Printable Fastener Tools

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

National Register of Historic Places Registration Form

NPS Form 10-900 OMB No. 1024-0018 (Rev. 10-90 United States Department of the Interior National Park Service NATIONAL REGISTER OF HISTORIC PLACES REGISTRATION FORM This form is for use in nominating or requesting determinations for individual profcertfes and districts^ ^Ojffstnlctiojhs in How to Complete the National Register of Historic Places Registration Form (National Register Bulletin 16A). 9<^r59?5?Slc^JieJ? bv marRingrx"/n the appropriate box or by entering the information requested. If any item does not apply to the property being d<jfcumernje!9p§ijl^^ For functions, architectural classification, materials, and areas of significance, enter only categories and S(hcetefg^^nnJa& fiOSfljidBans Place additional entries and narrative items on continuation sheets (NPS Form 10-900a). Use a typewriter, word processor, or^oTrtpttt^J^fi^gleTic'fflI/items. 1. Name of Property_______________________________________________ historic name Coco Plum Woman's Club___________________________________________ other names/site number Coco Plum Thimble Club: Woman's Club of Larkins/ DA 00189________________ 2. Location______________________________________________________ street & number 1375 Sunset Drive (SW 72nd Street)__________________N/A D not for oublication citvortown Coral Gables____________________________________N/A D vicinitv state Florida__________ code FL county Miami-Dade_____code 025 zip code 33143 3. State/Federal Agency Certification As the designated authority under the National Historic Preservation Act, as amended, I hereby certify that this ^ nomination D request for determination of eligibility meets the documentation standards for registering properties in the National Register of Historic Places and meets the procedural and professional requirements set forth in 36 CFR Part 60. In my opinion, the property 13 meets D does not meet the National Register criteria. -

Leadscrew Brochure

• High Repeatability • High accuracy • Short Lead times • Fast Prototyping High Precision Lead Screws Offering smooth, precise, cost effective positioning, lead screws are the ideal solution for your application. Thomson Neff precision lead screws from Huco Dynatork are an excellent economical solution for your linear motion requirements. For more than 25 years, Thomson has designed and manufactured the highest quality lead screw assemblies in the industry. Our precision rolling proc- ess ensures accurate positioning to .075mm/300mm and our PTFE coating process produces assemblies that have less drag torque and last longer. Huco Dynatork provides a large array of standard plastic nut assemblies in anti-backlash or standard Supernut® designs. All of our standard plastic nut assemblies use an internally lubricated Acetal providing excellent lubricity and wear resistance with or without additional lubrication. With the introduction of our new unique patented zero backlash designs, Huco Dynatork provides assemblies with high axial stiffness, zero back- lash and the absolute minimum drag torque to reduce motor requirements. These designs produce products that cost less, perform better and last longer. Both designs automatically adjust for wear ensuring zero backlash for the life of the nut. Huco Dynatork also provides engineering design services to aid in your design requirements producing a lead screw assembly to your specifica- tions. Call Huco Dynatork today on 01992 501900 to discuss your application with one of our experienced application engineers Huco Dynatork Products Deliver Performance To ensure precise positioning, the elimination of backlash is of primary concern. Several types of anti-backlash mechanisms are common in the market which utilise compliant pre- loads. -

PMPA Member H & R Screw Machine Products Finds Success in Its Wide

Helping Precision Machine Shops Be More Productive and Profitable Helping Precision Machine Shops Be More Productive and Profitable PMPA Member H & R Screw Machine Products Finds Success in its Wide Customer Base and Diverse Machining Capabilities When it was founded in 1976, H & R Screw Machine Products was no more than a single Brown & Sharpe screw machine in a small building located behind the home of founder, David Halladay. Mr. Halladay, who spent years as a technician in several screw machine shops, dreamed of owning his own company one day. So, with the help of his business partner, Walter Randolph, the two opened H & R Screw Machine Products. What started as a small operation with just two customers evolved into a company that manufactures millions of precision machined components each month in a 38,000-square-foot facility in Reed City, Michigan. Today, the company is run by Mr. Halladay’s sons, Tim and Tom Halladay, who spent most of their lives working their way up through the company. “As a company, we all work very closely together and we try to treat our employees like family,” says Tom Halladay, president of H & R Screw Machine Products. “We have many people on staff who’ve been with the company 10 to 30 years, and they’re a major reason why we’ve succeeded over headquarters also features aqueous parts washing systems, a the years.” quality assurance lab and a scrap and oil processing system. The company’s state-of-the-art scrap and oil processing In the company’s early years, 100 percent of sales came system conveys steel and aluminum scrap material from its from the automotive industry. -

