Jameed Processing Poster

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

MARKET SYSTEM ASSESSMENT for the DAIRY VALUE CHAIN Irbid & Mafraq Governorates, Jordan MARCH 2017

Photo Credit: Mercy Corps MARKET SYSTEM ASSESSMENT FOR THE DAIRY VALUE CHAIN Irbid & Mafraq Governorates, Jordan MARCH 2017 Table of Contents EXECUTIVE SUMMARY 3 METHODOLOGY 4 TARGET POPULATION 4 JUSTIFICATION FOR MARKET SELECTION 4 AREA OVERVIEW 5 MARKET SYSTEM MAP 9 CONSUMPTION & DEMAND ANALYSIS 9 SUPPLY ANALYSIS & PRODUCTION POTENTIAL 12 TRADE FLOWS 14 MARGINS ANALYSIS 15 SEASONAL CALENDAR 15 BUSINESS ENABLING ENVIRONMENT 17 OTHER INITATIVES 20 KEY FACTORS DRIVING CHANGE IN THE MARKET 21 RECOMMENDATIONS & SUGGESTED INTERVENTIONS 21 MERCY CORPS Market System Assessment for the Dairy Value Chain: Irbid & Mafraq 2 EXECUTIVE SUMMARY The dairy industry plays an important role in the economy of Jordan. In the early 70’s, Jordan established programmes to promote dairy farming - new breeds of more productive dairy cows were imported, farmers learned to comply with top industry operating standards, and the latest technologies in processing, packaging and distribution were introduced. Today there are 25 large dairy companies across Jordan. However inefficient production techniques, scarce water and feed resources and limited access to veterinary care have limited overall growth. While milk production continues to steadily increase—with 462,000 MT produced (78% of the market demand) in 2015 according to the Ministry of Agriculture—the country is well below the production levels required for self-sufficiency. The initial focus of the assessment was on cow milk, however sheep and goat milk were discovered to play a more important role in livelihoods of poor households, and therefore they were included during the course of the assessment. Sheep and goats are better adapted to a semi-arid climate, and sheep represent about 66 percent of livestock in Jordan. -

Sudan University of Science and Technology College of Graduate Studies

Sudan University of Science and Technology College of Graduate Studies Yoghurt Partially Supplemented with Barley Flour fermented with Probiotic Bifidobacterium longum BB536 الزبادي المدعم جزئيا بدقيق الشعير المخمر بالبكتريا الصديقة Bifidobacterium longum BB536 Dissertation Submitted to Sudan University of Science and Technology in Partial Fulfillment for the Requirements of the Degree of Master of Science in Food Science and Technology By Manal Ahmed Mustafa Mohammed B.Sc. (Honors) in Food Science and Technology, Sudan University of Science and Technology (2010) Supervisor Associated Professor Dr. Barka Mohammed Kabier Barka Department of Food Science and Technology, College of Agriculture Studies, SUST October 2017 2 اﻵية قال تعالي: )وَإِنَّ لَكُمْ فِي الْأَنْعَامِ لَعِبْرَةً نُسْقِيكُمْ مِمَّا فِي بُطُونِهِ مِنْ بَيْنِ فَرْثٍوَدَمٍ لَبَنًا خَالِصًا سَائِغًا لِلشَّاِِبِينَ( صدق اهلل العظيم سوِة النحل اﻵية )66( I Dedication this dissertation is dedicated to soul of my late father Ahmed Mustafa To dear my mother Nafisa Khalid To my dear Grandmother To my dear Aunts and Uncles To my dear Brothers and sisters To my all Relative for their kind helps and support II Acknowledgment First, almost grateful thanks to Allah for giving me health, patience, and assistance to complete this work. Thanks and all thanks to my supervisor, Dr. Barka Mohamed Kabeir Barka for supervising and nice cooperation and help. Especially thanks to my dear Ustaza Eshraga and all staff at animal production department for kind help and support. Finally thanks to my -

