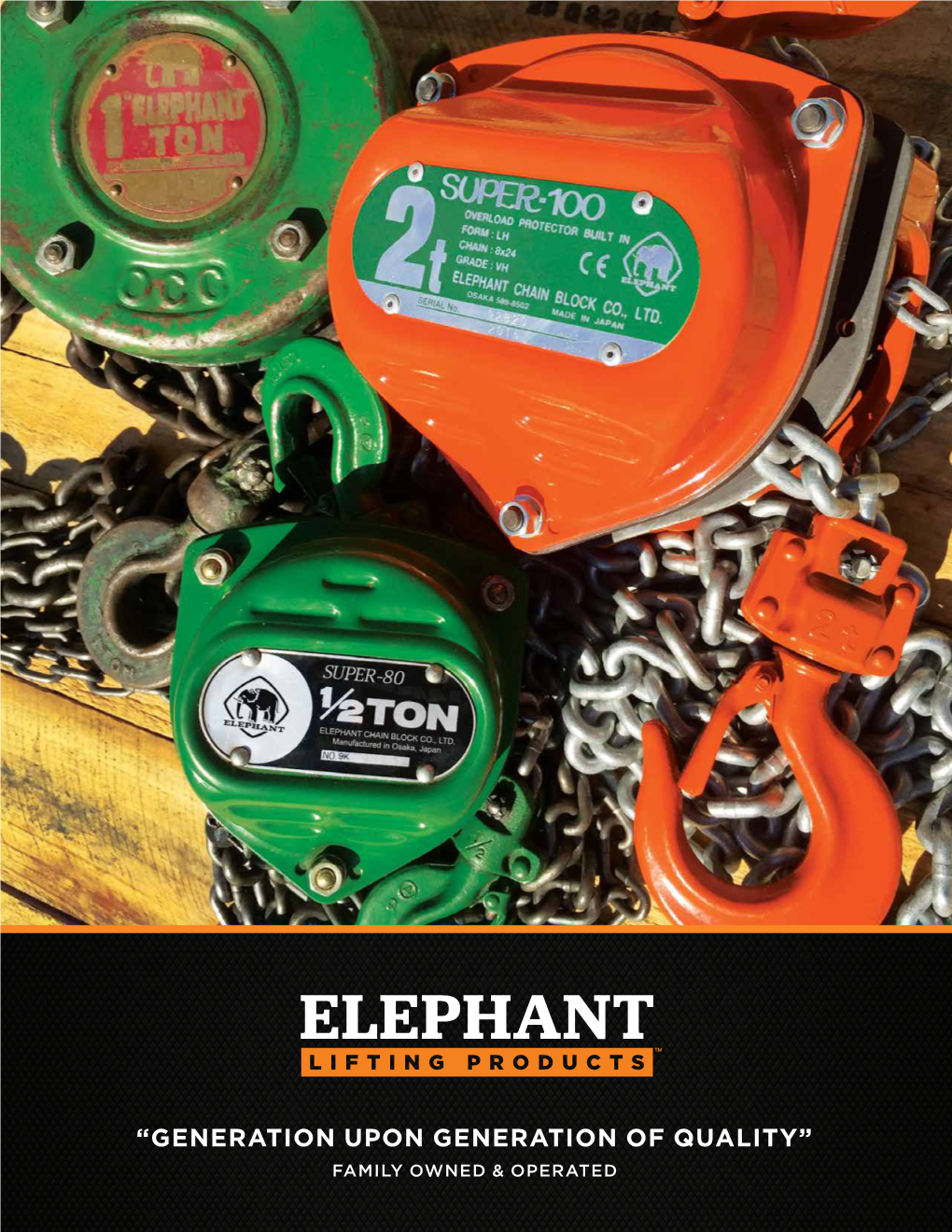

Elephant Lifting Product Catalog

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

2009-08-21 La Cholla Final Sealed Special Provisions.Pdf

Special Provisions 8/21/2009 PCDOT La Cholla Boulevard, Ruthrauff Road to River Road Project No. 4LCITR INDEX TO THE SPECIAL PROVISIONS: LA CHOLLA BOULEVARD, RUTHRAUFF ROAD TO RIVER ROAD GENERAL NOTES .........................................................................................................................1 SECTION 101 - ABBREVIATIONS AND TERMS ....................................................................10 SECTION 102 - BIDDING REQUIREMENTS AND CONDITIONS ........................................10 SECTION 103 - AWARD AND EXECUTION OF CONTRACT ...............................................10 SECTION 104 - SCOPE OF WORK.............................................................................................11 SECTION 105 - CONTROL OF WORK ......................................................................................12 SECTION 106 - CONTROL OF MATERIAL ..............................................................................12 SECTION 107 - LEGAL RELATIONS AND RESPONSIBILITY TO PUBLIC ........................12 SECTION 108 - PROSECUTION AND PROGRESS ..................................................................17 SECTION 109 - MEASUREMENT AND PAYMENT ................................................................20 SECTION 202 - REMOVAL OF STRUCTURES AND OBSTRUCTIONS ...............................24 ITEM 2020005 – REMOVAL OF EXISTING PILES ..................................................................25 SECTION 203 - EARTHWORK ...................................................................................................26 -

