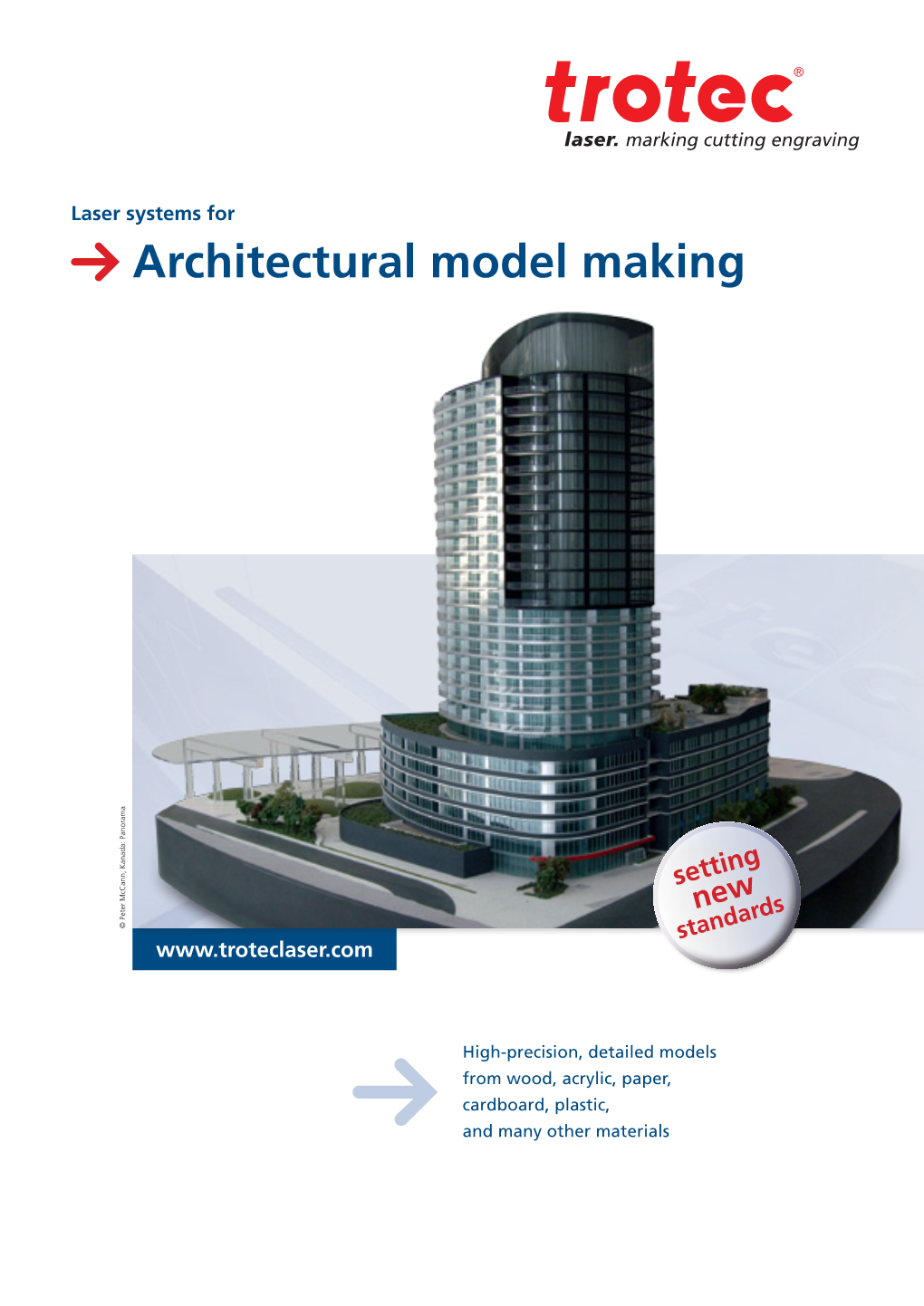

Architectural Model Making

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Medtech Companies

VOLUME 5 2020 Medtech Companies Exclusive Distribution Partner Medtech needs you: focused partners. Medical Technology Expo 5 – 7 May 2020 · Messe Stuttgart Enjoy a promising package of benefits with T4M: a trade fair, forums, workshops and networking opportunities. Discover new technologies, innovative processes and a wide range of materials for the production and manufacturing of medical technology. Get your free ticket! Promotion code: MedtechZwo4U T4M_AZ_AL_190x250mm_EN_C1_RZ.indd 1 29.11.19 14:07 Medtech Companies © BIOCOM AG, Berlin 2020 Guide to German Medtech Companies Published by: BIOCOM AG Luetzowstrasse 33–36 10785 Berlin Germany Tel. +49-30-264921-0 Fax +49-30-264921-11 [email protected] www.biocom.de Find the digital issues and Executive Producer: Marco Fegers much more on our free app Editorial team: Sandra Wirsching, Jessica Schulze in the following stores or at Production Editor: Benjamin Röbig Graphic Design: Michaela Reblin biocom.de/app Printed at: Heenemann, Berlin Pictures: Siemens (p. 7), Biotronik (p. 8), metamorworks/ istockphoto.com (p. 9), Fraunhofer IGB (p. 10) This book is protected by copyright. All rights including those regarding translation, reprinting and reproduction reserved. tinyurl.com/y8rj2oal No part of this book covered by the copyright hereon may be processed, reproduced, and proliferated in any form or by any means (graphic, electronic, or mechanical, including photocopying, recording, taping, or via information storage and retrieval systems, and the Internet). ISBN: 978-3-928383-74-5 tinyurl.com/y7xulrce 2 Editorial Medtech made in Germany The medical technology sector is a well-established pillar within the healthcare in- dustry in Germany and one of the major drivers of the country’s export-driven eco- nomic growth. -