Eastern Mediterranean Know Before You Go

Eastern Mediterranean Know Before You Go A step by step guide to your Trafalgar trip. Your insider’s journey begins… Thank you for choosing Trafalgar to show you the insider’s view of the Eastern Mediterranean. A wealth of experience has taught us that your journey begins well before you leave home. So we have compiled this guide to provide you with as much information as possible to help you prepare for your travels. We look forward to welcoming you on the trip of a lifetime! Temple of Zeus and Acropolis, Greece 2 Before you go… Travel Documents Other benefits include: A couple of weeks prior to your vacation you will receive your • You won’t be required to show your passport at each hotel Trafalgar wallet with your travel documents and literature. • Your Travel Director will have all your important These documents are valuable and contain a wealth of advice details immediately and essential information to make your vacation as enjoyable • You’ll receive useful information and tips before you go as possible. Please read them carefully before your departure. and compelling offers from our partners Passports and Visas It should take less than 10 minutes to register and you should have the following information ready: You will require a passport valid for six months beyond the • Your booking number and last name conclusion of your trip, with appropriate visas. Some itineraries • The passport details of everyone on your booking may require multiple-entry visas for certain countries. You • The emergency contact details of your nominated person must contact your travel agent or applicable government (should an unlikely event arise) authorities to get the necessary documentation. -

Isolation and Characterization of Bacteriophages from Laban Jameed

Food and Nutrition Sciences , 2013, *, **-** doi:10.4236/fns.2013.***** Published Online *** 2013 (http://www.scirp.org/journal/fns) Isolation and Characterization of Bacteriophages from Laban Jameed Murad Mohammad Ishnaiwer and FawziAl-Razem * Biotechnology Research Center, Palestine Polytechnic University, P.O.BOX 198, Hebron, Palestine. *Email: [email protected] Received July 25, 2013. ABSTRACT Laban jameed is a dried salty dairy product obtained by fermentation of milk using a complex population of lactic acid bacteria. Jameed is considered a traditional food product in most eastern Mediterranean countries and is usually made from sheep or cow milk. The aim of this study was to assess phage contamination of jameed dairy product. Two phages were isolated; one from sheep milk jameed (PPUDV) and the other from cow milk jameed (PPURV). Each of the two bacteriophages was partially characterized. The PPUDV phage was identified as a single stranded DNA virus with an approximately 20 kb genome that was resistant to RNase, whereas PPURV phage possessed a double stranded RNA genome of approximately 20 kb and was resistant to DNase. The phage bacterial strain hosts were identified as Lactoba- cillus helveticus and Bacillus amyloliquefaciens for PPUDV and PPURV, respectively. One step growth curve using a double layer plaque assay test was carried out to monitor the phage life cycle after host infection. PPUDV showed a latent period of about 36 h, burst period of 70 h and a burst size of about 600 Plaque Forming Units (PFU) per infected cell. PPURV phage showed latent period of about 24 h, burst period of 47 h and a burst size of about 700 PFU per infected cell. -

Traditional Dairy Products in Algeria: Case of Klila Cheese Choubaila Leksir1, Sofiane Boudalia1,2* , Nizar Moujahed3 and Mabrouk Chemmam1,2

Leksir et al. Journal of Ethnic Foods (2019) 6:7 Journal of Ethnic Foods https://doi.org/10.1186/s42779-019-0008-4 REVIEW ARTICLE Open Access Traditional dairy products in Algeria: case of Klila cheese Choubaila Leksir1, Sofiane Boudalia1,2* , Nizar Moujahed3 and Mabrouk Chemmam1,2 Abstract The cheese Klila occupies a very important socio-economic place established in the rural and peri-urban environment. It is a fermented cheese produced empirically in several regions of Algeria. It is the most popular traditional cheese and its artisanal manufacturing process is still in use today. The processing consists of moderate heating of “Lben” (described a little farther) until it becomes curdled, and then drained in muslin. The cheese obtained is consumed as it stands, fresh, or after drying. When dried, it is used as an ingredient after its rehydration in traditional culinary preparations. In this review, we expose the main categories of traditional Algerian dairy products; we focus mainly on the traditional Klila cheese, its history, origin, and different manufacturing stages. We recall the different consumption modes and incorporation of Klila cheese in the culinary preparations. Keywords: Traditional cheese, Klila, Terroir Introduction Traditional dairy products in Algeria In Algeria, the consumption of dairy products is an old History and origin of cheeses tradition linked to livestock farming, since dairy prod- According to Fox and McSweeney [9], the word “cheese” ucts are made by means of ancient artisanal processes, comes from the Latin “formaticus” meaning “what is using milk or mixtures of milk from different species done in a form.” The discovery of cheese was probably [1–4]. -