Professional Asp.Net Mvc 3

ffirs.indd ii 7/4/2011 4:27:38 PM Download from Wow! eBook <www.wowebook.com> ffirs.indd i i INTRODUCTION . INTRODUCTION FOREWORD. 3 MVC ASP.NET PROFESSIONAL INDEX . INDEX CHAPTER 14 CHAPTER 13 CHAPTER 12 CHAPTER 11 CHAPTER 10 CHAPTER 9 CHAPTER 8 CHAPTER 7 CHAPTER 6 CHAPTER 5 CHAPTER 4 CHAPTER 3 CHAPTER 2 CHAPTER 1 Advanced Topics . 339 . Extending315 MVC . Unit Testing 291 . Dependency Injection 271 . .239NuGet . .211Routing AJAX. 179 ApplicationSecuring Your . 135 Data Annotations and Validation . 117 . 93 Forms and HTML Helpers Models. 69 Views . 39 . 23 Controllers Getting. .1 Started 389 xxiii xxv 7/4/2011 4:27:37 PM 4:27:37 PM ffirs.indd ii 7/4/2011 4:27:38 PM PROFESSIONAL ASP.NET MVC 3 Jon Galloway Phil Haack Brad Wilson K. Scott Allen ffirs.indd iii 7/4/2011 4:27:38 PM Professional ASP.NET MVC 3 Published by John Wiley & Sons, Inc. 10475 Crosspoint Boulevard Indianapolis, IN 46256 www.wiley.com Copyright © 2011 by John Wiley & Sons, Inc. Indianapolis, Indiana Published simultaneously in Canada ISBN: 978-1-118-07658-3 ISBN: 978-1-118-15535-6 (ebk) ISBN: 978-1-118-15537-0 (ebk) ISBN: 978-1-118-15536-3 (ebk) Manufactured in the United States of America 10 9 8 7 6 5 4 3 2 1 No part of this publication may be reproduced, stored in a retrieval system or transmitted in any form or by any means, electronic, mechanical, photocopying, recording, scanning or otherwise, except as permitted under Sections 107 or 108 of the 1976 United States Copyright Act, without either the prior written permission of the Publisher, or authorization through payment of the appropriate per-copy fee to the Copyright Clearance Center, 222 Rosewood Drive, Danvers, MA 01923, (978) 750-8400, fax (978) 646-8600. -

