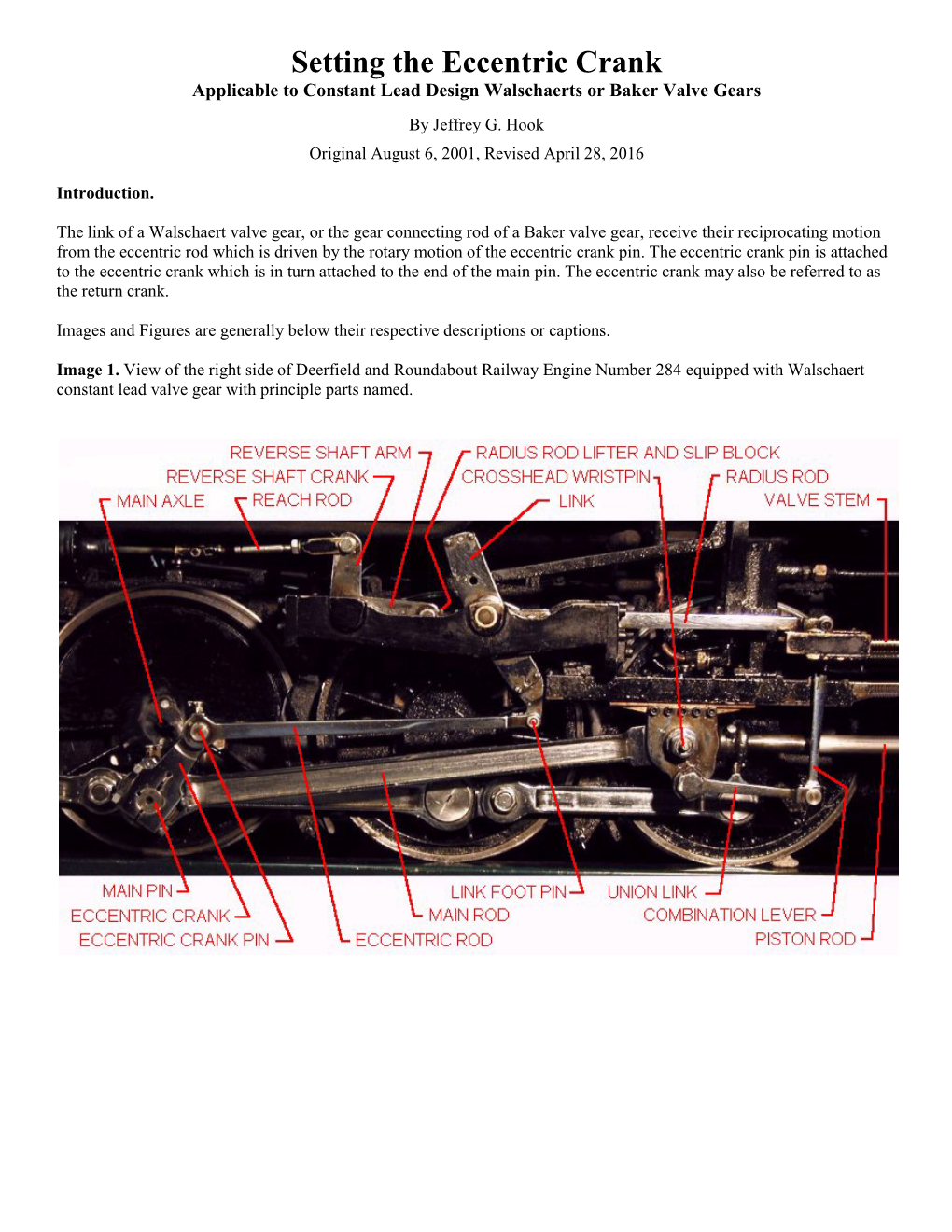

Setting the Eccentric Crank Applicable to Constant Lead Design Walschaerts Or Baker Valve Gears