Rapid Lifestyle, Diet and Health Changes Among Urban

K. ABU-SAAD, S.WEITZMAN, Y. ABU-RABIAH, H. ABU-SHAREB AND D. FRASER Rapid lifestyle, diet and health changes among urban Bedouin Arabs of southern Israel Kathleen Abu-Saad, MA, is Coordinator and Haijer Abu-Shareb ver the past half cen- cess to running water, mains electricity and tury, with the forma- telephone services and numerous small is Research Assistant for the tion of nation states neighbourhood grocery stores. There are Bedouin Dietary Study, and the encroachment few jobs, so most urban Bedouin work out- of modernization, as- side their places of residence (Lithwick, Simon Weitzman, MD, MPH pects of Bedouin life 2000). In 1998, the Negev Bedouin popu- and Drora Fraser, Ph.D. Othroughout the Middle East have been lation numbered 111 475, of whom 56 per- gradually changing. Traditionally, the cent lived in the government-planned are professors of epidemiology. Bedouin Arabs of the Negev desert in towns. The remaining 44 percent continued All are with the Epidemiology and southern Israel had a nomadic/semi- to live more traditionally in shantytowns nomadic lifestyle based upon herding and and extended family groups that were not Health Services Evaluation seasonal agriculture. After the establish- recognized by the governmental planning Department, Faculty of Health ment of Israel in 1948, their land base and authorities (Ben-Gurion University, 1999), mobility were greatly reduced. Most and thus not connected to central water, Sciences, Ben-Gurion Bedouin, however, maintained their tradi- electricity and telephone services University of the Negev, Israel. tional lifestyle until the mid-1960s when (Lithwick, 2000). they began to integrate with the modern Dr Weitzman Israeli labour market (Marx, 1967). -

The Food and Culture Around the World Handbook

The Food and Culture Around the World Handbook Helen C. Brittin Professor Emeritus Texas Tech University, Lubbock Prentice Hall Boston Columbus Indianapolis New York San Francisco Upper Saddle River Amsterdam Cape Town Dubai London Madrid Milan Munich Paris Montreal Toronto Delhi Mexico City Sao Paulo Sydney Hong Kong Seoul Singapore Taipei Tokyo Editor in Chief: Vernon Anthony Acquisitions Editor: William Lawrensen Editorial Assistant: Lara Dimmick Director of Marketing: David Gesell Senior Marketing Coordinator: Alicia Wozniak Campaign Marketing Manager: Leigh Ann Sims Curriculum Marketing Manager: Thomas Hayward Marketing Assistant: Les Roberts Senior Managing Editor: Alexandrina Benedicto Wolf Project Manager: Wanda Rockwell Senior Operations Supervisor: Pat Tonneman Creative Director: Jayne Conte Cover Art: iStockphoto Full-Service Project Management: Integra Software Services, Ltd. Composition: Integra Software Services, Ltd. Cover Printer/Binder: Courier Companies,Inc. Text Font: 9.5/11 Garamond Credits and acknowledgments borrowed from other sources and reproduced, with permission, in this textbook appear on appropriate page within text. Copyright © 2011 Pearson Education, Inc., publishing as Prentice Hall, Upper Saddle River, New Jersey, 07458. All rights reserved. Manufactured in the United States of America. This publication is protected by Copyright, and permission should be obtained from the publisher prior to any prohibited reproduction, storage in a retrieval system, or transmission in any form or by any means, electronic, mechanical, photocopying, recording, or likewise. To obtain permission(s) to use material from this work, please submit a written request to Pearson Education, Inc., Permissions Department, 1 Lake Street, Upper Saddle River, New Jersey, 07458. Many of the designations by manufacturers and seller to distinguish their products are claimed as trademarks. -

Impact of Innovative Formson the Chemical Composition and Rheological Properties of Jameed

