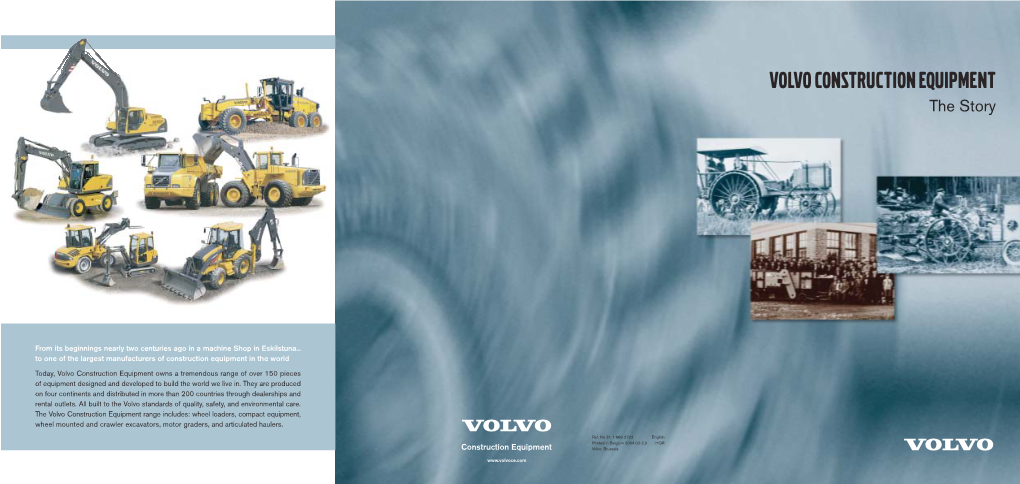

VOLVO CONSTRUCTION EQUIPMENT the Story

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Heavy Equipment

Heavy Equipment Code: 5913 Version: 01 Copyright © 2007. All Rights Reserved. Heavy Equipment General Assessment Information Blueprint Contents General Assessment Information Sample Written Items Written Assessment Information Performance Assessment Information Specic Competencies Covered in the Test Sample Performance Job Test Type: The Heavy Equipment assessment is included in NOCTI’s Teacher assessment battery. Teacher assessments measure an individual’s technical knowledge and skills in a proctored prociency examination format. These assessments are used in a large number of states as part of the teacher licensing and/or certication process, assessing competency in all aspects of a particular industry. NOCTI Teacher tests typically oer both a written and performance component that must be administered at a NOCTI-approved Area Test Center. Teacher assessments can be delivered in an online or paper/pencil format. Revision Team: The assessment content is based on input from subject matter experts representing the state of Pennsylvania. CIP Code 49.0202- Construction/Heavy Career Cluster 2- 47-2073.00- Operating Engineers Equipment/Earthmoving Architecture and Construction and Other Construction Equipment Operation Equipment Operators NOCTI Teacher Assessment Page 2 of 12 Heavy Equipment Wrien Assessment NOCTI written assessments consist of questions to measure an individual’s factual theoretical knowledge. Administration Time: 3 hours Number of Questions: 232 Number of Sessions: This assessment may be administered in one, two, or three -

Volvo Group: Building the Case for Electric Buses

VolvoClient case — Group: Building the case for electric buses About the Transforming to a low-carbon economy brings disruptive changes to Volvo Group many industry sectors. Industry leaders must not only deal with The Volvo Group disruption effectively, but also identify the upside of risks and act on is one of the those opportunities. world’s leading manufacturers In the transport sector, Volvo Group of Sweden, supported by of trucks buses, KPMG in Sweden, has carried out pioneering work on the case for construction low-carbon electric buses by building environmental and social impacts equipment into the total cost of ownership. We asked Niklas Gustafsson, Volvo and marine Group’s Chief Sustainability Officer, how this analysis has helped to and industrial reinforce Volvo Group’s position as a leader in sustainable engines. transport solutions. The Group also provides complete There is a shift to cleaner, quieter reach an estimated annual sales volume solutions for and more efficient cities approaching 35,000 units by 2020.1 Volvo Group is already embarking on a mission to financing and Momentum is building worldwide behind a address this demand. service. The technological shift towards low-carbon city transport including fully electric bus systems. group, with its True cost of ownership goes headquarters The C40 Cities Climate Leadership Group is committed to accelerate the implementation of beyond direct financial costs in Gothenburg, ultra-low emission bus technologies and 23 of Municipalities and transport authorities must Sweden, its members have signed the Clean Bus base their investment decisions on the best employs about Declaration calling on the finance and transport available data which traditionally focuses solely 100,000 people, sectors to support them through technology on direct financial costs. -