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Walschaerts Valve-Gear 2 Return Cranks with Steel Screws & Nuts

This pack contains the following parts: - Walschaerts Valve-Gear 2 Return Cranks with steel screws & nuts. 2 Expansion links with bushes & This kit contains parts to construct 2BA nuts. a set of Walschaerts type valve- 2 Lifting arms with grub screws & Allen key. gear as used on ROUNDHOUSE 2 Lifting links. locomotives. It is of a simplified 4 M2 steel screws & nuts. design, which does not use a 6 5BA steel washers. combination lever and is intended 2 Radius rods. for use with the ROUNDHOUSE 2 Weigh shaft brackets 1 Weigh shaft. Cylinder set. 2 Starlock washers 2 Roll pins. NOTE:- Frames, Cylinders, 6 Short crank pins. Coupling Rods, Connecting Rods, 2 Plain crank pins Axles and Outside Cranks are not included with this set of parts. 1 Push Rod Connector, Screw & Starlock. 1 Stainless Steel spring & Long Crank Pin. 1 Reversing lever handle. 1 Reversing lever base. 3 M2 screws and nuts. 2 M3 mounting screws. 1 Steel push rod & quicklink connector. Roundhouse Engineering Co. Ltd 2 Eccentric rods. Units 6 to 9, Churchill Business Park, Churchill Road, Wheatley, Doncaster. DN1 2TF. England. Tel 01302 328035 Fax 01302 761312 Email: [email protected] www.roundhouse-eng.com 1 Walschaerts Valve-Gear Part Number WVG Assembly of Walschaerts type valve-gear 1). Radius Rod. 2). Lifting Link. 3). Lifting Arm. Diagram4). Expansion showing Linkgeneral Bush. arrangement 5). Weigh of Walschaerts Shaft Bracket valve (Penguin). gear. NOTE:- Frames, Coupling rods, connecting rods and outside cranks are not included6). Weigh with this Shaft. set of 7). parts. Starlock Washer. 8). 2BA Nut. -

Lima 2-8-0 “Consolidation”, Developed for TS2013, by Smokebox

Union Pacific 4000 Class 4884-1 "Big Boy" circa 1948-49 Developed by Smokebox TM for Dovetail Games' Train Simulator © Smokebox 2021, all rights reserved Issue 1 Union Pacific 4000 Class 4884-1 "Big Boy" Steam Locomotive Page 2 Contents Introduction ....................................................................................................................................................... 7 32- and 64-bit TS ................................................................................................................................................ 7 Expert or Simple Controls mode, HUD and Automatic Fireman ....................................................................... 7 "All-in-one" .................................................................................................................................................... 7 Standard TS Automatic Fireman .................................................................................................................... 8 F4 HUD ........................................................................................................................................................... 8 High Detail (HD) and Standard Detail (SD) ........................................................................................................ 8 Recommended Settings ..................................................................................................................................... 9 Cab Layout ...................................................................................................................................................... -

Engine Base Timing

Front Gear Assembly Configuration Two front gear train combinations are presently utilized on the Signature™, ISX, and QSX15 engines. Signature™, ISX3, ISX2, and QSX15 engines use a scissor gear for the lower idler gear and the injector cam gear. ISX1 does not use a scissor gear at the idler location. ISX2 engines built between January 1999, and January 2000, utilize a scissor gear for the lower idler gear only. The injector cam gear is a straight cut spur gear, similar to the ISX1. After January, 2000, the ISX2 has scissor gears for both the cam and lower idler. This procedure describes the removal, inspection, and installation of the different gear combinations. Front Gear Assembly without Scissor Gear View shown is from left to right and top to bottom. Valve camshaft gear Injector camshaft gear Adjustable idler gear Lower idler gear Accessory gear Crankshaft gear. 1 of 28 5/20/17, 2:06 PM Front Gear Assembly with Scissor Gear View shown is from left to right and top to bottom. Valve camshaft gear Injector camshaft scissor gear Adjustable idler gear Lower idler scissor gear Accessory gear Crankshaft gear. Scissor Gear Definitions Do not attempt to remove any gears before reading scissor gear definitions. Serious personal injury or engine damage can result if instructions are not followed. The following terms describe the conditions of the scissor gears for removal, installation, and operation. Unloaded The gear will be unloaded when removing, installing, and setting gear backlash. Unload the gear by backing out two gear adjusting screws until the gear teeth align. The idler scissor gear is loaded when the gear backlash is set. -

