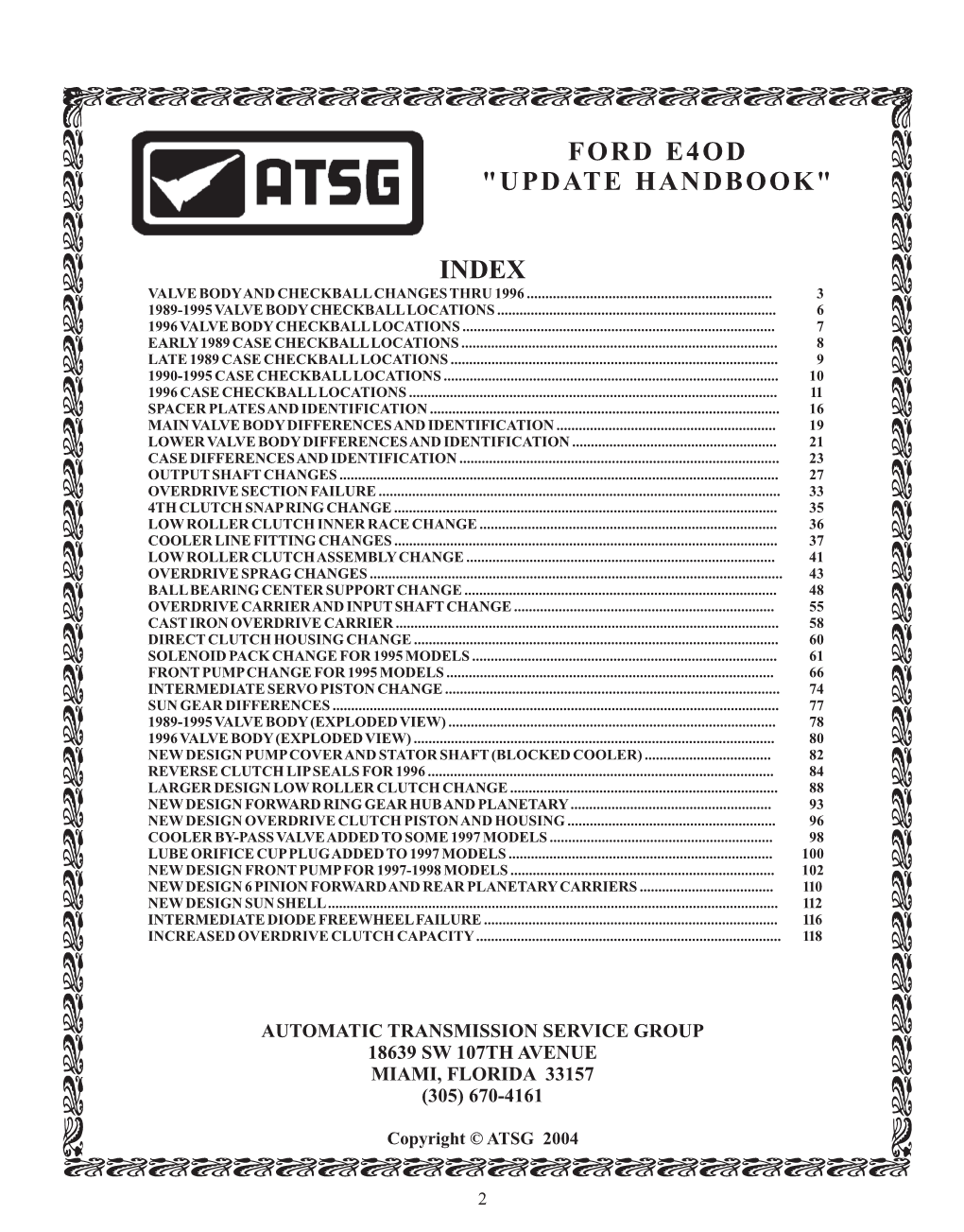

Index Ford E4od "Update Handbook"

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Aut 221 Automatic Transmission/Transaxle

