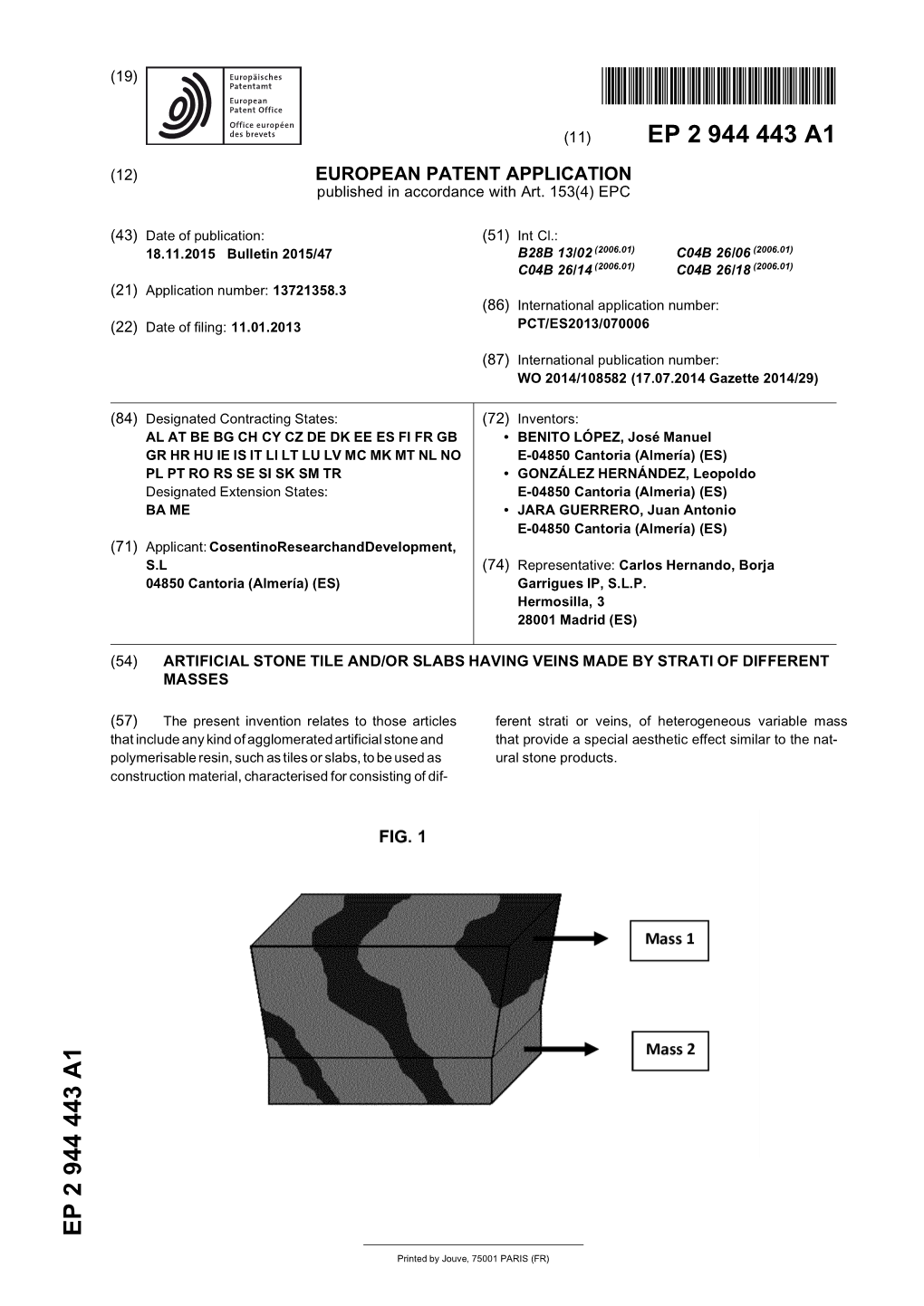

Artificial Stone Tile And/Or Slabs Having Veins Made by Strati of Different Masses

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Stone Veneer Mortar High Strength, Polymer Modified Mortar

