Improving Solar Cell Efficiency Using Lead Selenium Nanocrystals

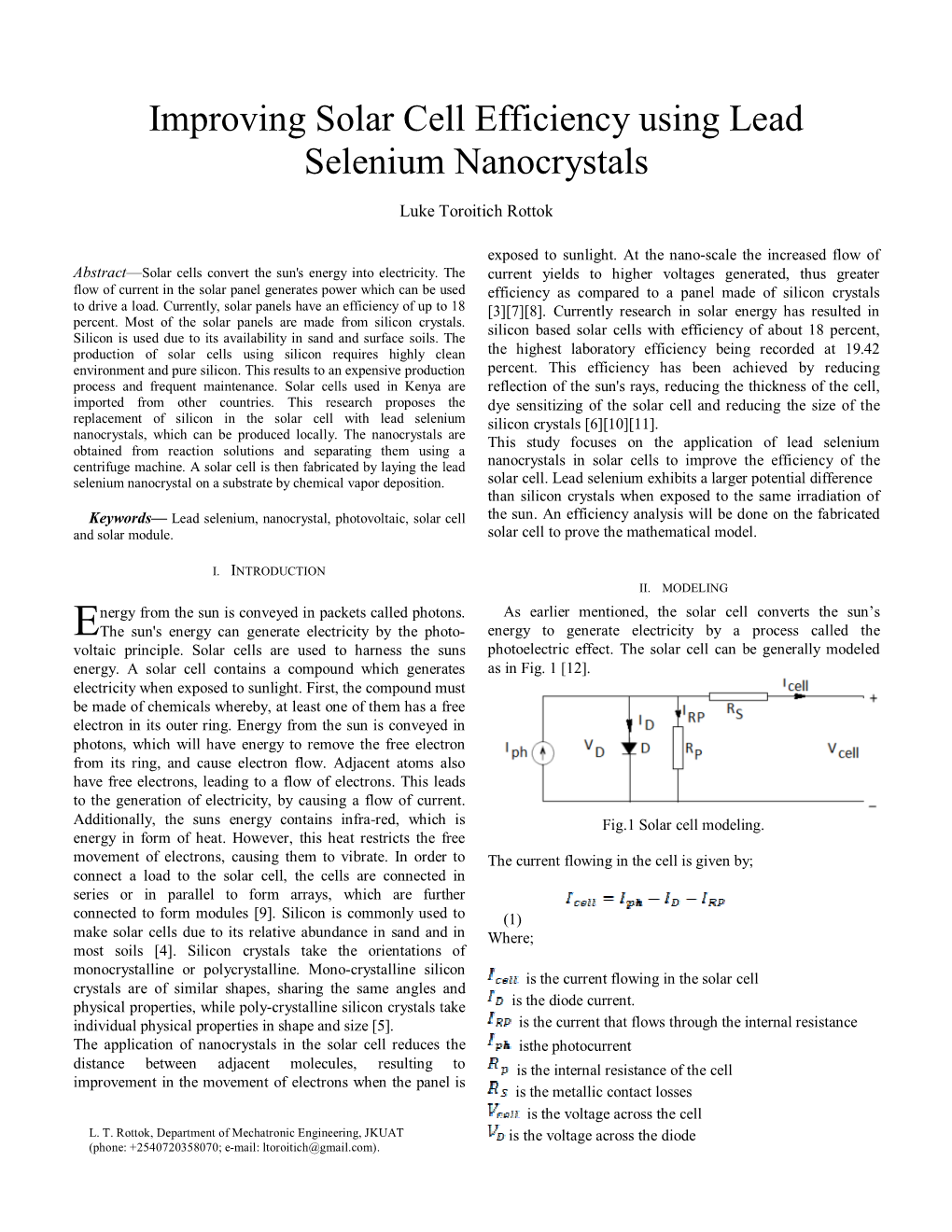

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Nanocrystal Quantum Dot Devices: How the Lead Sulfide (Pbs) System Teaches Us the Importance of Surfaces