Health Industry Business Communications Council

Health Industry Business Communications Council Registered Labelers: Accredited Auto-ID Labeling Standards Argentina New MedTek Devices Pty Ltd Oxavita SRL Norseld Pty Ltd. Novadien Healthcare Pty Ltd The following companies Odontit S.A. (and/or their subsidiaries/ PAMPAMED S.R.L. Numedico Technologies Pty Ltd divisions) have applied PATEJIM SRL Opto Global Pty. Ltd. for a Labeler Identification Orthocell Limited Code (LIC) assignment with Austria Prolotus Technologies Pty Ltd HIBCC*. By doing so, they afreeze GmbH Red Milawa Pty Ltd dba Magic Mobility have demonstrated their AMI GmbH SDI Limited commitment to patient safety Bender Medsystems GmbH Signostics Ltd. and logistical efficiency for BHS Technologies GmbH Sirtex Medical Pty Ltd their customers, the industry Metasys Medizintechnik GmbH Smith & Nephew Surgical Pty. Ltd. and the public at large. PAA Laboratories GmbH Staminalift International Limited Safersonic Medizinprodukte Handels The Pipette Company Pty. Ltd. Any organization that is GmbH Thermo Electron Corporation interested in using the HIBC W & H Dentalwerk Burmoos GmbH Vush Pty Ltd uniform labeling system may apply for the assignment of VUSH STIMULATION Australia one or more LICs. William A Cook Australia Pty. Ltd. Adv. Surgical Design & Manufacture, Ltd. Last updated 9-21-2021 AirPhysio Pty Ltd Belgium Annalise-AI Pty Ltd 3M Europe Apollo Medical Imaging Technology Pty Advanced Medical Diagnostics SA/NV Ltd Analis SA/NV Benra Pty Ltd dba Gelflex Laboratories Baxter World Trade Bioclone Australia Pty. Ltd. Bio-Rad RSL Candelis, Inc. Bio-Rad Lab Inc Clinical Diag. Group DePuy Australia Pty. Ltd. Biosource Europe SA For more information, please dorsaVi Ltd Cilag NV contact the HIBCC office at: EC Certification Service GmbH Coris Bioconcept Fink Engineering Pty Ltd Fuji Hunt Photographic Chemicals NV 2525 E. -

