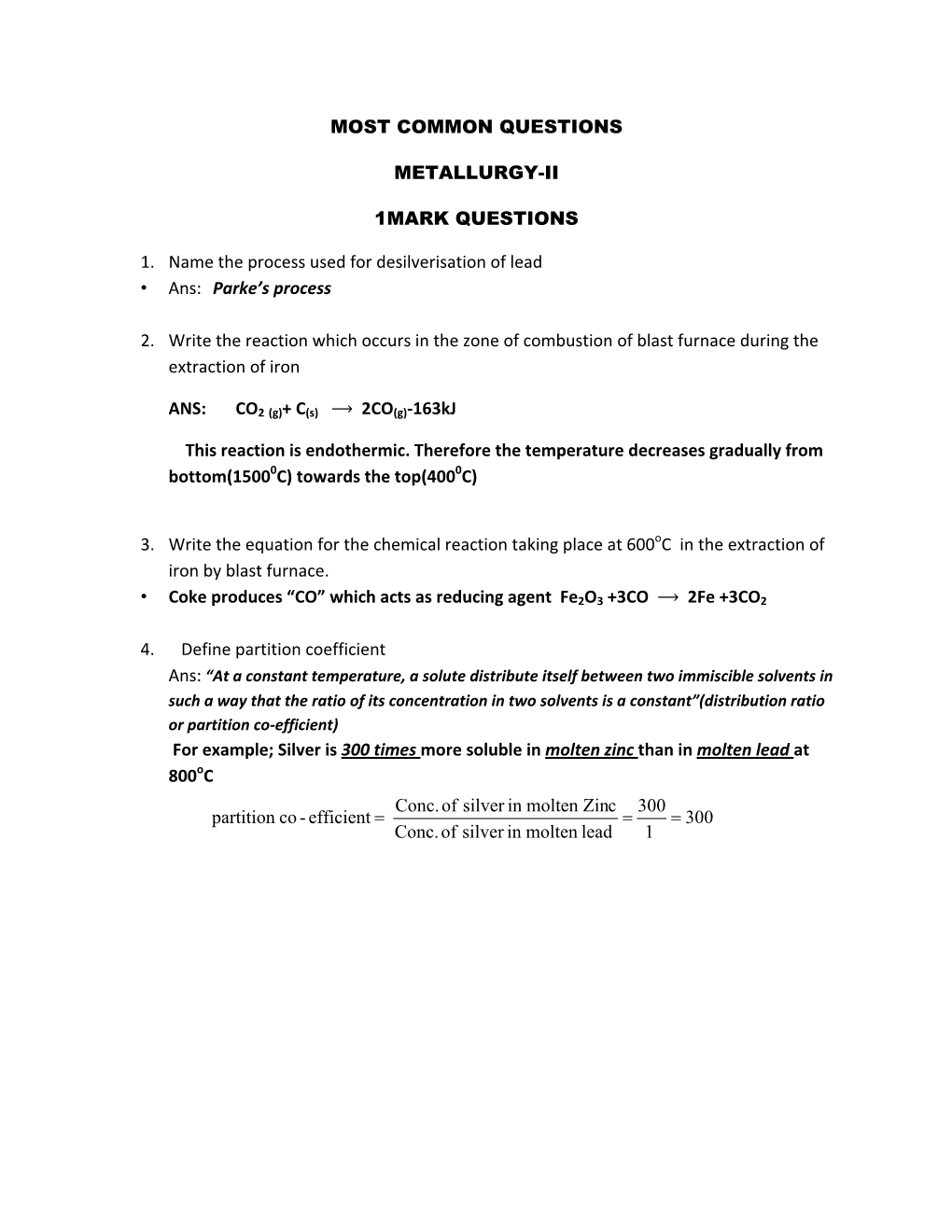

Most Common Questions Metallurgy-Ii 1Mark

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Metal Extraction Processes for Electronic Waste and Existing Industrial Routes: a Review and Australian Perspective