STONE VENEER MORTAR HIGH STRENGTH, POLYMER MODIFIED MORTAR DESCRIPTION: STONE VENEER MORTAR is polymer modified PLACEMENT: mortar designed to provide a high performance bond for veneer 1. Apply STONE VENEER MORTAR at approximately 3/8”-1/2” units to base surfaces. thick to the lath and surface. Before the mortar begins to harden, scratch or scarify the mortar surface with the appropri- USES: STONE VENEER MORTAR is ideal for grouting and placing ate scratching tool. thin clay brick, natural or artificial stone veneer units. It is de- 2. Trowel a thin layer on the scratch, brown or substrates, as signed to be cohesive with excellent workability and superior well, apply a thick layer of mortar to the back of each stone. bond strength. STONE VENEER MORTAR will create an aestheti- 3. Place and press the stone into place and allow the mortar to cally pleasing, non load bearing, exterior or interior stone veneer squeeze out around edges. In certain applications, the use of finished wall. temporary shims is needed between the stones until the mor- STONE VENEER MORTAR can be used as a: tar sets. This is to maintain even spacing between the stones. scratch or brown coat 4. After placing the stone and the mortar has set to thumb print bond coat hard (approximately 1 hour), remove the shims. Use a grout joint fill grout bag or pointing trowel to fill in joints where additional mortar is needed. ADVANTAGES: STONE VENEER MORTAR offers the fol- 5. Using a metal jointing tool, compact and seal edges around lowing advantages: stone and rake out excess mortar. -

Contractor License Definitions

Sec. 3-2-1. - Definitions. (a) General. As used in this chapter, "the board" will mean construction industry license board, and the following words and terms shall have meanings as found in F.S. section 489.105: certificate, certified contractors, contractor, contracting, air conditioning contractors (class A), air conditioning contractors (class B), air conditioning contractors (class C), building contractors, general contractors, mechanical contractors, plumbing contractors, residential contractors, roofing contractors, sheet metal contractors, commercial swimming pool/spa contractors, residential swimming pool/spa contractors, maintenance swimming pool/spa contractors, underground utility and excavation contractors, specialty contractors, primary qualifying agent, secondary qualifying agent, registered contractors, and registration. The term electrical contractor shall have the meaning as found in F.S. section 489.505. (b) Journeyman electrician means any person qualified to perform work in the electrical trade while employed and supervised by a master electrician and who is licensed under the provisions of this chapter. All electricians, whether master or journeyman will be issued cards indicating the type of license held and will be required to exhibit them upon the request of the building official, building inspectors or code compliance officers. (c) Local specialty contractors: Local specialty contractors are engaged in, but not necessarily limited to, one (1) or more of the following trades: (1) Acoustical and insulation contractors are those who are qualified to install, maintain, repair, alter, or extend any insulation primarily installed to prevent loss or gain of heat from rooms or buildings. They are also those who are qualified to install, maintain, repair, alter, or extend any insulation primarily installed to prevent loss or gain of heat from internal or external sources in pipes, vessels, ducts, or built-up refrigerated boxes or rooms. -

Denselement® Barrier System and NFPA 285 Acceptance Criteria

DensElement® Barrier System and NFPA 285 Acceptance Criteria Current and past building codes have generally required combustible water resistive barriers (WRBs) to be tested for compliance with NFPA 285 acceptance criteria. In 2018, IBC section 1402.5 was modified to clarify that “water-resistive barrier flashings and accessories at other locations, including through wall flashings shall not be considered part of the water resistive barrier” for purposes of the NFPA 285 testing requirement. Within the DensElement® Barrier System, the DensElement® Sheathing is noncombustible (per ASTM E136), and the DensDefy™ Liquid Flashing is the water-resistive barrier flashing that is no longer considered a part of the water-resistive barrier for purposes of the NFPA testing requirement under IBC section 1402.5. Thus, with this change, DensElement® Barrier System should be considered a non-combustible WRB, and the NFPA testing requirements in IBC Section 1402.5 for combustible water-resistive barriers should not be applicable, as DensElement® Sheathing is exempt from NFPA assembly testing under the 2018 IBC. However, not all jurisdictions have adopted the 2018 IBC. In those cases, the following tables list wall assemblies featuring DensElement® Barrier System that are included in NFPA 285 engineering evaluations. Brick, Natural Stone, Artificial Stone Priest & Associates Manufacturer Cladding Notes Project # reference Brick 10261K, Revision 4 Stucco 10261K, Revision 4 Limestone 10261K, Revision 4 Terracotta 10261K, Revision 4 Natural Stone Veneer 10261K, -