398 CHIMIA 2021, 75, No. 5 COLLOIDAL NANOCRYSTALS doi:10.2533/chimia.2021.398 Chimia 75 (2021) 398–413 © W. Lin, M. Yarema*, M. Liu, E. Sargent, V. Wood Nanocrystal Quantum Dot Devices: How the Lead Sulfide (PbS) System Teaches Us the Importance of Surfaces Weyde M. M. Lina, Maksym Yarema*a, Mengxia Liub, Edward Sargentb, and Vanessa Wood*a Abstract: Semiconducting thin films made from nanocrystals hold potential as composite hybrid materials with new functionalities. With nanocrystal syntheses, composition can be controlled at the sub-nanometer level, and, by tuning size, shape, and surface termination of the nanocrystals as well as their packing, it is possible to select the electronic, phononic, and photonic properties of the resulting thin films. While the ability to tune the properties of a semiconductor from the atomistic- to macro-scale using solution-based techniques presents unique opportunities, it also introduces challenges for process control and reproducibility. In this review, we use the example of well-studied lead sulfide (PbS) nanocrystals and describe the key advances in nanocrystal synthesis and thin-film fabrication that have enabled improvement in performance of photovoltaic devices. While research moves forward with novel nanocrystal materials, it is important to consider what decades of work on PbS nanocrystals has taught us and how we can apply these learnings to realize the full potential of nanocrystal solids as highly flexible materials systems for functional semiconductor thin-film devices. One key lesson is the importance of controlling and manipulating surfaces. Keywords: Lead sulfide colloidal nanocrystals · Nanocrystal quantum dot devices · Semiconductor nanocrystals Weyde M. -

Copyright by Vikas Reddy Voggu 2017

Copyright by Vikas Reddy Voggu 2017 The Dissertation Committee for Vikas Reddy Voggu Certifies that this is the approved version of the following dissertation: Development of Solution Processed, Flexible, CuInSe2 Nanocrystal Solar Cells Committee: Brian A. Korgel, Supervisor John G. Ekerdt Delia Milliron Thomas Truskett David A. Vanden Bout Development of Solution Processed, Flexible, CuInSe2 Nanocrystal Solar Cells by Vikas Reddy Voggu Dissertation Presented to the Faculty of the Graduate School of The University of Texas at Austin in Partial Fulfillment of the Requirements for the Degree of Doctor of Philosophy The University of Texas at Austin December 2017 Dedication For my loving parents, Prabhakar Reddy Voggu and Mallika Voggu. For all those who are working towards the development of clean energy technologies. Acknowledgements Graduate study at UT Austin has been a time where I learnt the most in my life. I have grown as a scientist, leader, and effective communicator while pursuing my PhD. I am thankful for all the mentors and peers who helped me to gain this knowledge and become a better person. First of all, I would like to thank my adviser Dr. Brian Korgel, who always kept his trust in me while guiding me with tough projects. Right from the moment he called me the “(photovoltaic) device guru,” I have been inspired, and in times when the experiments do not go as planned, it is his belief in me and motivation that I received from him that kept me going. Apart from learning how to approach scientific problems, I have also developed collaboration and mentorship skills from him. -

SCIENCE BEHIND the NANO SOLAR CELL Kshitij Yograj Patil 1 , Dr

SCIENCE BEHIND THE NANO SOLAR CELL Kshitij Yograj Patil 1 , Dr. Vishali P.Sonawane 2 , Yograj Gorakh Patil 3 1. Student in First year Engineering , Sapkal Knowledge Hub , Anjneri (NASIK). 2. Asstent prof in Engineering Chemistry ,Brahama Valley,Engg.College,Anjneri –(NASIK) 3.Siniour Executive Officer in Glenmark ABSTRACT The Global Warming is today’s major problem of the world. Nano-technology has to come as boon in the energy sources in the form of solar –cell. It is eco-friendly device Nanotechnology, with its unprecedented control over the structure of materials, can provide us with superior materials that will unlock tremendous potential of many energy technologies currently at the discovery phase. The quest for more sustainable energy technologies is not only a scientific endeavor that can inspire a whole generation of scientists, but the best way to establish a new economy based on innovation, better paid jobs, and care for the environment I. INTRODUCTION As we know that Sun shines approximately 1000 watts of energy per square kilometer of Earth. If all this energy is to be converted into usable forms then it can light up our homes for many centuries that also free of cost. So this energy was collected in the form of panels called as solar panels. Solar panels are effective way to channelize sunlight and use it for electricity. An array of solar panels are also used to convert solar energy into electrical energy. solar cell were of larger size and having efficiency of 67.4% but changing the panel by silicon nano rods made it possible to capture 96.7% of light. -

