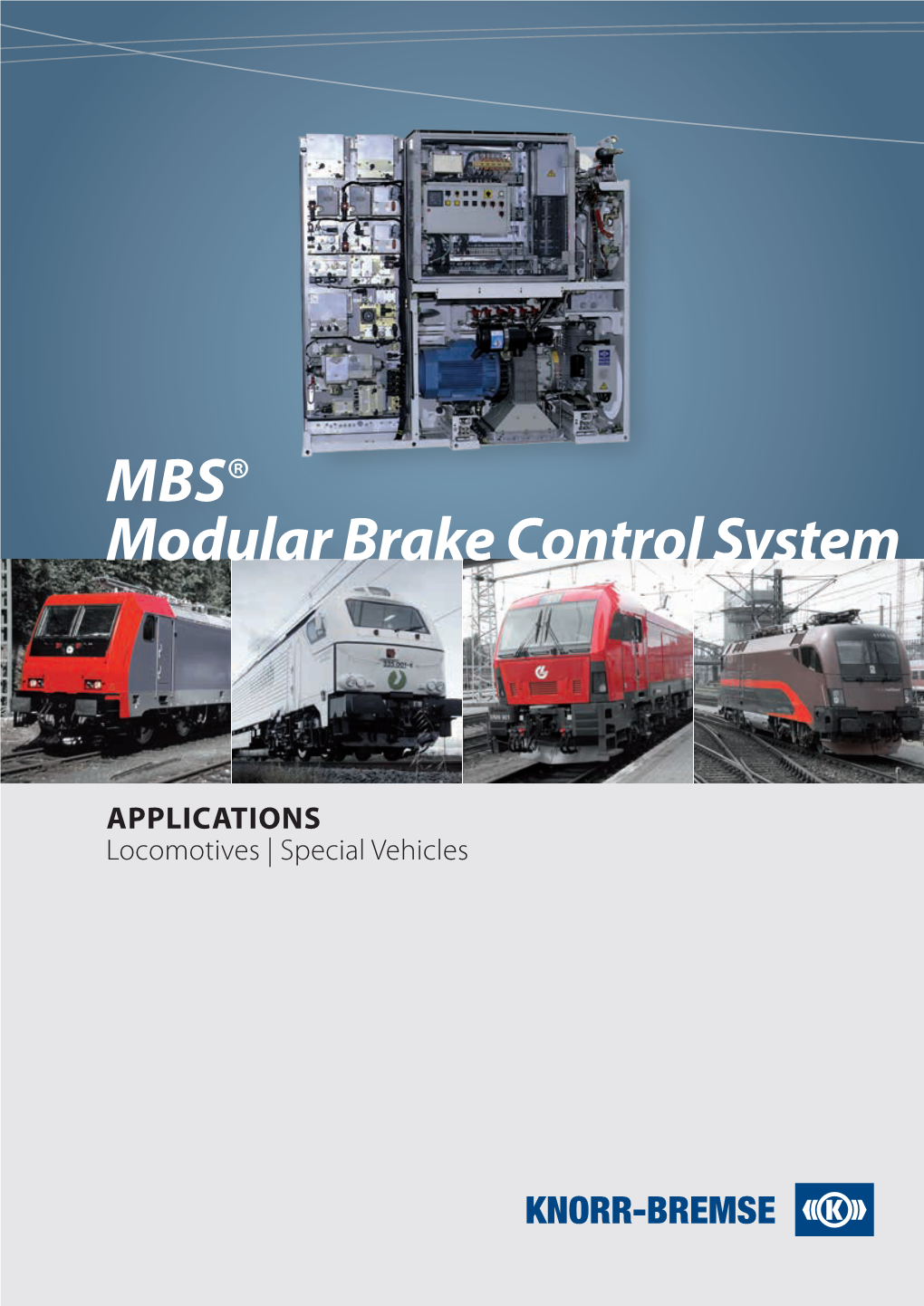

MBS® Modular Brake Control System

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

EP / BP Compact Product Family

EP / BP Compact Product Family Foto Siemens AG“ APPLICATIONS High-Speed Trains | Locomotives | Metros | Regional and Commuter Trains 2 EP / BP COMPACT PRODUCT FAMILY IS A FLEXIBLE AND POWERFUL BRAKE CONTROL SYSTEM providing not only brake cylinder pressure control for central and decentralized systems but also for brake pipe pressure control. Its modular design of electronic and pneumatic modules makes it configurable for all types of high-speed trains, multiple units and metros. With its variety of modules, EP / BP CUSTOMER BENEFITS DIVERSIFICATION Compact can be used for a wide n Lightweight and compact EP Compact offers control of various range of different applications of all n Flexible system layout functions of the braking systems: car builders across different markets. n Maximum economy thanks to n Service brake (direct and indirect) Every electropneumatic module standardized modules n Emergency brake (direct and controls either brake pipe n Discrete, highly integrable indirect) applications, single bogies components n Magnetic track brake separately or several bogies with n Straightforward service and n Parking brake identical braking requirements. maintenance concept n Wheel slide control Different electronic modules allow n For central or decentralized control n Continuous load correction and the use of different communication n Multifunctional for numerous load limitation interfaces: wheel slide protection, system configurations pressure regulation and diagnosis n Innovative use of proven Electronic control functions: functions. Anti-skid valves as well as technology n Blending / brake management different auxiliary control functions n Integrated electronics for n Diagnostics and monitoring can be integrated into the module underfloor or separate electronics n Sanding and other auxiliary systems as an option. -