Roller Screws

1213E_MSD_EXCO 1/11/06 10:06 AM Page 37 SIZEWISE Edited by Colleen Telling Sizing and applying ROLLER SCREWS Gary Shelton Roller screw shaft Principal Design Engineer Ground shaft Exlar Corp. Timing gear planetary Chanhassen, Minn. Roller screw nut roller screw How it works Roller screws convert ro- tary motion into linear mo- Roller screws’ tion just like acme and numerous ballscrews. Comparably contact points sized roller screws, however, vs. ballscrews’, have better efficiency than lengthen their acme screws and can carry lives and Spacer larger loads than ballscrews. washer increase load In addition, they can cycle Roller timing gear capacity and more often and turn signifi- stiffness. They Roller cantly faster than either, contain ground suiting them to precise, con- Retaining clip leadscrews for high- tinuous-duty applications. Roller journal precision applications Radiused flanks on the and come in tolerance rollers deliver point contact classes G1, G3, G4, and G5. like balls on a raceway, and only the radius is part of the profile. Therefore, a larger radius transversely and a precision- and additional contact points can ground spacer is inserted be- be packed into the available tween the front and back halves. space, thus lowering stress. In ad- The double nut is another alter- dition, the rolling contact be- native. As the name suggests, it tween components has low fric- uses two nuts preloaded against tion, yielding high efficiency. Be- each other on one screw. There is cause the rolling members are no sacrifice of life for its de- fixed relative to each other and creased backlash, but the double never touch adjacent rollers, nut costs more than standard sin- roller screws can turn at speeds gle-nut arrangements. -

2 Simple Machines

Name Class Date CHAPTER 13 Work and Energy SECTION 2 Simple Machines KEY IDEAS As you read this section, keep these questions in mind: • What are simple machines? • What simple machines are in the lever family? • What simple machines are in the inclined plane family? • What are compound machines? What Are Simple Machines? We are surrounded by many different electronics and READING TOOLBOX machines. In physics, a machine is a mechanical device Compare As you read that changes the motion of an object. Remember that this section, make a chart machines make work easier by changing the way a force showing the similarities and is applied. Many machines, such as cars and bicycles, differences between the six simple machines. Describe are complicated. However, even the most complicated how each machine affects machine is made from a combination of just six simple input and output forces machines. Simple machines are the most basic machines. and distances. Include the Scientists divide the six simple machines into two fam- mechanical advantage each machine provides. ilies: the lever family and the inclined plane family. The lever family includes the simple lever, the pulley, and the wheel and axle. The inclined plane family includes the simple inclined plane, the wedge, and the screw. The lever family Simple lever Pulley EHHDBG@<EHL>K Wheel and axle 1. Infer What do you think The is the reason that the wedge inclined and the simple inclined plane plane are in the same family of simple machines? family Screw Simple inclined Wedge plane How Do Levers Work? If you have ever used a claw hammer to remove a nail from a piece of wood, you have used a simple lever. -

1.5 Mm Headless Compression Screw Surgical Technique

For Fixation of Small Bones and Small Bone Fragments 1.5 mm Headless Compression Screw Surgical Technique Table of Contents Introduction 1.5 mm Headless Compression Screw 2 Technique Overview—Lag Screw Technique 3 with Compression Sleeve Indications 4 Surgical Technique Predrill 5 Determine Screw Length 6 Pick Up Screw 6 Insert Screw and Compress 8 Countersink Screw 9 Screw Extraction 11 Product Information Implants 12 Instruments 13 Set Lists 15 MR Information The Headless Compression Screws System has not been evaluated for safety and compatibility in the MR environment. It has not been tested for heating, migration or image artifact in the MR environment. The safety of the Headless Compression Screws System in the MR environment is unknown. Scanning a patient who has this device may result in patient injury. Image intensifier control 1.5 mm Headless Compression Screw Surgical Technique DePuy Synthes 1 1.5 mm Headless Compression Screw T4 StarDriveTM Recess For optimal torque transmission Cutting fl utes on screwhead Facilitate countersinking of the screw Identical pitch of head and 2.2 mm diameter shaft threads head thread Maintains compression when countersinking the head Available in stainless steel and titanium All Headless Compression Screws from DePuy Synthes are available in both implant quality 316L stainless steel and titanium alloy (Ti-6Al-7Nb) 1.2 mm shaft diameter 1.5 mm diameter shaft thread Self-drilling and self-tapping tip For simplifi ed surgical technique 2 DePuy Synthes 1.5 mm Headless Compression Screw Surgical Technique Technique Overview—Lag Screw Technique With Compression Sleeve 1 2 3 Insert screw Compress Countersink Thread the head of the screw into the The tip of the compression sleeve acts Once the desired amount of compression tip of the compression sleeve. -