Pilvandmetöötluse Rakendused

TALLINNA TEHNIKAÜLIKOOL Infotehnoloogia teaduskond Arvutitehnika instituut IAG40LT Anett Kann 120903 PILVANDMETÖÖTLUSE RAKENDUSED Bakalaureusetöö Juhendaja: Vladimir Viies PhD Dotsent Tallinn 2015 Autorideklaratsioon Olen koostanud antud töö iseseisvalt. Kõik töö koostamisel kasutatud teiste autorite tööd, olulised seisukohad, kirjandusallikatest ja mujalt pärinevad andmed on viidatud. Käesolevat tööd ei ole varem esitatud kaitsmisele kusagil mujal. Autor: Anett Kann 24.05.2015 2 BAKALAUREUSETÖÖ ÜLESANNE Üliõpilane: Anett Kann Matrikkel: 120903 Lõputöö teema eesti keeles: Pilvandmetöötluse rakendused Lõputöö teema inglise keeles: Cloud computing applications Juhendaja (nimi, töökoht, teaduslik kraad, allkiri): Vladimir Viies Konsultandid: - Lahendatavad küsimused ning lähtetingimused: Anda ülevaade rakenduse koostamise vahenditest pilvandmetöötluses, lähtudes Eestist. Koostada juhis rakenduse loomiseks ja realiseerida sellest lähtuvalt vabalt valitud näidisrakendus. Eritingimused: - Nõuded vormistamisele: Vastavalt Arvutitehnika instituudis kehtivatele nõuetele Lõputöö estamise tähtaeg: 08.06.2015 Ülesande vastu võtnud: ________________________________kuupäev: 24.05.2015 (lõpetaja allkiri) 3 Annotatsioon Käesolev töö uurib pilvandmetöötluse mõistet Eesti näitel, tüüplahenduste raamistikke ning lihtsa avalikel teenustel põhineva rakenduse loomise ülesehitust ning protsessi, milles realiseeritakse päikesekalkulaator. Iseloodud projekt põhineb Google Maps API’l, mis võimaldab rakenduses kasutada hõlpsasti maailmakaarti ja OpenWeatherMap -

James Reynolds What Is a Ruby on Rails Why Is It So Cool Major Rails Features Web Framework

Ruby On Rails James Reynolds What is a Ruby on Rails Why is it so cool Major Rails features Web framework Code and tools for web development A webapp skeleton Developers plug in their unique code Platforms Windows Mac OS X Linux Installation Mac OS X 10.5 will include Rails Mac OS X 10.4 includes Ruby Most people reinstall it anyway From scratch Drag and drop Locomotive Databases Mysql Oracle SQLite Firebird PostgreSQL SQL Server DB2 more Webservers Apache w/ FastCGI or Mongrel LightTPD WEBrick "IDE's" TextMate and Terminal (preferred) RadRails jEdit Komodo Arachno Ruby Has "inspired" Grails CakePHP Trails PHP on TRAX Sails MonoRail Catalyst TrimPath Junction Pylons WASP ColdFusion on Wheels And perhaps more... Why is it so cool? Using the right tool for the job y = x^2 vs y = x^0.5 Right tool Rails is the most well thought-out web development framework I've ever used. And that's in a decade of doing web applications for a living. I've built my own frameworks, helped develop the Servlet API, and have created more than a few web servers from scratch. Nobody has done it like this before. James Duncan Davidson, Creator of Tomcat and Ant y = x ^ 2 vs y = x ^ 0.5 Features Features Work Work Typical Rare y = x ^ 2 vs y = x ^ 0.5 Feature ceiling Features Features Work Work This is a no-brainer... Ruby on Rails is a breakthrough in lowering the barriers of entry to programming. Powerful web applications that formerly might have taken weeks or months to develop can be produced in a matter of days. -

