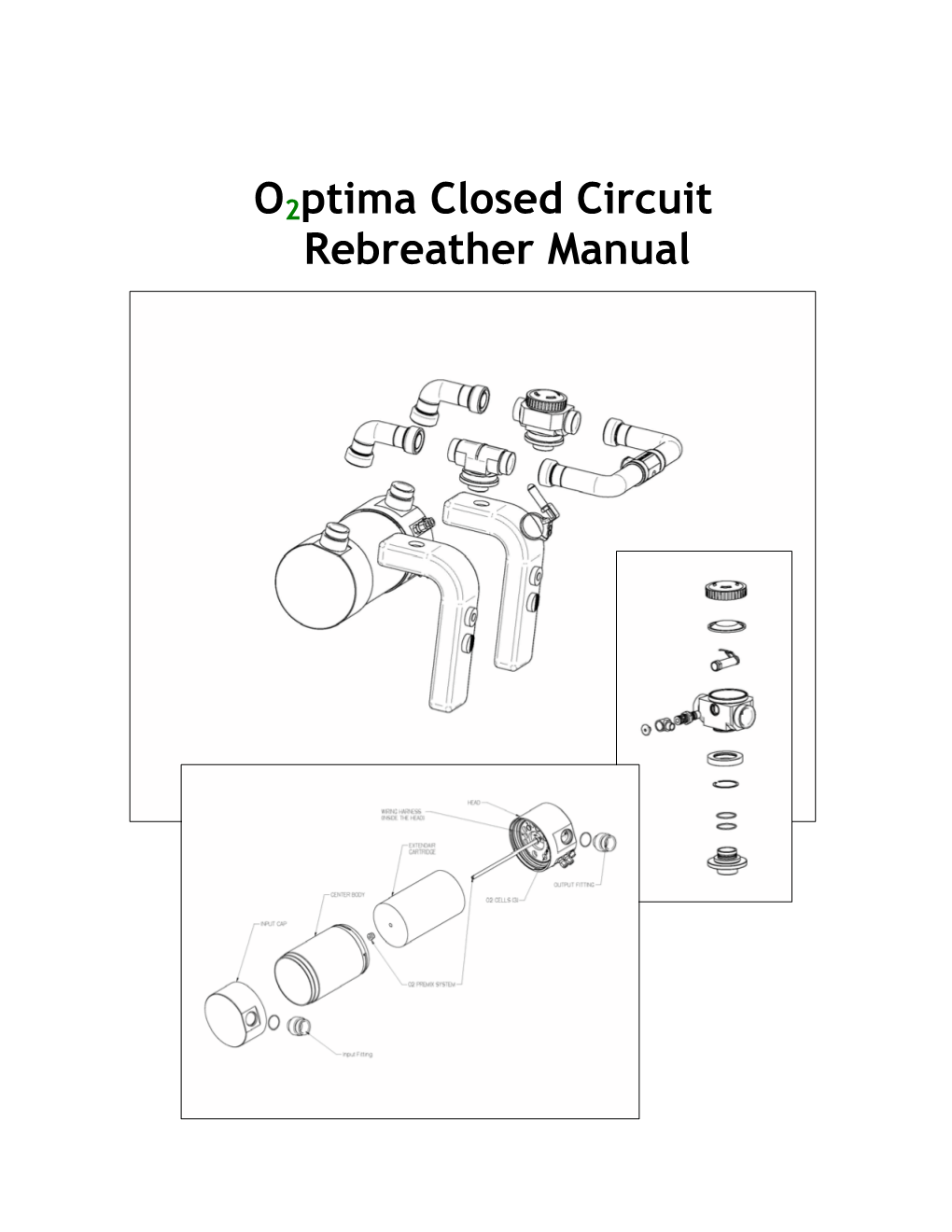

O2ptima Closed Circuit Rebreather Manual

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Juergensen Marine

Juergensen Marine Hammerhead CCR Instruction Manual Revision 3.0 Written by Joseph Radomski Kevin Juergensen Copyright ©2003, Juergensen Marine All Rights Reserved 2 Table of Contents Introduction...........................................................................................................................3 Setup and Installation.............................................................................................................3 Hardware Revisions................................................................................................................ 6 Battery Life ............................................................................................................................. 6 System Overview ................................................................................................................. 11 Threat Matrix ........................................................................................................................ 13 Primary Wrist Unit ............................................................................................................. 15 Handset Display Details........................................................................................................ 15 Set-Point Operation............................................................................................................... 16 Options and Programming .................................................................................................... 17 Gas Selection ............................................................................................................... -

