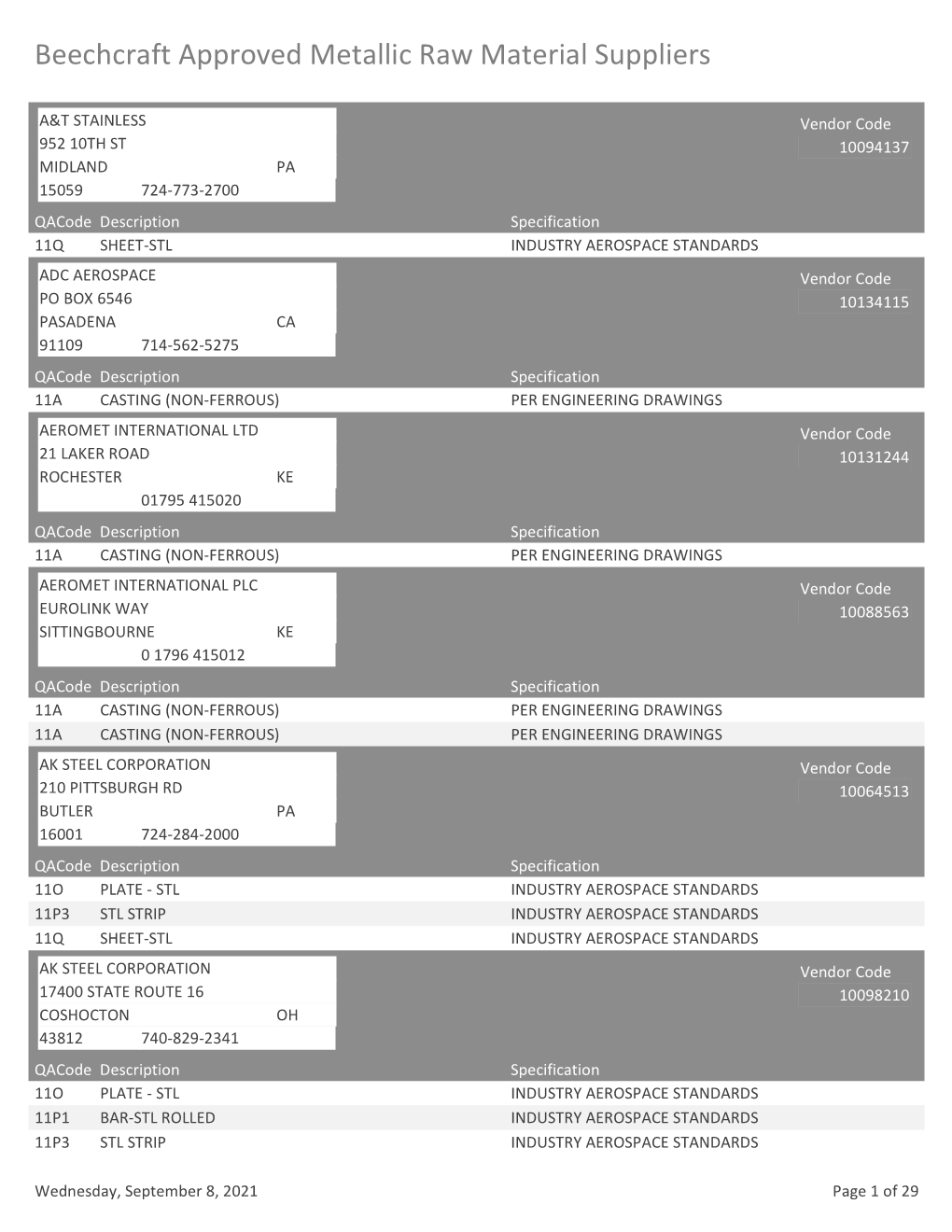

Raw Suppliers

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Crucible Industries

CRUCIBLE DATA SHEET CPM 20CV is a unique tool steel made by the Crucible Particle ® Metallurgy Process. It is a martensitic stainless steel with a high CRUCIBLE CPM 20CV volume of vanadium carbides for exceptionally good wear resistance. CPM 20CV contains the highest amount of chromium of any high- Issue #1 vanadium stainless steel currently available. The chromium rich Carbon 1.9% matrix provides outstanding corrosion resistance. CPM 20CV an Chromium 20.0% excellent steel for plastic injection feed screws, barrel liners, screw Vanadium 4.0% tips and mold cavities, especially for plastic resins which contain abrasive fillers. Molybdenum 1.0% Tungsten 0.6% The CPM process results in a finer, more uniform carbide distribution imparting improved toughness and grindability to highly alloyed steels. The CPM process also alloys for the design of more highly Physical Properties alloyed grades which cannot be produced by conventional Density: 0.275 lb/in3 (7616 kg/m3) steelmaking. Modulus of Elasticity: 31x106 psi (214 GPa) Machinability: 35-40% of a 1% carbon steel Coefficient of Thermal Expansion: CPM Steel Conventional Steel Steel Comparagraph Relative Relative Values CPM 20CV CPM 9V CPM Rex M4 440C 420 58HRC 53 HRC 63 HRC 56 HRC 50 HRC Wear Resistance Toughness Corrosion Resistance Typical Applications Edge Retention (CATRA Test Relative to 440C) High Performance, Long-Wearing Specialty Cutlery (CATRA Test Relative to 440C) Plastic Injection and Extrusion Feed Screws and Dies Granulator Knives Pelletizing Equipment Wear Components for Food and Chemical Processing The CATRA (Cutlery & Allied Trade Research Association) test machine Crucible Industries LLC measures the total number of silica impregnated cards cut in a sequence of Crucible Industries, Crucible Industries logo, CPM, and 9V are all trademarks passes along a blade. -