Classic-Web-Design-Resume

James M. Curran 18 John St., # 2B Bloomfield, NJ 07003-5149 +1 (973) 743-9002 (H) +1 (973) 978-6269 (C) [email protected] www.NovelTheory.com www.HonestIllusion.com https://github.com/jamescurran Summary: Experienced developer with familiarity in front end, back end and middle tier design for desktop and web applications, with special skill in writing and refactoring code for greater efficiency and maintainability. Education 1993 MA Montclair State University Computer Science 1984 BS Montclair State College Computer Science (minor in Math) Technical Skill Set: ● Languages & Technologies: C#, C++, C, Javascript, jQuery, KnockoutJs, HTML, XML, XPath, XSL, RSS, .NET Generics, C++ Templates, .NET Extension methods, Regex, LINQ, XLINQ, DLINQ, Sockets, Multi-Threading, Custom web controls, COM, COM Interop, COM+, Castle Monorail, Castle Windsor Inversion of Control, Model-View-Presenter, STL, ● Platforms: .NET Framework, v4.0, v3.5, v2.0, v1.1, ASP.NET MVC & WebForms, WinForms, Classic ASP, WIN32, MFC. ● Databases: MS SQL Server 2008-2000, T-SQL, Oracle, PL/SQL, MSAccess, Sybase, Watcom, ADO.NET, ADO, ODBC, OLEDB. ● Tools: Visual Studio.Net 2002-2012, TeamCity, Visual SourceSafe, CVS, Subversion, GIT, CruiseControl.Net, nAnt, nUnit, MbUnit, PowerShell, MyGeneration, CodeSmith, SQL Management Studio, Oracle Sql Developer, Recent Work Experience (Long Term Projects) AFS Technologies (January 2013-present) 19 W. 44th St New York, NY • Maintained and added new features to AFS’s line of handheld Direct Store Delivery Management Windows CE devices. • Led project converting existing VisualBasic.Net code base into C#. • Designed JavaScript/Angular Sales management app for iPad • Maintained ASP.NET Webform management tool. • Mentored remote team on creation of ASP.NET MVC tool NJTheater.Com (1997–present) Owner/Director/Webmaster • Design, implementation, and maintenance of a website for the promotion of theater companies in New Jersey. -

SBA Office of Business Development 2010 Report to Congress

Office of Business Development 2010 Report to Congress Karen Mills Administrator U.S. Small Business Administration Joseph Jordan Associate Administrator Office of Government Contracting and Business Development CONTENTS Page Executive Summary 7 Program Initiatives 8 Net Worth of Newly Certified Program Participants 9 Benefits and Costs of the 8(a) Program to the Economy 13 Evaluation of Firms that Exited the Small Business and Capital Ownership Development Program (8(a) Business Development Program)1 15 Compilation of Fiscal Year 2009 Program Participants 17 Total Value of Contracts and Options Awarded During Fiscal Year 2009 18 Requested Resources and Program Authorities 19 LIST OF TABLES Table I: Total Personal Net Worth 10 Table II: Total Adjusted Personal Net Worth 12 Table III: Status of Participants that Completed Their Program Term 16 Table IV: Contract and Modifications Dollars Expressed as a Percentage of Firms’ 18 Total Revenue in Each of the Nine Years of Program Participation APPENDICES A. Value of 8(a) Contracts and Modifications by Standard Industrial Classification System 21 B. Value of 8(a) Contracts and Modifications to Program Participants by Region and State 22 C. 7(a) Loans to Program Participants 23 D. 504 Loans to Program Participants 24 1 Minority Small Business and Capital Ownership Program herein referenced as the 8(a) Business Development Program. 2 3 This is the report on the U.S. Small Business Administration’s (SBA) 8(a) Business Development Program as required by the Business Opportunity Development Reform Act of 1988 [15 U.S.C.§636(j)16(A) & (B)] and section 7(j)(16) (A)of the Small Business Act requires the following: (16) (A) The Administrator shall develop and implement a process for the systematic collection of data on the operations of the Program established pursuant to paragraph (10). -

A Pattern-Based Development Approach for Interaction Flow Modeling Language

Hindawi Scientific Programming Volume 2019, Article ID 7904353, 15 pages https://doi.org/10.1155/2019/7904353 Research Article A Pattern-Based Development Approach for Interaction Flow Modeling Language Roberto Rodriguez-Echeverria ,1 Juan C. Preciado ,1 A´ lvaro Rubio-Largo ,2 Jose´ M. Conejero ,1 and A´ lvaro E. Prieto 1 1Quercus Software Engineering Group, University of Extremadura, Ca´ceres 10003, Spain 2Universidade Nova de Lisboa, 1099-085 Lisboa, Portugal Correspondence should be addressed to A´ lvaro Rubio-Largo; [email protected] Received 30 September 2018; Revised 24 January 2019; Accepted 17 March 2019; Published 14 April 2019 Academic Editor: Michele Risi Copyright © 2019 Roberto Rodriguez-Echeverria et al. -is is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. Development and deployment technologies for data-intensive web applications have considerably evolved in the last years. Domain- specific frameworks or model-driven web engineering approaches are examples of these technologies. -ey have made possible to face implicit problems of these systems such as quick evolving business rules or severe time-to-market requirements. Both ap- proaches propose the automation of redundant development tasks as the key factor for their success. -e implementation of CRUD operations is a clear example of repetitive and recurrent task that may be automated. However, although web application frameworks have provided mechanisms to automate the implementation of CRUD operations, model-driven web engineering approaches have generally ignored them, so automation has not been properly faced yet. -