AUT 221 (A2) AUTOMATIC TRANSMISSION/TRANSAXLE Prerequisites: TRN 120 Corequisites: None COURSE DESCRIPTION: This course covers operation, diagnosis, service, and repair of automatic transmissions/transaxles. Topics include hydraulic, pneumatic, mechanical, and electrical/electronic operation of automatic drive trains and the use of appropriate service tools and equipment. Upon completion, students should be able to explain operational theory and diagnose and repair automatic drive trains. Course Hours per Week: Class, 2; Lab Hours, 3; Semester Hours Credits, 3. SAFETY DISCLAIMER: Automotive work presents many hazards. A moment’s carelessness can cause injury to oneself or to others. Such mishaps can occur quickly due, in part, to the nature of the industrial tools used in automotive work. The weight of automobiles and the equipment used to fix them can even cause fatal injuries. Therefore, great care must always be taken in checking out equipment before use, and in using that equipment to work on automobiles. As we work to insure the safety of everyone in the Durham Tech automotive lab, it is the instructor’s responsibility to introduce students to equipment and to advise them on its safe operation. Those health and safety procedures are also presented in each textbook for each course in the automotive program. Students are responsible for mastery of that safety information. Durham Tech holds each student in every class responsible for reading and applying all of the information regarding personal and public safety and personal and public health in the required text. While working in the Durham Tech automotive lab, safety glasses must be worn by everyone. -

Mitchell Overdrive Installation by Tom Endy Westminster, California

Mitchell Overdrive Installation By Tom Endy Westminster, California A suitable and safe spring spreader. This series of 23 photos and comments illustrated are offered as an aid to the installation of a Mitchell overdrive in a Model A Ford. A Mitchell overdrive can be installed in a Model A without completely disassem- bling the rear axle assembly. If the Model A is a good running car with no rear axle assembly issues the installation can be accomplished at a technical seminar in about six hours with the help of four willing workers. The photos in this article show a rear axle housing with wheels, brake drums, back- ing plates, and rear radius rods removed. However, none of these need be removed to accommodate the installation of a Mitchell overdrive. #1. The rear axle assembly is removed from the car and read- The first task is to remove the rear axle assembly from the car. A suitable spring ied for the Mitchell install. It is not necessary to remove rear wheels, brake drums, backing plates, and rear radius rods. spreader should be used. Once the spring has been spread the shackle bolts are removed. The spring and spring spreader are left installed under the car until the rear axle assembly with the Mitchell overdrive connected to it is ready for re- installation. This is the safe method of going about the task of removal. Pulling the rear axle assembly from the car with the spring attached to it is unsafe. The center bolt holding the spring leafs together was never meant to hold the amount of ten- sion packed into the rear spring. -

TWO OVERDRIVES INTO TWO SUNBEAM ALPINES by Roger Davis and Body

A Chapter of the North American MGB Register A Zone of the Vintage Triumph Register British Motor Club of Utah www.BMCUTAH.org November 2013 Volume 24 Number 11 END OF SEASON DINNER BOHEMIAN BREWERY at 94 E. 7200 S. 6:30pm SATURDAY NOV 9, 2013 We have a 6:30PM reservation, upstairs, ordering off the menu, separate checks, at the Bohemian Brewery, on November 9. The Bohemian is at 94 East 7200 South in Midvale. This is just EAST of State St., on the South side of the street. Easy to reach off the 7200 South exit of I-15. Everyone had a great time at the Bohemian last year. The food, company, and conversations were great. Don’t miss it this year! BMCU End of Season Dinner 2012 Upstairs at the Bohemian Bohemian Menu on next page... Page 2 If you zoom in a bit you can actually read the menu! Or, follow this link to the Bohemian website and menu... http://www.bohemianbrewery.com/ Bohemian_Brewery_&_Grill/Menu.html There’s something here for everybody! Page 3 Mt. Nebo Loop Fall Colour Run October 5, 2013 The Fall Colour Run began early at 90th South and Redwood Rd. Page 4 SL Valley-east of Utah Lake-Goshen Canyon-Nephi-Nebo (No I-15) Recombobulation stop following Roger Davis Kevin Cowan the drain and gain stop. Roger and Jill Davis were chief Event and route information were navigators. provided by Kevin and Roger. TR6 Salt Creek Canyon Rd. Bear Canyon Picnic Area Jag XJS Page 5 BMCU at the Bear Canyon picnic area. -

