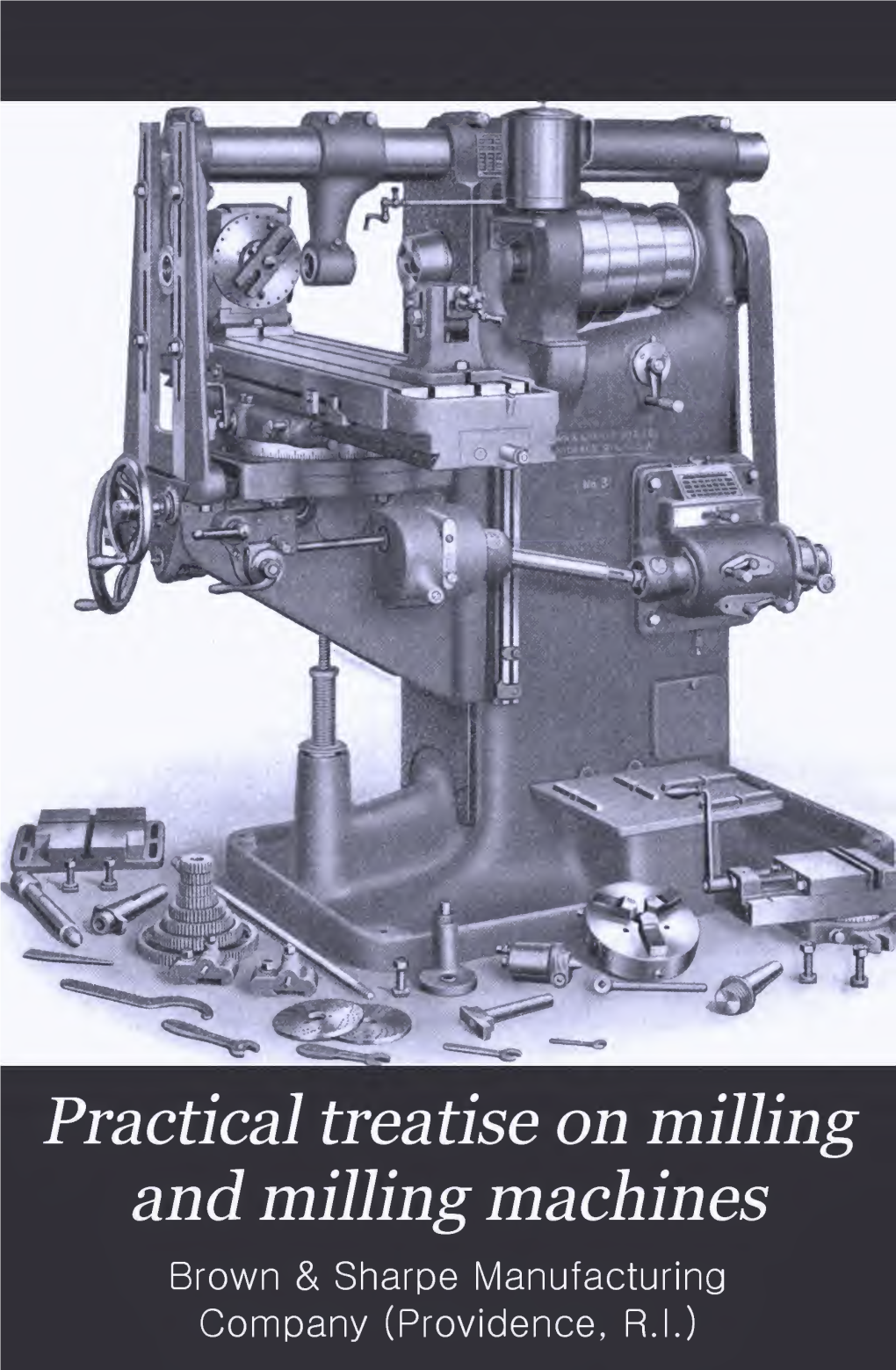

Practical Treatise on Milling and Milling Machines

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Transmission Errors in Precision Worm Gear Drives