The Maintenance, Repair and Replacement of Historic Cast Stone Richard Pieper

0 Home > How to Preserve > Preservation Briefs > 42 Cast Stone Some of the web versions of the Preservation Briefs differ somewhat from the printed versions. Many illustrations are ne Captions are simplified and some complex charts are omitted. To order hard copies of the Briefs, see Printed Publicatio PRESERVATION BRIEFS 42 The Maintenance, Repair and Replacement of Historic Cast Stone Richard Pieper An Imitative Building Material with Many Names History of Use and Manufacture Mechanisms and Modes of Deterioration Maintenance of Cast Stone Installations Methods of Repair Detail of ornamen Replacement of Historic Cast Stone Installations New Yor Richard Appropriateness of GFRC as a Replacement Material Summary and References Reading List Download the PDF An Imitative Building Material with Many Names The practice of using cheaper and more common materials on building exteriors in imitation of more expe materials is by no means a new one. In the eighteenth century, sand impregnated paint was applied to w quarried stone. Stucco scored to simulate stone ashlar could fool the eye as well. In the 19th century, cas often detailed to appear like stone. Another such imitative building material was "cast stone" or, more pre concrete building units. http://www.nps.gov/tps/how-to-preserve/briefs/42-cast-stone.htm 11/6/2013 0 Cast stone was just one name given to various concrete mixtures that emplo shapes, decorative aggregates, and masonry pigments to simulate natural st mixtures included water, sand, coarse aggregate, and cementing agents. Nat portland cements, oxychloride cements, and sodium silicate based cements w binding agents. The differences in the resulting products reflected the differe aggregates, binding agents, methods of manufacture and curing, and system finishing that were used to produce them. -

LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, E.G. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE {(Roofi

CPC - C04B - 2021.08 C04B LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE {(roofing granules E04D 7/005)}; CERAMICS (devitrified glass-ceramics C03C 10/00); REFRACTORIES; TREATMENT OF NATURAL STONE Definition statement This place covers: Chemical aspects of the processing of lime, magnesia or dolomite and of molten slag. Compositional aspects of: • inorganic binders, such as hydraulic cements ; • mortars, concrete and artificial stone, e.g. the choice of fillers or active ingredients therefore; • shaped ceramic products, e.g. clay-wares, refractories , non-oxides. Physico-chemical aspects of methods for obtaining mortars, concrete, artificial stones or ceramics , e.g. for delaying the setting time of mortar compositions. Treatment including defibrillating of materials such as fillers , agglomerated or waste materials, or refuse to enhance their filling properties in mortars, concrete or artificial stone. Porous mortars, concrete, artificial stone or ceramic ware, and the preparation thereof. Methods and apparatus for: • burning or slaking lime; • obtaining mineral binders, e.g. Portland cement or hemihydrate plaster; • the expansion of mineral fillers , such as clay, perlite or vermiculite. After- treatment of artificial stones, mortars, concrete and ceramics , e.g. coating or impregnation of green concrete after primary shaping. Non-mechanical treatment of natural stone. Processing powders of inorganic compounds in preparation to the manufacturing of ceramic products . 1 C04B (continued) CPC - C04B - 2021.08 Definition statement The joining of burned ceramics with other articles by heating. References Limiting references This place does not cover: Granulating apparatus B01J 2/00 Mechanical features relating to the working of mortars, concrete, stone, B28 clay-wares or ceramics , e.g. -

Architectural Design Ordinance

Ordinance No. ___-20 Ordinance regarding architectural design The City of St. Louis Park does ordain: Section 1. The city council has considered the advice and recommendation of the planning commission (Case No. 20-17-ZA) for amending the zoning ordinance Section 36- 366. Section 2. Chapter 36, Section 366 of the St. Louis Park City Code is hereby amended by adding underscored text and deleting the strike through text. Section breaks are represented by ***. *** (b) Standards. (b)(1) Building Design. Buildings shall be designed to enhance the attractiveness of the city’s streetscape by minimizing monotonous structures and long, blank walls. Additionally, buildings shall, through use of architectural details and scale, have architectural features and patterns that provide visual interest from the perspective of the pedestrian. The following techniques shall be incorporated into building design in order to accomplish such requirements. (1)a. Architectural design elements that will be considered in the review of building and site plans include building materials, color and texture, building bulk, general massing, roof treatment, proportion of openings, facade design elements and variation, window and openings. Site plan design elements that will be considered in the determination as to whether site plan design is superior include quantity, quality, variation, compatibility and size of plant materials, landscape berms and screening walls. Also considered will be the overall order, symmetry and proportion of the various elements within the site and within the larger context of the area or corridor. (2)b. The height, bulk, general massing, roof treatment, materials, colors, textures, major divisions, and proportions of a new or remodeled building shall be compatible with that of other buildings on the site and on adjacent sites. -

Building Tecniques of Fortified Structures in Kinik Höyük Archaeological Excavation (Turkey)