Green Financing Framework

VOLVO CARS GREEN FINANCING FRAMEWORK SEPTEMBER 2020 1 INTRODUCTION Volvo Cars Volvo Car AB and its consolidated subsidiaries (“Volvo Cars”) is a truly global organisation with Scandinavian roots. Founded in 1927, it is today, one of the most well-known and respected premium car brands in the world with sales of over 700,000 cars in 2019 in about 100 countries. Volvo Cars has been under the direct ownership of Geely Sweden Holdings AB and ultimately by Zheijang Geely Holding Group Co ltd since 2010. In 2019, Volvo Cars employed on average approximately 41,500 full-time employees. Volvo Cars’ Head Office, product development, marketing and administration functions are mainly located in Gothenburg, Sweden. The company’s main car production plants are located in Gothenburg (Sweden), Ghent (Belgium), South Carolina (US), Chengdu and Daqing (China), while engines are manufactured in Skövde (Sweden) and Zhangjiakou (China) and body components in Olofström (Sweden). Our group comprises of Volvo Cars including the car sub- scription and mobility businesses Care by Volvo and M. Our non-consolidated, independent joint venture companies Polestar and Lynk & Co are important strategic affiliates, ena- bling us to deliver on our strategy. Through collaboration between the different brands, greater competitiveness and/or synergies are created within the areas of electrification, mass market sales and ADAS/AD software technology. 2 SUSTAINABILITY Central to our business and key to our future success As a human-centric mobility provider company, we are a brand We commit to the highest standard of sustainability in mobil- for people who care about other people and the world in which ity. -

Skid Steer Backhoe Loader | 1Cx and 1Cxt

NEW SKID STEER BACKHOE LOADER | 1CX AND 1CXT Gross power: 36.3kW (49hp) Maximum dig depth: 3.05m Loader load over height: up to 2.65m THE BEST OF BOTH WORLDS JUST GOT BETTER. AT JCB, WE UNDERSTAND THE IMPORTANCE OF VERSATILITY AND THE DIFFERING DEMANDS OF SOME VERY DIVERSE SECTORS. THAT’S WHY WE’VE TAKEN THE WORLD’S SMALLEST BACKHOE LOADER TO NEW LEVELS. THE 1CX HAS ALWAYS BEEN A VERSATILE COMPACT MACHINE, OFFERING SKID STEER AND EXCAVATOR PERFORMANCE IN ONE PACKAGE. NOW, WE GIVE YOU THE OPTION OF RUNNING ON TRACKS FOR REDUCED GROUND DAMAGE, SUPERLATIVE CLIMBING, EXCEPTIONAL PUSHING POWER, UNPARALLELED STABILITY AND IMPROVED SOFT GROUND PERFORMANCE. 2 1CX AND 1CXT SKID STEER BACKHOE LOADER A HISTORY OF INNOVATION A HISTORY OF INNOVATION. THE 1CX SKID STEER BACKHOE LOADER IS THE LATEST IN A LONG LINE OF JCB WORLD FIRSTS. In fact, the entire concept of the backhoe loader itself was dreamt up by our company founder Joseph Cyril Bamford. We were also first to produce skid COMPETITORS’ steer loaders with a single-side loader arm; there are COMBINED numerous benefits to that unique layout, including side MARKET SHARE entry for greater safety. In 1994, we introduced the JCB 1CX which, for the first time, brought together the key features of a skid steer and a mini excavator. In 2012, we improved on our concept by adding Extradig, a handheld tool circuit, air conditioning, enhanced cab ergonomics and our Power Management System (PMS). As global market leader, JCB sells around Today, the 1CX boasts a choice of wheels or tracks half of all the world’s backhoe loaders. -