Pioneering the Application of High Speed Rail Express Trainsets in the United States

Parsons Brinckerhoff 2010 William Barclay Parsons Fellowship Monograph 26 Pioneering the Application of High Speed Rail Express Trainsets in the United States Fellow: Francis P. Banko Professional Associate Principal Project Manager Lead Investigator: Jackson H. Xue Rail Vehicle Engineer December 2012 136763_Cover.indd 1 3/22/13 7:38 AM 136763_Cover.indd 1 3/22/13 7:38 AM Parsons Brinckerhoff 2010 William Barclay Parsons Fellowship Monograph 26 Pioneering the Application of High Speed Rail Express Trainsets in the United States Fellow: Francis P. Banko Professional Associate Principal Project Manager Lead Investigator: Jackson H. Xue Rail Vehicle Engineer December 2012 First Printing 2013 Copyright © 2013, Parsons Brinckerhoff Group Inc. All rights reserved. No part of this work may be reproduced or used in any form or by any means—graphic, electronic, mechanical (including photocopying), recording, taping, or information or retrieval systems—without permission of the pub- lisher. Published by: Parsons Brinckerhoff Group Inc. One Penn Plaza New York, New York 10119 Graphics Database: V212 CONTENTS FOREWORD XV PREFACE XVII PART 1: INTRODUCTION 1 CHAPTER 1 INTRODUCTION TO THE RESEARCH 3 1.1 Unprecedented Support for High Speed Rail in the U.S. ....................3 1.2 Pioneering the Application of High Speed Rail Express Trainsets in the U.S. .....4 1.3 Research Objectives . 6 1.4 William Barclay Parsons Fellowship Participants ...........................6 1.5 Host Manufacturers and Operators......................................7 1.6 A Snapshot in Time .................................................10 CHAPTER 2 HOST MANUFACTURERS AND OPERATORS, THEIR PRODUCTS AND SERVICES 11 2.1 Overview . 11 2.2 Introduction to Host HSR Manufacturers . 11 2.3 Introduction to Host HSR Operators and Regulatory Agencies . -