Ogee Direct Set Commercial Store Fronts Have Never Looked Better

Ogee Direct Set Commercial store fronts have never looked better. It’s not the first time Kolbe has combined authentic historic charm with modern day innovation. In fact, it is one of the things that they are best known for. So it’s no surprise that the Ogee Direct Set window was designed with the same traditional details that adorned commercial store fronts of the past, but with all the latest technology to make it perfect for today’s new commercial or restoration projects. The ogee profile integrated directly into the heavy duty extruded aluminum frame adds a new dimension to a window that is built with great strength. Plus, unlike most store front windows, you get the rich warmth of wood on the interior. This design ensures the beauty of your project will live on for many more years to come. The Ogee Direct Set window can be mulled to complement Kolbe Ultra Series windows and doors or can be used as a stand-alone unit in a variety of shapes and sizes. Either way, there is no shortage of options available. Kolbe doesn’t just let history repeat itself – they make it better. See the Difference Quality Makes® www.kolbe-kolbe.com KOLBEO GEE D IRECT S ET STANDARD FEATURES: ➢ 2-7/16" overall jamb width ➢ Constructed of unfinished pine, with pine interior stops and wood mull casings on mulled units ➢ 7/8" LoE2 insulating glass filled with argon gas* ➢ Glazing is direct set to the interior ➢ All exterior wood parts are preservative-treated ➢ .050" thick, 6063 extruded aluminum alloy frame is applied to the wood frame exterior of all units ➢ -

Tool Holders & Attachments

Screw Machine Attachments 2019 Tool Holders & Attachments Providing quality attachments for any screw machine challenge through original innovative design and engineering, with proven results! Screw Machine Attachments About BME.. BME is a Screw Machine Rebuilder and Custom tooling supplier located in southeast Michigan. Founded on the principle that quality attachments and accessories for multi spindles can be manufactured and supported right here in our own country. We pride ourselves on our quality of work and exceeding our customer’s expectations. Founded, in 2007, BME provided attachments for Acme-Gridley's, mainly Flat Generators and Sync attachments, but over the years we’ve expanded our product line to include attachments for New Britains, Wickmans, Davenports, and any multi-spindles we’ve been maintaining steady growth while continuing to expand our knowledge and skill base. Our growth over the years has also led to the purchase and integration of Precision Form and Grind, and in 2016, Schlitter Tool/ Genius Inc product line. We attribute a majority of this growth to our ability to solve the screw machine industries’ challenges, along with our commitment to our customers, and meeting their deadlines. Our 15,000 square foot facility also contains a variety of CNC manufacturing equipment, that allows us to manufacture a majority of components in house. Our staff includes personnel that have a combined 80 plus years of experience in diagnosing, designing, and debugging a variety of solutions to customer challenges on screw machines. Have you ever been told that “you can’t do that on a screw machine”? Give us a call and let us solve your problems! Why BME? • Our engineering is unsurpassed, with years of experience working on machines and attachments to blend with years of experience in mechanical design. -

