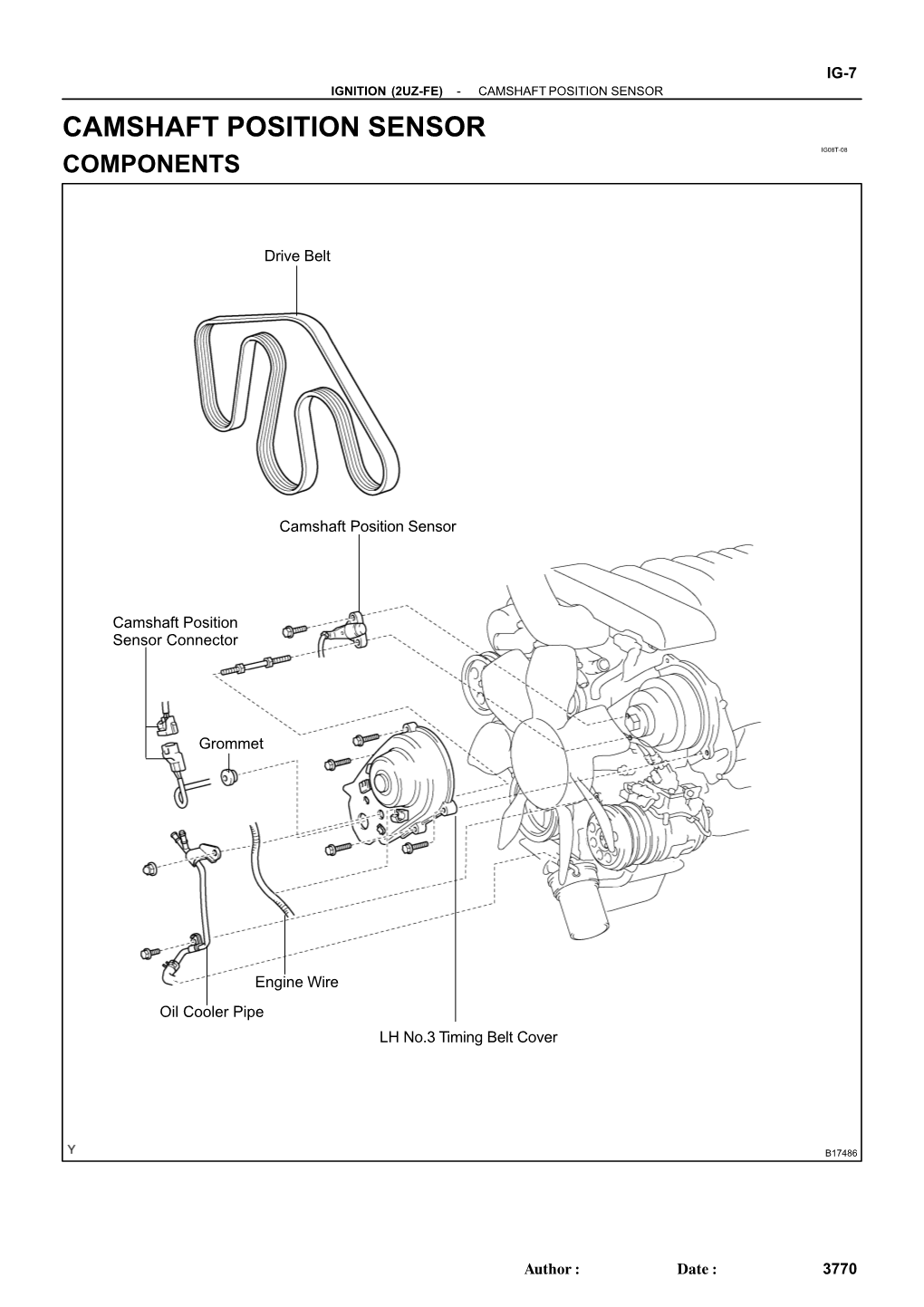

Camshaft Position Sensor Camshaft Position Sensor Ig08t-08 Components

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Harrop Camshaft Grind Specifications