Air Brake & Train Handling Rules

Air Brake & Train Handling Rules Effective March 25, 2019 AIR BRAKE & TRAIN HANDLING RULES TABLE OF CONTENTS 100.0 Train Air Brake Tests and Inspections 5 100.1 Compliance with FRA and Transport Canada Regulations 5 100.2 Safety Inspection of Freight Cars 5 100.3 Coupling and Securing Air Hoses 6 100.4 Operative Brakes - US Only 6 100.5 Person in Charge of Air Brake Test 7 100.6 Standard Brake Pipe Pressures 7 100.7 Charging Air Brake System 7 100.8 Air Brake Tests Using End-of-Train Telemetry Devices (ETD) Continuity Tests 7 100.8.1 Air Brake Tests Using Handheld Gauges 8 100.9 Brake Pipe Leakage Test 8 100.10 Initial Terminal and Road Air Brake Test (Class 1 Air Brake Test) Canadian Class 1 Brake Test and Class 1-A Brake Tests 9 100.11 Transfer Train Movements Test – United States 12 100.12 Transfer Movements – Canada 13 100.13 Running Air Brake Test 13 100.14 Air Brake Test When Cutting Off and Recoupling 14 100.15 Application and Release Test (Class 3 Air Brake Test) United States and Canada 14 100.16 Air Brake Test When Adding Pre-Tested Cars 14 100.17 Inbound Train Inspection 14 100.18 Piston Travel Limits 15 100.19 Dynamic Brake Requirements 15 100.20 Inoperative Dynamic Brake on Lead, Controlling Locomotive 15 101.0 Locomotive Air Brake Tests and Inspections 16 101.1 General Requirements 16 101.2 Locomotive Daily Inspection 16 101.3 Defects Other Than Non-Complying Conditions 20 101.4 Non-Complying Condition Found En Route 21 101.5 Major Internal Defects Found En Route 21 101.6 Locomotive Air Brake Test 22 101.7 Standard Air Pressures -

The 26-L Brake Equipment

INSTRUCTION PAMPHLET No. 74 June 1964 THE 26-L BRAKE EQUIPMENT with 26-C BRAKE VALVE and 26-F CONTROL VALVE arranged for SAFETY CONTROL OVERSPEED CONTROL DYNAMIC INTERLOCK and MULTIPLE-UNIT CONTROL for LOCOMOTIVES THE 26-L BRAKE EQUIPMENT WITH 26-C BRAKE VALVE AND 26-F CONTROL VALVE ARRANGED FOR SAFETY CONTROL OVERSPEED CONTROL DYNAMIC INTERLOCK AND MULTIPLE-UNIT CONTROL FOR LOCOMOTIVES INSTRUCTION PAMPHLET NO. 74 JUNE 1964 (Supersedes Issue of September 1960) CONTENTS Paqe The Equipment .................................................................................................................................. 3 26-C Brake Valve .............................................................................................................................. 5 Automatic Brake Operation .................................................................................................... 9 Independent Brake Operation ................................................................................................. 11 26-F Control Valve ........................................................................................................................... 13 J-1 Relay Valve ................................................................................................................................. 20 MU-2-A Valve ................................................................................................................................... 23 F-1 Selector Valve ........................................................................................................................... -

Parking Brakes for Passenger Locomotives and Cars

APTA STANDARDS DEVELOPMENT PROGRAM APTA PR-M-S-006-98, Rev. 3 STANDARD First Published: March 4, 1999 American Public Transportation Association First Revision: February 13, 2004 1300 I Street, NW, Suite 1200 East, Washington, DC 20006 Second Revision: June 2, 2007 Third Revision: June 1, 2017 PRESS Mechanical Working Group Parking Brakes for Passenger Locomotives and Cars Abstract: This document provides standards for parking brake systems for passenger locomotives and passenger cars. Keywords: grade holding, handbrake Summary: Design standards for parking brake systems for passenger locomotives and cars for the passenger railroad industry are provided. Scope and purpose: This standard applies to North American passenger locomotive and car parking brake systems and is intended to promote safe, efficient and reliable operation. This standard recognizes the existence of service proven equipment that may not meet all provisions of this standard, primarily in areas of required brake actuating force and design safety factors. In these cases, the existing requirements are accepted and indicated accordingly; however, it is intended that all new designs shall meet the updated requirements. Specific areas addressed are grade-holding requirements; prevention of equipment damage; and human interface for parking brake operation, as well as annunciation, manual release provisions, validation and related safety issues. This document represents a common viewpoint of those parties concerned with its provisions, namely operating/ planning agencies, manufacturers, consultants, engineers and general interest groups. The application of any standards, recommended practices or guidelines contained herein is voluntary. In some cases, federal and/or state regulations govern portions of a transit system’s operations. In those cases, the government regulations take precedence over this standard. -