Speedy Series Laser Engraving Systems Profitability by Design Profitability by Design

Speedy Series Laser Engraving Systems Profitability by Design Profitability By Design The Speedy series of laser engravers will inspire you with their speed, smart features and innovative technical design. For sign makers, graphic artists, schools and universities, creative or industrial users, our world-class solutions provide a true competitive advantage. Personalisation or customisation creates significant added value for products made of wood, plastic or glass. Laser processing achieves crystal clear cut edges with no additional material processing required on acrylics. Serial numbers on metal parts are permanently marked for traceability. Prototypes can be created from cardboard or MDF. Whether you are starting your business or are wanting to work more efficiently, our laser systems are designed for 24/7 operation and let you work quickly, productively and reliably. Speedy 360 Highest efficiency with the smallest footprint The "Speedy" has been the fastest laser engraver on the The product line is 100% developed and manufactured market since its launch in 1999 and continues to set new in Austria and sold through 17 sales offices, increasing standards. Its current engraving speed is 4.3 m/second at 5g profitability for customers in more than 90 countries. We acceleration. The patented InPack Technology™ guarantees advise and support our customers. The Trotec Academy offers maximum runtime of the axles for reliable production. Full training on materials and technology, and we make sure control and flexibility allow bi-directional communication that our service and field team are always up to date on their between the laser and software. With a CO2 and a fiber laser knowledge. -

Speedmarker Series Laser Marking Systems Created for Automation Created for Automation

SpeedMarker Series Laser marking systems Created for automation Created for Automation The use of the laser markers of the SpeedMarker series leads to enormous productivity, supports automation processes and inspires by the simple handling - both in data preparation and in daily work. By marking dynamic data and endless possibilities with AdvancedScripting, the SpeedMarker series is exactly the right choice for machine manufacturers, toolmakers, engravers and job shoppers. Individual components as well as large batch sizes are marked with a laser class 2 system for complete traceability, brand communication or with functional markings. This saves time and reduces your unit and running costs. The efficient production of permanent markings on almost all metals and, with the MOPA option, on many plastics is guaranteed. By infinity we mean the design of direct component markings, logos, designs, dynamic data (barcodes, serial numbers, etc.), photos as well as readable 1-point fonts and smallest geometries. Trotec’s laser markers meet the highest quality requirements in terms of legibility and durability of the markings - enabling compliance with the most stringent guidelines such as UID, UDI, etc. The laser cells have a robust design, are designed for longevity and comply with laser class 2. SpeedMarker 300 Desktop laser for small components SpeedMarker 700 Precise marking with minimum space requirement The laser processing cells also offer maximum flexibility in The product line is 100% developed and manufactured in terms of size and number of components. Especially with Austria and Germany and sold through 18 sales subsidiaries, SpeedMarker 1300, SpeedMarker 1350 and SpeedMarker increasing profitability for customers in more than 90 1600, individual large or heavy components can be handled countries. -