Resources 2014, 3, 152-179; doi:10.3390/resources3010152 OPEN ACCESS resources ISSN 2079-9276 www.mdpi.com/journal/resources Review Metal Extraction Processes for Electronic Waste and Existing Industrial Routes: A Review and Australian Perspective Abdul Khaliq, Muhammad Akbar Rhamdhani *, Geoffrey Brooks and Syed Masood Faculty of Science, Engineering and Technology, Swinburne University of Technology, Hawthorn, VIC 3122, Australia; E-Mails: [email protected] (A.K.); [email protected] (G.B.); [email protected] (S.M.) * Author to whom correspondence should be addressed; E-Mail: [email protected]; Tel.: +61-3-9214-8528; Fax: +61-3-9214-8264. Received: 11 December 2013; in revised form: 24 January 2014 / Accepted: 5 February 2014 / Published: 19 February 2014 Abstract: The useful life of electrical and electronic equipment (EEE) has been shortened as a consequence of the advancement in technology and change in consumer patterns. This has resulted in the generation of large quantities of electronic waste (e-waste) that needs to be managed. The handling of e-waste including combustion in incinerators, disposing in landfill or exporting overseas is no longer permitted due to environmental pollution and global legislations. Additionally, the presence of precious metals (PMs) makes e-waste recycling attractive economically. In this paper, current metallurgical processes for the extraction of metals from e-waste, including existing industrial routes, are reviewed. In the first part of this paper, the definition, composition and classifications of e-wastes are described. In the second part, separation of metals from e-waste using mechanical processing, hydrometallurgical and pyrometallurgical routes are critically analyzed. -

Lead Dross Bismuth Rich (Updated 15.11.2019).Xlsx 1

Lead Dross, Bismuth Rich Substance Name: Substance Information Page: Lead, dross bismuth rich https://echa.europa.eu/registration-dossier/-/registered-dossier/14687 Legend Decisive substance sameness criterion Indicative substance sameness criterion Substance description: EC description: A scum formed on the surface of molten lead during the process of removing No substance sameness bismuth by the addition of calcium and magnesium. It consists of lead containing calcium and criterion magnesium bismuthides. Original / SIEF description: Lead, dross bismuth rich is formed when calcium and/or magnesium are added to molten lead bullion to remove bismuth. Lead dross, bismuth rich consists of variable amounts of lead, zinc, silver, bismuth and other metals in either alloy form or as compounds such as oxides. Substance Identity EC/list name: Lead, dross, bismuth SMILES: not applicable rich IUPAC name: InChl: not applicable Other names Type of substance: UVCB EC/List no.: 273-792-0 origin: Inorganic CAS no.: 69029-46-5 Molecular formula: not applicable Substance listed SID parameters Sameness criteria Indication of variability (fixed, low or high variation) Sources (input materials) The main starting material is lead, bullion (EC 308-011-5) typically from the primary sector but Low may include lead, bullion produced from non-battery scrap and other secondary sources. The lead, bullion starting material has usually been desilverised via the Parkes Process and dezinced by vacuum distillation, as required); calcium and/or magnesium are added to the molten lead bullion bath. Process The manfacture of 'lead, dross, bismuth rich' relies on the formation of high melting point Fixed intermetallic compounds which have lower density than lead via the Kroll-Betterton process in a refining kettle. -