Street Nursery Infant/Primary Junior

STREET NURSERY INFANT/PRIMARY JUNIOR SECONDARY ABBEY DRIVE Crookesbroom Primary Crookesbroom Primary Ash Hill Academy Academy Academy ABBEY GARDENS Crookesbroom Primary Crookesbroom Primary Ash Hill Academy Academy Academy ABBEY GREEN Crookesbroom Primary Crookesbroom Primary Ash Hill Academy Academy Academy ABBEY GROVE Crookesbroom Primary Crookesbroom Primary Ash Hill Academy Academy Academy ABBEY ROAD Crookesbroom Primary Crookesbroom Primary Ash Hill Academy Academy Academy ABBEY WALK Crookesbroom Primary Crookesbroom Primary Ash Hill Academy Academy Academy ABBEY WALK Scawsby Saltersgate Infant Scawsby Saltersgate Infant Scawsby Ridgewood School School School Saltersgate Junior School ABBEY WALK Crookesbroom Primary Crookesbroom Primary Ash Hill Academy CARAVAN SITE Academy Academy ABBEY WAY Crookesbroom Primary Crookesbroom Primary Ash Hill Academy Academy Academy ABBEYFIELD St Oswald's C of E St Oswald's C of E The Hayfield School Academy Academy ABBEYFIELD ROAD Hatfield Sheep Dip Lane Hatfield Sheep Dip Lane Ash Hill Academy Primary School Primary School ABBOTT STREET Hexthorpe Primary School Hexthorpe Primary School Balby Carr Community Academy ABERCONWAY Rossington Tornedale Rossington Tornedale Infant Pheasant Rossington All Saints CRESCENT Infant School School Bank Academy Academy ABERCORN ROAD Plover Primary School Plover Primary School Danum Academy ABINGDON ROAD Sandringham Primary Sandringham Primary Danum Academy School School ACACIA COURT Bentley New Village Bentley New Village Primary Don Valley Academy Primary School -

Improved Processing Techniques for Inclusion-Free Steel for Bearing and Mechanical Component Applications