Journal of Nutritional Health & Food Engineering Research Article Open Access Impact of innovative formson the chemical composition and rheological properties of jameed Abstract Volume 6 Issue 1 - 2017 Jameed is a fermented dried dairy product in the form of stone hard balls or other shapes. Mohamed Nour EdinHamad,1 Magdy The aim of this study was to introduce a new jameed forms. Nine treatments of jameed 2 2 were made from sheep buttermilk, goat and cow skim milk. Sheep buttermilk jameed took Mohamed Ismail, Reham Kamal El-Menawy 1Department of Dairying, Faculty of Agriculture, Damietta a spherical shape whereas goat or cow skim milk jameed was formed as a ball, triangle, University, Egypt square and cylinder. Utilization of square and cylinder molds in jameed manufacturing 2Dairy Technology Department, Animal Production Research lowered total solids, fat and protein values. Square and cylinder forms jameed possessed Institute, Agricultural Research Center, Egypt the lowest total viable bacterial count, lactic acid bacteria and proteolytic bacteria. Using of triangle or square molds increased jameed wettability levels. The spherical and cylindrical Correspondence: Magdy Mohamed Ismail, Dairy Technology shapes had the minimum values of hardness, cohesiveness, gumminess and chewiness Department, Animal Production Research Institute, Agricultural whereas the triangle and square forms possessed the maximum levels. The scanning Research Center, Dokki, Giza, Egypt, Tel +20507230566, electron microscopy showed that in triangle jameed some compact protein masses with Email [email protected] coarse structure contained little spaces were observed. In square and cylinder jameed, protein network possessed rigid plates structure, little aggregates and more gaps scattered Received: December 16, 2016 | Published: February 02, 2017 in matrix. -

FOOD PRODUCTION MANAGEMENT II OBJECTIVES at the End of This Lesson, Students Should Be Able to Demonstrate Appropriate Skills, A

FOOD PRODUCTION MANAGEMENT II OBJECTIVES At the end of this lesson, students should be able to demonstrate appropriate skills, and show an understanding of the following: Meat Cooker Mutton and Lamb Beef and Veal Parks, Bacon, Ham and Gammon Game Poultry and Chicken INTRODUCTION In basic food preparation, meat is generally considered to be the flesh of any animal and includes beef, veal, lamb, and pork along with poultry, fish, and shellfish. Poultry and fish, however, often differ from the red meats in preparation and tests for doneness (rare, medium and well done). The word meat comes from the Old English word mete, which referred to food in general. The narrower sense that refers to meat, which does not include sea food, developed over the past few hundred years and has religious influences. Meat, especially beef, is prepared in many ways, as steaks in stews, fondue, or as dried meat. It may be ground then formed into patties (as hamburgers or croquettes), loaves, or sausages, or used in loose form (as in "sloppy Joe" or Bolognese sauce). Some meat is cured by smoking, pickling, preserving in salt or brine (see salted meat and curing). Other kinds of meat are marinated and barbecued, or simply boiled, roasted, or fried. Meat is generally eaten cooked, but there are many traditional recipes that call for raw beef, veal or fish. Meat is often spiced or seasoned, as in most sausages. Meat dishes are usually described by their source (animal and part of carcass) and method of preparation. Meat is a typical base for making sandwiches. -

