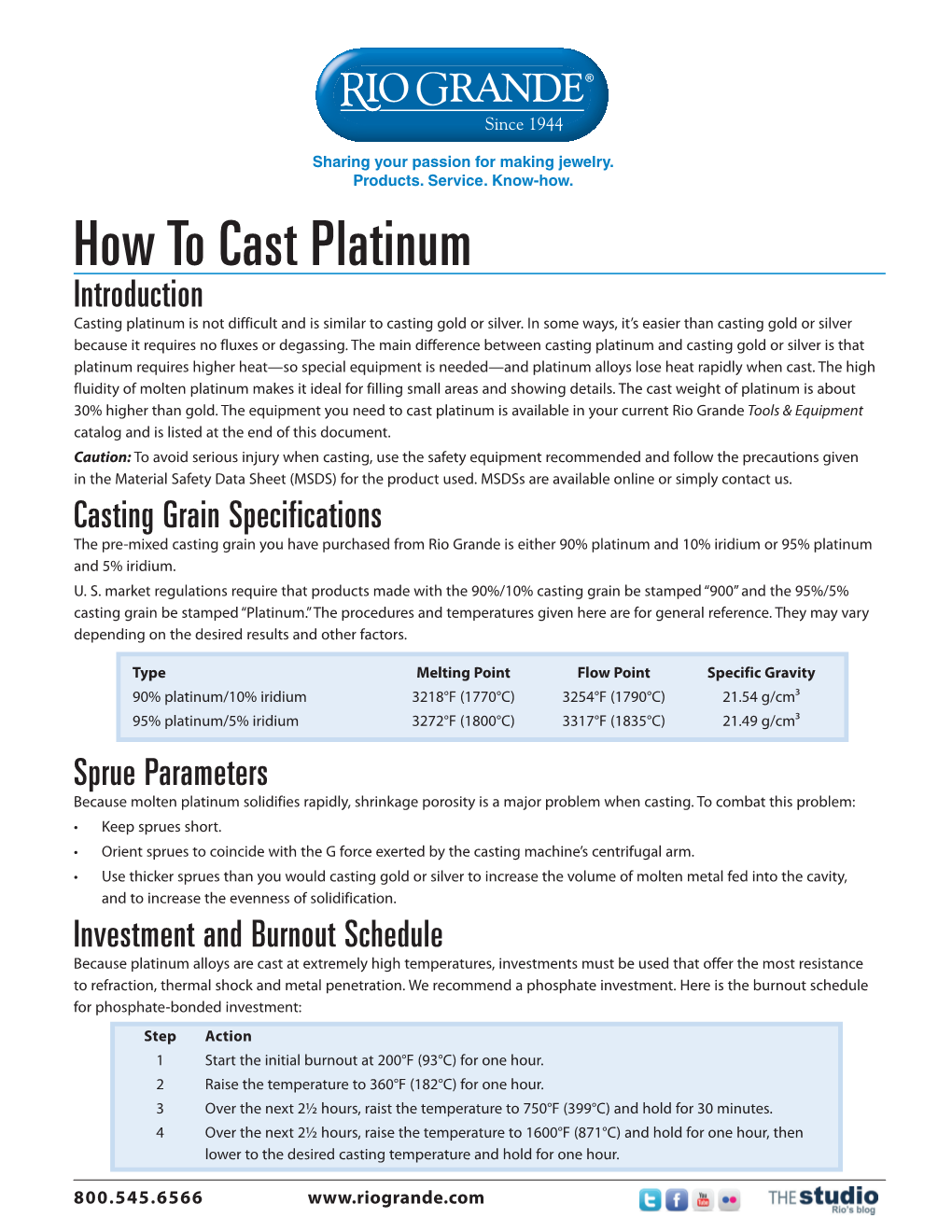

How to Cast Platinum Introduction Casting Platinum Is Not Difficult and Is Similar to Casting Gold Or Silver