Direct Laser Written Nano- & Micro-Optical Textures For

Direct Laser Written Nano- & Micro-Optical Textures for Photovoltaics Applications Zur Erlangung des akademischen Grades eines DOKTOR-INGENIEURS von der KIT-Fakultät für Elektrotechnik und Informationstechnik des Karlsruher Instituts für Technologie (KIT) genehmigte DISSERTATION von M.Sc., Stephan Dottermusch geb. in: Pforzheim Tag der mündlichen Prüfung: 06. Juni 2019 Hauptreferent: Prof. Dr. Bryce Richards Korreferenten: Prof. Dr. Christiane Becker Prof. Dr. Heinz Kalt Kurzfassung xiv Kurzfassung Im Gegensatz zu anderen Technologien, welche der Gewinnung von elektrischer Energie dienen, basierte die Photovoltaik nicht auf einer langen Umwandlungskette. Anstatt einen Kraftstoff zu verbrennen, die Abwärme dieses Prozesses zur Wassererwärmung zu nutzen um schließlich mit Wasserdampf eine Turbine zu betreiben, welche einen elektrischen Generator antreibt, gelingt in der Photovoltaik die Umwandlung von Lichtenergie in elektrische Energie direkt. Dieser Vorgang ermöglicht eine Dezentralisierung der elektrischen Energiegewinnung. Des Weiteren besitzt die Photovoltaik mit der Sonne eine erneuerbare Energiequelle, welche auf menschlichen Zeitskalen nicht erlischt. Zusätzlich entstehen im Betrieb keine Treibhausgase, welche den Klimawandel weiter anheizen. Trotz der vielen Vorteile der Photovoltaik loht sich die Produktion von Solarzellen, als Herzstücke der elektrischen Energiegewinnung in der Photovoltaik, erst dann im großen Stil, wenn der Preis pro erzeugte kWh elektrische Energie mit dem anderer herkömmlicher Energieträger mithalten kann. Insbesondere der Wirkungsgrad einer Solarzelle hat signifikanten Einfluss auf die Kosten für die elektrische Energie. Der Wirkungsgrad hängt zum einen ab von der Effizienz, mit der einfallendes Licht in freie Ladungsträger umgewandelt werden kann, und zum anderen davon, mit welcher Effizienz die Ladungsträger extrahiert werden können. Diese Dissertation beschäftigt sich mit Oberflächenstrukturen, welche eine gesteigerte Nutzung des einfallenden Lichtes ermöglichen. -

Cost Boundary in Silicon Solar Panel

International Journal of Chemical Engineering and Applications, Vol. 2 , No. 5 , October 2011 Cost Boundary in Silicon Solar Panel V.K.Sethi, Mukesh Pandey, and Priti Shukla high-efficiency, high-output concentrator solar cells work in Abstract—Photovoltaic is a solar power technology that uses areas with minimal cloud cover, independent of temperature solar cells or solar photovoltaic arrays to convert light directly or latitude into electricity with no emission of dangerous gases and with Most solar-cell technology is silicon based. There are least amount of industrials waste. Solar cells are a key three primary types of silicon solar cells, each named after technology in the drive toward cleaner energy production. the crystalline structure of the silicon used during Unfortunately, solar technology is not yet economically competitive and the cost of solar cells needs to be brought fabrication: down. Growth of the photovoltaic (PV) market is still • Mono-crystalline silicon has a single and continuous constrained by high initial capital costs of PV. One way to crystal lattice structure with practically zero defects or overcome this problem is to reduce the amount of expensive impurities. semiconductor material used. The materials cost and manufacturing cost of thin-film solar is much lower than wafer • Poly-crystalline silicon, also called poly-silicon, comprises based and drops much faster than wafer based in large-scale discrete grains, or crystals, of mono-crystalline silicon that manufacturing, but thin-film solar cells tend to have lower create regions of highly uniform crystal structures performance compared with conventional solar cells. separated by grain boundaries. Developments in PV technologies may lead to cheaper systems at the likely expense of life expectancy and efficiency. -