Name Tareq M

Curriculum Vita Tareq M. Osaili, PhD Nationality and date of birth: Jordanian, December 23, 1975. Marital status: Married. Address (work): Department of Clinical Nutrition and Dietetics College of Health Sciences University of Sharjah Sharjah, UAE P.O. Box: 27272, Sharjah, UAE Tele: +971-6-5057565 Mobile: +971-544498075 Email: [email protected] 1 1.0 Education • PhD, Food Science, University of Arkansas, Fayetteville, Arkansas, USA, Dec, 2004. • MSc, Nutrition and Food Science, University of Jordan, Amman, Jordan, Aug, 1999. • BSc, Nutrition and Food Technology, Jordan University of Science and Technology, Irbid, Jordan, Jun, 1997. 2.0 Experience 2.1 Administration • Vice Dean, College of Health Sciences, University of Sharjah, UAE, September 2018- Present • Vice Dean, Faculty of Agriculture, Jordan University of Science and Technology, September 1, 2016-January 31, 2017. • Head of the Nutrition and Food Technology Department, Jordan University of Science and Technology, September 1, 2007-August 31, 2011. In the department 14 faculty members, 360 undergraduate students and 40 graduate students. 2.2 Academic experience • Professor at Clinical Nutrition and Dietetics Department, College of Health Sciences, University of Sharjah, United Arab Emirates, January 2017-present. • Professor of Food Safety at Jordan University of Science and Technology, January 2016- January 2017. • Associate Professor of Food Safety at Jordan University of Science and Technology, September 2013-January 2016. • Associate Professor, University of Hail, Hail, Saudi Arabia, September 2011- August 2012 (Sabbatical leave). • Associate Professor of Food Safety at Jordan University of Science and Technology, January 2010-August 2011. • Assistant Professor of Food Safety at Jordan University of Science and Technology, January 2005- January 2010. -

