is an excellent example of how on a pilot scale synergies can be used effectively in this way 16 Novel silica fillers for the rubber and tire industry to develop new and original solutions. -

Lehigh Technologies

CONFIDENTIAL “Technology and Innovation in the use of Micronized Rubber Powder in today’s Green World” 11 April, 2013 CONFIDENTIAL • Setting the Stage and What we are Learning • Who is Lehigh Technologies • Technical Presentation • What Does it All Mean in Terms of Green? 1 | Lehigh Technologies Inc. Millions of End-of-Life Tires Generated Each Year Energy Recovery Civil Engineering Landfill Stockpiled Data Not Available 292 250 112 80 30 2 | Lehigh Technologies Inc. 2 CONFIDENTIAL The First Chemical Revolution 1800s 1850-1900 1900-1930 dyes/pigments oil and gas cracking/refining discoveries metals synthetic chemistry carbohydrates soaps atomic theory and the chemical bond 3 | Lehigh Technologies Inc. 3 The World Today – 3 Challenges 4lbs /person/day oil prices over $80 world population and spiking to 7B people >$100/bbl over 200 million tons per year 1 billion in the borrow-buy-burn developed world is US energy consume as much strategy energy as the other 6B. 4 | Lehigh Technologies Inc. 4 The Second Chemical Revolution Bury or burn is not a solution infinite cycles of Vast resource pools available use • Huge technology challenge • • sustainable Must be waste based. production of Amyris, Kior, Renmatix, Genomatica building blocks • Small companies leading • • efficient use of Principles of Green Chemistry existing carbon Chemical companies leading sources • • 5 | Lehigh Technologies Inc. 5 Micronized Rubber Powder Industry – Lehigh Experience Image of industry: Reliability of supply-process safety; quality Scale-not capable of supporting -

Toyo Tire Talk

TOYO TIRE TALK Subject: Rubber Compound ··· Polymers As you will all know well, a tire is mainly made of "rubber" and cords. In the past, we have talked about the important functions of cords. Therefore, this time we would like to talk about the most important material in tires "rubber". When we talk about rubber, we generally mean the rubber compound to be exact. The compound is made by mixing polymer, reinforcement material, softener and various chemicals. Different characteristics are required for every type of tire or tire part. For example, a TBR tire requires heat, wear and cut resistance for the tread rubber, while the sidewall requires good weather resistance. We therefore need many kinds of rubber compounds. In this chapter, we'll talk about polymers, their types, characteristics and uses, that all perform very important functions. The main polymers used for tires are as follows : 1) Natural Rubber (NR) 2) Styrene Butadiene Rubber (SBR) 3) Butadiene Rubber (BR) 4) Isoprene Rubber (IR) 5) Halogenated Butyl Rubber All of the above are synthetic rubber except Natural Rubber of course. 1) Natural Rubber (NR) Characteristics NR is made from latex taken from rubber Advantage Disadvantage trees, mainly grown in Southeast Asia. Tear Strength Uniformity of quality Although there are now various kinds of Wear Resistance Aging Resistance synthetic rubber available, Natural Rubber Impact Resilience Fatigue Resistance is still used extensively in tires. Low Heat Generation Ozone Resistance 2) Styrene Butadiene Rubber (SBR) Characteristics SBR is now the most common synthetic Advantage Disadvantage rubber being used in tires. It is made by Processability Impact Resilience polymerizing Styrene and Butadiene Uniform quality Heat Generation together, it is also possible by changing Aging by heat Styrene content and polymerization process Frictional Force to make various types of SBR's with different characteristics. -