Symposium: 12th International Symposium on Rolling Bearing Steels – Progress in Bearing Steel Metallurgical Testing and Quality Assurance Improved Processing Techniques for Inclusion-Free Steel for Bearing and Mechanical Component Applications Christopher DellaCorte1 ABSTRACT High-hardness, high-carbide powder metallurgy tool steels such as M62 enable the use of ball bearings at extremely high load and stress levels. Operation under such conditions increases the potential for rolling contact fatigue failure attributed to nonmetallic inclusions. To address this challenge, industry has sought ever-cleaner steels, but the results have been uneven, owing to the random nature of the occurrence of such material flaws. Careful melting processes and thorough ingot inspections prior to bearing manufacture are common approaches to avoid inclusions. Selecting only the cleanest portions of an ingot may result in bearings relatively free from material flaws. This approach is not always successful because detrimental flaws that exist deep within an ingot can pass inspections undetected, potentially causing subsequent failure. Recent efforts to commercialize an intermetallic material, 60NiTi, for rolling element bearings demonstrates a pathway to produce bearing steel that is free from unwanted ceramic particle inclusions. In this paper, the process used to make bearing-grade inclusion-free NiTi alloys is 1 NASA Glenn Research Center, Cleveland, Ohio, 44135, USA; ORCID (Note: Go to www.orcid.org for details) Page 1 of 30 described and applied to steelmaking. At its core, the NiTi process differs from steelmaking in one key aspect. NiTi alloys are made from elementally pure starting materials that are melted, blended, and processed in equipment that minimizes exposure to oxygen and other sources of contamination, ensuring an inclusion-free product. -

Road Safety Education, Training and Publicity Update – All Wards 4

ROTHERHAM BOROUGH COUNCIL – REPORT TO MEMBERS 1. Meeting: Economic Development, Planning and Transportation Matters 2. Date: 21 st September 2009 3. Title: Road Safety Education, Training and Publicity update – All Wards 4. Directorate: Environment & Development Services 5. Summary To inform the Cabinet Member of the work undertaken by the Road Safety Education, Training and Publicity staff between August 2008 and August 2009 6. Recommendations That the Cabinet Member notes the contents of the report and refers to Regeneration Scrutiny Panel for information. 7. Proposals and Details Road Safety staff continue to forge links with partners to increase Education, Training and Publicity activity within the Borough Education Schools We have provided: • Talks and demonstrations of crossing roads using miniature equipment for infant children and playgroup children at Aston Lodge, Aston C.E , Rawmarsh Ashwood, Maltby St Marys’, High Greave,Aston Springwood, Aughton, Kilnhurst, Rawmarsh Monkwood, Swallownest, St Ann’s, canklow, Brinsworth Howarth, Brinsworth Whitehill, Rockingham, Rawmarsh Thorogate, Brinsworth Manor, Wath Victoria, Meadowview, Coleridge, Rawmarsh Childrens’ Centre, and Arnold Centre schools, Harthill, Ravenfield, Mommas, Anston Hillcrest, Coleridge Centre pre school groups and Greasbrough rising fives. • An interactive talk for parents and children at Canklow. This was arranged following a request by the local PCSO. • Road safety assemblies at all primary schools in the Wath, West Melton and Brampton areas and at Maltby Redwood, Brinsworth Whitehill, Rawmarsh Ryecroft, Swinton Fitzwilliam and Anston Greenlands • Practical help with a topic on Friction for all year 6 pupils at High Greave School. • Practical session on colour and light for 2 infant classes at Wickersley Northfield Primary and 3 groups at Brinsworth Manor Infants. -

Valid From: 01 September 2019 Bus Service(S) What's Changed Areas

Bus service(s) 208 Valid from: 01 September 2019 Areas served Places on the route Sheffield Sheffield Interchange Carbrook Ice Sheffield Meadowhall Tinsley Brinsworth Meadowhall Interchange Canklow Dinnington Interchange Whiston Thurcroft Laughton Common Dinnington What’s changed Route and timetable changes. Operator(s) How can I get more information? TravelSouthYorkshire @TSYalerts 01709 51 51 51 Bus route map for service 208 01/02/2019 Scholes Parkgate Dalton Thrybergh Braithwell Ecclesfield Ravenfield Common Kimberworth East Dene Blackburn ! Holmes Meadowhall, Interchange Flanderwell Brinsworth, Hellaby Bonet Lane/ Bramley Wincobank Brinsworth Lane Maltby ! Longley ! Brinsworth, Meadowhall, Whiston, Worrygoose Lane/Reresby Drive ! Ñ Whitehill Lane/ Meadowhall Drive/ Hooton Levitt Bawtry Road Meadowhall Way 208 Norwood ! Thurcroft, Morthen Road/Green Lane Meadowhall, Whiston, ! Meadowhall Way/ Worrygoose Lane/ Atterclie, Vulcan Road Greystones Road Thurcroft, Katherine Road/Green Arbour Road ! Pitsmoor Atterclie Road/ Brinsworth, Staniforth Road Comprehensive School Bus Park ! Thurcroft, Katherine Road/Peter Street Laughton Common, ! ! Station Road/Hangsman Lane ! Atterclie, AtterclieDarnall Road/Shortridge Street ! ! ! Treeton Dinnington, ! ! ! Ulley ! Doe Quarry Lane/ ! ! ! Dinnington Comp School ! Sheeld, Interchange Laughton Common, Station Road/ ! 208! Rotherham Road 208 ! Aughton ! Handsworth ! 208 !! Manor !! Dinnington, Interchange Richmond ! ! ! Aston database right 2019 Swallownest and Heeley Todwick ! Woodhouse yright p o c Intake North Anston own r C Hurlfield ! data © y Frecheville e Beighton v Sur e South Anston c ! Wales dnan ! r O ! ! ! ! Kiveton Park ! ! ! ! ! ! Sothall ontains C 2019 ! = Terminus point = Public transport = Shopping area = Bus route & stops = Rail line & station = Tram route & stop 24 hour clock 24 hour clock Throughout South Yorkshire our timetables use the 24 hour clock to avoid confusion between am and pm times. -