O-Steam-Price-List-Mar2017.Pdf

Part # Description Package Price ======== ================================================== ========= ========== O SCALE STEAM CATALOG PARTS LIST 2 Springs, driver leaf........................ Pkg. 2 $6.25 3 Floor, cab and wood grained deck............. Ea. $14.50 4 Beam, end, front pilot w/coupler pocket...... Ea. $8.00 5 Beam, end, rear pilot w/carry iron.......... Ea. $8.00 6 Bearings, valve rocker....................... Pkg.2 $6.50 8 Coupler pockets, 3-level, for link & pin..... Pkg. 2 $5.75 9 Backhead w/fire door base.................... Ea. $9.00 10 Fire door, working........................... Ea. $7.75 11 Journal, 3/32" bore.......................... Pkg. 4. $5.75 12 Coupler pockets, small, S.F. Street Railway.. Pkg.2 $5.25 13 Brakes, engine............................... Pkg.2 $7.00 14 Smokebox, 22"OD, w/working door.............. Ea. $13.00 15 Drawbar, rear link & pin..................... Ea. $5.00 16 Handles, firedoor............................ Pkg.2. $5.00 17 Shelf, oil can, backhead..................... Ea. $5.75 18 Gauge, backhead, steam pressure.............. Ea. $5.50 19 Lubricator, triple-feed, w/bracket, Seibert.. Ea. $7.50 20 Tri-cock drain w/3 valves, backhead.......... Ea. $5.75 21 Tri-cock valves, backhead, (pl. 48461)....... Pkg. 3 $5.50 23 Throttle, nonworking......................... Ea. $6.75 23.1 Throttle, non working, plastic............... Ea. $5.50 24 Pop-off, pressure, spring & arm.............. Ea. $6.00 25 Levers, reverse/brake, working............... Kit. $7.50 26 Tri-cock drain, less valves.................. Ea. $5.75 27 Seat boxes w/backs........................... Pkg.2 $7.50 28 Injector w/piping, Penberthy,................ Pkg.2 $6.75 29 Oiler, small hand, N/S....................... Pkg.2 $6.00 32 Retainers, journal........................... Pkg. -

Spare Parts Catalog in PDF Format

- The Baker Talt,e $ear I K Locomotive Talye $ears foIanufactured by THE PILLIOD COMPANY 3o Church St., New York Railway Exchange, Chicago ORKS: SWANTON, OHIO - - THE BAKER LOCOMOTIVE VALVE GEAR HE LocoMorrvE Valvr GneR, governing as it does the distribution of steam to the cylinders, performs one of the most important functions of the loco- motive machinery. It should be well designed, manufactured with mechanical precision, and, last but not least it nrust be maintain.ed in every day service. Mainte- nance, as we understand it, means first, proper and ample lubrication, inspection and adjustment and lastly, replace- ment of worn parts. Considering that a force of some five thousand pounds is put in operation to move a locomotive valve and that this force momentum changes its direction twice with each reyo- lution of the drivers, it must be evident even to those not experienced in locomotive operation that a wearing process is taking place in the yalve gear parts. When this wear develops into lost motion between parts, the efficiency of the valve gear is impaired and the locomotive loses its tractive power, consumes more coal and water, and eventually fails because of broken parts, resulting in train delays and other expensiye operating difficulties. THr Bercn Ver.vr Gran has been designed through many years of experience, first, to give efficient seryice and second, to provide easy and inexpensive maintenance; it is manufac- tured as nearly perfect as any machinery can be. Our manu- facturing plant located on the New York Central Lines at Swanton, Ohio, just west of Toledo, is engaged exclusively in building locomotive valve gears and parts and is the only plant in this country, perhaps in the world, devoted to this one line. -