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Mold Making for Glass Art

Mold Making for Glass Art a tutorial by Dan Jenkins When Dan Jenkins retired he did not originally intend to make tools and molds for glass artists. However, his wife and friends who work in fused glass were constantly calling on the skills he developed during 30 years as a marine engineer in the Canada Navy to produce items that were needed but unavailable. He began his career on steam driven ships for which it was impossible to get parts. The engineers had to fabricate their own parts out of whatever was available to them. Dan has drawn on his knowledge of woodworking, metalworking, design, engineering and making something out of nothing. He discovered that he enjoys the challenge of designing new tools that are practical economical, and easy to use. Dan has always enjoyed teaching and spent much of his time in the navy as an instructor both at sea and onshore. Dan currently lives in Victoria B.C. with his wife, two cats, and 3 dogs. Mold Making For Glass Art by Dan Jenkins Choosing a Prototype The first projects you wish to tackle should be fairly simple because failure the first few times is Making molds for your own use or for not only possible it is probably inevitable. The reproduction is fairly easy to do and very first objects I tried to cast were self-produced satisfying. Making your own molds frees you wood blocks in the form of squares and from relying on molds made by others and triangles, simple shapes which should have allows you to tailor your mold for your own taste. -

METAL ENAMELING Leader Guide Pub

Arts & Communication METAL ENAMELING Leader Guide Pub. No. CIR009 WISCONSIN 4-H PUBLICATION HEAD HEART HANDS HEALTH Contents Before Each Meeting: Checklist ..............................1 Adhesive Agents or Binders ....................................6 Facilities Tools, Materials and Equipment Safety Precautions..................................................6 Resource Materials Kiln Firing and Table-Top Units Expenses Metal Cutting and Cleaning Planning Application of Enamel Colors Youth Leaders Other Cautions Project Meeting: Checklist ......................................3 Metal Art and Jewery Terms ...................................7 Purposes of 4-H Arts and Crafts ...........................................8 Components of Good Metal Enameling Futher Leader Training Sources of Supplies How to Start Working Prepare a Project Plan Bibiography ............................................................8 Evaluation of Projects Kiln Prearation and Maintenance ...........................6 WISCONSIN 4-H Pub. No. CIR009, Pg. Welcome! Be sure all youth are familiar with 4H158, Metal Enameling As a leader in the 4-H Metal Enameling Project, you only Member Guide. The guide suggests some tools (soldering need an interest in young people and metal enameling to be irons and propane torches), materials and methods which are successful. more appropriate for older youth and more suitable for larger facilities (school art room or spacious county center), rather To get started, contact your county University of Wisconsin- than your kitchen or basement. Rearrange these recommen- Extension office for the 4-H leadership booklets 4H350, dations to best suit the ages and abilities of your group’s Getting Started in 4-H Leadership, and 4H500, I’m a 4-H membership and your own comfort level as helper. Project Leader. Now What Do I Do? (also available on the Wisconsin 4-H Web Site at http://www.uwex.edu/ces/4h/ As in any art project, a generous supply of tools and pubs/index.html). -

Fabrication of Ceramic Moulds Using Recycled Shell Powder and Sand with Geopolymer Technology in Investment Casting

