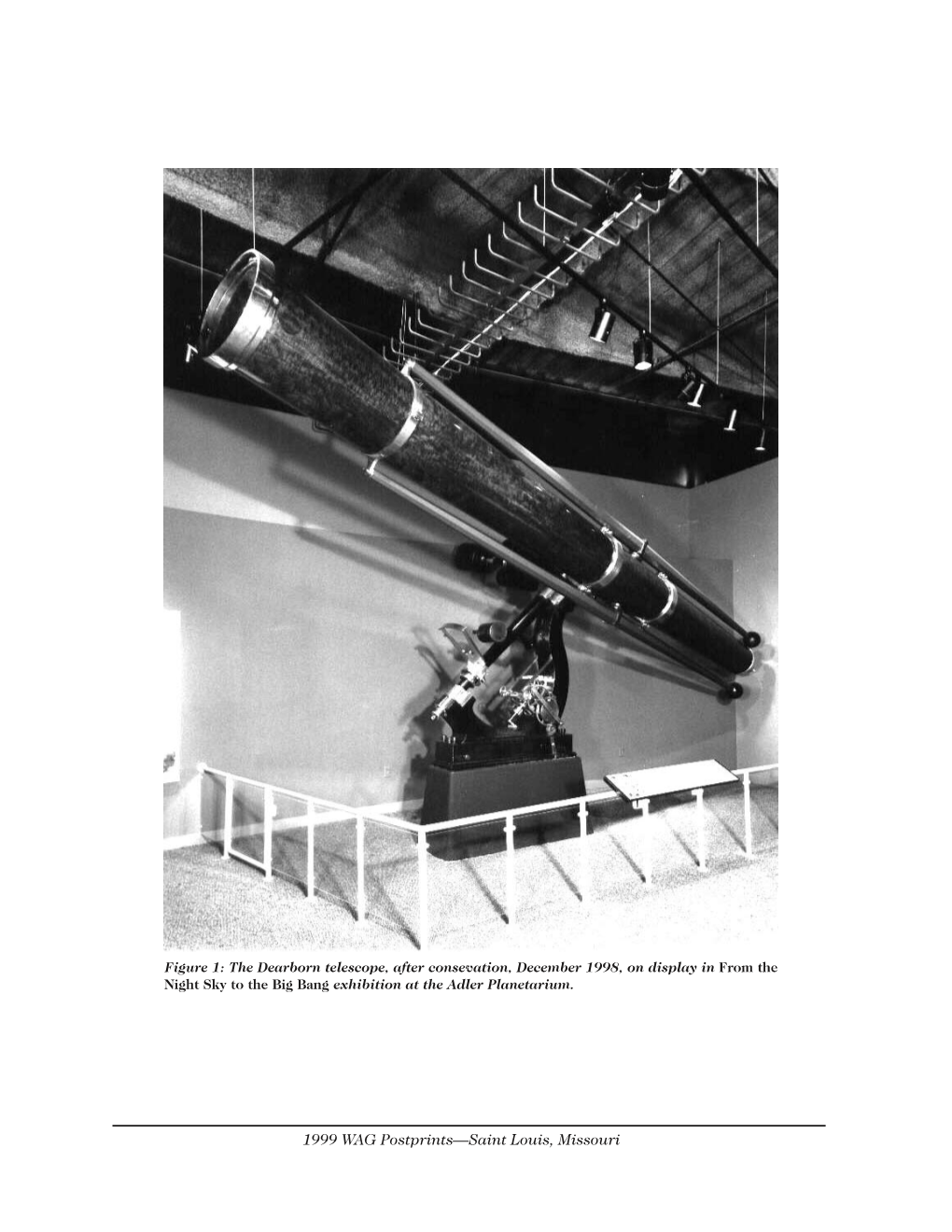

The Conservation of the Historic Dearborn Telescope

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Public Events September 2018

Public Events September 2018 Subscribe to this publication by emailing Carol Chen atSubscribe [email protected] to this publication by emailing Shayla Butler at [email protected] Table of Contents Overview Fall Event Highlights ............................................................................................. 3 Northwestern Events Arts and Performances .......................................................................................... 8 Living Neighborhood and Community Relations Leisure and Social ......................................................................................... 10 1603 Orrington Avenue, Suite 1730 Norris Mini Courses Evanston, IL 60201 Around Campus www.northwestern.edu/communityrelations ARTica (art studio) Norris Outdoors Northwestern Music Academy Dave Davis Religious Services ......................................................................................... 13 Executive Director [email protected] Sports, Health, and Wellness 847-491-8434 Northwestern Wildcat Athletics ................................................................... 14 Recreation ..................................................................................................... 18 Academic Lectures To receive this publication electronically One Book, One Northwestern: Danielle Allen, Our Declaration .............. 20 every month, please email Shayla Butler at Academic Lectures ....................................................................................... 21 [email protected] -