2019 Dodge Charger Pursuit Specifications

2019 DODGE CHARGER PURSUIT SPECIFICATIONS 2019 Dodge Charger Pursuit SPECIFICATIONS Specifications are based on the latest product information available at the time of publication. All dimensions are in inches (millimeters) unless otherwise noted. All dimensions measured at curb weight with standard tires and wheels. GENERAL INFORMATION Vehicle Type E-segment sedan Assembly Plant Brampton Assembly Plant, Ontario, Canada EPA Vehicle Class Large car Introduction Date 2014 as a 2015 model (fleet customers only — www.fleet.chrysler.com) BODY AND CHASSIS Layout Longitudinal front engine, rear-wheel drive (RWD) or all-wheel drive (AWD) Construction Unitized steel body and aluminum hood ENGINE: 3.6-LITER PENTASTAR DOHC 24-VALVE V-6 Availability Standard Type and Description 60-degree V-type, liquid-cooled Displacement 220 cu. in. (3,604 cu. cm) Bore x Stroke 3.78 x 3.27 (96.0 X 83.0) Valve System Chain-driven DOHC, 24 valves, hydraulic end-pivot roller rockers Fuel Injection Sequential, multiport, electronic, returnless Construction Aluminum deep-skirt block with aluminum-alloy heads Compression Ratio 10.2:1 Power (SAE net) 292 bhp (218 kW) @ 6,350 rpm (81.1 bhp/liter) Torque (SAE net) 260 lb.-ft. (353 N•m) @ 4,800 rpm MaX. Engine Speed 6,400 rpm (electronically limited) Fuel Requirement Unleaded regular, 87 octane (R+M)/2; and E-85 (Federal Bin 5, 37 state compliant) Oil Capacity 6 quarts (5.7 liters) with dry filter Coolant Capacity 14.0 quarts (13.25 liters) Emission Controls Dual three-way catalytic converters, heated oxygen sensors and internal engine features(a) MaX. -

TREMEC TR-3160 6-Speed Manual Transmission

TREMEC TR-3160™ Transmission 6-Speed RWD Manual Transmission ® Torque Transfer Solutions® The TR-3160 is designed for either a single or double overdrive transmission. Ideal for light delivery vans, light commercial vehicles and performance vehicle applications, this transmission incorporates the latest design and manufacturing technologies to provide the highest torque capacity and best-in- class shift feel. Based on an 81mm center distance, the TR-3160 utilizes high strength steel on all gears and shafts - maximizing torque capacity and durability while minimizing weight and package size. The multi-rail shift system accommodates direct mount and semi-remote shifter locations that provide greater flexibility while reducing noise, vibration and harshness (NVH) Product Highlights High capacity tapered bearings and high-capacity synchronizers that contribute to low shift efforts and shifter travel. All gears are hard-finished, which contributes to the transmission’s refined feel and low noise. TR-3160 Features at a Glance: • Rear wheel drive, six-speed manual transmission available with single or double overdrive • Double and triple cone synchronizers featuring hybrid and sintered bronze friction material. • Multi-rail shift system accommodates direct mount or semi-remote shifter locations • High-precision guide plate • Advanced interlock system • Anti-friction roller ball detents • Hollow shafts and webbed gears • Three-piece “end load design” aluminum housings • Low-friction linear shift rail bearings Shift Pattern R 1 3 5 N 2 4 6 Optional Shift pattern 1 3 5 N 2 4 6 R 46643 Ryan Court | Novi, MI 48377 U.S.A. | www.tremec.com Copyright © 2017TREMEC. All Rights Reserved. F-TR3160-1017_v1 TREMEC TR-3160™ Transmission ® 6-Speed RWD Manual Transmission Torque Transfer Solutions® TREMEC TR-3160 Transmission Specifications Type: Rear wheel drive, six-speed manual overdrive transmission; single or dual overdrive Maximum gross vehicle weight:* 3,000 kg (6,614 lb) *For reference only. -