applied sciences Article Fabrication of Ceramic Moulds Using Recycled Shell Powder and Sand with Geopolymer Technology in Investment Casting Wei-Hao Lee, Yi-Fong Wu, Yung-Chin Ding and Ta-Wui Cheng * Institute of Mineral Resources Engineering, National Taipei University of Technology, Taipei 10608, Taiwan; [email protected] (W.-H.L.); [email protected] (Y.-F.W.); [email protected] (Y.-C.D.) * Correspondence: [email protected] Received: 1 June 2020; Accepted: 29 June 2020; Published: 1 July 2020 Abstract: Lost-wax casting, also called precision casting, is the process of casting a duplicate metal sculpture cast an original sculpture. The ceramic shell mould used in lost-wax casting usually consists of several layers formed with fine zircon and granular mullite particles using silica gel as a binder. However, it is a complicated and time-consuming process. Large amounts of waste moulds that need to be disposed and recycled become an environmental concern. In this study, waste shell sand from the recycled mould and calcium carbonate/metakaolin were used as raw materials to prepare geopolymer slurry and coating. The influence of mixing ratio and the SiO2/K2O modulus of the alkali solution on the setting time and green/fired strength were evaluated. Ceramic shells with one to four layers of geopolymer slurry and waste sand sprinkling were fabricated and tested for their permeability and green/fired strength. It was found that geopolymer shells had higher green/fired strength and better permeability than the original zircon/mullite shell. For foundry practice, metal casts were fabricated using recycled ceramic shell moulds with one to four layers of geopolymer coating. -

DROSS in DUCTILE IRON by Hans Roedter, Sorelmetal Technical Services

98 DROSS IN DUCTILE IRON by Hans Roedter, Sorelmetal Technical Services WHAT IS “DROSS ”? magnesium with other elements. Dross also Dross is a reaction product which is formed from occurs in the form of long stringers instead of Mg treatment and during subsequent reoxidation concentrated “slag like” areas. When it occurs in of Mg rejected from the molten metal before it this string like form it acts like cracks or flake solidifies. It is therefore just another word for a graphite in the structure and so fatigue strength specific type of slag (reaction product). and impact strength of the material are lowered considerably. The reaction binds magnesium with sulphur, oxygen and silicon and forms continuously. This “dross” is light weight and so it will generally be found in the upper surfaces and under cores, but it can be entrained throughout the metal as well, especially with colder pouring tempera - tures. It is very difficult to completely avoid the reaction of magnesium with these other elements, since we need magnesium to form nodules. We are always confronted with the problem of dross in the production of Ductile Iron. WHAT IS PROMOTING “DROSS ” AND WHAT CAN BE DONE TO KEEP THE “DROSS ” OUT OF THE CASTING ? Since “dross” is always connected with magnesium, it is necessary to keep the magnesium level as low as possible. Good inoculation practice with some late inoculation in conjunction with sufficient magnesium will When looking at “dross” in the microscope you produce nice round small nodules. See will almost always find flake graphite in Suggestion Sheet 76. -

JMD How to Enamel Jewelry

PRESENTS How to Enamel Jewelry: Expert Enameling Tips, Tools, and Techniques Jewelry Making Daily presents How to Enamel Jewelry: Expert Enameling Tips, Tools, and Techniques 7 3 21 ENAMELING TIPS BY HELEN I. DRIGGS 12 10 TORCH FIRED ENAMEL ENAMELING MEDALLION NECKLACE BY HELEN I. DRIGGS BY HELEN I. DRIGGS ENAMELED FILIGREE BEADS BY PAM EAST I LOVE COLOR! In jewelry making, enamel is one of the most In “Enameled Filigree Beads,” Pam East walks you through a versatile sources of pure, luscious color – powdered glass you simple technique of torch firing enamel onto a premade bead can apply with great precision onto silver, gold, copper, and using a handheld butane torch instead of an enameling kiln. other jewelry metals. With enamels, you can paint with a broad The enamel adds color to the bead, while the silver filigree brush or add minute and elaborate detail to pendants, brace- creates the look of delicate cells like those in cloisonné enamel lets, earrings, and more. You can work in rich, saturated tones work. And in “Torch Fired Enamel Medallion Necklace,” Helen or in the subtlest of pastels. You can create a world of sharp Driggs shows you how to create your own torch fired enamel contrast in black and white or one entirely of shades of gray. “cabochons,” how to tab set those cabs, and how to stamp You can even mimic the colors of the finest gemstones, but you and patinate the surrounding metalwork, which you can put can also produce hues and patterns you’d never find among the together using the chain of your choice. -