Local Environment Agency Plan

EA-NORTH EAST LEAPs local environment agency plan SOUTH YORKSHIRE AND NORTH EAST DERBYSHIRE CONSULTATION REPORT AUGUST 1997 BEVERLEY LEEDS HULL V WAKEFIELD ■ E n v ir o n m e n t A g e n c y Information Services Unit Please return or renew this item by the due date Due Date E n v ir o n m e n t A g e n c y YOUR VIEW S Welcome to the Consultation Report for the South Yorkshire and North East Derbyshire area which is the Agency's view of the state of the environment and the issues that we believe need to be addressed during the next five years. We should like to hear your views: • Have we identified all the major issues? • Have we identified realistic proposals for action? • Do you have any comments to make regarding the plan in general? During the consultation period for this report the Agency would be pleased to receive any comments in writing to: The Environment Planner South Yorkshire and North East Derbyshire LEAP The Environment Agency Olympia House Gelderd Road Leeds LSI 2 6DD All comments must be received by 31st December 1997. All comments received on the Consultation Report will be considered in preparing the next phase, the Action Plan. This Action Plan will focus on updating Section 4 of this Consultation Report by turning the proposals into actions with timescales and costs where appropriate. All written responses will be considered to be in the public domain unless consultees explicitly request otherwise. Note: Whilst every effort has been made to ensure the accuracy of information in this report it may contain some errors or omissions which we shall be pleased to note. -

Table of Contents

Table of Contents INTRODUCTION…………………………………………………………………………………………………. 3 SUNY-ESF FIRST DESTINATION SURVEY: SUMMARY REPORT FOR 2016……………………... 7 Overall Responses…………………………………………………………………………………………. 7 Employment Information……………………..…………………………………………………………… 8 Continuing Education Information……………..…………………………………………………………. 11 Participation In University Programs…………..………………………………………………………….. 11 DEPARTMENT OF CHEMISTRY…………………..………………………………………………….……... 12 Overall Responses………………………………..…………………………………………………….….. 12 Employment Information………………………..………………………………………………………… 12 Continuing Education Information……………..…………………………………………………………. 14 Participation in University Programs……………..……………………………………………………….. 14 DEPARTMENT OF ENVIRONMENTAL and FOREST BIOLOGY……………………………..………. 15 Overall Responses…………………………………………………………………………………………. 15 Employment Information…………………………………………………………………….……………. 15 Continuing Education Information…………………………………………………………….………….. 21 Participation in University Programs……………………………………………………………………… 22 DEPARTMENT OF ENVIRONMENTAL RESOURCES ENGINEERING……………………..……….. 23 Overall Responses………………………………………………………………………………………….. 23 Employment Information…………………………………………………………………………………... 23 Continuing Education Information…………………………………………………………………………. 26 Participation in University Programs………………………………………………………………………. 27 DEPARTMENT OF ENVIRONMENTAL SCIENCE……………………………..………............................. 28 Overall Responses………………………………………………………………………………………….. 28 Employment Information………………………………………………………………………………….. 28 Continuing Education -