LAYCOCK TYPE a OVERDRIVE UNITS – a Different Perspective – 12 MODES

LAYCOCK TYPE A OVERDRIVE UNITS – A different perspective – 12 MODES. Also: Calculating the O/D ratios and speedometer calibration issues in TR cars: H. Holden 2010. There has been much information published on the functionality of the Laycock type A units, however it seemed to me that some of it has led to some myths relating to the function of the unit. For example on one website dedicated to triumph matters the remark was made that the cone clutch return springs were increased from 4 to 8 to allow for the extra torque of the higher performance motors when in fact the return springs have no role in the transfer of power in the forward direction in overdrive mode or not (see below). Undoubtedly the Laycock O/D units were a futuristic design and still today are very impressive pieces of mechanical and hydraulic engineering. The symmetry of the epicyclic gear system with the sun gear, three planet gears and an annulus gear is very appealing. Brief description of the unit: The Laycock O/D has a number of working components including a pair of hydraulically operated pistons which move after the driver selects O/D. These move a cone clutch attached on splines to a sun gear, to stall them both onto a brake ring attached to the O/D body. This running surface on the cone clutch is important in engaging the overdrive. The input power to the O/D unit is applied via the input shaft (the gearbox’s output shaft) to a “planet carrier” containing 3 planet gears which interface both with the output annulus (which is part of the output shaft) and with the sun gear. -

Eaton Fuller Heavy-Duty Transmissions Troubleshooting Guide (TRTS0910)

Troubleshooting Guide Fuller® Heavy-Duty Transmissions TRTS0910 EN-US October 2007 Models FR-11210B RTLO-14610B RTLOF-15610B-T2 RTOF-11909MLL RTX-14709A FR-12210B RTLO-14610B-T2 RTLOF-16610B RTOF-13707DLL RTX-14709B FR-13210B RTLO-14613B RTLOF-16610B-T2 RTOF-13707MLL RTX-14709H FR-14210B RTLO-14618A RTLOF-16618A RTOF-14608LL RTX-14710B FR-15210B RTLO-14713A RTXF-15615 RTOF-14708LL RTX-14710C FR-9210B RTLO-14718B RTLOF-16713A RTOF-14709MLL RTX-14715 FRF-11210B RTLO-14913A RTLOF-16713A-T2 RTOF-14908LL RTX-15615 FRF-12210B RTLO-14918B RTLOF-16718B RTOF-14909ALL RTXF-16709H FRF-13210B RTLO-14918B-T2 RTLOF-16913A RTOF-14909MLL RTX-15710B FRF-14210B RTLO-15610B RTLOF-16913A-T2 RTOF-16908LL RTX-15710C FRF-15210B RTLO-15610B-T2 RTLOF-16918B RTOF-16909ALL RTX-15715 FRF-9210B RTLO-16610B RTLOF-16918B-T2 RTX-11509 RTX-16709B FRO-11210B RTLO-16610B-T2 RTLOF-17610B RTX-11608LL RTX-16709H FRO-11210C RTLO-16618A RTLOF-17610B-T2 RTX-11609A RTX-16710B FRO-12210B RTXF-14710C RTLOF-18610B RTX-11609B RTX-16710C FRO-12210C RTLO-16713A RTLOF-18718B RTX-11609P RTXF-11509 FRO-13210B RTLO-16713A-T2 RTLOF-18913A RTX-11609R RTXF-11608LL FRO-13210C RTLO-16718B RTLOF-18913A-T2 RTXF-15715 RTXF-11609A FRO-14210B RTLO-16913A RTLOF-18918B RTX-11610 RTXF-11609B FRO-14210C RTLO-16913A-T2 RTLOF-18918B-T2 RTX-11615 RTXF-11609P FRO-15210B RTLO-16918B RTLOF-20913A RTX-11708LL RTXF-11609R FRO-15210C RTLO-16918B-T2 RTLOF-20918B RTX-11709A RTXF-11610 RTXF-14615 RTLO-17610B RTLOF-20918B-T2 RTX-11709B RTXF-11615 RTXF-14708LL RTLO-17610B-T2 RTLOF-22918B RTX-11709H RTXF-11708LL FRO-16210B -