Harrop Engineering Australia Pty Ltd www.harrop.com.au ABN: 87 134 196 080 Phone: +61 3 9474 - 0900 96 Bell Street, Preston, Fax: +61 3 9474 – 0999 Melbourne, VIC, 3072, Australia Email: [email protected] Harrop Camshaft Grind Specifications Harrop HO1 Camshaft 226/232 .607”/.602” @ 112 LSA Great NA camshaft Lumpy idle but acceptable driveability, Great power and torque Manual or auto standard gear ratios are ok but 3.7 or 3.9 would be preferred. Automatic may require stall converter. Could be used in boosted application but due to low LSA Would require smaller pulley to be increase boost. Harrop HO2 camshaft 224/232 .610” / .610” @ 114 LSA Great blower camshaft offering acceptably lumpy idle and great drivability, this camshaft will give great power through the mid to high RPM range. As this camshaft is more aggressive then the H05. Normally this would require a stall converter, it can be run on a standard converter but it may push on it slightly. Sound clip: https://www.youtube.com/watch?v=NvOGohRd7-k Harrop H03 Camshaft 232/233 .610” / .602” @ 112 LSA Will give great lumpy cammed affect, Low LSA would take boost out of a forced induction motor. Largest recommend camshaft for a 5.7 N/A , Acceptable in 6.0L and 6.2L square port engines, Must have 3.7 (square port) or 3.9 (LS1) for the best results in a manual car. Auto would require stall converter. 1 / 2 File: Harrop Letter Head “Commercial in Confidence” Issue:12th January 2018 designdevelop deliver Print: Friday, 25 September 2020 ` Harrop HO4 camshaft 234/238 .593” / .595” @ 114 LSA The H04 is designed with Forced induction in mind but can be used as a naturally aspirated camshaft as well. -

Understanding Overhead-Valve Engines Once Unheard of These Engines Now Supply the Power for Nearly All of Your Equipment

Understanding Overhead-Valve Engines Once unheard of these engines now supply the power for nearly all of your equipment. By ROBERT SOKOL Intertec Publishing Corp., Technical Manuals Division You've all heard about overhead valves when shopping Valve-Design Characteristics for power equipment, but what do they mean to you? Do The valves consist of a round head, a stem and a groove you need overhead valves? Do they cost more? What will at the top of the valve. The head of the valve is the larger they do for you? Twenty years ago, overhead valves were end that opens and closes the passageway to and from the unheard of in any type of power equipment. Nowadays, it combustion chamber. The stem guides the valve up and is difficult to find a small engine without them. down and supports the valve spring. The groove at the top In an engine with overhead valves, the intake and of the valve stem holds the valve spring in place with a exhaust valve(s) is located in the cylinder head, as opposed retainer lock. The valves must open and close for the air- to being mounted in the engine block. Many of the larger and-fuel mix to enter, then exit, the combustion chamber. engine manufacturers still offer "standard" engines that Proper timing of the opening and closing of the valves is have the valves in the block. Their "deluxe" engines have required for the engine to run smoothly. The camshaft con- overhead valves and stronger construction. Overhead trols valve sequence and timing. -

Poppet Valve

POPPET VALVE A poppet valve is a valve consisting of a hole, usually round or oval, and a tapered plug, usually a disk shape on the end of a shaft also called a valve stem. The shaft guides the plug portion by sliding through a valve guide. In most applications a pressure differential helps to seal the valve and in some applications also open it. Other types Presta and Schrader valves used on tires are examples of poppet valves. The Presta valve has no spring and relies on a pressure differential for opening and closing while being inflated. Uses Poppet valves are used in most piston engines to open and close the intake and exhaust ports. Poppet valves are also used in many industrial process from controlling the flow of rocket fuel to controlling the flow of milk[[1]]. The poppet valve was also used in a limited fashion in steam engines, particularly steam locomotives. Most steam locomotives used slide valves or piston valves, but these designs, although mechanically simpler and very rugged, were significantly less efficient than the poppet valve. A number of designs of locomotive poppet valve system were tried, the most popular being the Italian Caprotti valve gear[[2]], the British Caprotti valve gear[[3]] (an improvement of the Italian one), the German Lentz rotary-cam valve gear, and two American versions by Franklin, their oscillating-cam valve gear and rotary-cam valve gear. They were used with some success, but they were less ruggedly reliable than traditional valve gear and did not see widespread adoption. In internal combustion engine poppet valve The valve is usually a flat disk of metal with a long rod known as the valve stem out one end. -