SAHC2014 – 9th International Conference on Structural Analysis of Historical Constructions F. Peña & M. Chávez (eds.) Mexico City, Mexico, 14–17 October 2014 BUILDING TECNIQUES OF FORTIFIED STRUCTURES IN KINIK HÖYÜK ARCHAEOLOGICAL EXCAVATION (TURKEY) V. Cinieri1, L. D'Alfonso2 and M. Morandotti1,3 1 Department of Civil Engineering and Architecture, University of Pavia via Ferrata, 1, Pavia, Italy e-mail: [email protected] 2 Institute for the Study of the Ancient World, New York University 15 E 84th St, New York, NY 10028, United States e-mail: [email protected] 3 Directorate of the Interdepartmental Centre of Studies and Research on cultural heritage Conserva- tion (CISRiC), University of Pavia, Italy e-mail: [email protected] Keywords: Archaeological Heritage, Stone Masonry, Mud plaster, Building Techniques. Abstract. The archaeological heritage is the result of a phase of the human civilization and, beyond the artistic-monumental values, it is material testimony of the human work and «un- limited» source of knowledge. In this perspective, archaeological excavations at Kınık Höyük, in southern Cappadocia (Turkey) started on initiative of a multidisciplinary team of research- ers from the University of Pavia (Italy), the New York University (USA), CNRS (France) and the Universities of Niğde and Erzurum (Turkey). At Kınık Höyük there were found traces of a site that was inhabited for about 4000 years. Among the remains revealed, it is especially im- portant the portion of the citadel walls along the north side of the mound in the centre of the archaeological site, which presents different architectural phases, the last one dating back to the Late Bronze Age (15th-12th c. -

Features and Decay of Cast Stone Elements in New York City Buildings in Comparison with Cast Stone in Milan

12th International Congress on the Deterioration and Conservation of Stone Columbia University, New York, 2012 FEATURES AND DECAY OF CAST STONE ELEMENTS IN NEW YORK CITY BUILDINGS IN COMPARISON WITH CAST STONE IN MILAN Roberto Bugini1, Mariachiara Faliva2 and Luisa Folli3 1 CNR – ICVBC, Istituto per la Conservazione e la Valorizzazione dei Beni Culturali, via Roberto Cozzi 53, 20145 Milan (Italy) 2 Thornton Tomasetti, Inc., 51 Madison Avenue, New York, NY 10010 (USA) 3 Independent Researcher, viale Calabria 18/B, Lodi (Italy) Abstract Cast stone was a new construction material introduced in the second half of the 19th century for the production of architectural elements such as sills, window frames, cornices, ornamentations, statues; technological advances allowed use of this material for complicated shapes with considerable savings in costs compared to carved natural stone. Cast stone use followed similar patterns in North America and Europe. This paper compares and contrasts production and performance of this innovative material between two countries by analyzing material samples from historic structures in New York and Milan. Samples dating to the first decades of the 20th century were analyzed using petrographic methods. Samples were described in terms of aggregate composition, aggregate grain size and binder colour. The main decay observed was surface erosion of the cementing matrix. This decay can be attributed to exposure to the elements and pollution, but can be accelerated by the type of tooling used to finish the cast stone surface. Keywords: cast stone, artificial stone, New York City, Milan 1. Introduction Since the first half of the 19th century improvements in material science studies and technologies led to many attempts at finding new and better methods of construction. -

Building Stone and Tiles

-Building Stone and Tiles- Building Stone and Tiles Stone types to be covered include natural raw stone such as marble and granite, which are used mainly for building or worked monuments and gravestones, cut or polished natural stone, or artificially colored natural stone. Also included are ceramic tiles for building use. Scope of coverage Item Definition HS Code Building stone (including worked Raw stone and slabs monuments and gravestones) Marble (Including travertines) 2515.11, 12 Granite and sandstone 2516.11, 12, 20 Other stone 2515.20, 2516.90 Processed products Marble 6802.21, 91 Granite and sandstone 6802.23, 93 Other stone 6802.10, 29, 92, 99 Ceramic tiles for building use Unglazed ceramic tiles 6907 Glazed ceramic tiles 6908 Note 1: "Slabs" are raw stone that has been cut into blocks or rectangular or square shapes, by sawing or otherwise. Note 2: "Travertines" are calcareous chemical precipitation rocks that arise from hot or mineral springs. Note 3: "Tiles" refer to fired ceramic tiles made from a mixture of natural sand and stone (earthenware, potter’s clay, etc.) Note 4: "Glaze" is a vitreous substance that covers the surface of pottery or porcelain enamel. 1. Points to Note in Exports to and Sales in Japan (1) Import Regulation and Procedures There are no legal regulations, in principle, governing the import of stone into Japan. The import of products containing asbestos is, however, prohibited under the "Industrial Safety and Health Act" and the "Foreign Exchange and Foreign Trade Act." Consequently, the import of stone (particularly tile products) containing the asbestos is subject to regulation. -