Poseidon SE7EN User Manual Chapter 1 Page 1

Poseidon SE7EN User Manual Chapter 1 Page 1 POSEIDON SE7EN USER MANUAL Poseidon SE7EN User Manual Chapter 1 Page i Table of Contents Table of Contents ...................................................................................................i Part 2 – Assembly Conventions Used in this Guide ............................................................................ iv Preface .................................................................................................................v Assembly ................................................................................................................. 12 Conformance With CE Requirements .................................................................... vi 1. Stabjacket / BCD / Wing. ................................................................................13 2. Cylinder attachment. .......................................................................................14 3. Counter lungs to BCD / Harness. ....................................................................16 Chapter 1 - Preparation & Assembly 4. Rear CC hoses to counter lung. ......................................................................17 5. Rear CC loop hoses. .......................................................................................19 Part 1 – Preparation 6. Attaching the cylinders. ...................................................................................21 7. E-module. .......................................................................................................22 -

• Zrmanjin Zov • Prince Rupert Expedition • TBM Avenger

• Zrmanjin Zov • Prince Rupert Expedition • TBM Avenger • Mystifying Leviathans of Cay Sal • Submerged Ghost Town of Minnewanka Landing • Introduction to Tech Video • New Cave – Old Species • Harvest Refugia • Ricks Spring Exploration • Wreck Fest 2009 • B-24 Liberator “DRIP” • Rouse Simmons Publisher’s Notes This summer has been a busy dive season with excursions from the Florida Keys and Silent World’s Wreckfest 2009 where we explored some of the deeper shipwrecks in the upper Florida Keys. Then it was on to the rough scrub jungles of the Dominican Republic where we beat the bush and crawled through every small subterranean hole we could discover in search of virgin cave passages. And we found more than we could have hoped for! The discovery of ancient animal fossils, extinct in all of the Caribbean islands, would bring us back a month later to recover these unique artifacts for the Domini- can Republic’s archeological department and the Museum of Publisher................. Curt Bowen Dominican Man. Finally, southeast to the amazing Blue Holes of the Co-Publisher............ Linda Bowen Cay Sal Bank where divers pushed some of these mysterious giants to extreme depths. Copy Editor..................... Victoria Leigh Chief Staff Writer............ John Rawlings Chief Photojournalist...... Jeff Toorish Of course, in addition to traveling to all these far-flung points of the Video Chief of Staff........ David Ulloa globe, there was the gathering of editorial materials from ADM Web Master..................... Jakub Rehacek writers and contributors, the operations of Rebreatherworld.com, First Grade.................. Savannah Bowen and continued promotion of the ADM Exploration Foundation. Add ADM Staff Writers & Photographers in the hundreds of hours that are required for me to complete the Mel Clark • Erik Foreman magazine layout from cover to cover…. -

ADM Issue 28 • 7 Sitting in 110 Feet of Water, the 200-Foot Long Superior Producer Provides an Excellent Recreational Dive Location

• CURACAO ABC Islands • Richard Harris Photography • Virgins, Violence & Videotape Yucatan, Mexico • Leigh Bishop’s Shipwreck Photography • Wreck ofof thethe RBJRBJ Florida, USA • NOOTKA SOUND Vancouver Island, BC • DOC DEMILLE or Bust Florida Keys, USA • MOZAMBIQUE Whalesharks, Mantas, & Wildlife Africa Virgins, • Wreck of the USSR GORDYI Gulf of Finland Violence, • Gold Hound Treasure Divers & Florida’s Treasure Coast Videotape • Wreck of the MARQUETTE Lake Superior Customized CCR Systems The only multi-mission, multi-tasking CCR in the world. Features: • Customized electronics and decompression systems • Custom CO2 scrubber assemblies • Custom breathing loop and counterlung systems • Modularized sub systems • Highly suitable for travel • Suitable for Science, commercial, and recreational diving www.customrebreathers.com Ph: 360-330-9018 [email protected] ADM FEATURES Issue 28 9 • Curacao • Depths Unexplored Text and Photography by Curt Bowen 15 • Richard Harris Photography ADM Featured Photographer 21 • Virgins, Violence & Videotape Text by Jeff Toorish Photography by Curt Bowen and Jeff Toorish 31 • Leigh Bishop Shipwreck Photography 37 • Wreck of the RBJ Text and Photography by Mel Clark 43 • Nootka Sound Jewel in the Wilderness Text and Photography by John Rawlings 51 • Doc Demille or Bust Text and Photography by Mel Clark 57 • MOZAMBIQUE Whalesharks, Mantas & Wildlife Text and Photography by Gaby Nenadal 63 • GORDYI Destroyer Destroyed Text and Photography by Sten Stockmann 66 • Manufacturer’s Products 71 • Gold Hound Treasure Divers Text and Photography by Curt Bowen 76 • Wreck of the Marquette Text and Photography by Tamara Thomsen and Keith Meverden Cover Issue 28 Pixnat producer and videographer Nathalie Lasselin documents ancient human remains discovered deep within a Yucatan cenote. -