The Eddy-Current Brake Compatibility Project

GENERAL ENGINEERING Taking the brakes off Dr Daniel Valderas, leader of a project investigating the compatibility of state-of-the-art electromagnetic brakes with high-speed train systems across Europe, reveals some surprising findings from the research Could you outline how you came to work no mechanical contact between the brake and damage. This temperature limit can now on the Eddy CUrrent brake Compatibility track, there is no wear, fine dust, smell or noise be observed from the point of view of ECB (ECUC) project? from its usage. It can be used as both a service performance superimposed on the current and an emergency brake. Catenary power agents that increase rail temperature. In Our department at the Centro de supply is not essential in all ECBs. the case of electromagnetic emissions, the Investigaciones Técnicas de Gipuzkoa (CEIT), standard that probably lies closest to our a non-profit research institute in Spain, has a How has the project used electromagnetic and case study is the CLC TS 50238-3, which wealth of experience in the railway sector and thermal modelling to anticipate the behaviour defines compatibility between rolling stock provides technology to train manufacturers of railway systems? and train detection systems, particularly such as the Constructions and Auxiliary of in regard to axle counters. However, this Railways (CAF) and has coordinated high- Two computer models have been developed standard ignores the usage of ECBs. ECUC profile European Union projects. Together with in ECUC: one thermal, to anticipate the does not intend to directly impact on any major manufacturers such as Knorr-Bremse temperature of the track, and another standard, but can initiate a review by and Deutsche Bahn, we have encountered electromagnetic, to calculate the interference providing insights and recommendations. -

NEW YORK AIR BRAKE CORPORATION a KNORR BRAKE COMPANY 748 Starbuck Avenue, Watertown, New York 13601

NEW YORK AIR BRAKE CORPORATION A KNORR BRAKE COMPANY 748 Starbuck Avenue, Watertown, New York 13601 C.W. 307 COMPONENT WRITE-UP OF CCB-26 LOCOMOTIVE BRAKE SYSTEM ISSUE NO. 1 C.W. 307 JUNE 28, 2006 14 PAGES GENERAL The CCB-26 system is a microprocessor based electronic air brake system designed to function as a direct replacement for an AAR freight 26L system, with an added pneumatic penalty brake function with provisions for pipes #3 (suppressible) & #10 (non-suppressible). This system is not intended for locomotives that have a locomotive computer and/or screen interface requirements. CCB-26 does not require an interface for cab electronics or screen displays. Instead, the engineers interface contains the basic two duplex gauges for pressure display and rotary selectors for mode selection. This system contains simple electronic modules that enable full closed loop pressure control, which allow for full time diagnostic health and performance monitoring and can take action to make a safe stop if system failure is detected. Equalizing reservoir, brake pipe control and IA&R pipe control are managed by computer electronics. Brake cylinder control is fully pneumatic and actuating pipe control is electro-pneumatic. This system does not include passenger mode (graduated release) functionality. The system performs several diagnostic functions like self test, calibrations, and a fault flagging via PTU software typically run on a laptop. Faults are detected and displayed on an LCD screen mounted on the driver’s brake valve (EBV). A “one wrench” maintenance philosophy allows for rapid replacement of failed modules based upon the displayed fault information. -