Low Cost Solar Cells to Enable Global Uptake of This Promising Technology

Fabrication and Characterisation of a Nanocrystal Activated Schottky Barrier Solar Cell Philippa Kate Hardy Submitted in accordance with the requirements for the degree of Doctor of Philosophy as part of the integrated MSc/PhD in Low Carbon Technologies The University of Leeds Energy Research Institute School of Process, Environment and Materials Engineering Doctoral Training Centre in Low Carbon Technologies November, 2014 i The candidate confirms that the work submitted is her own, except where work which has formed part of jointly authored publications has been included. The contribution of the candidate and the other authors to this work has been explicitly indicated below. The candidate confirms that appropriate credit has been given within the thesis where reference has been made to the work of others. Chapter 4, 5 and 6 includes the following work; Philippa Hardy, Robert Mitchell, Ross Jarett, Richard Douthwaite and Rolf Crook, Nanocrystal Activated Schottky Barrier PV Cell, Proceedings from PVSAT-9, Wales, UK, 9-11th April 2013. The work detailed within this paper was all the candidates own with the guidance of Dr Rolf Crook, with the exception of the following; Ross Jarett who produced the silver nanowires, Robert Mitchell and Richard Douthwaite who produced the CdS and CdSe nanocrystals. Chapter 5 includes the following work; Philippa Hardy and Rolf Crook, A Nanocrystal Test Bed for Excitonic Photovoltaic Cells, Proceedings from PVSAT-7, Edinburgh, UK, 6-8th April 2011. The work detailed within this paper was all the candidates own with the guidance of Dr Rolf Crook. This copy has been supplied on the understanding that it is copyright material and that no quotation from the thesis may be published without proper acknowledgement. -

JETIR Research Journal

© 2018 JETIR November 2018, Volume 5, Issue 11 www.jetir.org (ISSN-2349-5162) SIMULATION OF POLYCRYSTALLINE SILICON SOLAR CELL USING GPVDM SOFTWARE 1P.Shanmugaraja, 2M. Swathika, 3A. Santhoshini. a Associate Professor, Dept. of Electronics and Instrumentation Engineering, Annamalai University – 608002, India b PG Student, Dept. of Electronics and Instrumentation Engineering, Annamalai University – 608002, Tamilnadu, India c NPMaSS MEMS Design centre, Dept. of Electronics and Instrumentation Engineering, Annamalai University – 608002, Tamilnadu, India Abstract : Electricity is playing a vital role in our daily life. Solar energy is an alternative source to produce electricity. Different types of solar cells are available to convert solar energy into electrical energy. In this paper, polycrystalline silicon solar cell is simulated using GPVDM software. Solar cell and GPVDM software are slightly explained first. Then, how the efficiency of solar cell is changed with respect to the change in thickness of different layers of a polycrystalline silicon solar cell is simulated and the outputs are represented in the form of graph. Finally, this paper concludes that the variation in the thickness of base layer causes notable change in efficiency when compared to other layers. Keywords - Solar cell, Polycrystalline silicon solar cell, GPVDM simulation software. INTRODUCTION A solar cell or photovoltaic cell is an electrical device that converts the energy of light directly into electricity by the photovoltaic effect. It is a form of photoelectric cell whose electrical characteristics such as current, voltage or resistance vary, when exposed to light. Solar cells are photovoltaic, irrespective of whether the source is sunlight or an artificial light. Individual solar cell devices are combined to form modules, otherwise known as solar panels. -

Fabrication & Characterization of TCO-Less Cylindrical Dye

Fabrication & Characterization of TCO-less Cylindrical Dye-sensitized Solar Cells using Metallic Wires 著者 Kapil Gaurav year 2015 その他のタイトル メタル細線をバックコンタクト電極に用いた透明導 電膜を必要としない色素増感太陽電池の作製と光電 変換特性 学位授与年度 平成27年度 学位授与番号 17104甲生工第244号 URL http://hdl.handle.net/10228/5553 Fabrication & Characterization of TCO-less Cylindrical Dye-sensitized Solar Cells using Metallic Wires GRADUATE SCHOOL OF LIFE SCIENCE AND SYSTEMS ENGINEERING KYUSHU INSTITUTE OF TECHNOLOGY Thesis FOR THE DEGREE OF DOCTOR OF PHILOSOPHY GAURAV KAPIL ENROLLMENT NO: 12897016 JUNE 2015 PHD. SUPERVISOR PROFESSOR. SHYAM S. PANDEY TABLE OF CONTENTS ABSTRACT CHAPTER 1: INTRODUCTION. 1-23 1.1 General overview of solar cells 1 1.2 Flexible solar cells 3 1.2.1 Silicon based flexible solar cells 3 1.2.2 CIGS based flexible solar cells 3 1.2.3 Plastic solar cells 5 1.3 Gratzel solar cells or dye-sensitized solar cells 6 1.3.1 Introduction & general working principle 6 1.3.2 Energy band diagram & recombination process involved 7 1.4 TCO-less dye-sensitized solar cells 8 1.5 Cylindrical solar cells 10 1.5.1 Cylindrical TCO-less dye-sensitized solar cells 12 1.5.2 Calculation of photoconversion efficiency for cylindrical solar cells 13 1.6 Challenges & ideas to overcome 15 References 17 CHAPTER 2: INSTRUMENTATION & CHARACTERIZATION 24-46 2.1 Characterization of solar cells 24 2.1.1 Current voltage measurement under standard test conditions 25 2.1.2 Short circuit current density (Jsc) and Incident photon to current conversion efficiency (IPCE) 26 2.1.3 Dark current and current-voltage characteristics -