Overview the Ignition System Is Designed to Ignite the Compressed

« 1: Description and Operation» Overview The Ignition System is designed to ignite the compressed air/fuel mixture in an internal combustion engine by a high voltage spark from an ignition coil. The ignition system also provides engine timing information to the powertrain control module (PCM) for proper vehicle operation and misfire detection. Integrated Electronic Ignition System The Integrated Electronic Ignition (EI) system consists of a crankshaft position (CKP) sensor, coil pack(s), connecting wiring, and PCM. The Coil On Plug (COP) Integrated EI System uses a separate coil per spark plug and each coil is mounted directly onto the plug. The COP Integrated EI System eliminates the need for spark plug wires but does require input from the camshaft position (CMP) sensor. Operation of the components are as follows (Figure 49): 1. NOTE: Electronic Ignition engine timing is entirely controlled by the PCM. Electronic Ignition engine timing is NOT adjustable. Do not attempt to check base timing. You will receive false readings. The CKP sensor is used to indicate crankshaft position and speed by sensing a missing tooth on a pulse wheel mounted to the crankshaft. The CMP sensor is used by the COP Integrated EI System to identify top dead center of compression of cylinder 1 to synchronize the firing of the individual coils. 2. The PCM uses the CKP signal to calculate a spark target and then fires the coil pack(s) to that target shown in Figure 50. The PCM uses the CMP sensor not shown in Figure 50 on COP Integrated EI Systems to identify top dead center of compression of cylinder 1 to synchronize the firing of the individual coils. -

Design and Manufacturing of a Camshaft Used in Multi Cylinder Engine

ISSN 2348–2370 Vol.09,Issue.05, April-2017, Pages:0651-0654 www.ijatir.org Design and Manufacturing of a Camshaft Used in Multi Cylinder Engine DR. CH. S. NAGA PRASAD Professor & Principal, Dept of Mechanical, GIITS Engineering College, Aganampudi, Visakhapatnam(Dt), AP, India, Email: [email protected]. Abstract: The cam shaft and its associated parts control the It is often a part of a rotating wheel (e.g. an eccentric wheel) opening and closing of the two valves. The associated parts or shaft (e.g. a cylinder with an irregular shape) that strikes a are push rods, rocker arms, valve springs and tappets. It lever at one or more points on its circular path. The cam can consists of a cylindrical rod running over the length of the be a simple tooth, as is used to deliver pulses of power to a cylinder bank with a number of oblong lobes protruding steam hammer, for example, or an eccentric disc or other from it, one for each valve. The cam lobes force the valves shape that produces a smooth reciprocating (back and forth) open by pressing on the valve, or on some intermediate motion in the follower, which is a lever making contact with mechanism as they rotate. This shaft also provides the drive the cam. to the ignition system. The camshaft is driven by the II. LITERATURE REVIEW crankshaft through timing gears cams are made as integral DESIGN AND ANALYSIS OF CAM SHAFT FOR parts of the camshaft and are designed in such a way to open MULTI CYLINDER ENGINE and close the valves at the correct timing and to keep them The cam shaft and its associated parts control the open for the necessary duration. -

FAST® Supercharger & Cam Power Packages for GM Gen

FAST® Supercharger & Cam Power Packages for GM Gen III/IV LS Engines Memphis, TN – An Edelbrock® Supercharger Kit and COMP Cams® Cam Kit is the perfect pairing for performance enthusiasts looking for 850+ HP potential from their GM LS engines. The ultimate solution for engine swaps and serious performance applications, FAST® has put together the first ever supercharger and valve train packages from two of the automotive aftermarket’s biggest brands – Edelbrock® and COMP Cams®. The FAST® engineering team extensively dyno tested various combinations of camshaft specs, valve springs and supercharger pulleys to optimize the power and efficiency of the Edelbrock® superchargers. Dyno testing on a stock head 6.2L LS3 engine produced over 850 HP when running with E85 fuel. The FAST® Supercharger & Cam Power Packages include a pump gas friendly supercharger pulley for engine break-in, initial tuning and general performance driving, while a smaller pulley is also included when maximum power is desired on race fuel or E85. For those wishing to further fine tune boost levels, additional pulley sizes are available. Packages include the basics required to install the supercharger, but necessary accessory items such as fuel injectors, air intakes and heat exchanger pumps are left up to the installer, providing total flexibility for custom installations. The Edelbrock® Supercharger Kits include a 2300 TVS supercharger w/ integrated intercooler. The intercooler is a high capacity, dual bar and plate design that enables major power gains through lower inlet air charge temps. Also included are COMP Cams® application specific cam kits that contain state of the art Low Shock Technology™ Camshafts designed specifically for supercharger applications, along with perfectly matched pushrods, valve springs, retainers, locks, seats and seals. -