Town of Gilbert

TOWN OF GILBERT Reclaimed Valve Vault TECHNICAL SPECIFICATIONS Town Project No. WW108 Wilson Engineers Project No. 18-001 May 2018 SECTION 01010 SUMMARY OF WORK PART 1 - GENERAL 1.1 SUMMARY A. The Work to be accomplished under these Contract Documents consists of furnishing all labor, materials, and equipment for the construction of the Reclaimed Vault at Recker Road south of Warner Road, complete and ready for use in accordance with the Contract Documents. The CONTRACTOR shall be responsible for site and personnel safety during all phase and all aspects of construction. B. The Work includes, but is not limited to, the following Principal Unit Processes and Structures: 1. Site grading, concrete equipment pads and pre-cast vaults, and other site improvements as shown and specified in the Contract Documents. 2. Removal and replacement of existing piping, pavement, and curb as needed to install the work shown on the plans. Dispose of in accordance with the laws of the State of Arizona and ordinances of the Town of Gilbert. 3. Underground piping as shown and specified in the Contract Documents. 4. Installation of valves, actuators, and appurtenances as shown and specified in the Contract Documents. 5. Primary and secondary electrical power conduits, electrical equipment, instrumentation, conduit, wiring, service entrance, programming, and appurtenances as shown and specified in the Contract Documents. 6. Radio communications equipment and installation: a. 900Mhz licensed radio and antenna, with radio path study, to communicate with the existing radio at Gilbert’s North Yard Service Center. b. Alternate communication system with 4G/LTE cellular modems, antennas, path study, cable, and conduit, at the project site and at the North Yard Service Center. -

Enviroinfo Brno 2005 Layout Rules

Evaluation categorizes, technologies decision for a Composite Environmental Performance Indicators (LWC-EPI) solution Naoum Jamous1, Frederik Kramer1, Gamal Kassem1 Abstract Rapid environmental changes have necessitated a closer and more critical review of current environmental policies. In light of a myopic tendency to focus on short- to medium-term objectives within organizations, environmental is- sues are usually not given full attention. In this regard, recommendation- or dashboard-like systems are useful to in- crease the awareness of management as to the impact of their decisions on the environment on a more frequent and cost-effective basis. However, the role of current environmental management information systems (EMIS) in provid- ing organizations with the information enabling them to assess the current impact of their processes and operations on the environment has been given more prominence. Information technology is changing business in ever shortening cycles. Especially with the success of the Java plat- form, the standardization through the i386 hardware platform and last but not least the rivalry introduced by the Free, Libre and Open Source Software (F/LOSS) paradigm a sheer inconceivable amount of programming languages, inte- grated development environments, design patterns and programming frameworks have been disseminated. In this paper, we will start with a state of the art of the available tools support providing dashboard-type solutions to control and monitor the EPI’s in an organization, which may lead to reduce the gap between estimated values and current running values for environment on a more frequent basis than a mere yearly review. Furthermore, we will propose an evaluation categorizes to be used as a methodology to take the technologies decisions. -