Speedy 360 Fiber Operating Manual

Speedy 360 fiber Operating manual 8031 OM 8031_4.3_EN (07/2019) ENGLISH (Translation) Trotec Laser GmbH Trotec Laser Pty Ltd Trotec Laser België Trotec Laser Belgique +43 7242 239-7070 +61 26413-5904 [email protected] [email protected] +31 850 70 51 55 [email protected] Trotec Laser Canada Trotec Laser AG Trotec Laser GmbH +1 800 663 1149-902 +41 32387-1611 +86 189 500 735 62 [email protected] [email protected] [email protected] [email protected] Trotec Laser Deutschland Trotec Laser España Trotec Laser France SAS GmbH +34 93 102 50 50 +33 1 72 62 20 94 +49 89 322 99 65-13 [email protected] [email protected] [email protected] Trotec Laser UK Trotec Laser Srl Trotec Laser Japan Corporation +44 0191 4188 110 +39 02 9475 5447 [email protected] [email protected] Tokyo: +81 42 313 0740 Osaka: +81 6 6180 2200 [email protected] High Speed Laser Systems S. Trotec Laser B.V. Trodat Polska Sp. z o.o. de R.L. de C.V. +31 850 70 51 55 +48 22 339 35 39 +52 55 5351-7252 [email protected] [email protected] [email protected] Trotec Laser Inc. Rubber Stamp & Engraving +1 866 226 8505, Option 2 +27 875 509-335 [email protected] [email protected] 2 ENGLISH (Translation) Trotec Laser GmbH Freilingerstraße 99 4614 Marchtrenk, Austria Invoice Address: Linzerstraße 156 4600 Wels, Austria Tel.: +43 7242 239-0 General contact to Technical Support: Tel.: +43 7242 239-7000 E-mail: [email protected] www.troteclaser.com ENGLISH (Translation) 3 Technical Changes Technical specifications are subject to change without notice. -

SP Series the Standard in Laser Finishing for Signage and Display the Standard in Laser Finishing for Signage and Display

SP Series The Standard in Laser Finishing for Signage and Display The Standard in Laser Finishing for Signage and Display The SP series laser cutters provide a complete solution for processing large format materials. Whether for display production and shop fitting, print service providers, POP/POS applications or technical textiles, our laser systems are developed for 24/7 operation and let you work quickly, productively and reliably. SP2000 Makes your production more efficient SP3000 The standard in large format laser cutting As a technology leader with a worldwide sales network, Trotec The product line is 100% developed and manufactured in develops and produces first-class laser system solutions to Austria, and used by customers in more than 90 different make our customers more profitable. This also applies to countries to boost productivity. In addition to our industry- the SP series laser cutters for fast and precise processing leading laser systems, we provide our customers with a of large format materials. In addition to the highest cutting number of resources to help meximize a laser investment, performance on the entire processing area, our industry- including: The Trotec Academy offers training courses on leading SP Series laser cutters offer a number of productivity- materials and technology as well as best practices and boosting advantages, including four-sided access, loading optimised usage of the technology. Exhaust systems, laser and and unloading during material processing, and tandem assist, engraving material as well as service products complete the and integration into your data workflow thanks to RIP and CAD product portfolio. compatibility. SP500 Reliable and productive midsize format cutting SP1500 Closed machine for cutting materials that tend to generate high dust levels Laser Cutting in Display and Shop Fitting Produce perfectly polished acrylic edges in a single process step Acrylic is a popular material in display and store design. -

Centrotec SE

Consolidated and annual report 1999 CENTROTEC HOCHLEISTUNGSKUNSTSTOFFE AG 1 1 History of the company 1973 Initial plastics processing activities 1981 Founded as producer of plastic semi-finished products and prefabricated parts 1985 Introduction of CNC technology for chip removal 1990 Acquisition of Centroplast Kunststofferzeugnisse GmbH & Co. by current owner 1991 Start of production of films and panels by means of calendering 1992 Initial successes with high-performance plastics (PVDF) Development of French, Swiss and Austrian markets 1993 Start of production of calibrated hollow rods 1994 Founding of Centrotherm GmbH (gas flue systems) Sales activities are launched in Great Britain, the Netherlands and Benelux 1995 Gas flue development project with the backing of technology development programmes Accreditation to DIN ISO 9002 Sales activities launched in Scandinavia 1996 Construction approval granted by Deutsches Institut für Bautechnik (IFBT) for rigid gas flue systems Development and marketing of Centropack transport systems 1997 New high-performance thermoplastics added to range Entire group of companies accredited to DIN ISO 9001 Construction approval granted by Deutsches Institut für Bautechnik (IFBT) for flexible gas flue systems 1998 Prefabricated parts production in Marsberg extended Conversion into a joint stock company Listed on the Neuer Markt segment of the Frankfurt Stock Exchange 1999 Market breakthrough for plastic gas flue systems Acquisition of Ubbink Systemtechnik Represented throughout Europe by own subsidiaries 2 -