The Metallurgy of Lead & Silver

BOUGHT WITH THE INCOME FROM THE SAGE ENDOWMENT FUND THE GIFT OF ^.. Henrg W. Sage 1891 AdSJu -L 'i.j.kj.m^. * Cornell University Library The original of tiiis book is in tine Cornell University Library. There are no known copyright restrictions in the United States on the use of the text. http://www.archive.org/details/cu31924004582619 THE METALLURGY OF LEAD AND SILVER. ^^7^12)4(0 GRIFFIN'S METALLURGICAL, SERIES. EDITED BY SiK W. C. ROBERTS-AUSTEN, K.C.B., F.R.S., D.C.L., Chemist and Assayer o/the Royal Mint; Professor ofMetallurgy in the Boyai College of Science. In Large 8to, Handsome Cloth. With Illustrations. Fourth Sdition, Revised and Enlarged. 15s. INTRODUCTION TO THE STUDY OF METALLURGY. BY SIK W. C. ROBEBTS-AUSTEN. With additional Illustrations and Micro-Photographic Plates of Different Varieties of Steel. " No English text-hook at all approaches this in the completeness with which the most modem views on the subject are dealt with. Professor Austen's vnlume will be ikvaluable."—Cft«m. JVeiw.?. Third Edition. 21s. rrxxE: GOX^X*. BY T. KIBKE KOSB, D.SC, Assist. Assayer of the Royal Mint. Thoroughly Revised, Enlarged, and partly Re-written. Including the most recent Improvements in the Cyanide Process. With new Frontispiece and additional Illustrations. "A contribution to Metallurgical Literature of classical value."—iVaiure. In Two Volumes, Each Complete in itself. By H. F. COLLINS, ASSOO.R.S.M., M.lNST.M.M. ' Part I.— LKAD. 16s. Part II.—SILVER. A Complete and Exhaustive Treatise on Comprising Details Regarding the THE MANTJFACTTTRE OF LEAD, SOURCES AND TREATMENT OF SILVER ORES, WITH SECTIONS ON TOGETHER WITH nSSCRIPTIONS OP SMELTING AND DESILVBRISATION, PLANT, MACHINERY, AND PROCESSES OF MANHFACTURE, And Chapters on the Assay and Analysis of the Materials Involved. -

The Engineering and Mining Journal 1883-11-03

NOVEMBER 3, 1883. THE ENGINEERING AND MINING JOURNAL. 273 respondent desires to obtain, if he will give us a list. It must be stated, EER ING however, that the minor metals are generally controlled by a few parties, Tar ENGINe who allow very little correct and complete information to reach any but a “Manin JOU limited public. Entered at the Post-Office of New York, N. Y., as Second-Class Matter. THE reports of the discovery of tin ore in different parts of the country are multiplying. The Alabama mines, now we believe temporarily idle for Vou. XXXVI. No. 18. want of additional working capital to carry out some improvements, have been followed by the Black Hills tin deposits, so elaborately described RICHARD P, ROTHWELL, 6.E., M.E., by Professor BLAKE in these columns. Some time since, there floated to ROSSITER W. RAYMOND, Ph.D., Editors, us rumors of discoveries of the same metal in Virginia. They are now CHARLES KIRCHHOFF, Jr., M.E., authoritatively confirmed by Prof. Harry D. CAMPBELL, of the Wash- Note.—Communications relative to the editorial management should be addressed to Eprror, P.O. Box 1833, New York. ington and Lee University, Lexington, Va., who has reported on the subject Communications for Mr. RaymMonp should be addressed to Rossiter W. Raymonp P.O. in a letter to The Virginias, an advance-proof of which has been kindly Box 1465, New York. Articles written by Mr. Raymonp will be signed thus * ; and only for articles so signed is he responsible, sent to us by Major JED Hotcuxiss, the editor. -

In German Zinc and Lead Production FINAL DRAFT

Report on Best Available Techniques (BAT) in German Zinc and Lead Production FINAL DRAFT Deutsch-Französisches Institut für Umweltforschung (DFIU) French-German Institute for Environmental Research University of Karlsruhe (TH) o. Prof. Dr. O. Rentz Dipl.-Ing. Stephan Hähre, Dr. Frank Schultmann Karlsruhe, February 1999 On behalf of the German Federal Environmental Agency, Berlin (UBA) in the frame of the Research Project 109 05 006 Contents 3 Contents PREFACE.............................................................................................................................................................13 1 GENERAL INFORMATION.......................................................................................................................... 15 1.1 PRODUCTION AND USE OF ZINC AND LEAD ................................................................................................... 15 1.1.1 Zinc ..................................................................................................................................................... 15 1.1.2 Lead .................................................................................................................................................... 16 1.2 FIRST INDICATION OF ENVIRONMENTAL CONCERNS REGARDING THE PRODUCTION OF ZINC AND LEAD ........ 19 1.2.1 Emissions into the atmosphere............................................................................................................ 19 1.2.2 Potential releases into water.............................................................................................................. -