University of Huddersfield Repository Fish, Michael Anderson Transmission errors in precision worm gear drives Original Citation Fish, Michael Anderson (1998) Transmission errors in precision worm gear drives. Doctoral thesis, University of Huddersfield. This version is available at http://eprints.hud.ac.uk/id/eprint/4851/ The University Repository is a digital collection of the research output of the University, available on Open Access. Copyright and Moral Rights for the items on this site are retained by the individual author and/or other copyright owners. Users may access full items free of charge; copies of full text items generally can be reproduced, displayed or performed and given to third parties in any format or medium for personal research or study, educational or not-for-profit purposes without prior permission or charge, provided: • The authors, title and full bibliographic details is credited in any copy; • A hyperlink and/or URL is included for the original metadata page; and • The content is not changed in any way. For more information, including our policy and submission procedure, please contact the Repository Team at: [email protected]. http://eprints.hud.ac.uk/ TRANSMISSION ERRORS IN PRECISION WORM GEAR DRIVES MICHAEL ANDERSON FISH A thesis submitted to the University of Huddersfield in partial fulfilment of the requirements for the degree of Doctor of Philosophy School of Engineering 'University of Huddersfield November 1998 DEDICATION To my parents Mary and Geofffor their infinite patience and understanding. You have taught me so much. ABSTRACT Transmission error is a measure of the positioning accuracy of a gear system. -

ISCAR's Objective Is to Create People Are the Most Precious Asset! a Strategic Partnership with Leading Enterprises Productivity Starts on the Production Floor

Make the RIGHT CHOICE! The Global Network Marketing Support Marketing Support & Production Center Make the RIGHT ISCAR has global manufacturing facilities in each of the following countries: In Europe In the Americas In Asia France Argentina South Korea Germany Brazil China CHOICE Italy United States Israel A Global Metalworking Company Spain In a world of different languages and different bring ISCAR personnel and facilities as close as possible mentalities, it is important to have a fully equipped, to customer production sites. Switzerland knowledgeable local supplier to meet your needs. Many of our subsidiaries have fully equipped training Turkey ISCAR knows this. We have subsidiary offices and agents centers. These centers are dedicated to providing a local Hungary located in 52 major industrial countries. In some of the location where metalworking personnel can be trained larger countries, regional offices have been opened to in the latest techniques and products for metal removal. Slovenia Wind Turbine Components Major Components 1 Rotor blade 8 Nacelle Modern wind turbines employ four major component The tower supports the rotor and nacelle and raises them assemblies - the rotor, nacelle, tower, and balance of to a height where higher wind speeds maximize energy system. The rotor includes blades which are used to extraction. Modern utility-scale wind turbine towers are 2 Rotor hub 9 Yaw drive harness wind energy and convert it into mechanical typically up to ~160 meters (~525´) high, with blades energy and a hub to support the blades. In addition, that measure up to ~130 meters (~426´) in diameter 3 Pitch system 10 Yaw motor most wind turbines have a pitch mechanism to rotate and rotor and nacelle assemblies weighing several and change the angle of the blades, based on the hundred tons. -

Gear Manufacturing

SUBJECT:-PRODUCTION TECHNOLOGY (MECH. 2ND YEAR) NAME:-ABHAY SUNDRIYAL DATE:-06/04/2020 GEAR MANUFACTURING Gear manufacture can be divided into two categories, forming and machining. Forming consists of direct casting, molding, drawing, or extrusion of tooth forms in molten, powdered, or heat softened materials. Machining involves roughing and finishing operations. FORMING GEAR TEETH: Characteristics: In all tooth-forming operations, the teeth on the gear are formed all at once from a mold or die into which the tooth shapes have been machined. The accuracy of the teeth is entirely dependent on the quality of the die or mold and in general is much less than that can be obtained from roughing or finishing methods. Most of these methods have high tooling costs, making them suitable only for high production quantities . Gear Hobbing Machine Hobbing machines provide gear manufacturers a fast and accurate method for cutting parts. This is because of the generating nature of this particular cutting process. Gear hobbing is not a form cutting process, such as gashing or milling where the cutter is a conjugate form of the gear tooth. The hob generates a gear tooth profile by cutting several facets of each gear tooth profile through a synchronized rotation and feed of the work piece and cutter. As the hob feeds across the face of the work piece at a fixed depth, gear teeth will gradually be generated by a series of cutting edges, each at a slightly different position. The number of cuts made to generate the gear tooth profile will correspond to the number of gashes of the hob. -