Annual Report of the Director Bureau of Standards to the Secretary Of

ANNUAL REPORT OF THE DIRECTOR BUREAU OF STANDARDS TO THE SECRETARY OF COMMERCE FOR THE FISCAL YEAR ENDED JUNE 30, 1915 WASHINGTON GOVERNMENT PRINTING OFFICE 1915 ANNUAL REPORT OF THE DIRECTOR BUREAU OF STANDARDS TO THE SECRETARY OF COMMERCE FOR THE FISCAL YEAR ENDED JUNE 30, 1915 WASHINGTON GOVERNMENT PRINTING OFFICE 1915 CONTENTS. Page. I. Functions, organization, and location 11 1. Standards of measurement 11 2. Pliysical constants 12 3. Standards of quality 12 4. Standards of performance 13 5. Standards of practice 14 6. Relation of the Bureau's work to the public 14 7. Relation of the Bureau's work to the Government service 16 8. Organization 17 9. Location ^ 18 II. Scientific and technical divisions 19 1. Weights and measures 19 Weights and balances 19 Capacity and length measures 19 Sieve testing 20 Volumetric glassware 20 Density tables for petroleum oils 20 Barometry 20 Testing of watches 21 Precision and empirical equations 22 Inspecting and testing scales 22 Operation of test-car equipment 23 Condition of track scales 23 Linear expansion of materials 24 Annual conference on weights and measures 25 Tolerances and specifications 25 So-called net-weight amendment to the pure-food law 26 Standard-barrel act 26 Information furnished on subjects pertaining to measures of length, mass, capacity, and time 26 Publications on weights and measures 27 2. Thermometry, pyrometry, and heat measurements 27 Platinum resistance thermometers 27 A AVheatstone bridge for resistance thermometry 28 A multiple junction thermoelectric thermometer 28 -

Rotherham South Neighbourhood Newsletter – Christmas Edition

Rotherham South Neighbourhood Newsletter – Christmas Edition December 2019 You said, we did Community speedwatch We have been working with residents in the local community to tackle speeding drivers. This month, we have undertaken community speedwatch operations in Flanderwell, South Anston, Brinsworth and Treeton. This is in response to residents raising concerns about the manner in which vehicles travel through their area. Operation Shield Almost 2,500 Rotherham homes are now protected against thieves in Rotherham, as Operation Shield continues to expand across the district. In the South officers have been helping residents in areas of Dinnington to protect their home. Operation Shield sees officers work with residents to mark and register valuables using a unique forensic solution. This not only acts as a deterrent to thieves, but ensures that if items are stolen, they are much easier to trace and return to their owners. The visits are carried out in conjuction with South Yorkshire Fire and Rescue, who carry out fire safety checks. If you’re interested in learning more about Operation Shield, please email [email protected]. It is completely free! Crime and antisocial behaviour update Tackling drug use and supply We continue to carry out proactive patrols and stop and search anyone we believe to be involved in criminal activity or in possession of drugs. We recently seized cannabis in Bramley while on proactive patrols, which led to a man being arrested under suspicion of possession with intent to supply Class A and Class B drugs. We continue to execute warrants based on intelligence provided by members of the community, and we check licensed premises with a drugs dog to detect anyone in possession of drugs. -

CPM 20CV Powder Metal Stainless Tool Steel

DATA SHEET Issue 1 ® CPM 20CV Powder Metal Stainless Tool Steel LATROBE SPECIALTY STEEL your source for all Crucible CPM products Typical Composition C Mn Si Cr W Mo V 1.90 0.30 0.30 20.00 0.60 1.00 4.00 CPM 20CV is a highly wear resistant, powder metallurgy stainless tool steel. The steel contains a large volume of extremely hard vanadium carbides, which provide excellent wear resistance. CPM 20CV contains the highest amount of chromium of any high-vanadium stainless steel currently available. The chromium-rich matrix provides outstanding corrosion resistance. CPM 20CV is a versatile stainless tool steel with a unique combination of high wear resistance, high corrosion resistance, good impact toughness, and excellent polishability. This combination of properties is the result of the fine grain size, small carbides, and superior cleanliness of the powder metallurgy (PM) microstructure. CPM 20CV excels in applications, which require a combination of high wear resistance and high corrosion resistance. The unique combination of properties makes CPM 20CV an excellent steel for plastic injection feed screws, barrel liners, screw tips, and mold cavities, especially for plastic resins which contain abrasive fillers. Other applications include food processing equipment, pelletizer knives, granulator knives, and high- performance custom knives. Relative Properties Toughness Wear Resistance Corrosion Resistance CPM 20CV CPM 9V CPM Rex M4 440C 420 58 HRC 53 HRC 63 HRC 56 HRC 50 HRC Physical Properties Edge Retention (CATRA Test Relative to 440C) -