Mitchell Overdrive One Day Installation by Tom Endy 2019

Mitchell Overdrive One Day Installation by Tom Endy 2019 Three of us local Model A guys (Bryan Thompson, Larry McKinney, and Tom Endy, known as the BLT guys) have installed a good number of Mitchell overdrives in Model A Fords over the past few years. We believe we have it down to a science. Each of us has an assigned task and we go about it with little fanfare. We can usually complete an installation from start to finish is about four hours. We usually roll the car into position about 9 AM on a Saturday morning and are driving it around the neighborhood with the overdrive installed sometime shortly after 1 PM. We ask for no payment, and will accept none; however, we suggest a donation be made to the Model A Ford Youth Restoration Program. Two factors help expedite the task. First, we know exactly what we are doing, so there is no lost motion. Second, we have some excellent specialized tools. We have a set of very tall jack stands to set the rear of the frame on to provide adequate room to maneuver under the car. We have a rolling cradle we place under the rear of the car that we can drop the removed rear axle assembly into once it is unhooked from the car. We have a pinion gear assembly puller that is the daddy of them all. It will remove the tightest of pinion assemblies without fail. We have the proper tools to remove the pinion from the drive shaft. We also have the proper tools to press the pinion gear assembly with the Mitchell stub shaft back into the banjo. -

Gm Automatic Overdrive Transmission Builders and Swappers Guide Pdf, Epub, Ebook

GM AUTOMATIC OVERDRIVE TRANSMISSION BUILDERS AND SWAPPERS GUIDE PDF, EPUB, EBOOK Cliff Ruggles | 128 pages | 10 Nov 2008 | Cartech Inc | 9781932494501 | English | North Branch, United States GM Automatic Overdrive Transmission Builders and Swappers Guide PDF Book Q: Does this book show you how to decode the tags on 4L60E trans? Keeping the enthusiast in mind, Ruggles explains the history of these transmissions, presents critical identification guidelines, and leads the reader through the complete disassembly, repair and upgrade, and assembly processes. In this book, expert mechanic and drag racer Cliff Ruggles demystifies the popular GM R4 and 4L60 automatic transmissions. These transmissions are very heavy, hold many quarts of fluid, and wiggle room is scant, so regardless of your method, you must use a proper transmission jack to support the case and to move it back and forth. Remove the dipstick. View Details. If you are an international customer and would like to change the currency that prices are displayed in, you can do so here. Great book, lots of good info Great book for the beginner, very detailed with pictures. GM used two types of torque converter-to flexplate fasteners. You can learn more about how we plus approved third parties use cookies and how to change your settings by visiting the Cookies notice. The green line at peak represents engine speed at gear upshift under normal throttle. A must have when learning about the 4l60 trans. Under part-throttle, the shift should occur between 16 to 20 mph. If you are an international customer who ships to a US address choose "United States delivery" and we will estimate your ship dates accordingly. -