Download Conference Program

Conference Program Program at a glance Start End Monday, December 10, 2018 8:00 9:30 A10 Registration 9:30 10:45 A11 Inauguration 10:45 11:30 Coffee Break 11:30 13:45 A12 Keynotes 1 13:45 14:45 Lunch Energy production and Electronic and Magnetic 14:45 16:25 A13 B13 Storage 1 Applications 1 16:25 17:00 Coffee Break Nanomedicine – Water, Food and 17:00 19:00 A14 Synthesis, Assembly B14 Environment and Characterization Start End Tuesday, December 11, 2018 Evaporators and Nano Pharmaceuticals 9:00 10:20 A21 B21 chemical reactors at the and Nutraceuticals microscale 10:20 11:00 A22a Keynotes 2a 11:00 11:30 Coffee Break 11:30 13:30 A22b Keynotes 2b 13:30 15:00 Lunch 15:00 16:50 A23 Exhibitors & Poster session 1 16:50 17:20 Coffee Break Energy production and Electronic and Magnetic 17:20 19:00 A24 B24 Storage 2 Applications 2 Start End Wednesday, December 12, 2018 Nano-Imaging / 9:00 10:20 A31 B31 Industrial Applications Diagnostics 10:20 10:50 Coffee Break 10:50 12:50 A32 Keynotes 3 12:50 14:20 Lunch 14:20 15:20 A33 Exhibitors & Poster session 2 15:20 15:50 Coffee Break Biomedical applications Micro and Nano 15:50 17:30 A34 B34 of nanotechnology sensors 1 19:00 20:00 Entertainment 20:00 21:30 Gala Dinner and Awards Start End Thursday, December 13, 2018 Micro and Nano sensors Nanotechnology 9:00 10:40 A41 B41 2 Challenges 10:40 11:10 Coffee Break 11:10 12:30 A42 Nano Association 12:30 13:30 Lunch 13:30 14:30 A43 Panel 14:30 14:45 Coffee Break 14:45 15:00 A44 Closing session Session name is composed of 3 Characters: 1st character Hall: A or B -

Low-Temperature Induced Enhancement of Photoelectric Performance in Semiconducting Nanomaterials

nanomaterials Review Low-Temperature Induced Enhancement of Photoelectric Performance in Semiconducting Nanomaterials Liyun Wu 1,2, Yun Ji 2,3, Bangsen Ouyang 2,3, Zhengke Li 1,* and Ya Yang 2,3,4,* 1 School of Material Science and Engineering, Sun Yat-Sen University, Guangzhou 510275, China; [email protected] 2 Center for Excellence in Nanoscience, Beijing Key Laboratory of Micro-Nano Energy and Sensor, Beijing Institute of Nanoenergy and Nanosystems, Chinese Academy of Sciences, Beijing 101400, China; [email protected] (Y.J.); [email protected] (B.O.) 3 School of Nanoscience and Technology, University of Chinese Academy of Sciences, Beijing 100049, China 4 Center on Nanoenergy Research, School of Physical Science and Technology, Guangxi University, Nanning 530004, China * Correspondence: [email protected] (Z.L.); [email protected] (Y.Y.) Abstract: The development of light-electricity conversion in nanomaterials has drawn intensive attention to the topic of achieving high efficiency and environmentally adaptive photoelectric tech- nologies. Besides traditional improving methods, we noted that low-temperature cooling possesses advantages in applicability, stability and nondamaging characteristics. Because of the temperature- related physical properties of nanoscale materials, the working mechanism of cooling originates from intrinsic characteristics, such as crystal structure, carrier motion and carrier or trap density. Here, emerging advances in cooling-enhanced photoelectric performance are reviewed, including aspects Citation: Wu, L.; Ji, Y.; Ouyang, B.; of materials, performance and mechanisms. Finally, potential applications and existing issues are also Li, Z.; Yang, Y. Low-Temperature summarized. These investigations on low-temperature cooling unveil it as an innovative strategy to Induced Enhancement of further realize improvement to photoelectric conversion without damaging intrinsic components Photoelectric Performance in and foresee high-performance applications in extreme conditions. -