A Competence Management System Towards Increased Corporate Success

FACULDADE DE ENGENHARIA DA UNIVERSIDADE DO PORTO A Competence Management System towards Increased Corporate Success Ana Gabriela Teixeira Soares FINAL VERSION Report of Dissertation Master in Informatics and Computing Engineering Supervisor: Teresa Galvão Dias (PhD) 7th April 2010 A Competence Management System towards Increased Corporate Success Ana Gabriela Teixeira Soares Report of Dissertation Master in Informatics and Computing Engineering Approved in oral examination by the committee: Chair: Luís Paulo Reis (PhD) ____________________________________________________ External Examiner: Paulo Novais (PhD) Internal Examiner: Teresa Galvão Dias (PhD) 7th April, 2010 Abstract In an organization, the careful management of intellectual capital is crucial for the nourishment of a sustained competitive advantage, hardly replicable by its competitors. Particularly, a Competence Management (CM) strategy transversal to the different corporate business units is of pivotal importance, as all knowledge domains are considered. The main goal of this project – called iKnow - is to identify the requirements for the design of an effective Competence Management System (CMS) and to implement a working prototype. In particular, a study of CM concepts and key issues is intended as well as a state-of-the-art review of CMSs and main features. Additionally, the project contemplates the proposal and prototype deployment of a CMS for Critical Manufacturing (CMF), applying the acknowledged CM concepts to this corporate instance. Created in 2009, CMF is an organization devoted to the delivery of avant-garde solutions for the high-tech manufacturing market, aiming at becoming the prime provider for that niche. In particular, its Services Unit is involved in multiple projects, whose engineers are constantly exposed to new technologies. -

Course Descriptions

Course Descriptions Page 150 Course Numbering 150 Credit Hours 150 Prerequisites 150 Schedule of Classes 150 How to Read the Course Description 151 Subject Areas/ Subject Codes 152 Special Topics 152 Independent Study/Research 153 Cooperative Education 154 Honors Courses 154 Applied Music Course Enrollment 155 Course Descriptions Course Descriptions _________________________________________________________________ Course Numbering may be found in the Equivalent Courses list which is located To simplify the task of maintaining accurate and complete in Appendix V. academic records for all students at the College, an alpha- Course numbers do not indicate whether or not a course numeric code is used to identify all courses. In this code, the will be accepted for transfer to other institutions. Students are alpha digits indicate the subject area. For example, World advised to consult with their counselors regarding transfer of Regional Geography carries the course number GEOG-1010. courses and credits to other institutions. The letters GEOG refer to the subject area, Geography. The number 1010 has been assigned to a specific course, World Credit Hours Regional Geography, within that subject area. The number of semester credits for each course described in Subject areas are listed in alphabetical order by subject title, the Catalog is indicated after the course title. For example, not by the course Code. Courses are listed in numerical order three credits are indicted as 03 Semester Credits. The number within each subject area. The semester course numbering of credits for a course does not necessarily equal the number system defines the type of course it is. Courses numbered of hours that the course meets in one week. -

Monorail Rapid Transit for Los Angeles

~.’,.,0l’,ro RA T’ REPORT STUDY i954 TO THE LOS ANGELES METROPOLITAN TRANSIT AUTHORITY ON A MONORAIL RAPID TRANSIT LINE FOR LOS ANGELES JANUARY 15, 1954 COVERDALE & COLP|TTS CONSULT!NG ENGINEERS NEW YORK RUSCARDON ENGINEERS GIBBS & HILL, INC, LOS ANGELES NEW YORK~ LOS ANGELES ~ I I’n II I’ II .I ¯ ~ fIll I II II III II I I III JIJIIj[lllll!l II I iil I’!’ ’1 I1_ ..... ~~~~,:;~ LOS ANGELES METROPOLITAN TRANSIT AUTHORITY 2233 BEVERLY BOULEVARD LOS ANGELES 57, CALIFORNIA DUnkirk 5- 1738 SUMMARY OF CONCLUSIONS ECONOMIC ENGINEERING REPORT of COVERDALE & COLPITTS for LOS ANGELES METROPOLITAN TRANSIT AUTHORITY FIRST: This report is made to the Los Angeles Metropolitan Transit Authority pur- suant to the declared policy of the State of California to develop interurban rapid transit systems in various metropolitan areas of the State for the benefit of the people. (Chapter 1668, Legislative Session 1951, Chapter I, Section 1.1) The characteristics of Los Angeles as one of the great cities of the United States are different from those of any other city in the combination of its extent of area, the low density of its population, the high degree of automobile ownership and the lack of any system of surface-free mass rapid transit. SECOND: The monorail rapid transit route as proposed in this report and located within the area described in the act creating the Authority would, if adopted, be a proper beginning of mass rapid transit throughout Los Angeles County. THIRD: Monorail as an interurban railroad, rather than an urban distribution facil- ity, can be integrated appropriately with any future plan of rapid transit that may be adopted for the metropolitan area of Los Angeles County.