LOCOMOTIVE ENGINEER TRAINING HANDBOOK February, 2006

LOCOMOTIVE ENGINEER TRAINING HANDBOOK February, 2006 Locomotive Control Stand Orientation An important part of your Locomotive Engineer training will be operating locomotive simulators, and your first simulator activity will be very early in the class. The following pages are an introduction to some of the controls on a locomotive control stand. While there are some differences between locomotives, there are also many common items that are covered in the following pages. This material is intended more as an introduction; it will make your first simulator activities easier and will help you prepare for more material that will be covered in lessons on air brakes, preparing locomotives for service, dynamic braking and train handling. Your assignment for tonight is to read this material and answer the questions at the end. The assignment will be checked for completeness at the start of day one orientation. LET Staff The reverser handle is the lowest handle on the control stand. It has three positions: left, centered, and right. When the handle is moved to the right, circuits are set up for the locomotive to move in that direction. When the handle is moved to the left, the locomotive will move in that direction when power is applied. With the reverser handle centered, mechanical interlocking prevents movement of the dynamic brake handle, but the throttle can be moved. In such case, power will not be applied to the traction motors. Reverser Handle The reverser handle is centered and removed from the panel to lock the throttle in IDLE position and the dynamic brake handle in OFF position. -

Operating Practices Manual OP-1

Operating Practices Manual OP-1 Effective 0001 January 1, 2017 General Notice: The Operating Practices Section (OP-1) of the Belt Railway of Chicago Operating Manual is intended for all employees whose duties involve the operation or inspection of air brakes on locomotives or cars. Additionally, this section includes the instructions for the safe operation of remote control locomotives. Employees involved in these activities must maintain a thorough knowledge of these instructions, and must have a copy of these instructions with them to refer to while on duty. Additional information and training will be made available to these employees, upon request to their supervisor, the Director of Rules and Compliance, or the Manager Operating Practices. Additions or modifications to these instructions will be made by Operating Practices General Orders. Additional information will be provided in Transportation Notices, as needed. H.T. Kirman Director of Operating Rules and Compliance M.G. Labbe Manager of Operating Practices BRC OP-1 Page 2 Table of Contents: Rule Subject Page Rule Subject Page Section 1 Locomotive EQ and 5-23 Section 2 Train Air Brake Test 27-31 Operation and Inspection OP 1.1 Inspection 5 OP 2.4.3 Class I (Leakage Test) 27 OP 1.2 Inspection Procedure 5 OP 2.4.4 Yard Test Plant 28 OP 1.2.1 Conducting Inspection 7 OP 2.5 Class II Air Brake Test 28 OP 1.2.2 Results of Inspection 10 OP 2.5.1 Class II Application 28 OP 1.3 Non-Complying Conditions 12 OP 2.5.2 Class II Test Procedure 28 Enroute OP 1.4 Major Internal Defects 12 OP 2.6 -

Freight Cars F R E I G H T C a R S

Rail Vehicle Systems Freight Cars F r e i g h t C a r s Systems Solutions For Every Market Bogie equipment BraKe Control on-Board SyStemS What is Knorr-Bremse’s complete “one-stop solution” for freight cars ? Cutting-Edge Technologies K E K i n k - Compact Freight C o n t r o l V a l v e Curve Valve Car Brake – CFCB Tried and tested, Avoids wear and overload Reducing weight and highly adaptable operating costs First produced in 1954 and The kink-curve valve is an The CFCB compact bogie continuously improved ever additional valve for braking tread brake could reduce the since, the KE control valve is under load that is simply weight of freight cars by more synonymous with safe, rapid, attached to the KE control valve. than 1,000 kg, making them even, and controllable operation In freight trains consisting of considerably more economical of the braking system. More than cars with differing braking to operate. Braking force is 1.5 million valves are currently performance, it ensures even transferred directly via simple in operation around the world. braking according to the load slack adjusters, and the cylinder This proven platform can have and braking requirements, and transmission rod are fully many additional functions and reduces wheel surface insulated. All bearings are added to it. Its modular design temperatures by up to 150ºC. maintenance-free and the combines the cost advantages The valve comes into its own system automatically adjusts of standardization with the during long descents, when for block and wheel wear. -

