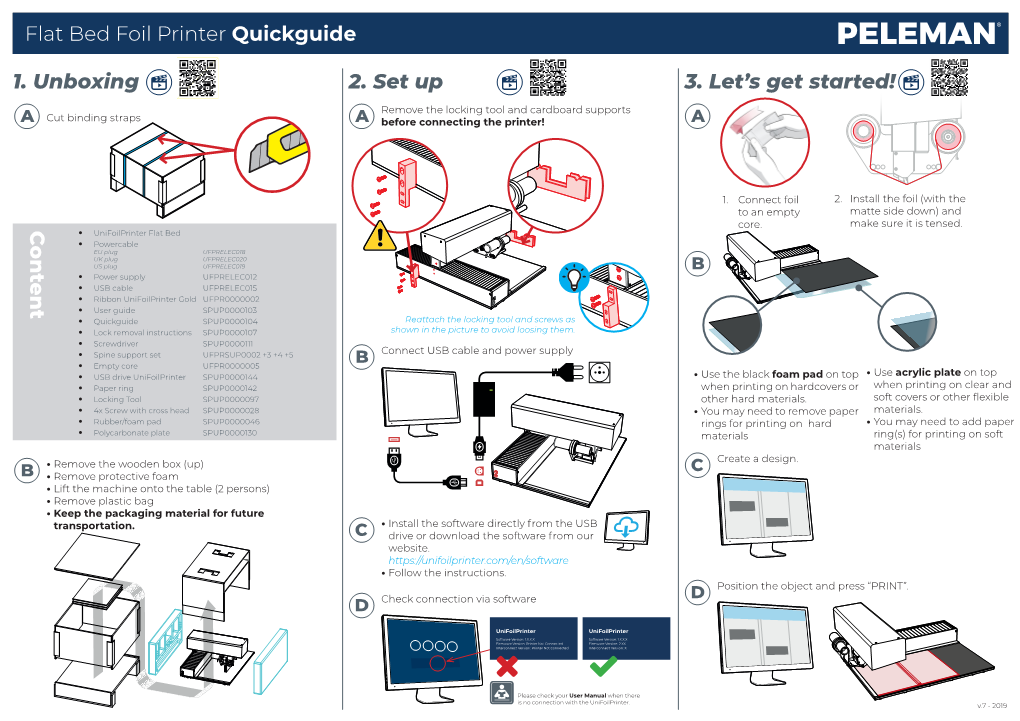

1. Unboxing 2. Set up 3. Let's Get Started! C Ontent C Ontent Flat Bed Foil Printer Quickguide

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Guidelines for Editorial Submissions

GUIDELINES FOR EDITORIAL SUBMISSIONS Thank you for your interest in contributing to Packaging Digest. We actively seek expert analysis and opinions to help engage our audience of packaging professionals. We accept topic ideas and story leads, as well as fully written contributed articles* that are relevant for our audience, compelling and, whenever possible, exclusive to Packaging Digest, the Voice of the Packaging Community since 1963. Now 100% digital, we post articles to our website and share them with our audience via enewsletters. Packaging Digest offers “peer-to-peer” insights that share experiences, advice and successes that enable “cross fertilization” of ideas and technologies across all markets. [*All contributors must sign our standard freelancer/contributor agreement, whether the work is free or paid. Contact any of the editors to get a copy of the form.] Speak to our readers: From packaging engineers and executives to designers and developers, our global audience is responsible for various packaging roles at end-user companies. Our readers are involved in all the functions involved in packaging a product for sale, including management, plant operations, material research and development, purchasing and shipping. They develop packages, as well as design and run the packaging production lines that create finished product(s). Our readers work in various markets in consumer packaged goods and healthcare, including foods, beverages, personal care products, pharmaceuticals, medical items, electronics and toys. What to submit: Professionals in our packaging community are interested in many topics that can be classified… 1. By market: Food, beverage, personal care, pharmaceutical, medical, electronics and more. 2. By topic/issue: Sustainability; ecommerce; food safety; recruitment, education and training; Industry 4.0; automation; optimization and more. -