12-Inch Alvan Clark Telescope Restoration

12-Inch Alvan Clark Telescope Restoration: Summary of Research and Final Recommendations Deborah Culmer and Hannah Johnson September, 2011 Introduction The first telescope installed at Lick Observatory was a second-hand purchase, with the telescope and its optic made by the premier telescope makers of the time, Alvan Clark and Sons of Cambridge, MA. The dome that housed it was the first structure built on Mt. Hamilton, from bricks fired in a kiln on location. That dome still stands; and until the 1970’s, the 12-inch refracting telescope was in operation, but without its original driver clock and gears (replaced with an electronic drive, perhaps in the 1950’s). Since it was decommissioned, the 12-inch has been in storage. The Lick Instrument Lab has retrieved it, and it is currently on location at UC Santa Cruz in anticipation of total restoration. In the summer of 2011, a research project was launched to determine to what era and condition the telescope should be restored. In recent years, there has been great interest in historical restoration of Alvan Clark telescopes (and others, to be sure). As a result of that interest, we had a pool of organizations and institutions from which to glean information. Two we visited in person; many more we contacted via email and conference calls. Based on our research and interviews, we offer our recommendations on the restoration of this historically important telescope. 1. Research In beginning this project, it was very important to understand the history of the 12-inch Alvan Clark, especially since it was the first telescope set up on Mt. -

Biographical Notice of Professor S. W. Burnham of Chicago

* 4' 509 7 142 Biographical Notice of Professor S. W. Burnham of Chicago. By the death in Chicago, March I I, 192 I, of Professor Sherburne Wesley Burnham, the celebrated dis- coverer of double stars, America has lost one of her most illustrious astronomers, and double-star astronomy its most eminent cultivator since the days of W. Herschel and K Struve, who laid the foundations of this branch of the science about a century ago. Professor Burnham was born at Thetford, Vermont, Dec. 12, 1838, and thus he attained the age of 82 years and 3 months. Though retired from active observing for about ten years, Bumham had enjoyed moderately good health for his years and somewhat frail build, and finally succumbed to weakness accentuated by a fall, in which a hip was broken. After this misfortune he lingered some three weeks, without extreme suffering, yet the shock proved too great for the feeble recuperative power incident to his advanced age. Burnham was married in the years of his early manhood, and is survived by his aged widow, several sons and daughters, including a number of grandchildren. A more detailed account of his family will be given by Professor 3.E. Barnard, in a biographical notice soon to appear in Popular Astronomy. Here it must suffice to give an outline of his scientific career, which has left so deep an impress on the science of his country and of his age. In his youth this future celebrated astronomer had received only a common school education; but already in the days of the civil war he happened to become possessed of a copy of Burritt's Geography of the Heavens, which so interested him that it turned his attention to astronomy, and he lived to devote to this science over half a century of active observation and research, with the largest telescopes in the world. -

Office Directory

Office Directory 1801 MAPLE AVENUE ACCESSIBLENU ACCOUNTING SERVICES Human Resources Compensation Suite 130, 2122 Sheridan Road, 2nd Floor, 619 Clark Street, Evanston, 847-491-7516 Evanston, IL 60201 IL 60208 Human Resources Staffing Services 847-467-5530 847-491-5337 847-491-7507 fax 847-467-5531 fax 847-467-7261 Human Resources Temp Staffing Center Lauren Blanchard Pourian, Associate Nicole Van Laan, Controller 847-467-1048 Director AccessibleNU 847-491-4722 Public Safety, Center for 847-467-5530 Nicole McDonald, Assistant Controller 847-491-5476 AccessibleNU, Chicago Trademark Licensing 312-503-4042 Amy Mykytiuk, Director Accounting 847-491-3274 AccessibleNU, Chicago Fax 847-467-2764 312-503-4173 Reginold C George, Manager ABBOTT HALL Accounting Abbott Hall, 710 N. Lake Shore Drive, ACCESS SERVICES DEPARTMENT, 847-467-1359 Chicago, IL 60611 UNIVERSITY LIBRARIES Veronica Hudgins, Executive Assistant Book Store, Northwestern University University Library, 1970 Campus Drive, 847-491-4727 +1 312-503-8486 Evanston, IL 60208 Accounting Services General Support Bursar's Office, Chicago Campus 847-491-7633 847-491-5337 +1 312-503-8525 fax 847-491-5685 (ILL) Facilities Management Circulation Desk +1 312-503-8000 847-491-7633 Financial Aid Interlibrary Loan Desk +1 312-503-8722 847-491-7630 Front Desk Mathematics Library +1 312-503-8507 847-491-7627 Housekeeping Mitchell Multimedia Center +1 312-503-8526 847-491-7678 Student Accounts/Finance Services Mudd Library Circulation Desk +1 312-503-8503 847-491-3362 Transportation & Parking Chicago Periodicals -