![United States Patent [19], [11] Patent Number: 4,736,717 Fujikawa Et Al](https://docslib.b-cdn.net/cover/8295/united-states-patent-19-11-patent-number-4-736-717-fujikawa-et-al-1378295.webp)

United States Patent [19], [11] Patent Number: 4,736,717 Fujikawa Et Al

United States Patent [19], [11] Patent Number: 4,736,717 Fujikawa et al. [45] Date of Patent: Apr. 12, 1988 [54] VALVE GEAR FOR FOUR-CYCLE ENGINE [56] References Cited " _ _ U.S. PATENT DOCUMENTS [75] Inventors: 351:: 1319;??? Egi’iii?uyukl 386,213 7/1888 Nash ......... .. 123/901 3 ’ 1 ’ "n ’ 779,328 1/1905 Svebilios 123/901 Kalmgwa, all Of Japan 1,248,597 12/1917 Baker ........... .. 123/901 1,409,710 3/1922 Haltenberger ................... .. 123/902 [73] Ass1gnee: JKasgilllsakl Jukogyo Kabushlkl Kaisha, Primary Examiner_lra s_ Lazarus [57] ABSTRACT [21] Appl. No.: 848,206 A valve gear for a four-cycle engine having an over hung crankshaft connecting with an output shaft, [22] Filed; AP“ 4, 1936 wherein a guide portion having such a shape folding the output shaft as to return back to a starting point in two . turns, is formed on the output shaft, and an interlocking [30] Forelgn Apphcatlon Pmmty Data mechanism guided by the guide portion is provided to APR 4, 1935 [JP] Japan - 60-71716 open the valves for the four-cycle engine. It is prefera F?‘b. 17, 1986 Japan ................................ .. 61-32539 ble that the guide pol-fig“ is formed as cam face displac ing the interlocking mechanism. The guide portion can [51] Int, (11,4 _ _ _ . _ _ _ , _ _ _ _ _ _ _ , , _ _ _ _ ,, F01L 1/04 be formed on a block other than the output shaft for [52] US. Cl. .......................... .. 123/90.2; l23/90.6 easy machining and also for adjustable valve timing. -

New Haven Steam

New Haven Steam I‐4‐e #1385 W‐10‐c tender A detail study for modelers By Chris Adams, Charlie Dunn, Randy Hammill and the NHRHTA Photo Library Overview Scope is classes with HO Scale models available Focus is on prototype and applies to all scales Highlight variations within a class Highlight modifications over time Switchers Freight Passenger o T‐2‐b o K‐1‐b/d o G‐4 J‐1 I‐2 o Y‐3 o o o L‐1 o I‐4 o Y‐4 o R‐1 o I‐5 o R‐3‐a Common Modifications Headlights o <1917 ‐ Oil headlights o 1917‐1920 ‐ Pyle National (?) cylindrical headlights. Not all were replaced. o 1920‐1924 ‐ Pyle National (?) on new locomotives except R‐1‐a class #3310‐#3339. o ESSCo Golden Glow headlights starting in 1926. Brass number boards red for passenger locomotives, and black for freight and switchers. Pilots <1937 – Boiler tube. >1937 –Steel Strap –phased in over time. >1931 – Pilot plows applied to many (most?) locomotives, often removed in spring/summer Footboard pilots on many locomotives in local freight service (often on tender as well). Other c1927+ – Spoked pilot wheels replaced with disc wheels c1940’s – Compressed air clappers applied to many bells Headlights Oil Pyle National (?) ESSCo Golden Glow Pyle National vs. Golden Glow Pyle National Headlight from UP Big Boy ESSCo Golden Glow Headlight Note side mounted hinge Note top mounted hinge Pilots Boiler Tube Boiler Tube with pilot plow Foot board Steel Strap with pilot plow Steel Strap The New Haven Railroad and Tenders o The New Haven frequently swapped tenders o Turntable length limited size of early tenders o Large tenders were purchased for Shoreline service o Tender class changed when a stoker was installed. -