Poseidon MKVI User Manual Chapter 1 Page 1

Poseidon MKVI User Manual Chapter 1 Page 1 POSEIDON MKVI USER MANUAL Poseidon MKVI User Manual Chapter 1 Page i Table of Contents Table of Contents ...................................................................................................i Cylinders and regulators ......................................................................................10 Conventions Used in this Guide ............................................................................ iv Filling the cylinders .......................................................................................11 Preface .................................................................................................................v Conformance With CE Requirements .................................................................... vi Part 2 – Assembly 1. Stabjacket / BCD / Wing. ................................................................................13 Chapter 1 - Preparation & Assembly 2. Tank band. ......................................................................................................14 3. Counter lungs to BCD / Harness. ....................................................................15 Part 1 – Preparation 4. Rear CC hoses to counter lung. ......................................................................16 5. Rear CC loop hoses. .......................................................................................18 An Overview of the Poseidon MKVI ........................................................................1 6. Attaching -

ADM Issue 21 Book

• Good Luck Comes in Threes • Jetsam Baby Gas Booster • Queen of Nassau Wreck • Bermuda High • USS Curb Wreck • Dive Rite O2ptima Rebreather • ADM Featured Photographer Jill Heinerth • Newfoundland’s Diving Diversity • Ouroboros Closed Circuit Rebreather • The Walls of Quadra Island • HIJMS Amagiri Wreck • Buford Sink & Little Gator Siphon • SS Metropole Wreck • Shipwrecks of Crimea Ukraine Black Sea Expedition • The Helmet Wreck / Palau • Doorway to Bloody Bay Wall Little Cayman Customized CCR Systems The only multi-mission, multi-tasking CCR in the world. Features: • Customized electronics and decompression systems • Custom CO2 scrubber assemblies • Custom breathing loop and counterlung systems • Modularized sub systems • Highly suitable for travel • Suitable for Science, commercial, and recreational diving www.customrebreathers.com Ph: 360-330-9018 [email protected] When only the highest quality counts… Double Cylinder Bands Stage Cylinder Bands Technical Harness Hardware Accessory Dive Hardware 8 Good Luck Comes in Threes SS Coolidge, Tui Tuata & Kathleen by Richard Harris 14 Baby Gas Booster by Gordon Smith and Curt Bowen 18 Queen of Nassau Wreck by Curt Bowen 21 Bermuda High by Jll Heinerth 26 USS Curb Wreck by Curt Bowen 31 Dive Rite O2ptima Rebreather by Jeff Gourley and Curt Bowen 36 ADM Featured Photographer Jill Heinerth 40 Newfoundland’s Diving Diversity by Bernie Chowdhury 45 Ouroboros Closed Circuit Rebreather by Leigh Bishop 51 The Walls of Quadra Island by John Rawlings 55 HIJMS Amagiri Wreck by Kevin Denlay 60 -