The Journal of Adhesion the Composition of Metal Surfaces After

This article was downloaded by: [EBSCOHost EJS Content Distribution - Current] On: 9 December 2010 Access details: Access Details: [subscription number 925797205] Publisher Taylor & Francis Informa Ltd Registered in England and Wales Registered Number: 1072954 Registered office: Mortimer House, 37- 41 Mortimer Street, London W1T 3JH, UK The Journal of Adhesion Publication details, including instructions for authors and subscription information: http://www.informaworld.com/smpp/title~content=t713453635 The Composition of Metal Surfaces After Atmospheric Exposure: An Historical Perspective J. E. Castlea a The Surface Analysis Laboratory, Surrey Materials Institute, University of Surrey, Guildford, UK To cite this Article Castle, J. E.(2008) 'The Composition of Metal Surfaces After Atmospheric Exposure: An Historical Perspective', The Journal of Adhesion, 84: 4, 368 — 388 To link to this Article: DOI: 10.1080/00218460802004477 URL: http://dx.doi.org/10.1080/00218460802004477 PLEASE SCROLL DOWN FOR ARTICLE Full terms and conditions of use: http://www.informaworld.com/terms-and-conditions-of-access.pdf This article may be used for research, teaching and private study purposes. Any substantial or systematic reproduction, re-distribution, re-selling, loan or sub-licensing, systematic supply or distribution in any form to anyone is expressly forbidden. The publisher does not give any warranty express or implied or make any representation that the contents will be complete or accurate or up to date. The accuracy of any instructions, formulae and drug doses should be independently verified with primary sources. The publisher shall not be liable for any loss, actions, claims, proceedings, demand or costs or damages whatsoever or howsoever caused arising directly or indirectly in connection with or arising out of the use of this material. -

C22 Metallurgy; Ferrous Or Non-Ferrous Alloys; Treatment of Alloys Or Non- Ferrous Metals

C22B C22 METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON- FERROUS METALS Note(s) [2012.01] (1) Processes or devices specific to the transformation of iron ore or iron carbonyl into iron, either solid or molten, are classified in subclass C21B. (2) Processes or devices specific to: – processing of pig-iron or cast iron; – manufacture of wrought-iron, wrought-steel or carbon steel; – treatment in molten state of ferrous alloys; are classified in subclass C21C. (3) The following processes or devices are classified in subclass C21D: – processes specific to heat treatment of ferrous alloys or steels; – devices for heat treatment of metals or alloys. XXXX C22B C22B XXXX C22B PRODUCTION OR REFINING OF METALS (making metallic powder or suspensions thereof B22F 9/00; production of metals by electrolysis or electrophoresis C25); PRETREATMENT OF RAW MATERIALS Note(s) In this subclass, groups for obtaining metals include obtaining the metals by non-metallurgical processes, and obtaining metal compounds by metallurgical processes. Thus, for example, group C22B 11/00 covers the production of silver by reduction of ammoniacal silver oxide in solution, and group C22B 17/00 covers the production of cadmium oxide by a metallurgical process. Furthermore, although compounds of arsenic and antimony are classified in C01G, production of the elements themselves is covered by C22B, as well as the production of their compounds by metallurgical processes. Subclass indexes PRETREATMENT OF RAW MATERIALS ..................... 1/00, 4/00, REFINING OR REMELTING METALS .................................... 9/00 7/00 OBTAINING SPECIFIC METALS ................................ 11/00-61/00 PROCESSES FOR OBTAINING METALS ..................... 3/00, 4/00, 5/00 1 / 00 Preliminary treatment of ores or scrap [1, 2006.01] 3 / 00 Extraction of metal compounds from ores or 1 / 02 . -