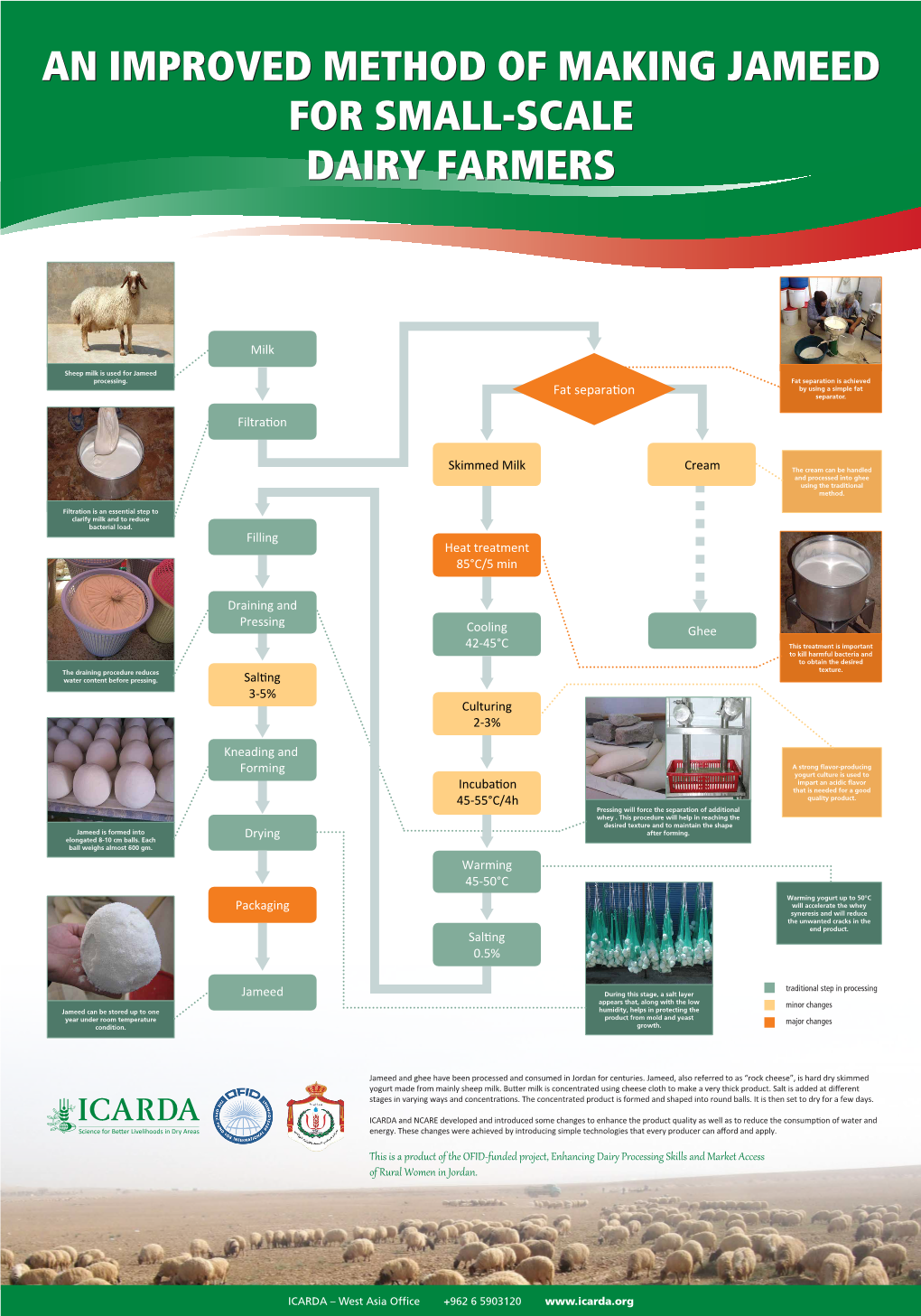

Enhancing Dairy Processing Skills

Working Paper 15 Enhancing the Dairy Processing Skills and Market Access of Rural Women in Jordan M. Al Hiary, Y. A. Yigezu, B. Rischkowsky, M. El-Dine Hilali, B. Shdeifat WHAT DONOR/PARTNERS LOGOS TO INCLUDE HERE? Acknowledgements Authors - M. Al Hiary, Y. A. Yigezu, B. Rischkowsky, M. El-Dine Hilali, B. Shdeifat We thank the technical team, comprising Eng. Raeda Maiteh, Eng. Majdoleen Shawawreh, Eng. Maisa Hadadin, and Dr. Bassam Shdifat, the coordinator of the project, for providing their valuable inputs and guidance for this analysis. Special thanks also go to all other team members whose names are not mentioned here, but who have contributed to this work. The contributions of the farmers are especially acknowledged; they are important partners who provided the vital information necessary for this study. We also thank the OPEC Fund for International Development (OFID) for funding this project. ICARDA Working Papers document the progress of the ICARDA research program and its support to country partners in more than 40 drylands countries. Working Papers are one of ICARDA’s global public goods; they capture and share knowledge and learning from projects and research partnerships. Each paper is internally reviewed as part of the center’s publishing process. ISBN: 92_9127_452_6 Key words: socioeconomic, dairy processing, marketing conditions, women, small ruminants, value addition International Center for Agricultural Research in the Dry Areas (ICARDA) PO Box 114/5055, Beirut, Lebanon Feedback ICARDA welcomes comment and feedback on this publication [email protected] www.icarda.org The views expressed are those of the authors, and not necessarily those of ICARDA. -

Dcm Pages Online.Pdf

Digital Atlas of Traditional Foods Made from Cereals and Milk Groningen Archaeological Studies Volume 33 Editorial board Prof. dr. P. A. J. Attema Dr. C. Çakirlar Prof. dr. R. T. J. Cappers Prof. dr. P. D. Jordan Prof. dr. D. C. M. Raemaekers Prof. dr. S. Voutsaki Groningen Institute of Archaeology Poststraat 6 9712 ER Groningen the Netherlands [email protected] Website www.plantatlas.eu Publisher’s address Barkhuis Kooiweg 38 9761 GL Eelde the Netherlands [email protected] www.barkhuis.nl Digital Atlas of Traditional Food Made from Cereals and Milk R. T. J. Cappers Barkhuis & University of Groningen Library Groningen 2018 Photos: René T. J. Cappers (RC), Dirk Fennema (DF), Hussein Madina (HM), Reinder Neef (RN) and Yasar Okur (YO). Book cover design: Ebel Kuipers Book interior design and typesetting: Ebel Kuipers Copy editor: Suzanne Needs-Howarth Printed by: KOPA, Kaunas, Lithuania Cover illustration: René T. J. Cappers ISBN 978-94-92444-70-7 Copyright © 2018 Groningen Institute of Archaeology (University of Groningen) and the Deutsches Archäologisches Institut (Berlin). All rights reserved. No part of this publication or the information herein may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic, mechanical, photocopying, recording or otherwise, without prior permission from the Groningen Institute of Archaeology (University of Groningen) or the Deutsches Archäologisches Institut (Berlin). Although all care is taken to ensure the integrity and quality of this publication and the information herein, no responsibility is assumed by the publishers nor the authors for any damage to property or persons as a result of operation or use of this publication and/or the information herein.