Stone Veneer Mortar

Stone veneer mortar The Pro’s Choice Since 1936 Testing: Sakrete® Stone Veneer Mortar is a Mortar should be tested in the field by ASTM C780, standard test method for high performance, polymer modi- preconstruction & construction evaluation for mortar for plain & reinforced unit fied mortar designed to set and masonry. Due to the procedure differences between ASTM C270 & ASTM C780, grout artificial stone and natural the compressive strength values resulting from field sampled mortar are not re- stone veneers. Can be used over quired nor expected to meet the minimum compressive strengths of the property nearly any solid wall including specifications of ASTM C270 as tested in controlled laboratory conditions. masonry units, poured concrete or plywood. Mortar is only a part DIVISION 4 of the larger process of installing Manufactured Stone Masonry - 04 73 00 stone veneer. As such, the information provided here should be used in conjunc- tion with “Installation Guidelines for Adhered Concrete Masonry Veneer and local Preparation/Application: building code requirements. For best results all materials should be stored between 400F (40C) and 800F (270C) 24 hours prior to installation. Features: • High Strength >1,800 psi Refer to: • Meets property requirements of ASTM C1714 and ASTM C270 - ACI 530.1 Specification for Masonry Structures • Applications from 3/8” to 1/2” (9.5 to 12.7 mm) - International Masonry Industry All-Weather Council (IMIAC) • Can be color pigmented with the Sakrete Cement Colors • Recommended Practices and Guild Specifications -

The Maintenance, Repair and Replacement of Historic Cast Stone

/ PRESERVATION 42 BRIEFS The Maintenance, Repair and Replacement of Historic Cast Stone Richard Pieper U.S. Department of the Interior National Park Service Cultural Resources Heritage Preservation Services An Imitative Building Material with Many Names The practice of using cheaper and more common materials were all used as binding agents. The differences in the on building exteriors in imitation of more expensive natural resulting products reflected the different stone aggregates, materials is by no means a new one. In the eighteenth cen binding agents, methods of manufacture and curing, and tury, sand impregnated paint was applied to wood to look systems of surface finishing that were used to produce like quarried stone. Stucco scored to simulate stone ashlar them. Versatile in representing both intricately carved could fool the eye as well. In the 19th century, cast iron ornament and plain blocks of wall ashlar, cast stone could was also often detailed to appear like stone. Another such be tooled with a variety of finishes. imitative building material was "cast stone" or, more pre cisely, precast concrete building units (Figs. 1,2 and 3). During a century and a half of use in the United States, cast stone has been given various names. While the term "artifi Cast stone was just one name given to various concrete cial stone" was commonly used in the 19th century, "con mixtures that employed molded shapes, decorative aggre crete stone," "cast stone," and "cut cast stone" replaced it in gates, and masonry pigments to simulate natural stone. the early 20th century. In addition, Coignet Stone, Frear The basic mixtures included water, sand, coarse aggregate, Stone, and Ransome Stone were all names of proprietary and cementing agents. -

Stone Veneer Mortar

Stone Veneer Mortar Sakrete® Stone Veneer Mortar is a high performance, polymer modified MIXING (Cont.): mortar designed to set and grout artificial stone on horizontal or vertical Mortar should always be mixed to a firm, moist consistency. A mix that is too dry and crumbly will not provide the proper bond. AVOID A SOUPY MIX. concrete or concrete masonry substrates. Mortar that is too wet will be weak and will not provide adequate bond of the stone to the substrate. Stone should not be applied in temperatures be- SAFETY: low freezing, as mortar will not develop proper strength. Re-tempering will READ and UNDERSTAND the Material Safety Data Sheet (MSDS) before reduce strength. Wind, temperature and absorption rate of the substrate using this product. WARNING: Wear protective clothing and equipment. affects performance and working time. In cold weather, use warm water to For emergency information, call CHEMTREC at 800-424-9300 accelerate the set. In hot weather, use cool water to slow set. or 703-527-3887 (outside USA). KEEP OUT OF REACH OF CHILDREN. Note: Water with a high mineral salt content can cause efflorescence. Efflorescence occurs naturally and is beyond the control of Sakrete. PREPARATION: Clean area and remove all unsound concrete, mortar, grease, oil, paint and PLACEMENT: any other foreign materials that will inhibit performance. Before applying 1. Determine the amount of stone needed by measuring the length x the the mortar, lay stones on flat surface, placing them together to determine height for walls or length x the width for horizontal surfaces to find the the best fit and appearance for your project area.