Hobs and Gear Hob G

MACHINERY ' S REFERENCE SERIES EACH NUMBER IS ONE UNIT I N A COMPLETE LIBRARY OF MACHINE DESIGN AND S HOP PRACTICE REV I SE D AND REPUBLISHED FROM MACHINERY NUMBER 133 HOBS AND GEAR HOB G B y J OH N E DGAR CON TE N TS Intro duction :P rinciples of the H obbing P roce ss Bobs f or S pur and S piral Gears S pecial H ob - tooth S hapes The Centering of the H ob in Ge ar I;I obbing e ar H obbing v s . M illing of G s b h M A C H I N E R Y p r h t 1 91 4 T h e n d s t r a P re ss , P s e rs , C , o y ig , I u i l u li of - L e t S t re e t N e w Y r% t 1 4 0 1 4 8 a fay t e , o Ci y Othe r boo%s in this series dealing with the subje ct o f Ge aring are as follows: —WORM GE R N G N o . l A I — E R N G , N o . 1 5 SPUR G A I — P1 RA E R NG N o . 20 S L G A I —B EV EL GE R N G N o . 37 A I M ACHI NERY The L e adin g Mech an ic al Jo u rnal M ACH IN E DE SIGN CON STR UCTION S HOP PR ACTICE TH E IN DUSTRIAL PRESS - 1 4 0 1 4 8 L afayett e St . -

Engineering Principles for Plastic Gears by Rudy Walter in Many Instances, Plastic Materials Perform Markedly Better Than Do Metals—Especially Pg

Also:Also: AA SuperSuper ToolTool forfor SUPERIORSUPERIOR GEARGEAR BLANKSBLANKS MakingMaking “Cents”“Cents” ofof DIEDIE CASTING COMPANYCOMPANY PROFILE:PROFILE: RaycarRaycar GearGear && MachineMachine Co.Co. SAFETYSAFETY MATTERS:MATTERS: EmployeeEmployee InputInput is Crucial TOOTHTOOTH TIPS:TIPS: DeterminingDetermining thethe CauseCause ofof EquipmentEquipment FailureFailure QQ&&AA withwith ChrisChris VianVian // TheThe BroachBroach MastersMasters A MEDIA SOLUTIONS PUBLICATION OCTOBER 2004 CLARKE GEAR COMPANY The QUIET company with more Gear technology per square foot than you’ll find anywhere. #1 in Service. • CNC Gear Grinding • CNC Hob Sharpening • Serrations • Face Gears (AGMA CL.15) • CNC Gear & Hob Inspection • Sprockets • Internal & External • CNC Gear Cutting • CMM Inspection Service • Spur to 12” Diameter • CNC Machining • Crown Gears • Helical • AS 9100 • CNC Gear Analysis • Splines • Worms • ISO 9000 CLARKE ENGINEERING, INC. Since 1954 50Ye a r s PH: 323-877-7590 • 818-768-0690 • FAX: 818-767-5577 of 8058 LANKERSHIM BLVD. • N. HOLLYWOOD, CA 91605 GEARS EMAIL: [email protected] • WWW.CLARKEGEAR.COM Gear Up with Clarke TOLL FREE: 888-277-GEAR (888-277-4327) OCTOBER 2004 A MEDIA SOLUTIONS PUBLICATION 6 industryNEWS 11 andyMILBURN – Tooth Tips New products, trends and developments in the Think like a detective when it comes to gear-manufacturing industry. determining the cause of equipment failure, because it will pay off in the long run. 10 terryMcDonald – Safety Matters departments Since employees are on the front lines of the manufacturing process, their input is crucial— especially when it comes to safety concerns. www.gearsolutionsonline.com features 12 Company Profile – Raycar Gear & Machine Co. By Russ Willcutt Paying attention to details and growing in a methodical manner has allowed this com- pany to break from the pack and emerge as an American success story. -