Raymond & Leigh Danielle Austin

PRODUCT TRENDS, BUSINESS TIPS, NATIONAL TONGUE PIERCING DAY & INSTAGRAM FAVS Metal Mafia PIERCER SPOTLIGHT: RAYMOND & LEIGH DANIELLE AUSTIN of BODY JEWEL WITH 8 LOCATIONS ACROSS OHIO STATE Friday, August 14th is NATIONAL TONGUE PIERCING DAY! #nationaltonguepiercingday #nationalpiercingholidays #metalmafialove 14G Titanium Barbell W/ Semi Precious Stone Disc Internally Threaded Starting At $7.54 - TBRI14-CD Threadless Starting At $9.80 - TTBR14-CD 14G Titanium Barbell W/ Swarovski Gem Disc Internally Threaded Starting At $5.60 - TBRI14-GD Threadless Starting At $8.80 - TTBR14-GD @fallenangelokc @holepuncher213 Fallen Angel Tattoo & Body Piercing 14G Titanium Barbell W/ Dome Top 14G Titanium Barbell W/ Dome Top 14G ASTM F-67 Titanium Barbell Assortment Internally Threaded Starting At $5.46 - TBRI14-DM Internally Threaded Starting At $5.46 - TBRI14-DM Starting At $17.55 - ATBRE- Threadless Starting At $8.80 - TTBR14-DM Threadless Starting At $8.80 - TTBR14-DM 14G Threaded Barbell W Plain Balls 14G Steel Internally Threaded Barbell W Gem Balls Steel External Starting At $0.28 - SBRE14- 24 Piece Assortment Pack $58.00 - ASBRI145/85 Steel Internal Starting At $1.90 - SBRI14- @the.stabbing.russian Titanium Internal Starting At $5.40 - TBRI14- Read Street Tattoo Parlour ANODIZE ANY ASTM F-136 TITANIUM ITEM IN-HOUSE FOR JUST 30¢ EXTRA PER PIECE! Blue (BL) Bronze (BR) Blurple Dark Blue (DB) Dark Purple (DP) Golden (GO) Light Blue (LB) Light Purple (LP) Pink (PK) Purple (PR) Rosey Gold (RG) Yellow(YW) (Blue-Purple) (BP) 2 COPYRIGHT METAL MAFIA 2020 COPYRIGHT METAL MAFIA 2020 3 CONTENTS Septum Clickers 05 AUGUST METAL MAFIA One trend that's not leaving for sure is the septum piercing. -

St Luke's Farnworth BELL CASTING

St Luke’s Farnworth BELL CASTING by Geoffrey Poole In the earliest days they were cast in different sizes to produce different notes but no attempt was made to tune bells until the 16th Century with the advent of change ringing. In those times bells were roughly tuned – where the inside of the bell or the edge of the lip was chipped away with a hammer and chisel – eight bells could be tuned to an octave of eight notes. Some deprived communities used a hagiosideron, a shaped piece of metal which was struck in a similar way to a bell. Also again due to lack of money bellcotes were used instead of costly towers. A bell-cot, bell-cote or bellcote is a small framework and shelter for one or more bells. Bellcotes are most common in church architecture but are also seen on institutions such as schools. The bellcote may be carried on brackets projecting from a wall or built on the roof of chapels or churches that have no towers. The bellcote often holds the Sanctus bell that is rung at the consecration of the Eucharist. Bellcote is a compound noun of the words bell and cot or cote. Bell is self-explanatory. The word cot or cote is Old English, from the Germanic. It means a shelter of some kind, especially for birds or animals (see dovecote), a shed, or stall. Examples of bellcotes In order St Luke’s Farnworth Bell-cot at St Edmund's Church, Church Road, Wootton, Isle of Wight, England Church of England parish church of St Alban the Martyr, CharlesStreet, Oxford. -