POSEIDON SE7EN Appendix 3, Version 1.2

POSEIDON SE7EN Appendix 3, version 1.2 SE7EN connected to M28 Poseidon SE7EN User Manual Appendix 3 Page 91 Appendix 3 - SE7EN connected to M28 Pre-dive procedures The Poseidon SE7EN is a compact and very powerful life-support system that offers an unprecedented new experience in recreational or technical diving. But it is also a complex assembly of high technology that includes sensors, actuators, computers, and software that DANGER: need to operate reliably in an underwater environment, for the important purpose of keeping a Failure to properly and completely conduct the Pre-Dive tests diver alive and healthy. For the same reasons that good pilots use pre-flight checklists to and to ensure that the rig is operating correctly could lead to ensure their flying machine has a high probability of successful take-off, flight, and landing; so permanent injury or death. Do NOT skip the Pre-Dive Procedure. does the rebreather diver need to formalize the process leading up to a dive. The SE7EN Your life depends on it. design team has gone to extraordinary measures to automate the pre-dive procedure and the operation of the rig during a dive. This chapter explains the pre-dive test procedures, including manual actions that are required by the user, and how to interpret the results of the automated tests, should any of them fail to complete successfully. How to connect M28 to SE7EN rebreather with Connecting cable. Initial Pre-dive procedures > Loosen the primary display cable. Gas supply cylinders > Fit the Connecting cable between SE7EN and M28. Before the dive, make sure there is enough diluent (air) and oxygen to carry out the dive you plan to do. -

Virginia Register of Regulations Vol. 7 Iss. 13

OF REGULATIONS VA DOC VOLUME SEVEN • ISSUE THIRTEEN March 25, 1991 Pages 1899 Through 2068 VIRGINIA REGISTER be after the expiration of the twenty-one day extension period; or (ii) the Governor exercises his authority to suspend the regulatory The Virginia Register is an official state publication issued process for solicitation of additional public comment, in which every other week throughout the year. Indexes are published event the regulation, unless withdrawn, becomes effective on the quarterly, and the last index of the year is cumulative. date specified which date shall be after the expiration of the The Virginia Register has several functions. The full text of all period for which the Governor has suspended the regulatory regulations, both as proposed and as finally adopted or changed process. by amendment are required by law to be published in the Proposed action on regulations may be withdrawn by the Virginia Register of Regulations. promulgating agency at any time before final action is taken. In addition, the Virginia Register is a source of other information about state government, including all Emergency EMERGENCY REGULATIONS Regulations issued by the Governor, and Executive Orders, the Virginia Tax Bulletin issued periodically by the Department of If an agency determines that an emergency situation exists, it Taxation, and notices of all public hearings and open meetings of then requests the Governor to issue an emergency regulation. The state agencies. emergency regulation becomes operative upon its adoption and filing with the Registrar of Regulations, unless a later date is ADOPTION, AMENDMENT, AND REPEAL OF REGULATIONS specified. Emergency regulations are limited in time and cannot exceed a twelve-months duration. -

Flame Eng Loca

heavya Man Sho By Pellet 1393114617249011401 #xCR 43 HCKSVL PUZS LIBZHELKER Gun At Mall 169 JERUSALEM Ave HICKSVILLE A 24-year- man wasallege shot in the righ le b apellet gun at Broadw Mall b youths, Nassau Police said. According the to Second Precinct report, s of Melius, - Wantagh was shot b a CO2 pellet gun in the parkin lo at the mall, Mid-Island formerl Plaza on December 1 sometime in the afternoon. Police Officer Raymon Kurz, while off du- in ty Syosse observed a blue Honda with three Incorporating The Hicksville Edition of the male white occupants. He noticed that Mid-!sland Herald one of the Vol. 2 No. passengers was holdin what 29 ap- Thursday, December 17, 1987 50¢ peared to be a gun out the window. When the car was at = stoppe Jackso Avenue and 5 dra Roa in Syosse Officer Kurz left his auto in and arrested three _ Flame teenagers at 333 p.m. Loca As result of the Eng a B arrest, subseque in- Off e € revealed vestigation that more than 1 cars i ; Saw 4 had Official = 2 their windows sho out in the Jericho Say SE Hicksville f ion and Plainview area between Aragin fire at alocal office 254 buildin may The pre-dawn fft and have N. Biedh 3:35 p.m, that da The three teenagers, caused close to # million in damag Hicksville “gutte the sect brand Steven Levine, 17, of fire official said. Woodbury Peter Ogur, roof of the 17 of and three- structure,&qu Owen: Syosse Robert Lehmann 17, of Jericho were arrested in the second floor connection with the gt and above incidents. -