FOR IMMEDIATE RELEASE September 2006 New Documents

FOR IMMEDIATE RELEASE September 2006 New Documents Published in Special Issue of Journal of the Antique Telescope Society Reveal Unknown Aspects of Early Career of Major American Telescope-Maker Alvan Clark More than two dozen documents previously unknown to historians shed new light on the early struggles of the nineteenth-century American telescope-maker Alvan Clark to establish his reputation for his astronomical expertise and optical skill. The documents, ranging from manuscript letters and notes to letters to newspaper editors—have been made public for the first time in the Summer/Fall 2006 issue of the Journal of the Antique Telescope Society, published this month as a single-topic double-length issue devoted to Clark’s early telescope-making efforts. “This special Alvan Clark issue of the Journal of the Antique Telescope Society is the most significant publica- tion of new material about Alvan Clark since 1995,” declared the Antique Telescope Society’s president, Dr. Mi- chael Reynolds, F.R.A.S., associate dean of mathematics and natural sciences and professor of astronomy at Florida Community College in Jacksonville, and executive director emeritus of the Chabot Space and Science Center in Oakland, California. (In 1995, Deborah Jean Warner and Robert B. Ariail published their now-classic biography and catalogue Alvan Clark & Sons: Artists in Optics [second edition, Richmond, Va.: Willmann–Bell, in association with the National Museum of American History, Smithsonian Institution].) Alvan Clark (1804-1887) was the United States’s -

EVENT GUIDE SPECIAL ADVERTISING SECTION: This Section Was Edited and Produced by the Chicago Architecture Foundation

ARCHITECTUREFREE FESTIVAL This weekend, get FREE, behind-the-scenes access to 200 buildings across Chicago. openhousechicago.org EVENT GUIDE SPECIAL ADVERTISING SECTION: This section was edited and produced by the Chicago Architecture Foundation. 1 PRESENTED BY About the Chicago Architecture Foundation Five years ago, the Chicago to embark on a tour, workshops for Architecture Foundation (CAF) students, lectures for adults and decided to bring a city-wide festival of field trip groups gathered around architecture and design to Chicago— our 1,000-building scale model of the quintessential city of American Chicago. architecture. London originated the In addition to Open House Chicago, “Open House” concept more than 20 CAF is best known for our 85 different years ago, New York City had several Chicago-area tours, including the top- years under its belt and even Toronto ranked tour in the city: the Chicago produced a similar festival. By 2011, it Architecture Foundation River Cruise was Chicago’s time and Open House aboard Chicago’s First Lady Cruises. Chicago was born. Our 450 highly-trained volunteer CAF was founded in 1966. As a docents lead more than 6,000 walking, STS. VOLODYMYR & OLHA UKRAINIAN CATHOLIC CHURCH (P. 10) photo by Anne Evans nonprofit organization dedicated boat, bus and L train tours each year. to inspiring people to discover why CAF also offers exhibitions, public designed matters, CAF has grown programs and education activities Ten things to know about over the years to become a hub for for all ages. Open House Chicago learning about and participating in Learn more about CAF and our architecture and design. -

EVENT GUIDE SPECIAL ADVERTISING SECTION: This Section Was Edited and Produced by the Chicago Architecture Foundation