Boilermaking Manual. INSTITUTION British Columbia Dept

DOCUMENT RESUME ED 246 301 CE 039 364 TITLE Boilermaking Manual. INSTITUTION British Columbia Dept. of Education, Victoria. REPORT NO ISBN-0-7718-8254-8. PUB DATE [82] NOTE 381p.; Developed in cooperation with the 1pprenticeship Training Programs Branch, Ministry of Labour. Photographs may not reproduce well. AVAILABLE FROMPublication Services Branch, Ministry of Education, 878 Viewfield Road, Victoria, BC V9A 4V1 ($10.00). PUB TYPE Guides Classroom Use - Materials (For Learner) (OW EARS PRICE MFOI Plus Postage. PC Not Available from EARS. DESCRIPTORS Apprenticeships; Blue Collar Occupations; Blueprints; *Construction (Process); Construction Materials; Drafting; Foreign Countries; Hand Tools; Industrial Personnel; *Industrial Training; Inplant Programs; Machine Tools; Mathematical Applications; *Mechanical Skills; Metal Industry; Metals; Metal Working; *On the Job Training; Postsecondary Education; Power Technology; Quality Control; Safety; *Sheet Metal Work; Skilled Occupations; Skilled Workers; Trade and Industrial Education; Trainees; Welding IDENTIFIERS *Boilermakers; *Boilers; British Columbia ABSTRACT This manual is intended (I) to provide an information resource to supplement the formal training program for boilermaker apprentices; (2) to assist the journeyworker to build on present knowledge to increase expertise and qualify for formal accreditation in the boilermaking trade; and (3) to serve as an on-the-job reference with sound, up-to-date guidelines for all aspects of the trade. The manual is organized into 13 chapters that cover the following topics: safety; boilermaker tools; mathematics; material, blueprint reading and sketching; layout; boilershop fabrication; rigging and erection; welding; quality control and inspection; boilers; dust collection systems; tanks and stacks; and hydro-electric power development. Each chapter contains an introduction and information about the topic, illustrated with charts, line drawings, and photographs. -

Metal Casting Terms and Definitions

Metal Casting Terms and Definitions Table of Contents A .................................................................................................................................................................... 2 B .................................................................................................................................................................... 2 C .................................................................................................................................................................... 2 D .................................................................................................................................................................... 4 E .................................................................................................................................................................... 5 F ..................................................................................................................................................................... 5 G .................................................................................................................................................................... 5 H .................................................................................................................................................................... 6 I .................................................................................................................................................................... -

Paisley and Filigree Diamond Wedding Band, RG-1747Wbd This

Paisley and Filigree Diamond Wedding Band, RG-1747wbd This 18k white gold filigree and diamond wedding band is elegant worn alone or paired with a filigree engagement ring. Twenty-two round brilliant cut diamonds accentuate the band along the top and shoulders and six additional diamonds add shimmer and sparkle on the sides. The combined weight of all 28 diamonds is 0.20 carats. Filigree swirls and milgraining further enhance the design of filigree wedding rings like this one. Options None Item # rg1747wbd Metal 18k white gold Weight in grams 2.35 Special characteristics This wedding band compliments engagement ring style RG-1747 as well as engagement ring style RG-2567. The band is also beautiful worn alone as it is not curved or notched to fit snugly against an engagement ring. Condition New Diamond cut or shape round brilliant cut Diamond carat weight 0.20 Diamond color G to H Diamond clarity VS2 Diamond # of stones 28 Top of ring width (E-W) 2.49 mm [0.10 in] Width of shank at shoulders 2.31 mm [0.09 in] Width of shank at base 2.04 mm [0.08 in] Ring height above finger 2.46 mm [0.10 in] Other ring info For new rings like this one, the gram weight, diamond and gemstone carat weights, color, and clarity, as well as other jewelry details, vary from the specifications shown on this page, but are similar in quality. Important Jewelry Information Each antique and vintage jewelry piece is sent off site to be evaluated by an appraiser who is not a Topazery employee and who has earned the GIA Graduate Gemologist diploma as well as the title of AGS Certified Gemologist Appraiser. -