Speedy Series Laser Engraving Systems Profitability by Design Profitability by Design

Speedy Series Laser Engraving Systems Profitability by Design Profitability By Design The Speedy series of laser engravers will inspire you with their speed, smart features and innovative technical design. For sign makers, graphic artists, schools and universities, creative or industrial users, our world-class solutions provide a true competitive advantage. Personalisation or customisation creates significant added value for products made of wood, plastic or glass. Laser processing achieves crystal clear cut edges with no additional material processing required on acrylics. Serial numbers on metal parts are permanently marked for traceability. Prototypes can be created from cardboard or MDF. Whether you are starting your business or are wanting to work more efficiently, our laser systems are designed for 24/7 operation and let you work quickly, productively and reliably. Speedy 360 Highest efficiency with the smallest footprint The „Speedy“ has been the fastest laser engraver on the The product line is 100% developed and manufactured market since its market launch in 1999 and continues to set in Austria and sold through 17 sales offices, increasing new standards. Its current engraving speed is 4.3 m/second at profitability for customers in more than 90 countries. We 5g acceleration. The patented InPack Technology™ guarantees advise and support our customers; the Trotec Academy offers maximum runtime of the axles for reliable production. training on materials and technology, and we make sure Bi-directional communication allows flexibility and control that our service and field team are always up to date on their between the laser and software. With a CO2 and a fiber laser knowledge. -

TRODAT SUSTAINABILITY REPORT 2017 JANUARY 2019 TRODAT SUSTAINABILITY REPORT REF 123456 M10C3A18 Printed in Austria TRODAT SUSTAINABILITY REPORT 2017

TRODAT SUSTAINABILITY REPORT 2017 www.trodat.net JANUARY 2019 TRODAT TRODAT SUSTAINABILITY REPORT SUSTAINABILITY REF_123456_M10C3A18_Printed in Austria TRODAT SUSTAINABILITY REPORT 2017 PUBLISHED JANUARY 2019 Please collect used paper for recycling. AT/028/011 1912 2017 PREFACE GRI 102-14 We are pleased to present to you Trodat’s first priority in our company for many years. For we Sustainability Report. As we are a traditional know that our employees are our most valuable Austrian company with more than 100 years resource and the source of our innovative of history, doing business sustainably has strength and market success. Hence we are always been an integral part of our way of proud that in recent years we have received thinking and acting. Today we are the No.1 on many awards for our employee commitment. the global market for self-inking stamps – and We are convinced that by publishing our first this success is closely interwoven with our Sustainability Report now we have reached holistic understanding of sustainability. another important milestone to make our One example of how we have been practising activities visible, and to continue setting sustainability for a long time in our company is ambitious growth and sustainability targets for our core product, the Original Printy 4.0. the future. What drives us is our desire to We have been offering this product with make things better – day by day. To do that, we climate neutrality as standard since the end of need to distinguish between the essential and 2010. Through reductions in terms of size and the insignificant, to manage resources weight, use of the technically possible properly, and to make the right maximum share of recycled materials, and entrepreneurial decisions. -

Speedy Series Laser Engraving Systems Profitability by Design Profitability by Design

Speedy Series Laser Engraving Systems Profitability by Design Profitability By Design The Speedy series of laser engravers will inspire you with their speed, smart features and innovative technical design. For sign makers, graphic artists, schools and universities, creative or industrial users, our world-class solutions provide a true competitive advantage. Personalisation or customisation creates significant added value for products made of wood, plastic or glass. Laser processing achieves crystal clear cut edges with no additional material processing required on acrylics. Serial numbers on metal parts are permanently marked for traceability. Prototypes can be created from cardboard or MDF. Whether you are starting your business or are wanting to work more efficiently, our laser systems are designed for 24/7 operation and let you work quickly, productively and reliably. Speedy 360 Highest efficiency with the smallest footprint The "Speedy" has been the fastest laser engraver on the The product line is 100% developed and manufactured market since its market launch in 1999 and continues to set in Austria and sold through 17 sales offices, increasing new standards. Its current engraving speed is 4.3 m/second at profitability for customers in more than 90 countries. We 5g acceleration. The patented InPack Technology™ guarantees advise and support our customers. The Trotec Academy offers maximum runtime of the axles for reliable production. Full training on materials and technology, and we make sure control and flexibility allow bi-directional communication that our service and field team are always up to date on their between the laser and software. With a CO2 and a fiber laser knowledge. -