Local Environment Agency Plan

6 o x I local environment agency plan SOUTH YORKSHIRE & NORTH EAST DERBYSHIRE FIRST ANNUAL REVIEW May 1999 BARNSLEY ROTHERHAM SHEFFIELD CHEST ELD E n v ir o n m e n t Ag e n c y NATIONAL LIBRARY & INFORMATION SERVICE HEAD OFFICE Rio House, Waterside Drive, Aztec West. Almondsbury, Bristol BS32 4UD South Yorkshire & North East Derbyshire LEA P First Annua! Review SOUTH YORKSHIRE AND NORTH EAST DERBYSHIRE AREA ADMINISTRATIVE BOUNDARIES W . 'H D i SwllhoJ* j Oram iRNSLEY DONCASTER ) ROTHERHAM SHEFFIELD (DERBYSHIRE DALES) KEY CHESTERF.IEUD) BOLSOVER - CATCWENT BOUNDARY RIVER ADMINISTRATIVE BOUNDARY MAIN ROAD SGRTH EAST \ 0 2 4 6 8 10km ___1 i_________ i_________ i_________ i_________ i Scale ENVIRONMENT AGENCY 032505 South Yorkshire & North East Derbyshire LEAP First Annual Review EXECUTIVE SUMMARY The South Yorkshire & North East Derbyshire LEAP First Annual Review reports on the progress made during the last year against LEAP actions. The actions published in the LEAP are supplemental to our everyday work on monitoring, surveying and regulating to protect the environment. Some of the key achievements on our everyday work include: i) In September 1998 Michael Clapham MP officially opened the Bullhouse Minewater Treatment Plant. The scheme is a pioneering £1.2m partnership project funded by European Commission, Coal Authority, Environment Agency, Hepworths Building Products, Barnsley MBC and Yorkshire Water. Within one week a visible reduction could be seen in ochre levels in the River Don, after more than 100 years of pollution. ii) Monckton Coke and Chemical Company have successfully commissioned a combined heat and power plant, costing approximately £7 million. -

CPM S60V Data Sheet

® DATA SHEET CPM S60V Typical Composition C Cr Mo V 2.15 17.0 .4 5.5 CPM S60V is a corrosion resistant, highly wear-resistant steel made by the Crucible Particle Metallurgy process. It is a martensitic stainless steel with a high volume of chromium and vanadium carbides for exceptionally good wear and corrosion resistance. S60V offers substantial improvements in wear resistance over 440C and D2, and other high chromium tool steels, with corrosion resistance much better than 440C. The CPM process results in a finer, more uniform carbide distribution imparting improved toughness and grind ability to high alloy steels. The CPM process also allows the design of more highly alloyed grades which cannot be produced by conventional steelmaking. Typical Applications: Plastic injection and extrusion feed screws, non-return valve components, pelletizing equipment, gate and nozzle inserts, industrial knives, slitters, and cutters, long-wearing specialty cutlery, injection molds and inserts, wear components for food and chemical processing, bearings, bushings, valves, rolls and gear pumps. Special Note to Knifemakers: The recommended hardness for blades is HRC 56/58, which is designed to provide an excellent combination of corrosion resistance, wear resistance and edge toughness. Mechanical Properties Hardness (1) Impact Toughness ft-lbs HRC Heat Treatment CPM S60V 56 (A) 16 CPM S60V 59 (B) 12 CPM S60V 60.5 (C) 11 1.) A=Hardened 1850°F (1010°C), double tempered 400°F (205°C). B=Hardened 1950°F (1065°C), double tempered 400°F (205°C). C=Hardened 2050°F (1120°C), double tempered 400°F (205°C). CONVENTIONAL STEEL CPM STEEL This data sheet is for informational purposes only.