Service Manual TABLE of CONTENTS MODELS: AMO/APO1000-4 & 1750-4

Bulletin No. SPTS001-0306 AMO1750-4 March 2006 AMO1750-4AMO1750-4 SeriesSeries AuxiliaryAuxiliary TTransmissionransmission MODELS: APO1750-4 APO1000-4 Service Manual TABLE OF CONTENTS MODELS: AMO/APO1000-4 & 1750-4 Page GENERAL INFORMATION AND DESCRIPTION Maintenance Lubrication & Power Flow 3-4 DISASSEMBLY Removal Shifter Housing and Shaft Assemblies 5 Mainshaft - Manual 6-8 Countershaft 10 Drive Gear and Bearing Retainer 11 Shifter Housing Manual 12 Shifter Housing Air Shift 21-23 REASSEMBLY Mainshaft - APO,AMO, ATO 13 Countershaft 14 Drive Gear and Bearing Retainer 15-16 Shifter Housing Manual 17 Mainshaft/Countershaft into case 18-20 Shifter Housing Air Shift 24-25 AIR SYSTEM CONTROLS 26 TOP MOUNTED PTO Removal and Disassembly 35-37 Reassembly 42-46 TROUBLE SHOOTING 47 CAUTION Do not tow vehicles equipped with Spicer transmissions without first pulling the axles or disconnecting the drive shaft. Lubrication of the internal gear train is inadequate when the vehicle is towed. 2 tTeechch llineine 8800-401-986600-401-9866 www.ttcautomotive.com 4 SPEED AUXILIARY TRANSMISSION MODELS: Manual & Air Shifted AMO/APO1000-4 & 1750-4 GENERAL INFORMATION MAINTENANCE INFORMATION: We recommend that the procedures as outlined in the manual be followed when performing maintenance work on all transmissions. REBUILD FACILITIES: A suitable holding fixture or overhaul stand is desirable but not necessary to rebuild this unit. The flat bottom of the transmission case provides a suitable working platform when the unit is placed on a sturdy shop table. For easier working conditions, table height should be 28 - 30 inches. A light chain hoist should be used to handle the mainshaft and countershafts during removal and reassembly procedures. -

New Product Information September 2016

New Product Information September 2016 Roamerdrive Overdrive Units Defender DA9017 Overdrive unit The distinctive third lever on the centre console of a Defender identifies it as a vehicle equipped with a Roamerdrive overdrive. This rugged, bolt on accessory has been proven in hundreds of installations and tested under the most demanding expedition conditions. No other modification improves the performance and economy of your Land Rover like a Roamerdrive. The DS model overdrive is an auxiliary gearbox that is easily fitted to a Defender 90 or 110 with standard five speed transmission. The unit adds an optional 28% to the ratio of the drive train giving improved fuel economy. Reduced engine speed contributes to quieter more comfortable travel under motorway conditions and reduces wear and tear on mechanical components. The Roamerdrive is a completely mechanical device built in the tradition of rugged dependability that has made Land Rover the world’s favourite expedition vehicle. These overdrives have no electronic or hydraulic components. They are controlled by moving the convenient hand lever. Unlike a high ratio transfer case that will permanently detract from the versatility of the gearbox, the Roamerdrive does not alter the vehicle’s designed gear ratios. Off road performance is enhanced as the overdrive ratio can be added to any gear in high or low range. The Roamerdrive uses the same epicyclical gear technology as a modern automatic transmission and runs quietly. This is particularly evident at high speeds and makes driving a Defender for long distances a pleasurable experience. On long journeys Roamerdrive users have reported fuel savings of up to 18% - not surprising when you consider that the engine lopes along the highway at about 2000 R.P.M. -

10-Speed Dual Counter Shaft Manual Transmission

TR-T-10 Series ® 10-Speed Torque Transfer Solutions™ Dual Counter Shaft Manual Transmission Service Manual SM_TR-T-10_0915 14700 Helm Ct. | Plymouth, MI 48170 U.S.A. | (800) 401-9866 | www.tremec.com Copyright © 2015 TREMEC. All Rights Reserved. SM_TR-T-10_0915 Table of Contents Section 1: General Information ........................................................................................................................................... 4 Safety First................................................................................................................................................................... 4 General Safety Precautions ............................................................................................................................................... 4 Driver Instructions: Shifting the TREMEC 10-Speed Transmission ............................................................................. 6 Specifications............................................................................................................................................................... 7 Section 2: Maintenance ...................................................................................................................................................... 9 Filter Regulator ............................................................................................................................................................ 9 Lubrication ..................................................................................................................................................................