1990 Undesired Emergency Brake Applications

Association of American Railroads Research and Test Department Undesired Emergency Brake Applications Transportation Test Center UDE Tests Report No. R-761 F. G. Carlson August, 1990 AAR Technical Center Chicago, Illinois 1. REPORT NO. 2. REPORT DATE 3. PERIOD COVERED R-761 August, 1990 1985-1989 4. TITLE AND SUBTITTE Undesired Emergency Brake Applications - Transportation Test Center UDE Tests 5. AUTHOR(S) Frederick G. Carlson, Senior Research Engineer 6 . PERFORMING ORGANIZATION NAME AND ADDRESS 7. TYPE OF REPORT Research Association of American Railroads Technical Center 8 . CONTRACT OR GRANT NO. 3140 South Federal Street Chicago, Illinois 60616 DTFR53-86-C-000111 9, SPONSORING AGENCY NAME AND ADDRESS 10. NO. OF PAGES 134 Federal Railroad Administration 400 Seventh Street, N.W. 11. NO. OF REFERENCES Washington, D.C. 20590 12. SUPPLEMENTARY NOTES AAR Project No. R-221 13. ABSTRACT This report covers the Federal Railroad Administration funded Undesired Emergency Tests performed at the Transportation Test Center in Pueblo, Colorado. This report also covers the AAR research conducted prior to the Transportation Test Center tests. This is necessary in order to provide a background to better understand why the test was designed as it was. The FRA Undesired Emergency Test proved that pressure fluctuations of up to 2 psi can occur due to slack action alone, independent of any intentional brake applications. Brake pipe pressure reduction rates of over 30 psi/sec lasting for about 15 milliseconds were created by harsh slack run-ins. These rates are very close to those necessary to produce Undesired Emergency Brake Applications. A possible cure to Undesired Emergencies was tested. -

Federal Railroad Administration, DOT § 232.10

Federal Railroad Administration, DOT § 232.10 penalty not to exceed $22,000 per viola- cars on such 2-foot-gauge railroads tion may be assessed. Each day a viola- measured in the same manner shall be tion continues shall constitute a sepa- 141¤2 inches. rate offense. § 232.3 Power brakes and appliances [54 FR 33230, Aug. 14, 1989, as amended at 63 for operating power-brake systems. FR 11623, Mar. 10, 1998] (a) The specifications and require- § 232.1 Power brakes; minimum per- ment for power brakes and appliances centage. for operating power-brake systems for On and after September 1, 1910, on all freight service set forth in the appen- railroads used in interstate commerce, dix to the report on further hearing, of whenever, as required by the Safety May 30, 1945, are hereby adopted and Appliance Act as amended March 2, prescribed. (See appendix to this part 1903, any train is operated with power for order in Docket 13528.) or train brakes, not less than 85 per- (b) [Reserved] cent of the cars of such train shall have their brakes used and operated by the RULES FOR INSPECTION, TESTING AND engineer of the locomotive drawing MAINTENANCE OF AIR BRAKE EQUIPMENT such train, and all power-brake cars in every such train which are associated § 232.10 General rules; locomotives. together with the 85 percent shall have (a) Air brake and hand brake equip- their brakes so used and operated. ment on locomotives including tender § 232.2 Drawbars; standard height. must be inspected and maintained in accordance with the requirements of Except on cars specified in the pro- the Locomotive Inspection and United viso in section 6 of the Safety Appli- States Safety Appliance Acts and re- ance Act of March 2, 1893 (sec.