ARCHITECTUREFREE FESTIVAL This weekend, get FREE, behind-the-scenes access to 200+ buildings across Chicago. openhousechicago.org EVENT GUIDE SPECIAL ADVERTISING SECTION: This section was edited and produced by the Chicago Architecture Foundation. 2 PRESENTED BY ABOUT THE CHICAGO ARCHITECTURE FOUNDATION Six years ago, the Chicago Architecture Foundation (CAF) launched the first Open House Chicago. This free, citywide festival drew 23,000 people in its first year. By 2016, it grew to 100,000 attendees, making it one of the largest architecture events in the world. This year is our biggest yet, with more than 200 sites. OHC is just one of many CAF programs that inspire people to discover why design matters. Today, when you visit CAF at 224 S. Michigan Ave., you’ll find visitors embarking on tours, FIRST CHURCH OF DELIVERANCE, BRONZEVILLE (p. 15) camps for children, lectures for adults and field trip groups gathered around our 3D model of Chicago. TEN THINGS TO KNOW ABOUT In summer 2018, CAF will open the Chicago Architecture Center at CHICAGO ARCHITECTURE CENTER — OPEN HOUSE CHICAGO (OHC) COMING IN SUMMER 2018 111 E. Wacker Dr. This new location is situated above the dock for the 1. OHC is a FREE public festival with behind-the-scenes access Chicago Architecture Foundation River CAF’s 450 expert volunteer docents to 200+ buildings across Chicago—no tickets required. Cruise aboard Chicago’s First Lady will lead 85+ tours from the Center, Cruises—the city’s top-ranked tour. by boat, bus, L train and on foot for SPECIAL CHICAGO ARCHITECTURE FOUNDATION ADVERTISING SECTION | THURSDAY, OCTOBER 12, 2017 ADVERTISING SECTION | THURSDAY, SPECIAL CHICAGO ARCHITECTURE FOUNDATION 2. -

Historyofthetelescope

HISTORY OF THE TELESCOPE Pedro Ré http://pedroreastrophotography.com/ Contents Joseph von Fraunhofer (1787 - 1826) and the Great Dorpat refractor .................................................. 3 Alvan Clark (1804-1887), George Bassett Clark (1827-1891) and Alvan Graham Clark (1832-1897): American makers of telescope optics. .................................................................................................. 13 William Parsons (1800-1867) e o Leviatã de Parsonstown (in Portuguese) ......................................... 21 O Telescópio de Craig (1852) (in Portuguese) ...................................................................................... 29 The 25-inch Newall Refractor ............................................................................................................... 37 The Kew Photoheliograph ..................................................................................................................... 43 O Grande Telescópio de Melbourne (in Portuguese) ........................................................................... 51 O Grande Refractor da Exposição de Paris (1900) (in Portuguese) ...................................................... 61 William Lassell’s (1799-1880) Telescopes and the discovery of Triton ................................................ 71 James Nasmyth’s (1808-1890) telescopes ............................................................................................ 77 The 36-inch Crosley Reflector .............................................................................................................. -

The University of Mississippi the Formative Years 1848-1906

University of Mississippi eGrove University of Mississippi Publications University Archives 1979 The niU versity of Mississippi: The orF mative Years 1848-1906 James B. Lloyd Thomas M. Verich Deborah J. Thiel Follow this and additional works at: https://egrove.olemiss.edu/um_pub Recommended Citation Lloyd, James B.; Verich, Thomas M.; and Thiel, Deborah J., "The nivU ersity of Mississippi: The orF mative Years 1848-1906" (1979). University of Mississippi Publications. 19. https://egrove.olemiss.edu/um_pub/19 This Book is brought to you for free and open access by the University Archives at eGrove. It has been accepted for inclusion in University of Mississippi Publications by an authorized administrator of eGrove. For more information, please contact [email protected]. The University of Mississippi The Formative Years 1848-1906 By James B. Lloyd Thomas M. Verich Contributing Ediror Deborah J. Thiel Phorography Ediror and Designer ' Contents and Photographs Introduction l The Beginning: 1848-1865 2 James A. Ventress 4 George F. Holmes 4 John Millington . ) Alben T. Bledsoe ) jacob Thompson . 6 Jacob Thompson, speech 7 The Universiry Campus, 1861 8,9 A. B. Longstreet . to F. A. P. Barnard. · II James J. Quarles Diploma. · l2 L Q. C. Lamar . · 12 Edward C. Boynton, portrait. · 13 Edward C. Boynton, (ener . · l4 The Lyceum . · l4 The Steward's Hall . · l4 Edward C. Boyneon, laboratory. .1) Young Girl . · l6 Woman in Indian Costume. · l7 The Chapel. · l7 Carriage House . · l8 Carriage House. detail · l8 Carriage House, detail · 19 The Lyceum, fight series, number one. .20 The Lyceum. fight series, number twO . .2l The Lyceum, fight series, detail. -