Development of an Electromechanical Valvetrain

University of Portland Pilot Scholars Engineering Undergraduate Publications, Presentations and Projects Shiley School of Engineering 4-12-2019 The Little Engine that Could : Development of an Electromechanical Valvetrain Ryan Clarke Follow this and additional works at: https://pilotscholars.up.edu/egr_studpubs Part of the Mechanical Engineering Commons Citation: Pilot Scholars Version (Modified MLA Style) Clarke, Ryan, "The Little Engine that Could : Development of an Electromechanical Valvetrain" (2019). Engineering Undergraduate Publications, Presentations and Projects. 8. https://pilotscholars.up.edu/egr_studpubs/8 This Student Project is brought to you for free and open access by the Shiley School of Engineering at Pilot Scholars. It has been accepted for inclusion in Engineering Undergraduate Publications, Presentations and Projects by an authorized administrator of Pilot Scholars. For more information, please contact [email protected]. SENIOR HONORS PROJECT The Little Engine that Could Development of an Electromechanical Valvetrain Ryan Clarke Department of Mechanical Engineering Donald P. Shiley School of Engineering University of Portland Fall 2018 - Spring 2019 Team Members: Ryan Clarke Joseph McKeirnan Emett Santucci Isaac Yako Special Thanks: Matthias Farveleder Faculty Advisor: Dr. Jordan Farina Industry Advisor: Ryan Jefferis Version April 12, 2019 i Table of Contents EXECUTIVE SUMMARY ........................................................................................................... iii ACKNOWLEDGEMENTS .......................................................................................................... -

Software Controlled Stepping Valve System for a Modern Car Engine

Available online at www.sciencedirect.com ScienceDirect Procedia Manufacturing 8 ( 2017 ) 525 – 532 14th Global Conference on Sustainable Manufacturing, GCSM 3-5 October 2016, Stellenbosch, South Africa Software Controlled Stepping Valve System for a Modern Car Engine I. Zibania, R. Marumob, J. Chumac and I. Ngebanid.* a,b,dUniversity of Botswana, P/Bag 0022, Gaborone, Botswana cBotswana International University of Science and Technology, P/Bag 16, Palapye, Botswana Abstract To address the problem of a piston-valve collision associated with poppet valve engines, we replaced the conventional poppet valve with a solenoid operated stepping valve whose motion is perpendicular to that of the piston. The valve events are software controlled, giving rise to precise intake/exhaust cycles and improved engine efficiency. Other rotary engine models like the Coates engine suffer from sealing problems and possible valve seizure resulting from excessive frictional forces between valve and seat. The proposed valve on the other hand, is located within the combustion chamber so that the cylinder pressure help seal the valve. To minimize friction, the valve clears its seat before stepping into its next position. The proposed system was successfully simulated using ALTERA’s QUARTUS II Development System. A successful prototype was built using a single piston engine. This is an ongoing project to eventually produce a 4-cylinder engine. ©© 2017 201 6Published The Authors. by Elsevier Published B.V. Thisby Elsevier is an open B.V. access article under the CC BY-NC-ND license (Peerhttp://creativecommons.org/licenses/by-nc-nd/4.0/-review under responsibility of the organizing). committee of the 14th Global Conference on Sustainable Manufacturing. -

Camshaft Degreeing Instructions Intake Centerline Method

Auto 64HP Camshaft Degreeing Instructions Intake Centerline Method - To verify the location of the intake centerline in reference to the piston position Step 1: Install the camshaft and timing set. Make sure that the timing marks on the cam and crank sprockets are aligned Step 2: Install the intake lifter for cylinder #1 Step 3: Attach the degree wheel to the crankshaft snout or balancer Step 4: Attach a pointer to the front of the block and position just on the outside of the degree wheel Step 5: With the #1 piston down in the cylinder bore, install a piston stop over the cylinder. Rotate the crankshaft until the piston touches the piston stop and mark the degree wheel adjacent to the pointer. Rotate the crankshaft the opposite direction so the piston travels down and back up to the piston stop. Make a second mark adjacent to the pointer Step 6: Remove the piston stop after marking the two points on the degree wheel. Rotate the crankshaft to the midpoint of the two marks. This point is TDC for cylinder #1. Without rotating the crankshaft, adjust the degree wheel to read 0 degrees at the pointer. You are now ready to locate the intake lobe centerline relative to TDC. This step is critical to proper cam alignment Step 7: Attach the dial indicator to the dial indicator mount. Position the dial indicator on the outer edge of the intake lifter. It is important that the indicator plunger be parallel to the lifter. Any variance in the angle of the indicator will introduce errors into the lift readings Step 8: Rotate the engine in the normal direction of rotation until you reach maximum lift. -