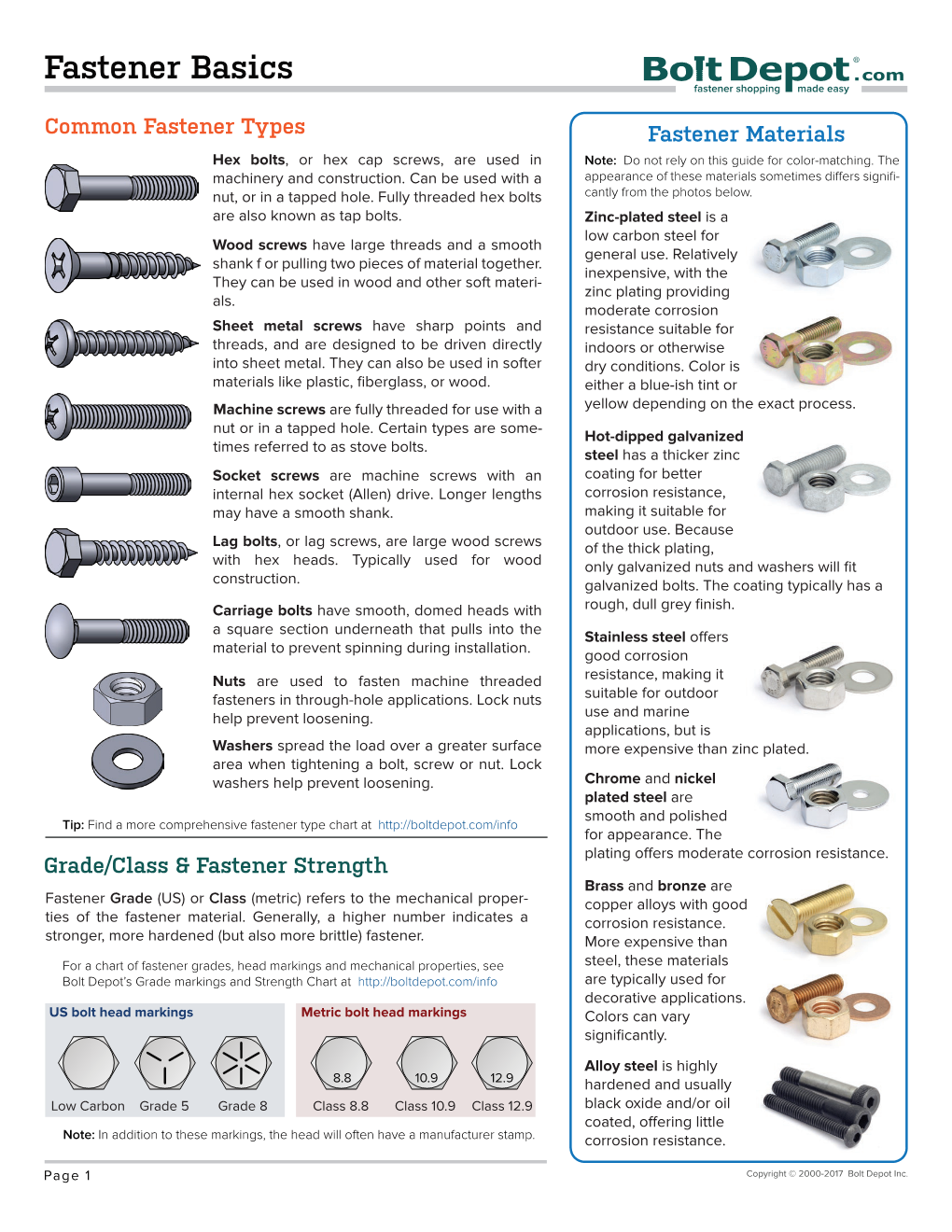

Fastener Identification Guide • 4.13 KM • Printed in the USA

HEAD STYLES Hex Cap Screw Bugle Hex cap screws feature a washer face on the Button Washer bearing surface, a chamfered point, and tighter body tolerances than hex bolts. Pan Binding Undercut Hex Bolt Similar to hex cap screw, hex bolts do not require a washer face or a pointed end and have a greater tolerance range in the body. Round Head Fillister Socket Head Cap Screw Socket heads feature an internal hexagonal drive DRIVES socket and close tolerances for precision assembly. Flat 82° Cross Recess Button Head Socket Cap Screw Type I FASTENER (Phillips) Button heads feature a dome shaped head, though Flat 100° this feature reduces the tensile capacity. Cross Recess Flat Head Socket Cap Screw Type IA Flat heads feature an 82° countersunk head for Flat Undercut (Pozidriv®) IDENTIFICATION flush connections. Like the button heads, this feature reduces the tensile capacity. Cross Recess Type II (Frearson) Low Head Socket Cap Screw Indented Hex Low heads are similar to standard socket heads, but with a shorter head for applications where clearance Cross Recess Square GUIDE is an issue. This head configuration also reduces the Combo strength capacity. Indented Hex Washer (Quadrex®) NUTS Carriage Bolt A round head bolt with a square neck under the Slotted head. These must be tightened with a nut. Serrated Hex Finished Hex Nuts: Hex Coupling Nuts: Washer Hexagonal shaped nuts with internal screw Designed to join two externally threaded Plow Bolt threads. Finished hex nuts are one of the most objects, usually threaded rod, together. Combination Similar to a carriage bolt, these have a flat head common nuts used. -