Understanding the Basic Principles of Power Skiving

GE AR SOLUTIONS MAGAZINE MAGAZINE AR SOLUTIONS UNDERSTANDING THE BASIC PRINCIPLES OF POWER SKIVING SKIVING POWER OF PRINCIPLES THE BASIC UNDERSTANDING Understanding the Basic Principles of Power Skiving ISSUE FOCUS Cutting Tools Workholding COMPANY PROFILE: Rochester Gear Inc. APRIL 2017 APRIL APRIL 2017 Your Resource for Machines, Services, and Tooling for the Gear Industry gearsolutions.com 1.Cover-2017-04.indd 1 3/31/17 11:03 AM GEAR FIXTURES ALL OPERATIONS LARGE GEAR PEDESTAL FIXTURES LEADERS ARBORS/MANDRELS in GEAR WORKHOLDING CHUCKS/ COLLETS for Over 60 YEARS PROVEN ROI’S • CASE STUDIES • Design and Build Custom Tooling • Outstanding On Time Delivery • Consultations and Installation • Rush Order Capability • Set Up Reduction Solutions • Attractive Pricing Drewco designs and builds European quality tooling and combines it with short lead-times and attractive prices. Tooling gears from 1” to 1,700lbs. Experts at Tooling Up Familes of Part Sizes USE BE A HERO IN YOUR OWN COMPANY 262.886.5050 | [email protected] | www.drewco.com IS YOUR GEAR DEBURRING STILL IN THE STONE AGE WWW.TOOLINK-ENG.COM • 303-776-6212 Reduce your manual labor and increase productivity with one of our Cutting-Edge 2017 James Engineering gear deburr machines. Please contact Toolink Engineering directly for additional information and to schedule machine demonstrations. First-Time Heat Treater Streamlines Production, Reducing Lead Times by Nearly 85% industry or an expert. As such, all TITAN furnaces are carefully designed and crafted with the end user in mind. “We used to send our products to a local heat treater before bringing them back in-house to finish the production process .. -

Gears & Gear Manufacturing

Gears & Gear Manufacturing Training Objective After watching the program and reviewing this printed material, the viewer will gain knowledge and understanding of the purpose and function of gears and become aware of the various manufacturing and finishing methods used to produce gears. • The basic physical elements of gears are explained • Gear terminology is explored • Gear manufacturing methods are demonstrated • Gear finishing techniques are shown Gear Descriptions and Functions Gears are mechanical components within machines and mechanical assemblies which transmit power and motion through successive engagement of their peripheral teeth. Gears perform certain key functions with machines and assemblies, including: • Reversing rotational direction • Altering angular orientation of rotary motion • Converting rotary to linear motion and vice-versa • Altering speed and power transmission ratios Gear design is based upon an involute curve form which imparts a rolling, rather than sliding action between engaging teeth. This rolling action provides a uniform rotary action that lowers both friction and wear of the gear teeth. Gear Terminology There are several gear and gear-tooth dimensions and terms important to the understanding of gear production and finishing processes. These terms include: • Base Circle: The diameter from which the involute tooth profile is developed. • Pitch Circle: The imaginary rolling circle produced by the meshing gears during rotation. Also known as the Pitch Diameter. • Line of Centers: Line connecting the Pitch Circle centers of mating gears. • Pitch Point: The point of tangency of two gear Pitch Circles, through the Line of Centers. • Line of Action: A line tangent to the Base Circles of mating gears, through the Pitch Point and thus the path of tooth contact. -