Volvo Brochure Backhoe Loader BL61B BL71B English

Bl61b, bl71b VOLVO BACKHOE LOADERS 7,08–9,80t 86–100hp 1 A passion for performance. At Volvo Construction Equipment, we’re not just coming along for the ride. Developing products and services that raise productivity – we are confident we can lower costs and increase profits for industry experts. Part of the Volvo Group, we are passionate about innovative solutions to help you work smarter – not harder. Helping you to do more. Doing more with less is a trademark of Volvo Construction Equipment. High productivity has long been married to low energy consumption, ease of use and durability. When it comes to lowering life-cycle costs, Volvo is in a class of its own. Designed to fit your needs. There is a lot riding on creating solutions that are suited to the particular needs of different industry applications. Innovation often involves high technology – but it doesn’t always have to. Some of our best ideas have been simple, based on a clear and deep understanding of our customers’ working lives. You learn a lot in 180 years. Over the years, Volvo has advanced solutions that have revolutionized the use of construction equipment. No other name speaks Safety louder than Volvo. Protecting operators, those around them and minimizing our environmental impact are traditional values that continue to shape our product design philosophy. We’re on your side. We back the Volvo brand with the best people. Volvo is truly a global enterprise, one that is on standby to support customers quickly and efficiently – wherever they are. We have a passion for performance. -

Freedom to Move in a Personal, Sustainable and Safe Way

VOLVO CAR GROUP ANNUAL REPORT 2020 Freedom to move in a personal, sustainable and safe way TABLE OF CONTENTS OVERVIEW 4 2020 Highlights 6 CEO Comment 8 Our Strenghts 10 The Volvo Car Group 12 Our Strategic Affiliates THE WORLD AROUND US 16 Consumer Trends 18 Technology Shift OUR STRATEGIC FRAMEWORK 22 Our Purpose 24 Strategic Framework HOW WE CREATE VALUE 28 Our Stakeholders 30 Our People and Culture 32 Product Creation 38 Industrial Operations 42 Commercial Operations MANAGEMENT REPORT 47 Board of Directors Report 52 Enterprise Risk Management 55 Corporate Governance Report FINANCIAL STATEMENTS 60 Contents Financial Report 61 Consolidated Financial Statements 67 Notes to the Consolidated Financial Statements 110 Parent Company Financial Statements 112 Notes to the Parent Company Financial Statements 118 Auditor’s Report 120 Board of Directors 122 Executive Management Team Freedom to move SUSTAINABILITY INFORMATION 124 Sustainability Management and Governance 129 Performance 2020 PERSONAL SUSTAINABLE SAFE 139 Sustainability Scorecard 144 GRI Index Cars used to be the symbol for personal freedom. Owning a car meant that you had the We commit to developing We commit to the highest We commit to pioneering 146 TCFD Index means to be independently mobile – that you owned not just a vehicle, but choice as and building the most per- standard of sustainability the safest, most intelligent 147 Auditor's Limited Assurance Report on sonal solutions in mobility: in mobility to protect technology solutions in Sustainability well. Nothing of that has changed, but the world we live in has. The earth, our cities and to make life less compli- the world we share. -

Technical, Organisational and Social Aspects of Language Integration for Complex Systems

Putting the Pieces Together { Technical, Organisational and Social Aspects of Language Integration for Complex Systems H˚akan Burden Computer Science and Engineering Chalmers University of Technology and University of Gothenburg Gothenburg, Sweden [email protected] Abstract. Dealing with heterogenuous systems is often described as a technical challenge in scientific publications. We analysed data from 25 interviews from a study of Model-Driven Engineering at three companies and found that while the technical aspects are important, they do not encompass the full challenge { organizational and social factors also play an important role in managing heterogenuous systems. This is true not only for the development phase but also for enabling early validation of interdependent systems, where processes and attitudes have an impact on the outcome of the integration. Keywords: Empirical and Exploratory Case Study, Model-Driven Engineering 1 Introduction Complex systems, consisting of numerous and interdependent subsystems [15], require a plethora of languages for efficient implementation [7]. From the as- pect of Model-Driven Engineering (MDE), the challenges are often described in technical terms [4] since heterogenuous languages imply different abstraction levels, representations and aspects of software [8], but also since the languages have their own domain-specific and platform-dependent constraints [11]. The one-sided focus on technical aspects is surprising since Kent already in 2002 pointed out that if MDE is to be successful it needs to encompass also the or- ganisational and social aspects of software engineering [10], a claim that has since been reiterated [1, 9]. To explore to what extent language integration for comlex systems is a chal- lenge in terms of technical, organisational and social aspects we analysed data collected at three different companies, looking for evidence regarding the mo- tivations and challenges of heterogenuous development of embedded systems. -