ON a NEW REVERSING and EXPANSIVE VALVE-GEAR. The

418 AUGUST1880. ON A NEW REVERSING AND EXPANSIVE VALVE-GEAR. - BY MR. DAVID- JOY, OF LONDON. The Reversing and Expansive Valve-Motion, which is the subject of the present paper, was originally drawn out by the writer in a crude state, but possessing all its present elements, in the year 1868-9 ; and has since been, at different times, the subject of frequent investigation and experiment on his part. In 1877 he made it a special study, first working it out on paper, and afterwards testing all the movements and positions by means of models. And thus, passing through innumerable forms under the correction of various errors of action, it has ended in the arrangement which is now submitted to the Institution. In passing, the writer may call attention to the fact, that this is only one of the many instances where inventions are the result of a long course of work, followed in a given and definite direction, and with a special end in view. It thus helps to disprove the theory of opponents of the patent system, who rather characterise inventions as lucky chances, which men of scheming brains fall upon without expecting it. A few such cases do occur, just to give colour to this statement ; but even these generally happen to men who have been working laboriously on some kindred subject. In the writer’s case, as an engineer, his attention has been specially directed by circumstances, and perhaps partly by, taste, to the question of the movement of the valves in steam and other engines. -

Full Page Photo

THE LIFE AND TIMES OF A DUKE Martyn J. McGinty AuthorHouse™ UK Ltd. 500 Avebury Boulevard Central Milton Keynes, MK9 2BE www.authorhouse.co.uk Phone: 08001974150 © 2011. Martyn J. McGinty. All rights reserved No part of this book may be reproduced, stored in a retrieval system, or transmitted by any means without the written permission of the author. First published by AuthorHouse 04/25/2011 ISBN: 978-1-4567-7794-4 (sc) ISBN: 978-1-4567-7795-1 (hc) ISBN: 978-1-4567-7796-8 (e) Front Cover Photo: Th e Duke at Didcot (Courtesy P. Treloar) Any people depicted in stock imagery provided by Th inkstock are models, and such images are being used for illustrative purposes only. Certain stock imagery © Th inkstock. Th is book is printed on acid-free paper. Because of the dynamic nature of the Internet, any web addresses or links contained in this book may have changed since publication and may no longer be valid. Th e views expressed in this work are solely those of the author and do not necessarily refl ect the views of the publisher, and the publisher hereby disclaims any responsibility for them. Born out of Tragedy and Riddles, his lineage traceable, unerasable, back through the great houses of Chapelon, Giffard, Stephenson, Belpaire and Watt, the Duke was laid to rust by the sea, a few meagre miles from the mills that shaped the steel that formed the frames that bore the machine that Crewe built. Time passed and the Duke was made well again by kindly strangers. -