Public Events September 2019

Public Events September 2019 1 Subscribe to this publication by emailing Shayla Butler at [email protected] Table of Contents Overview Fall Event Highlights ............................................................................................. 3 Northwestern Events Arts and Performances ........................................................................................... 7 Neighborhood and Community Relations 1800 Sherman Avenue, Suite 7-100 Living Evanston, IL 60208 Leisure and Social .......................................................................................... 8 www.northwestern.edu/communityrelations Norris Mini Courses Around Campus ARTica (art studio) Dave Davis Norris Outdoors Executive Director Religious Services ......................................................................................... 11 [email protected] 847-467-5762 Sports, Health, and Wellness Northwestern Wildcat Athletics ................................................................... 12 Recreation ..................................................................................................... 15 To receive this publication electronically Speaking Events every month, please email Shayla Butler at One Book, One Northwestern: Margaret Atwood, The Handmaid’s Tale…18 [email protected] Speakers and Presentations ......................................................................... 19 Evanston Campus Map and Parking Information Cover image Public pathways along the lake with views of the -

Ridge Road & Calumet Avenue Streetscape and Corridor

Ridge Road & Calumet Avenue Streetscape and Corridor Improvement Plan for the Town of Munster, Indiana Proposal to the Town of Munster October 30, 2019 Submitted by: Teska Associates in association with Sam Schwartz Consulting Mary-Ann Ervin, Purchasing Agent August 29, 2016 City of Quincy 730 Maine Street, Suite # 226 Quincy, Illinois 62301 Dear Ms. Ervin, On behalf of Teska Associates, Inc. and our team, I am pleased to submit our proposal for professional services as a Strategic Planning Consultant. We have assembled a team of experts specifically selected to address Quincy’s needs. We are joined in this submittal by Ticknor & Associates, specializing in economic development; Business Districts, Inc., focusing on market economics and business district revitalization; Poepping, Stone, Bach & Associates, Inc., a Quincy-based architecture, engineering and planning firm; Gewalt Hamilton Associates, a full service transportation planning and engineering firm; and Heritage Consulting, Inc., specializing in historic preservation, tourism and cultural planning. Together, our team has an approach to strategic planning that is well suited to serve the City of Quincy. Savvy, nimble, innovative, engaging, celebratory. We don’t just excel at our work, we deliver a great product, an enjoyable process, and satisfied participants. What will distinguish the results of the plan from our Teska Team is its utility for many years to come. It will be used and referred to by City and GREDF staff, appointed and elected officials, and by the other partners and stakeholders who will lead Quincy to an even more robust, vital and sustainable environment to live, work, invest and enjoy. Preparing a strategic plan is a rare and important event. -

Parking Stairs

MILBURN STREET Long Field Patten (Recreation) Gymnasium Inset is 3⁄4 mile northwest 2 10 LINCOLN STREET ISABELLA STREET Career Services Trienens Hall Sharon J. Drysdale Field Nicolet Rocky Miller Park Football Center Student Residences Student Residences Byron S.Coon Anderson Sports Center Norris Hall ASBURYAVENUE COLFAX STREET Aquatics Center Beach 13 Student 21 NORTH Ryan Residences Field Tennis CENTRAL STREET Courts 14 McGaw CAMPUS DRIVE ASHLANDAVENUE Memorial Hall/ Henry Crown Welsh-Ryan Arena Sports Pavilion/ DARTMOUTH PLACE Student 11 Combe Tennis Center Residences International Office Tennis Courts SHERIDAN ROAD Frances Leonard B. Thomas TECH DRIVE Searle Athletic Complex Building NOYES STREET Lakeside Fields Mudd Library Technological Cook Hall 13 Lutheran Institute Hogan Biological Center MAPLEAVENUE Sciences Building SHERMANAVENUE Pancoe-NSUHS Ford Motor Company ORRINGTONAVENUE Life Sciences HAVEN STREET Engineering Design Center Pavilion 9 Catalysis Center 12 GAFFIELD Shakespeare Ryan Garden Hall Student Residences Dearborn Allen 8 Center Observatory Silverman Hall Garrett- Annenberg GARRETT PLACE Evangelical Hall Theological CAMPUS DRIVE Seminary 15 Sheil Catholic 2020 Ridge SIMPSON STREET Center Shanley Swift Hall Hall 14 LIBRARY PLACE Cresap Central Family Laboratory Utility Institute Plant HAMLIN ST Chabad House Blomquist Lunt CAMPUS DRIVE Recreation Hall Center Owen L. Coon Canterbury Fiedler Forum House Hillel Center Jacobs Center FOSTER STREET SHERIDAN ROAD Chambers Hall Arthur Andersen McCormick Leverone 16 Auditorium