Poseidon MKVI User Manual Chapter 1 Page 1

Poseidon MKVI User Manual Chapter 1 Page 1 POSEIDON MKVI USER MANUAL Poseidon MKVI User Manual Chapter 1 Page i Table of Contents Table of Contents ...................................................................................................i Cylinders and regulators ......................................................................................10 Conventions Used in this Guide ............................................................................ iv Filling the cylinders .......................................................................................11 Preface .................................................................................................................v Conformance With CE Requirements .................................................................... vi Part 2 – Assembly 1. Stabjacket / BCD / Wing. ................................................................................13 Chapter 1 - Preparation & Assembly 2. Tank band. ......................................................................................................14 3. Counter lungs to BCD / Harness. ....................................................................15 Part 1 – Preparation 4. Rear CC hoses to counter lung. ......................................................................16 5. Rear CC loop hoses. .......................................................................................18 An Overview of the Poseidon MKVI ........................................................................1 6. Attaching -

Conditioning Studies in Focal Cerebral Ischemia: Model Selection, Physiological Monitoring, and Other Methodological Issues

Springer Series in Translational Stroke Research Series Editor John Zhang For further volumes: http://www.springer.com/series/10064 wwwwwwwwwwww Jeffrey M. Gidday Miguel A. Perez-Pinzon John H. Zhang Editors Innate Tolerance in the CNS Translational Neuroprotection by Pre- and Post-Conditioning Editors Jeffrey M. Gidday Miguel A. Perez-Pinzon Department of Neurosurgery Department of Neurology Washington University School of Medicine Leonard M. Miller School of Medicine St. Louis, MO, USA University of Miami, Miami, FL, USA John H. Zhang Loma Linda University Loma Linda, CA, USA ISBN 978-1-4419-9694-7 ISBN 978-1-4419-9695-4 (eBook) DOI 10.1007/978-1-4419-9695-4 Springer New York Heidelberg Dordrecht London Library of Congress Control Number: 2012945397 © Springer Science+Business Media New York 2013 This work is subject to copyright. All rights are reserved by the Publisher, whether the whole or part of the material is concerned, speci fi cally the rights of translation, reprinting, reuse of illustrations, recitation, broadcasting, reproduction on micro fi lms or in any other physical way, and transmission or information storage and retrieval, electronic adaptation, computer software, or by similar or dissimilar methodology now known or hereafter developed. Exempted from this legal reservation are brief excerpts in connection with reviews or scholarly analysis or material supplied speci fi cally for the purpose of being entered and executed on a computer system, for exclusive use by the purchaser of the work. Duplication of this publication or parts thereof is permitted only under the provisions of the Copyright Law of the Publisher’s location, in its current version, and permission for use must always be obtained from Springer. -

Dive Rite II Dive Rite

O2ptima FX CCR Owner’s Manual a product of Dive Rite II Dive Rite O2ptima FX CCR Owner’s Manual Dive Rite Optima Rebreather ©2007 Dive Rite All Rights Reserved. USA Copyright Registration: Copyright protection claimed includes all forms and matters of copyrightable material and information now allowed by statutory or judicial law or hereinafter granted, including without limitation all charts, photos, illustrations, displays, graphics, etc. Certain Graphics and text have been reproduced, with permission. These remain the property of the original owners. Juergensen Marine Copyright, Dive Rite All Rights Reserved June 2007 O2ptima FX Owner’s Manual III Table of Contents Introduction. ............................................................. V Chapter 1 Common Terms and Diving Systems............................. Ch. 1 Pg. 1 Objective (Ch. 1 Pg. 1); Glossary (Ch. 1 Pg. 1); Common Acronyms (Ch. 1 Pg. 2) ; Scuba System Overview (Ch. 1 Pg. 3); Open-Circuit Systems (Ch. 1 Pg. 3); Semi-closed Circuit Rebreathers (Ch. 1 Pg. 4); Closed-Circuit Systems (Ch. 1 Pg. 5) Chapter 2 Component Description. ...................................... Ch. 2 Pg. 1 Mouthpiece (Ch. 2 Pg. 1); Breathing Hoses and Connectors (Ch. 2 Pg. 1); Counter-lungs (Ch. 2 Pg. 2); Counter-Lung Fittings (Ch. 2 Pg. 2); T-Piece (Ch. 2 Pg. 2); Automatic Diluent Addition Valve (Ch. 2 Pg. 3); Manual Addition Valves (Ch. 2 Pg. 3); Loop Over-Pressure Valve (Ch. 2 Pg. 4); Canister (Ch. 2 Pg. 4); Oxygen First Stage and Connections (Ch. 2 Pg. 5); Diluent First Stage and Connections (Ch. 2 Pg. 6); Optima Solenoid (Ch. 2 Pg. 7); Mounting Frame (Ch. 2 Pg. 8); Protective Cover (Ch.