Recovering Gold from Scrap Electronic Solders by Drossing

Report of Investigations 8169 Recovering Gold From Scrap Electronic Solders by Drossing By E. F. Ferrell RenolMetallurgy Research Center, Reno, Nev. UNITED STATES DEPARTMENT OF THE INTERIOR Thomas S. Kleppe, Secretary BUREA U OF MINES Thomas V. Falkie, Director This publication has been cataloged as follows: Ferrell, Edward F Recovering gold from scrap electronic solders by drossing. [Washington] U.S. Bureau of Mines [1976] 9 p. illus., tables. (U.S. Bureau of Mines. Report of investiga tions 8169) Includes bibliography. 1. Gold. I. U.S. Bureau of Mines. II. Title. (Series) TN23.U7 no. 8169 622.06173 U.S. Dept. of the Int. Library CONTENTS Abstract ................. '" ... .. ........ .. .. .. ..... .....• . .•. ...... .... 1 Introduction. .. 1 Materials, equipment, and procedure for drossing......................... 2 Results and discussion................................................... 3 Separation of dross from treated solders........................ .... 4 Recovery of gold from aluminum dross....... ...... ..........•........ 5 Purification of treated solders............ ...... ................... 8 Cone Ius ions. • . 8 References. • . 9 I LLUS TRA TI ON 1. Flowsheet for treatment of scrap electronic solders with aluminum.... 7 TABLES 1. Analyses of some as-received, scrap electronic solders.... ........... 2 2. Density and melting point data............................... ...... 3 3. Extraction of gold from electronic solders with aluminum at 5500 C... 4 4. Recovery of aluminum dross from solder by skimming and filtration.... 5 5. Effect of filtering temperature on solders treated with aluminum..... 5 RECOVERING GOLD FROM SCRAP ELECTRONIC SOLDERS BY DROSSING by E~ F. Ferrell 1 ABSTRACT Gold was recovered from scrap electronic 60-40 (tin-lead) solders by drossing with aluminum or zinc at elevated temperatures. The gold, together with other metallic impurities, collected in the dross phase which could then be separated from the molten solder by skimming or filtering. -

Indium Oxidation Thermodynamics

Thermodynamics and Kinetics of Oxidation and Temperature Dependent Mechanical Characterization of Pure Indium Solder BY HARRY E. SCHOELLER BSME, State University of New York at Binghamton, 2005 THESIS Submitted in partial fulfillment of the requirements for the degree of Masters of Science in Materials Engineering in the Graduate School of Binghamton University State University of New York 2007 UMI Number: 1447566 UMI Microform 1447566 Copyright 2008 by ProQuest Information and Learning Company. All rights reserved. This microform edition is protected against unauthorized copying under Title 17, United States Code. ProQuest Information and Learning Company 300 North Zeeb Road P.O. Box 1346 Ann Arbor, MI 48106-1346 © Copyright by Harry Schoeller 2007 All Rights Reserved Accepted in partial fulfillment of the requirements for the degree of Masters of Science in Materials Engineering in the Graduate School of Binghamton University State University of New York 2007 November 19, 2007 Dr. Junghyun Cho, Department of Mechanical Engineering, Binghamton University Dr. Bruce Murray, Department of Mechanical Engineering, Binghamton University Dr. Seungbae Park, Department of Mechanical Engineering, Binghamton University iii Abstract MicroElectroMechanical System (MEMS) devices often require low-temperature, fluxless soldering techniques due to their high temperature sensitivity and the performance requirements of specific components. While seeking the development of a soldering technology using pure indium, the major focus of this study is to assess the thermodynamics and kinetics of indium oxidation at various solder reflow environments that will ultimately provide a processing window for solder reflow and surface oxide cleaning. The stability of oxidation and reduction reactions for indium is presented in terms of several thermodynamic models. -