Performer RPM Camshaft for AMC V8 343-401 130909

PERFORMER RPM CAMSHAFT / LIFTERS / LUBE KIT ® For 343-401 c.i.d. AMC V8 Engines CATALOG # 7132 INSTALLATION INSTRUCTIONS PLEASE study these instructions carefully before beginning this installation. Most installations can be accomplished with common tools and procedures. However, you should be familiar with and comfortable working on your vehicle. If you do not feel comfortable performing this installation, it is recommended to have the installation completed by a qualified mechanic. If you have any questions, please call our Technical Hotline at: 1-800-416-8628, 7:00 am - 5:00 pm, Pacific Standard Time, Monday through Friday. • These instructions are designed to give general installation guidelines. A complete step-by-step procedure manual would require many pages. If you are a novice or just learning to work on automotive engines, we recommend consulting either Chilton or Motors automotive manuals before you begin. You may also wish to contact an experienced mechanic. Be advised: Improper installation may result in LOW MILEAGE, POOR PERFORMANCE, COSTLY REINSTALLATION AND EVEN ENGINE DAMAGE. Installing a camshaft is a complex procedure. Please follow these instructions carefully. Failure to do so may void your warranty. • Before you begin the removal and installation process, please examine the kit for possible shipping damage. If the camshaft is damaged, contact your dealer immediately. Also, make sure you have all the recommended tools and parts as listed below. As you read through these instructions the first time, use the preparation checklist to check off the exact items you will need. • Performer RPM camshafts are ground specifically for use with the corresponding RPM Air-Gap manifold #7530 or #7531, and Performer RPM Cylinder Heads #60119 or 60139. -

Recall Notification

February 2017 Dealer Service Instructions for: Safety Recall S89 / NHTSA 16V-907 Crankshaft Camshaft Sensor Wire Harness Models 2016 (JC) Dodge Journey 2016 (MK) Jeep Compass and Jeep Patriot NOTE: This recall applies only to the above vehicles equipped with a 2.0L (sales code ECN or ECT) or 2.4L (sales code ED3 or ED7) engine built from May 08, 2016 through July 12, 2016 (MDH 050800 through 071216). IMPORTANT: Some of the involved vehicles may be in dealer new vehicle inventory. Federal law requires you to complete this recall service on these vehicles before retail delivery. Dealers should also consider this requirement to apply to used vehicle inventory and should perform this recall on vehicles in for service. Involved vehicles can be determined by using the VIP inquiry process. Subject The crankshaft sensor and/or camshaft sensor electrical connector terminal(s) on about 43,000 of the above vehicles may have been improperly manufactured. Improperly manufactured crankshaft or camshaft sensor electrical connector terminal(s) could result in an intermittent electrical connection. An intermittent electrical connection could cause a “no start” condition, the engine to stall while driving, and/or the illumination of the Malfunction Indicator Lamp (MIL). An engine stall event while driving could cause a crash without warning. Copyright 2017, FCA US LLC, All Rights Reserved tdb Safety Recall S89 -- Crankshaft Camshaft Sensor Wire Harness Page 2 Repair The crankshaft sensor electrical connector and terminals must be replaced on all involved (JC) Dodge Journey vehicles. The crankshaft sensor and camshaft sensor electrical connector and terminals must be replaced on all involved (MK) Jeep Compass and Jeep Patriot vehicles. -

Analyzing the Implementation of Six Stroke I.C. Engine with Optimal Design of Camshaft Mr

Analyzing the Implementation of Six Stroke I.C. Engine with Optimal Design of Camshaft Mr. Vivek Raut, Mr. Hitanshu Dalal, Poster Advisor: Dr. Jeremy (Zheng) Li Department of Mechanical Engineering University of Bridgeport, Bridgeport, CT Abstract: Camshaft Modification The aim of the presented paper is to understand the latest In the six-stroke engine the 360 degree of the cam has trends in Internal Combustion Engine while maintaining its been divided into 60 degree among the six-strokes. The prime focus on six stroke engines. The engine works through exhaust cam has 2 lobes to open the exhaust valve at harnessing wasted heat energy created by the fuel fourth stroke (first exhaust stroke) and at the sixth stroke combustion. After the combustion stage water is injected into to push out the steam. the superheated cylinder. The water explodes into steam and force the piston down. It in turn helps to cool the engine. That resulted in normal levels of power but using much less fuel. It also has the advantage of not requiring an external cooling system. Principle Working of Six Stroke Engine: 4-stroke Camshaft Designed Six-Stroke Camshaft Following changes has been made in Design of Exhaust A six-stroke engine describes a number of different Cam in Six-Stroke Engine. The two lobes in exhaust cam approaches in the internal combustion engine to capture the allows the camshaft to close the Exhaust valve twice, first waste heat from the four stroke Otto cycle and use it to for the fuel exhaust and then for steam exhaust. Power an additional power and exhaust stroke of the piston.