Patent Model Index

Smithsonian Institution Scholarly Press smithsonian contributions to history and technology • n u m b e r 5 4 Smithsonian Institution Scholarly Press PatentA Chronology Models Index of MiddleGuide to Missouri the Collections of Plains the NationalVillage Museum of AmericanSites History, Smithsonian Institution Volume 1: Listings by Patent NumberBy Craig and M. InventionJohnson Name with contributions by Stanley A. Ahler, Herbert Haas, and Georges Bonani Barbara Suit Janssen SerieS PublicationS of the SmithSonian inStitution Emphasis upon publication as a means of “diffusing knowledge” was expressed by the first Secretary of the Smithsonian. In his formal plan for the Institution, Joseph Henry outlined a program that included the following statement: “It is proposed to publish a series of reports, giving an account of the new discoveries in science, and of the changes made from year to year in all branches of knowledge.” This theme of basic research has been adhered to through the years by thousands of titles issued in series publications under the Smithsonian imprint, com- mencing with Smithsonian Contributions to Knowledge in 1848 and continuing with the following active series: Smithsonian Contributions to Anthropology Smithsonian Contributions to Botany Smithsonian Contributions to History and Technology Smithsonian Contributions to the Marine Sciences Smithsonian Contributions to Museum Conservation Smithsonian Contributions to Paleobiology Smithsonian Contributions to Zoology In these series, the Institution publishes small papers -

Steam Engine Collection

STEAM ENGINE COLLECTION The New England Museum of Wireless And Steam Frenchtown Road ~ East Greenwich, R.I. International Mechanical Engineering Heritage Collection Designated September 12, 1992 The American Society of Mechanical Engineers INTRODUCTION It has been said that an operating steam engine is ‘visual music’. The New England Museum of Wireless and Steam provides the steam engine enthusiast, the mechanical engineer and the public at large with an opportunity to experience the ‘music’ when the engines are in steam. At the same time they can appreciate the engineering skills of those who designed the engines. The New England Museum of Wireless and Steam is unusual among museums in its focus on one aspect of mechanical engineering history, namely, the history of the steam engine. It is especially rich in engines manufactured in Rhode Island, a state which has had an influence on the history of the steam engine in the United States out of all proportion to its size and population. Many of the great names in the design and manufacture of steam engines received their training in Rhode Island, most particularly in the shops of the Corliss Steam Engine Co. in Providence. George H. Corliss, an important contributor to steam engine technology, founded his company in Providence in 1846. Engines that used his patent valve gear were built in large numbers by the Corliss company, and by others, both in the United States and abroad, either under license or in various modified forms once the Corliss patent expired in 1870. The New England Museum of Wireless and Steam is particularly fortunate in preserving an example of a Corliss engine built by the Corliss Steam Engine Company. -

Expand Your Envelope with New Training Experiences

Malibu M-Class Owners and Pilots Association JULY / AUGUST 2020 MAGAZINE Volume 10 Issue 4 Expand Your Envelope With New Training Experiences Meet our S&EF Scholarship Winners Understanding the MOS Forecast RVSM PIREP Atlantic Crossing in the COVID-19 Era Legacy Flight Training Full Page 4/CAd 4/C IFC IFC IFC www.legacyflighttraining.com 2 MMOPA MAGAZINE JULY / AUGUST 2020 EXECUTIVE DIRECTOR’S NOTE MAGAZINE by Dianne White Executive Director and Editor Dianne White 18149 Goddard St. Overland Park, KS 66013 E-mail: [email protected] (316) 213-9626 Publishing Office 2779 Aero Park Drive 2020: Making Traverse City, MI 49686 Phone: (660) 679-5650 Advertising Director Go/No-Go Decisions John Shoemaker MMOPA 2779 Aero Park Drive Traverse City, MI 49686 Phone: 1-800-773-7798 ow’s your summer going? If you’re like most, your plans for travel, Fax: (231) 946-9588 vacation and business trips required some rerouting or outright E-mail: [email protected] cancelation. Making a go/no-go decision on a trip also involved Advertising Administrative looking at virus hotspots and what quarantine mandates exist at Coordinator & Reprint Sales Betsy Beaudoin your home base and at your destination. Presently, my home state of 2779 Aero Park Drive HKansas has a list of states that if you visit you must undergo a 14-day quarantine Traverse City, MI 49686 Legacy Flight Training Phone: 1-800-773-7798 upon returning home. But, I’ve been fortunate to do quite a bit of flying the past Fax: (231) 946-9588 45 days, which helped keep my skills sharp and logbook current.