Synthetic Rubber Outperforms Natural Rubber 1 April 2019

Synthetic rubber outperforms natural rubber 1 April 2019 rubber tree, the fungus Microcyclusulei is laying waste to whole plantations. If the fungus crosses over to Asia, where major cultivation areas are located today, the global production of rubber will be threatened. Biomimetic synthetic rubber with optimized abrasion behavior (BISYKA) In view of this threat, researchers at the Fraunhofer Institutes for Applied Polymer Re-search IAP, for Microstructure of Materials and Systems IMWS, for Molecular Biology and Applied Ecology IME, for Mechanics of Materials IWM and for Silicate Research ISC have now optimized the characteristics of synthetic rubber. "Our synthetic rubber BISYKA – that's a German abbreviation for Initial testing of tires made from the nature-identical, "biomimetic synthetic rubber" – actually has biomimetic synthetic rubber BISYKA shows that they superior characteristics to natural rubber," says Dr. achieve around 30 to 50 percent less abrasion compared to natural rubber tires. Credit: Fraunhofer Ulrich Wendler, who heads up the project at the IAP/Till Budde Fraunhofer Pilot Plant Center for Polymer Synthesis and Processing PAZ in the German municipality of Schkopau. Fraunhofer PAZ is a joint initiative be-tween Fraunhofer IAP and Fraunhofer Natural rubber from rubber trees is a raw material IMWS. "Tires made of the synthetic rubber lose 30 with a limited supply. Synthetically produced percent less mass than equivalent tires made of rubber, on the other hand, has not yet been able to natural rubber. On top of that, the synthetic tires match the abrasion behavior of the natural product, have only half the tread loss. Furthermore, the rendering it unsuitable for truck tires. -

Malaysian Rubber Board

MRC INDUSTRY LINKAGE FUND Industry-University Interaction Session 2021 MALAYSIAN RUBBER BOARD 29 Jun 2021 Copyright © Malaysian Rubber Board MALAYSIAN RUBBER BOARD : OVERVIEW TECHNOLOGY & ENGINEERING DIVISION (BAHAGIAN TEKNOLOGI & KEJURUTERAAN, BTK) Economy, licensing & DOWNSTREAM R&D, CONSULTANCIES AND SPECIAL SERVICES enforcement Services & Support Dr Azhar Ahmad, PhD Ketua, Unit Pemprosesan & Dr Fatimah Rubaizah MR, PhD Kelestarian Ketua, Unit Pembangunan & ([email protected]) Inovasi Bahan Termaju ([email protected]) Upstream Dr Nazirah Ahmad, PhD Dasar & Ketua, Unit Kejuruteraan Operasi Rekabentuk & KETUA Downstream Pembangunaan Produk PENGARAH Penyelidikan Dr Mok Kok Lang, PhD ([email protected]) Relevant to MILF Divisional Director, & Inovasi Quality & Bahagian Teknologi & Standards Kejuruteraan ([email protected]) Expansion • Corporate • Legal • Strategic Planning Dr Yong Kok Chong, PhD Dr Asrul Mustafa, PhD • Human Resource Ketua, Unit Inovasi & Ketua, Unit Sains & • Audit Teknologi Elastomer Teknology Lateks • Integrity ([email protected]) ([email protected]) Copyright © Malaysian Rubber Board SCOPE, OBJECTIVE & FUNCTION of UNITS • Develop and diversify value- • R&D in natural and synthetic added dry rubber products latex-based thin-wall and foam • Focus on Industrial Rubber products Goods, General Rubber • Product degradation, energy Goods, Tire Technology and efficiency in product advanced composites manufacture, latex stability and • Provide consultative and preservation, blends, 01 technical advisory services on 03 nanocomposite -

Rubber Compounds QUALITY | VALUE | SERVICE Rubber Compounds Rubber Where Rubber Compounds Abound