Selecting the Proper PFPE

BRICATI g the Prope O U ctin r P N L le FP e E Measuring S POLYMER GEARING REDUCING Planetary Gear Whine Successful ROTARY BROACHING SITE SAFETY COMPANY PROFILE: Chamfermatic, Inc. TOOTH TIPS Q&A: Tom Treuden, Butler Gear MARCH 2008 0308Cover.indd FC1 2/18/08 3:00:06 PM GleasonFP0806.indd IFC1 2/18/08 3:00:23 PM KAPP_0208.indd IFC1 2/18/08 3:00:48 PM 2 GEAR SOLUTIONS • MARCH 2008 • gearsolutionsonline.com Page2.indd 2 2/18/08 3:01:04 PM RP_FP_0208.indd 3 2/18/08 3:01:26 PM Nachi FP 0206.indd 4 2/18/08 3:01:52 PM MARCH 2008 VOLUME 6 NO. 60 FEATURES companyPROFILE CHAMFERMATIC, INC. 18 BY RUSS WILLCUTT Ease of use, sturdy construction, reasonable cost, and a host of excellent standard features are just a few of the attributes this company’s deburring machines provide. MEASURING EXCELLENCE IN POLYMER GEARING 20 BY DOUGLAS FELSENTHAL While the art may be found in the manufacturing of polymer gears, the science involves mea- p. 20 surement, and Kleiss Gear is the expert in combining the two. REDUCING GEAR WHINE IN PLANETARY GEAR TRANSMISSIONS 26 BY SHOUNAK M. ATHAVALE, PH.D. In an article penned by a technical specialist at the Ford Research Laboratory, two assembly tech- niques to reduce transmission error in planetary gear systems are examined. SELECTING THE RIGHT PFPE LUBRICANT 34 BY GEORGE B. MOCK Extreme environments call for extreme lubricating measures, and perfluoropolyethers provide the characteristics required for these—and other—demanding applications. -

Elements of Spherical Turning

ELEMENTS OF SPHERICAL TURNING A review of methods and appliances for machining contours involving circular arcs by Edgar T. Westbury THE NEED to machine components to spherical to finished shape as possible, and then chucked contours is often encountered in mechanical engi- crosswise, and at other angles, to its original axis, neering, and many devices varying in design and for the correction of spherical errors. These complexity, have been produced for this purpose. operations, needless to say, call for a special skill Several of these have been described at various of both hand and eye, they may, perhaps, have times in Model Engineer, but in view of the many now been completely superseded by modern pro- queries concerning spherical turning which have duction processes, but were certainly employed up arisen, there is a call for a general review of the to quite recent years. principles employed and the methods applicable to particular kinds of work. Cutting angles The tools and techniques employed in turning Freehand methods wood and other relatively soft materials (Fig. 2A) A great deal obviously depends on the degree are not so well suited to working on hard metals, of accuracy required in the spherical contour of in which cutting angles, and to some extent the work, and when using simple devices, this calls methods of application, are necessarily different. for considerable skill on the part of the operator. Tools for metal are usually applied with the top More positive accuracy can be obtained by devices with mechanical control of the tool movement, PRONG DRIVING CENTRE but only provided that these are well designed and properly adjusted. -

A Manufacturing Model for Ball-End Mill Gashing Based on a CAM System

12 The Open Mechanical Engineering Journal, 2012, 6, 12-17 Open Access A Manufacturing Model for Ball-End Mill Gashing Based on a CAM System Fei Tang*,1, Min Jin1, Xiaofeng Yue2, Zhanhua You2, Shuzhe Li1 and Xiaohao Wang1 1State Key Laboratory of Precision Measurement Technology and Instruments, Department of Precision Instruments and Mechanology, Tsinghua University, Beijing, 100084, China 2School of Electronics and Computer Science and Technology, North University of China, Taiyuan, Shanxi, 030051, China Abstract: To facilitate the manufacturing of a ball-end mill, this paper presents an algorithm for ball-end mills gashing by using a five-axis computer numerical control (CNC) grinding machine. In this study, the normal helix models are proposed. Then, based on the cutting edge geometric model and the machining mode of the five-axis computer numerical control (CNC) grinding machine, the coordinate of the grinding point when the step of the gash out is grinded will be calculated. With the input data of ball-end mill geometry, wheels geometry, wheel setting and machine setting, the NC code for machining will be generated. Then the code will be used to simulate the ball-end mill machining in 3 Dimension. The 3D simulation system of the ball-end mill grinding is generated by VBA and AutoCAD2008. The algorithm of ball- end mill gashing can be verified by the 3D simulation system. Result shows that the algorithm presented in this paper provides a practical and efficient method for the manufacture of a ball-end mill gashing. Keywords: CNC grinding, ball-end mill, gash out, grinding wheel. -