Loader Backhoes and Tractor Loader B95c I B95c Tc I B95c Lr I B110c I U80c C Series Loader Backhoes – Build More Time Into Your Day

LOADER BACKHOES AND TRACTOR LOADER B95C I B95C TC I B95C LR I B110C I U80C C SERIES LOADER BACKHOES – BUILD MORE TIME INTO YOUR DAY New C Series loader backhoes with Tier 4 Final certified engines deliver the power and torque needed so you can dig, load, trench or push faster, while reducing the impact on the environment. MAINTENANCE-FREE BRAKES Outboard wet disc brakes with separate Spring Applied Hydraulically Released (SAHR) parking brake provide enhanced control and significantly increased brake life. The “low effort” braking system allows the operator to apply stopping power with a minimum amount of force. POWERSHUTTLE OR POWERSHIFT TRANSMISSION Choose from our robust Power Shuttle and our advanced Powershift. Our reliable PowerShuttle transmission is easy to operate, with a right-hand gear shift lever and convenient FNR shuttle lever. Choose Powershift transmission for maximum operator comfort. Operators appreciate the convenience of the powershift transmission that shifts smoothly up or down through the gears automatically locating the correct gear for the conditions. 2 C SERIES LOADER BACKHOES – BUILD MORE TIME INTO YOUR DAY OUTSTANDING LOADER BUCKET BREAKOUT By using a straight arm loader design, C series Loader backhoes deliver unmatched loader lift capacities and the loader bucket location on top of the loader frame produces exceptional bucket breakout forces. FAST, COMPLETE SERVICE ACCESS The tilt-forward hood and checkpoints that are grouped together reduce maintenance time so you can maximize uptime and profits. INDUSTRY-LEADING COMFORT AND VISIBILITY Comfortable operators are more productive operators, and the C Series cab is designed for maximum productivity with: • Comfortable seating • Available pilot controls for improved productivity and comfort • Greater visibility • Auto Glide Ride™ option with speed setting. -

2019 Annual and Sustainability Report

2019 Annual and Sustainability Report Contents Swedbank in brief 2 Income, balance sheet and notes, Group The year in brief 4 Income statement 54 CEO statement 6 Statement of comprehensive income 55 Goals and results 8 Balance sheet 56 Value creation 10 Statement of changes in equity 57 Business model 12 Statement of cash flow 58 Sustainability 14 Notes 59 The share and owners 24 Income, balance sheet and notes, Parent company Board of Directors’ report Income statement 154 Financial analysis 26 Statement of comprehensive income 154 Swedish Banking 30 Balance sheet 155 Baltic Banking 31 Statement of changes in equity 156 Large Corporates & Institutions 32 Statement of cash flow 157 Group Functions & Other 33 Notes 158 Corporate governance report 34 Alternative performance measures 192 Board of Directors 46 Group Executive Committee 50 Sustainability Disposition of earnings 52 Sustainability report 194 Materiality analysis 195 Sustainability management 197 Notes 199 GRI Standards Index 212 Signatures of the Board of Directors and the CEO 217 Auditors’ report 218 Sustainability report – assurance report 222 Annual General Meeting 223 Market shares 224 Five-year summary – Group 225 Three-year summary – Business segments 228 Definitions 231 Contacts 233 Financial information 2020 Annual General Meeting 2020 Q1 Interim report 23 April The Annual General Meeting will be held on Thursday, 26 March at 11 am (CET) at Cirkus, Djurgårdsslätten Q2 Interim report 17 July 43–45, Stockholm, Sweden. The proposed record day for the dividend is 30 March 2020. The last day for Q3 Interim report 20 October trading in Swedbank’s shares including the right to the dividend is 26 March 2020. -