Thermodynamic Studies of Liquid Au-Zn and Ag-Zn Systems

Thermodynamic Studies of Liquid Au-Zn and Ag-Zn Systems By Akira Yazawa* and Alzbeta Gubcova** In order to clarify the basic principle of the Parkes process, in which precious metals are extracted from the crude lead by the addition of zinc, thermodynamic studies have been carried out for the liquid Au-Zn and Ag-Zn systems for which thermo- dynamic data have not been satisfactorily available. The electromotive force was measured using the following type of the cell: The error arising from volatilization of zinc was carefully avoided. The break points on the electromotive force curves against temperature suggest that the liquidus lines for the Au-Zn system recommended by Hansen are not acceptable, and that higher liquidus temperature may be reasonable. The activity curves obtained from the electromotive force values show considerably negative deviations from Raoult's law, especially in the Au-Zn system, suggesting the large affinity of zinc for gold and silver. In connection with the present data obtained, the properties of alloys between groups IB and II have been discussed in terms of the electronegativity, ionic radius and electron configurations. It is proved phenomenologically that the obtained data may be also interesting from the standpoint of recent stability theories of alloy phases. To understand the principle of the Parkes process, the results in the present study are combined with the data of the Au-Pb and Ag-Pb systems, and the free energy of mixing for the ternary Au-Pb-Zn and Ag-Pb-Zn systems has been calculated. Moreover, the removal limit of the precious metals from lead has been explained under the simplified assumptions. -

"O.Sible II .Xpen4.« but It, Ia Al"'Y8 Better to Build a Small

Metallurgy of lead Item Type text; Thesis-Reproduction (electronic) Authors Jones, Edward Horton Publisher The University of Arizona. Rights Copyright © is held by the author. Digital access to this material is made possible by the University Libraries, University of Arizona. Further transmission, reproduction or presentation (such as public display or performance) of protected items is prohibited except with permission of the author. Download date 26/09/2021 22:03:32 Link to Item http://hdl.handle.net/10150/306119 D!ALLURGY OF LEAD. Although lead orea are mined and smelted in only one state in the, UUlted Stat•• tor lead alone, the treatment of 1_4 or•• 18 of muoh prant!cal importa.noe, since lead. is used •• a ..4ita for extr&otins other _tales. In smelting goJ.d a or an4 silver or•• , lea4 ores are used aa part ef t�e flux, the lea orea the..elve. etten oarry 1014 and, sil?er In this way the leal "ell.eta tiie prec10ua JIIl.tal. carrying them into the bullion. !he bullion 18 then worked. �. tor the a.,pa�ate metals. It 18 our intention in this article to 4i.cuss, firat, the seleotion of a furnace '.ite and the general arrangement of the Sllant, 'aacon', the pr,inc1pal aethoda ot 8111e1 t1ng lead. cree and thlrct, the _tter of c'btaining th. pure metal. trota t,he, turnace product,. In .elect.ing '. furnaoe 8ite, a i p*lnt. of economy are sought tort teclUlioal con.tel.ration being ot ••concla.rl' r.�our8e. !he �1r.t que.tion that �r�.nt. -

The Thermochemistry of Transition Metal Carbides

Oxidation of Metals, Vol. 13, No. 2, 1979 The Thermochemistry of Transition Metal Carbides Stephen R. Shatynski* Received March 29, 1978 Revised May 18, 1978 A general survey is made of the available data for the standard Gibbs energies of formation of solid carbides of transition metals'. The results are plotted as standard Gibbs energy vs. temperature diagrams. The equations and the estimated accuracy when available are given for each substance. KEY WORDS: standard Gibbs energy of formation; transition metal carbides; Ellingham diagrams. INTRODUCTION A review of the equilibrium and thermodynamic data of the transition metal carbides is presented with particular emphasis on the Gibbs energy of formation. This work reviews, updates, and extends the earlier surveys performed by Richardson 1 and Kubaschewski et al., 2 and the more recent ones by Reed 3 and Wicks and Block. 4 Much of Reed's compilation of carbide thermochemical data was gathered from Richardson. 1 Data for the Gibbs energies of formation for carbides as a function of temperature are presented as Ellingham plots as shown in Figs. 1 and 2. In this paper, the Gibbs energies are normalized with respect to 1 mole of C. The general reaction considered is: xM+C-~MxC For these reactions the standard states are as followst: (1) for solid or liquid metal, a coexistence with its lowest carbide, (2) for C, a solid of unit activity, and (3) for carbides, the solid and liquid carbide in coexistence *Rensselaer Polytechnic Institute, Materials Engineering Department, Troy, New York 12181. tMany of the existing data are based on coexistence standard states, not pure standard states.