Conference Programme

Monday, 25 September 2017 Monday, 25 September 2017 CONFERENCE PROGRAMME ORAL PRESENTATIONS 1AO.1 13:30 - 15:00 Devices & Characterisation Please note, that this Programme may be subject to alteration and the organisers reserve the right to do so without giving prior notice. The current version of the Programme is available at www.photovoltaic-conference.com. Chairpersons: Martin C. Schubert (i) = invited Fraunhofer ISE, Germany Albert Polman AMOLF, Netherlands Monday, 25 September 2017 1AO.1.1 Analysis for Efficiency Potential of High Efficiency Solar Cells M. Yamaguchi OPENING TTI, Nagoya, Japan H. Yamada PLENARY SESSION 1AP.1 NEDO, Kawasaki, Japan Y. Katsumata 08:30 - 09:30 Stairway to High Efficiency JST, Chiyoda, Japan 1AO.1.2 Special Introductory Presentation: Efficiency Limit of a 17.8% Efficiency Nanowire Chairpersons: Solar Cell Nicholas J. Ekins-Daukes J.E.M. Haverkort, D. van Dam, Y. Cui, A. Cavalli, N.J.J. van Hoof, P.J. van Veldhoven & Imperial College London, United Kingdom E.P.A.M. Bakkers John Van Roosmalen Eindhoven University of Technology, Netherlands ECN, Netherlands S.A. Mann & E.C. Garnett AMOLF, Amsterdam, Netherlands 1AP.1.1 Indirect to Direct Bandgap Transition in Methylammonium Lead Halide Perovskite J. Gómez Riva T. Wang, B. Daiber, S.A. Mann, E.C. Garnett & B. Ehrler DIFFER, Eindhoven, Netherlands AMOLF, Amsterdam, Netherlands J.M. Frost & A. Walsh 1AO.1.3 EU PVSEC Student Award Winner Presentation: Multi-Segment Photovoltaic Laser Imperial College London, United Kingdom Power Converters and Their Electrical Losses R. Kimovec & M. Topic 1AP.1.2 EU PVSEC Student Award Winner Presentation: Maximum Power Extraction Enabled University of Ljubljana, Slovenia by Monolithic Tandems Using Interdigitated Back Contact Bottom Cells with Three H. -

SCIENCE BEHIND the NANO SOLAR CELL Kshitij Yograj Patil 1 , Dr

SCIENCE BEHIND THE NANO SOLAR CELL Kshitij Yograj Patil 1 , Dr. Vishali P.Sonawane 2 , Yograj Gorakh Patil 3 1. Student in First year Engineering , Sapkal Knowledge Hub , Anjneri (NASIK). 2. Asstent prof in Engineering Chemistry ,Brahama Valley,Engg.College,Anjneri –(NASIK) 3.Siniour Executive Officer in Glenmark ABSTRACT The Global Warming is today’s major problem of the world. Nano-technology has to come as boon in the energy sources in the form of solar –cell. It is eco-friendly device Nanotechnology, with its unprecedented control over the structure of materials, can provide us with superior materials that will unlock tremendous potential of many energy technologies currently at the discovery phase. The quest for more sustainable energy technologies is not only a scientific endeavor that can inspire a whole generation of scientists, but the best way to establish a new economy based on innovation, better paid jobs, and care for the environment I. INTRODUCTION As we know that Sun shines approximately 1000 watts of energy per square kilometer of Earth. If all this energy is to be converted into usable forms then it can light up our homes for many centuries that also free of cost. So this energy was collected in the form of panels called as solar panels. Solar panels are effective way to channelize sunlight and use it for electricity. An array of solar panels are also used to convert solar energy into electrical energy. solar cell were of larger size and having efficiency of 67.4% but changing the panel by silicon nano rods made it possible to capture 96.7% of light.