Financial Reporting and the Swedish Annual Accounts Act

Freedom to move in a personal, sustainable and safe way. VOLVO CAR GROUP INTERIM REPORT FIRST SIX MONTHS 2021 VOLVO CAR GROUP First Six Months 2021 • Retail sales increased 41.0% to 380,757 (269,962) • In May the Board announced its intention to evaluate units resulting in a total of 773,000 sold cars for the the possibility of an Initial Public Offering (IPO) later last 12 months. this year. A final decision to list will be subject to • Recharge line-up grew significantly and accounted for market conditions and there can be no certainty that 25% (14%) of total sales. a listing will proceed. • Revenue increased 26.3% to MSEK 141,131 (111,759) • Volvo Cars announced that it will become fully electric driven by strong demand and positive mix effects. by 2030. • Operating income increased to MSEK 13,238 (–989), • Volvo Cars initiated the process of carving out all com- corresponding to an EBIT margin of 9.4% (–0.9%). bustion engine operations. A major step was taken in June when Volvo Cars distributed its shares in Power- • Net income was MSEK 9,627 (–1,171). Basic earnings train Engineering Sweden AB and in Volvo Car Services per share was SEK 163.63 (–35.99). 5 AB, to the majority owner. • Cash flow from operating and investing activities was • Fully electric Volvo C40 was launched, to be offered MSEK –6,899 (–12,803). online only. • Volvo Cars’ investment in Polestar increased its value as • In June, Volvo Car Group and Northvolt announced the a private placement triggered a valuation effect of MSEK intention to join forces in battery development and 2,039 for Volvo Cars. -

Creating the Technology to Connect the World

Nokia Annual Report on Form 20-F 2019 on Form Nokia Annual Report Creating the technology to connect the world Nokia Annual Report on Form 20-F 2019 As filed with the Securities and Exchange Commission on March 5, 2020 UNITED STATES SECURITIES AND EXCHANGE COMMISSION Washington, D.C. 20549 FORM 20-F ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 For the fiscal year ended December 31, 2019 Commission file number 1-13202 Nokia Corporation (Exact name of Registrant as specified in its charter)) Republic of Finland (Jurisdiction of incorporation) Karaportti 3 FI-02610 Espoo, Finland (Address of principal executive offices) Esa Niinimäki, Deputy Chief Legal Officer, Corporate, Telephone: +358 (0) 10 44 88 000, Facsimile: +358 (0) 10 44 81 002, Karakaari 7, FI 02610 Espoo, Finland (Name, Telephone, E-mail and/or Facsimile number and Address of Company Contact Person) Securities registered pursuant to Section 12(b) of the Securities Exchange Act of 1934 (the “Exchange Act”): Title of each class Trading Symbol(s) Name of each exchange on which registered American Depositary Shares NOK New York Stock Exchange Shares New York Stock Exchange(1) (1) Not for trading, but only in connection with the registration of American Depositary Shares representing these shares, pursuant to the requirements of the Securities and Exchange Commission. Securities registered pursuant to Section 12(g) of the Exchange Act: None Securities for which there is a reporting obligation pursuant to Section 15(d) of the Exchange Act: None Indicate the number of outstanding shares of each of the registrant’s classes of capital or common stock as of the close of the period covered by the annual report. -

Backhoe Loaders N SERIES

Backhoe Loaders N SERIES 580N EP 580N 580 Super N 580 Super N WT 590 Super N SINCE 1842 580N EP 580N 580 Super N 580 Super N WT 590 Super N 2 Outmuscle, Outpower, Outperform, Outlast When your legacy goes back to creating the world’s first fully integrated backhoe loader you tend to understand a thing or two about how to engineer them. Meet the Tier 4 Final N Series—some of the most versatile machines in the industry—and built to outdo. The best breakout force. The highest lifting capacity. Fast roading speeds. One of the quietest cabs. Their list of credentials is impressive. Whether it’s excavating, grading, craning, loading or removing snow, the Tier 4 Final N Series are the machines made for the job. + PowerLift™* + Greater Coupler Compatibility + Over-Center Backhoe Design and Design*** + ProControl System (PCS)** + Second-to-None Serviceability + Comfort Steer™*** *Not available on the 580N EP or 580N **Optional on 580N EP ***Optional 3 STRENGTH FROM WITHIN FUEL-SAVING FEATURES* ECO-mode minimizes fuel burn while still providing full power to hydraulics. Other features such as auto-idle and auto-shutdown help take efficiency even further to lower operating costs. *ECO-mode, auto-idle and auto-shutdown not available on 580N EP SMARTCLUTCH – DECIDE HOW IT DRIVES Aggressive or soft, operators can customize the feel of forward-to-reverse transitions with our industry-exclusive SmartClutch modulation. CUT TURNS IN HALF WITH COMFORT STEER™ CASE’s Comfort Steer option reduces lock-to-lock rotations when moving from full right to full left (and vice versa).