Manufacturing Technology I Unit I Metal Casting

MANUFACTURING TECHNOLOGY I UNIT I METAL CASTING PROCESSES Sand casting – Sand moulds - Type of patterns – Pattern materials – Pattern allowances – Types of Moulding sand – Properties – Core making – Methods of Sand testing – Moulding machines – Types of moulding machines - Melting furnaces – Working principle of Special casting processes – Shell – investment casting – Ceramic mould – Lost Wax process – Pressure die casting – Centrifugal casting – CO2 process – Sand Casting defects. UNIT II JOINING PROCESSES Fusion welding processes – Types of Gas welding – Equipments used – Flame characteristics – Filler and Flux materials - Arc welding equipments - Electrodes – Coating and specifications – Principles of Resistance welding – Spot/butt – Seam – Projection welding – Percusion welding – GS metal arc welding – Flux cored – Submerged arc welding – Electro slag welding – TIG welding – Principle and application of special welding processes – Plasma arc welding – Thermit welding – Electron beam welding – Friction welding – Diffusion welding – Weld defects – Brazing – Soldering process – Methods and process capabilities – Filler materials and fluxes – Types of Adhesive bonding. UNIT III BULK DEFORMATION PROCESSES Hot working and cold working of metals – Forging processes – Open impression and closed die forging – Characteristics of the process – Types of Forging Machines – Typical forging operations – Rolling of metals – Types of Rolling mills – Flat strip rolling – Shape rolling operations – Defects in rolled parts – Principle of rod and wire drawing – Tube drawing – Principles of Extrusion – Types of Extrusion – Hot and Cold extrusion – Equipments used. UNIT IV SHEET METAL PROCESSES Sheet metal characteristics – Typical shearing operations – Bending – Drawing operations – Stretch forming operations –– Formability of sheet metal – Test methods – Working principle and application of special forming processes – Hydro forming – Rubber pad forming – Metal spinning – Introduction to Explosive forming – Magnetic pulse forming – Peen forming – Super plastic forming. -

Filigree Jewelry Product Differentiation (Case Study Filigree Kota Gede Yogyakarta)

Filigree Jewelry Product Differentiation (Case Study Filigree Kota Gede Yogyakarta) Asep Sufyan Muhakik Atamtajani1 1Product Design, Faculty of Creative Industries, Telkom University, Indonesia [email protected](Asep Sufyan Muhakik Atamtajani)1 Abstract The reason that product design differentiation is important because it maintains a product’s existence last longer in the market and keep the consumer interested into the product. Differentiation means increasing the quality, selling value, and visual value of a product. To develop a product, a creator are trying to create a new, creative, and distinguish product that different with other similar products in the market, in this case is traditional and modern jewelry. Traditional jewelry has its own unique dimension in terms of design process, production techniques, and aesthetic aspects that combine several elements of material. Along with the development of industrialization and market segmentation becomes broader, jewelry becomes an appealing commodity. Time flies and jewelry has shifted from a meaning of self-philosophy of the user into a universal meaning as a consumptive identity in cultural society. Filigree with his trademark can survive by showing its value in the international market. Filigree itself is one of the oldest techniques that have been abandoned for a long period of time because some reasons, especially about the process and other considerations. Kotagede Yogyakarta is one of the cities that still maintain the technique of design process filigree, although until now not a few of the craftsmen have started to spread to other cities. Keywords: Differentiation, Product Design, Jewelry, Filigree. 1. INTRODUCTION Once the problems can be demonstrated factually, further information needs to be gathered as the Jewelry has a universal meaning and local material for specific product planning that is expected significance, especially the Indonesian silver filigree to address the problem.