3657 SIMPLE MACHINES: INCLINED PLANE, WEDGE and SCREW Grade Levels: 7-12 15 Minutes CAMBRIDGE EDUCATIONAL 1998

#3657 SIMPLE MACHINES: INCLINED PLANE, WEDGE AND SCREW Grade Levels: 7-12 15 minutes CAMBRIDGE EDUCATIONAL 1998 DESCRIPTION Uses animated graphics and real examples to illustrate an inclined plane, wedge, and screw. Offers a definition of each and examines the relationship between the three. Shows how they have been used historically. Also defines simple machines and mechanical advantage. Reviews main concepts. ACADEMIC STANDARDS Subject Area: Science ¨ Standard: Understands motion and the principles that explain it · Benchmark: Knows the relationship between the strength of a force and its effect on an object (e.g., the greater the force, the greater the change in motion; the more massive the object, the smaller the effect of a given force) · Benchmark: Knows that when a force is applied to an object, the object either speeds up, slows down, or goes in a different direction Subject Area: Historical Understanding ¨ Standard: Understands and knows how to analyze chronological relationships and patterns · Benchmark: Knows how to construct time lines in significant historical developments that mark at evenly spaced intervals the years, decades, and centuries · Benchmark: Knows how to identify patterns of change and continuity in the history of the community, state, and nation, and in the lives of people of various cultures from times long ago until today AFTER SHOWING 1. Point out objects in the classroom that incorporate inclined planes, wedges and screws. 2. Dissect a toy or household gadget. Record progress in science notebooks with written notations and drawings. Identify each part as to type of simple machine and function. 3. Study the history of simple machines. -

Threaded Fasteners

Threaded Fasteners Introduction If you are designing and building a Formula SAE vehicle, threaded fasteners will likely be used to join the various components and systems together and allow the vehicle to function as a unified machine. The reliability of your vehicle is key to realize your potential at the competition. Even though threaded fasteners have been in use for hundreds of years and are in products that we use every day, their performance is dependent on a wide range of factors. This chapter covers some of the main factors that can influence reliability and is intended as an aid in joint design, fastener selection, and installation. The first portion of this chapter covers several design and installation factors that can work together to improve the reliability of your vehicle’s bolted joints. These topics include, the importance of generating and maintaining clamp load, and how clamp load, along with joint stiffness, can work together to prevent self-loosening and improve fatigue performance. The second portion of this chapter reviews how installation method and torque are related to clamp load, and also includes a comparison between common fastener types to aid in selection. The chapter concludes with a short tutorial showing how to obtain Mil Spec information on fasteners and similar hardware. Disclaimer – Multiple factors on each component in a bolted joint affect its performance. Additionally, service requirements for every joint differ. Each joint must be evaluated and tested for its ability to perform the desired function. The information in this chapter provides general background and does not represent how a specific design or piece of hardware will perform. -

Cord Buckles Center-Release Spaenaur Home Spaenaur 2 All Rights Rights All Reserved

1-800-265-8772 [email protected] Spaenaur Home Full Spaenaur Catalog Contact Us Français Metric Center-Release Buckles / Cord Locks & Cord Ends Métrique Boucles à dégagement central / Autobloqueurs et embouts de cordon EXTRA STRONG CLIP BUCKLE (Clip and Hold) Suitable for webbings of Terylene, Nylon, etc. Special protection against accidental opening. Used on Life-Saving Jackets, heavy Rucksacks, etc. 86 mm 122-A01-1M. Suitable for 40 mm strap of 1.4 - 1.5 mm thickness. The surface of the strap should not be too smooth. Mounting without sewing or rivets. Insert the strap in the clip and holder to the desired length. The Clip Buckle remains in position whether the strap is in use or not, but is nevertheless adjustable. Adjust the position by pushing the outer part of the strap inwards in order to release the strap. The loose end is hidden by the outer 122-A01-1M part of the strap. SPAENAUR Strap Strap PKG No. Colour Width Thickness QTY. 122-A01-1M Black 40 mm 1.4 to 1.5 mm 10 M All CORD BUCKLE Buckles Holder and locking wheel have supplied separately. White Locking Used for bags and clothing. E.g. ruck- Wheel sacks, duffel bags, laundry bags, CATALOG 14 C CATALOG AT sleeping bag covers, anoraks, ALOG 1 swimming trunks, sou’westers. 4 SPAENAUR No. For Cord Size WHITE BLACK PKG QTY. 25 2 mm 122-652 122-655 3-4 mm 122-660 122-663 MOUNTING: After threading the cord through the holder, push in the locking wheel. Knot the ends of the cord.