Piston Seals Wipers O-Rings & Kits Custom Parts Specialty Parts Services Wear Guides Rod Seals Rubber Compounds QUALITY | VALUE | SERVICE Rubber Compounds Rubber Where rubber compounds abound. Why make the rounds searching for rubber compounds when they’re all right here in one convenient place? All Seals has developed nearly 500 different rubber compounds, in a variety of materials and hardnesses, to satisfy virtually every conceivable requirement. And if your application requires unique properties and/or capabilities, we’ll develop a compound for you! This brochure describes the most commonly specified rubber compounds. As such, the information presented here is necessarily general in nature and abbreviated. For more specific information or expert advice, contact us and speak directly to an experienced compound professional. Please call us at 800.553.5054, or visit our website at www.allsealsinc.com. QUALITY | VALUE | SERVICE ® AFLAS BUTYL RUBBER CARBOXYLATED NITRILE (TFE/P, FEPM) (IIR) (XNBR) Aflas® or TFE/P is a member of a recent generation of fluoroelastomers Butyl is a specialty rubber more frequently specified for its physical Carboxylated nitrile, or XNBR, is produced by adding a carboxylic acid formulated specially to provide unique properties for specific applications. properties than chemical resistance. It has excellent shock absorption side group to nitrile rubber, thereby adding more crosslinking sites than The primary uses for Aflas® are in the oil/gas, chemical processing, and vibration damping capabilities, as well as good electrical properties. traditional NBR. As a result, solvent swell and abrasion resistance are pharmaceutical and automotive industries. It can be crosslinked (cured) Butyl’s unusually low gas permeability makes it ideal for vacuum significantly improved, as well as modulus, tensile strength and tear using a variety of systems, but generally peroxides are used to provide applications, while its high degree of saturation makes it inherently resistance. -

Recycled Micronized Rubber Formulation Having Improved Abrasion Resistance

(19) TZZ¥Z _T (11) EP 3 045 492 A1 (12) EUROPEAN PATENT APPLICATION (43) Date of publication: (51) Int Cl.: 20.07.2016 Bulletin 2016/29 C08J 11/04 (2006.01) C08J 11/06 (2006.01) B29B 17/02 (2006.01) B29B 17/04 (2006.01) (2006.01) (2006.01) (21) Application number: 16151911.1 B60C 1/00 C08L 21/00 C08L 19/00 (2006.01) (22) Date of filing: 19.01.2016 (84) Designated Contracting States: (72) Inventors: AL AT BE BG CH CY CZ DE DK EE ES FI FR GB • JASIUNAS, Chad Aaron. GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO Copley, OH Ohio 44321 (US) PL PT RO RS SE SI SK SM TR • PAPP, Frank P. Designated Extension States: Fort Mill, SC South Carolina 29707 (US) BA ME • ROSENMAYER, Charles T. Designated Validation States: Decatur, GA Georgia 30030 (US) MA MD • MURTHY, Kedar D. Boston, MA Massachusetts 02117 (US) (30) Priority: 19.01.2015 US 201562105076 P (74) Representative: Mullen, Lee Bryan (71) Applicant: Lehigh Technologies, Inc. Elkington and Fife LLP Tucker, GA 30084 (US) Thavies Inn House 3-4 Holborn Circus London EC1N 2HA (GB) (54) RECYCLED MICRONIZED RUBBER FORMULATION HAVING IMPROVED ABRASION RESISTANCE (57) This invention is based upon the discovery that nized solution styrene-butadiene rubber can then be micronized solution styrene-butadiene rubber from post- blending into desired virgin rubbers and cured without consumer sourcescan be included inrubber formulations significantly compromising the abrasion resistance of the without severely compromising abrasion resistance. The rubber formulation. -

Chemicals, Rubber and Plastics

Chapter 5: chemicals, rubber and plastics Chemicals, rubber and plastics The chemicals, rubber and plastics Authorisation of CHemical substances) The manufacture of chemicals, rubber and manufacturing sector covers the manufacture system (1). This environmental and social policy plastics are covered by NACE Subsections DG of basic organic and inorganic chemicals, initiative aims to improve the protection of and DH; the first of these two subsections also pharmaceutical products and pesticides and human health and the environment through includes the manufacture of man-made fibres. rubber tyres and plastic tubes. the better and earlier identification of the properties of chemical substances. Following a NACE The main raw materials used within this long period of negotiation, the European 24: manufacture of chemicals and manufacturing sector include oils, minerals, Council reached a common position on chemical products; 24.1: manufacture of basic chemicals; metals and certain agricultural products (such 27 June 2006. A second reading, at which final 24.2: manufacture of pesticides and other as natural rubber and fats). Many of the key agreement may be reached, is currently agro-chemical products; ingredients for chemical, rubber and plastic planned before the end of 2006. The 24.3: manufacture of paints, varnishes and goods are derived from fractions of chemicals, rubber and plastics sector also has to similar coatings, printing ink and hydrocarbons from the oil industry which are consider other environmental and social mastics; subsequently