Economics of CNC Gear Gashing Vs. Large D.P. Hobbing

Economics of CNCGear Gashing Vs. Large D~ Hobbing by Joseph W. Coniglio Vic:e .President, Engineering Gould' &: Eberhardt Gear Macltinery Co. Gashing Gear gashing is a gear machining process, very much like tools, has proven mandatory to meet the production de- gear milling, utilizing the principle of cutting one or more mand's of today. Asa result of the "back seat" position, the tooth (or tooth space) at a time. The term "GASHINC" to- gear cutting industry two years ago was far behind all other day applies to the roughing, or roughing and finishing, of machine tools in all applications of machine design. and tool- coarse diametral pitch gears and sprockets. Manufacturing ing technology. 'these large coarse gears by conventional methods of rough and finish hobbing can lead to very long machining cycles and uneconomical madtine utilizat.ion. Gear Milling Gear gashing is gear milling, but the tenn "GASHING" is Gear milling is still alive in both small and large shops. used to designate the application of using gear milling ma- Most of them, however, are using 40 to SO year-old chines and tools designed with today's technology in mind underpowered mechanical machines with undersize tool ar- and in effect (Fig. 1). Gear cuUing tool development has bars and high-speed cutters designed more than a generation taken a "back seatUto the advances in modem tooling tech- ago. They are on our production floors nibbling away, nology. The advent of carbide and numerical controls has led creeping through material at a snaili's pace and increasing to complete tooling .systems for all other types of machine manufacturing 'costs. -

Optimization of Surface Roughness, Material Removal Rate and Cutting Tool Flank Wear in Turning Using Extended Taguchi Approach

OPTIMIZATION OF SURFACE ROUGHNESS, MATERIAL REMOVAL RATE AND CUTTING TOOL FLANK WEAR IN TURNING USING EXTENDED TAGUCHI APPROACH A thesis submitted in partial fulfillment of the requirements for the degree of Master of Technology In Production Engineering By UMESH KHANDEY Roll No. 207ME208 NATIONAL INSTITUTE OF TECHNOLOGY ROURKELA 769008, INDIA OPTIMIZATION OF SURFACE ROUGHNESS, MATERIAL REMOVAL RATE AND CUTTING TOOL FLANK WEAR IN TURNING USING EXTENDED TAGUCHI APPROACH A thesis submitted in partial fulfillment of the requirements for the degree of Master of Technology In Mechanical Engineering By UMESH KHANDEY Under the guidance of DR. SAURAV DATTA NATIONAL INSTITUTE OF TECHNOLOGY ROURKELA 769008, INDIA ii NATIONAL INSTITUTE OF TECHNOLOGY ROURKELA 769008, INDIA Certificate This is to certify that the project report entitled “OPTIMIZATION OF SURFACE ROUGHNESS, MATERIAL REMOVAL RATE AND CUTTING TOOL FLANK WEAR IN TURNING USING EXTENDED TAGUCHI APPROACH” submitted by Sri Umesh Khandey has been carried out under my supervision in partial fulfillment of the requirements for the degree of Master of Technology in Production Engineering at National Institute of Technology, Rourkela and this work has not been submitted elsewhere before for any academic degree/diploma. ------------------------------------------ Dr. Saurav Datta Lecturer Department of Mechanical Engineering NIT Rourkela Rourkela-769008 Date: iii ACKNOWLEDGEMENT I would like to express my sincere gratitude to Dr. Saurav Datta, Lecturer of Department of Mechanical Engineering, NIT Rourkela, for his guidance and help extended at every stage of this project work. I am deeply indebted to him for giving me a definite direction and moral support to complete the project successfully. I am also thankful to Prof.