Iris Um Oifig Maoine Intleachtúla Na Héireann Journal of the Intellectual Property Office of Ireland

Iris um Oifig Maoine Intleachtúla na hÉireann Journal of the Intellectual Property Office of Ireland Iml. 96 Cill Chainnigh 21 July 2021 Uimh. 2442 CLÁR INNSTE Cuid I Cuid II Paitinní Trádmharcanna Leath Leath Official Notice 2207 Official Notice 1538 Applications for Patents 2208 Applications for Trade Marks 1539 Applications Published 2209 Oppositions under Section 43 1607 Patents Granted 2209 Application(s) Amended 1607 European Patents Granted 2210 Application(s) Withdrawn 1609 Applications Withdrawn, Deemed Withdrawn or Trade Marks Registered 1609 Refused 2341 Trade Marks Renewed 1610 Patents Lapsed 2341 Unpaid Renewal Fees 1612 Request for Grant of Supplementary Protection Trade Marks Removed 1616 Certificate 2342 International Registrations under the Madrid Supplementary Protection Certificate Granted 2343 Protocol 1619 Supplementary Protection Certificate Rejected 2343 International Trade Marks Protected 1654 Cancellations effected for the following goods/services under the Madrid protocol 1655 Errata 1658 Dearachtaí Designs Information under the 2001 Act Designs Registered 2344 Designs Renewed 2352 Design Rights Expired 2352 The Journal of the Intellectual Property Office of Ireland is published fortnightly. Each issue is freely available to view or download from our website at www.ipoi.gov.ie © Rialtas na hÉireann, 2021 © Government of Ireland, 2021 2207 (21/07/2021) Journal of the Intellectual Property Office of Ireland (No. 2442) Iris um Oifig Maoine Intleachtúla na hÉireann Journal of the Intellectual Property Office of Ireland Cuid I Paitinní agus Dearachtaí No. 2442 Wednesday, 21 July, 2021 NOTE: The office does not guarantee the accuracy of its publications nor undertake any responsibility for errors or omissions or their consequences. In this Part of the Journal, a reference to a section is to a section of the Patents Act, 1992 unless otherwise stated. -

Architectural Model Making

marking cutting engraving Laser systems for Architectural model making © Peter McCann, Kanada: Panorama www.troteclaser.com High-precision, detailed models from wood, acrylic, paper, cardboard, plastic, and many other materials The advantages of Laser technology The use of laser technology in the construction of One tool for all geometries and materials architectural models offers unbeatable advantages Milling various materials, geometric shapes and over other technologies: thicknesses of material requires different tool heads. The laser beam is the universal “tool” for all geometric shapes and materials. Not only that, the beam is High-precision and attention to detail always “laser sharp”. You therefore no longer have to Using laser technology you can produce your own very think about the cost of tools or sharpening. detailed geometric shapes to a high level of precision. This No post-processing of material required allows you absolute freedom when designing your own PMMA is often used in architectural model making. models. The quality of engraving of surface textures and However, the manual fl ame polishing of the milled facades also enables you to produce presentation or edges of the acrylic parts is costly and time-intensive. competition models of high quality and great detail. There is also the risk that the work piece may become Unlimited choice of materials damaged or even destroyed if mishandled. Laser A range of materials are used in the construction of cutting produces crystal-clear edges and inner architectural models: textiles, wood, veneers, MDF, cardboard, contours without the need for further processing. paper, foam, polystyrene, fi lms and many more.