Future of Packaging

INDEPENDENT PUBLICATION BY RACONTEUR.NET #0533 18 / 07 / 2018 FUTURE OF PACKAGING WHAT NEXT AFTER TIME IS NOW FOR BACK TO THE FUTURE 03 BLUE PLANET? 06 CREATIVE DESIGN 22 FOR PAST WRAP RACONTEUR.NET 03 SUSTAINABILTY FUTURE OF Less is More PACKAGING This is our answer to the important question of how to ship the growing number of parcels sustainably. We do What next after this by using air in an innovative way. Air makes up more than 99% of our protective packaging; less than 1% is fully recyclable material. FP International is an expert in air cushions, which solve your packaging challenges by Distributed in increasing packaging speed and reducing packaging material, transport costs, storage space and return rates. Blue Planet? Published in association with As oceans drown in plastic and the developed world launches a clean-up campaign, the tide of pollution is still rising Event partners More E-commerce With the growth of online shopping, it is time for innovative JIM McCLELLAND carbon footprint of heavy, spatial- ly-ineffi cient packaging.” ways to reduce packaging and minimize the impact on the cean plastic is not a new For Garçon Wines, the fl at, plastic environment. problem, however it took design actually addresses sustaina- David Attenborough and bility in the round, being 87 per cent Josh Spires/Unsplash Josh Blue Planet II to turn the lighter and spatially 40 per cent smaller Otide of public opinion. than its traditional glass equivalent. CONTRIBUTORS Prime-time endorsement of the At the other end of the scale, global core sustainability message was a brands and high street retailers are Less Energy DAVID BENADY MAGDA IBRAHIM global game-changer, says Oliver also reaching out for help, often to one Specialist writer on Award-winning consumer Staple, director at EY. -

Industrial Printer User Guide

INDUSTRIAL PRINTER USER GUIDE INDUSTRIAL PRINTER USER GUIDE 1 Markforged 480 Pleasant St Watertown MA 02472 USA https://support.markforged.com [email protected] For the latest PDF version of this document, visit our support website. Copyright © 2019 Markforged, Inc. All rights reserved. Changes are periodically made to the information herein which will be incorporated in revised editions of this publication. Markforged may make changes or improvements to the product(s) described in this publication at any time and without notice. Version 1.4.1 / April 2020 INDUSTRIAL PRINTER USER GUIDE TABLE OF CONTENTS FCC COMPLIANCE 4 UPDATING FIRMWARE 75 USER NOTES 5 ADJUSTING BELT TENSION 77 UNBOXING AND ASSEMBLY 6 REPLACING THE FIBER NOZZLE 79 QUICK START GUIDE 8 REPLACING THE PLASTIC NOZZLE 83 MANAGING EIGER ORGANIZATIONS 16 BED LEVEL TEST PRINT 88 CONNECTING YOUR PRINTER 18 ADJUSTING LASER OFFSETS 91 NETWORK REQUIREMENTS 23 ADJUSTING THE XY-OFFSET 96 IMPORTANT PLASTIC INFORMATION 25 CALIBRATING STEPPER ENCODERS LOADING PLASTIC 26 101 SET UP PLASTIC FOR LOADING ONYX PILLARS TEST PRINT 104 METER LOAD PLASTIC DIAGNOSE PRINTING PROBLEMS QUICK LOAD PLASTIC WET PLASTIC PURGE 109 LOADING FIBER 36 DIAGNOSE WET NYLON SET UP FIBER FOR LOADING METER LOAD FIBER AUTO-PAUSE FEATURE 112 QUICK LOAD FIBER MATERIAL STORAGE 116 LEVELING THE PRINT BED 45 FIBER JAM DETECTION 117 RUN LASER BED LEVEL UTILITY RUN SHIM BED LEVEL UTILITY OFFLINE PRINTING 122 ADJUST FIBER NOZZLE HEIGHT CLEARING THE BOWDEN TUBES 124 ADJUST Z-OFFSET REPLACING THE BOWDEN TUBES 127 62 PREPARING THE PRINT BED REPLACE PLASTIC BOWDEN TUBE PRINTING A PART 63 REPLACE THE FIBER BOWDEN TUBE SAFELY REMOVING PRINTED PARTS 67 DEBUG MODE 141 REMOVING SUPPORT MATERIAL 68 UNDEREXTRUSION 142 UNLOADING PLASTIC 69 TROUBLESHOOTING PREVENTIVE MAINTENANCE SCHEDULE 148 UNLOADING FIBER 73 3 INDUSTRIAL PRINTER USER GUIDE FCC COMPLIANCE Note: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of the FCC Rules. -

Apass Services

APASS SERVICES . AMAZON PACKAGING SUPPORT AND SUPPLIER NETWORK PARTNER . ABLE TO CERTIFY PRODUCTS IN ALL 3 TIERS - APASS EDUCATED STAFF FROM COURSES AT FFP, SIOC, AND PFP THE AMAZON PACKAGING LAB POTENTIAL TO REDUCE CHARGEBACKS, KNOWLEDGEABLE ON FORM-FACTOR PACKAGING COSTS & TRANSPORT COSTS CERTIFICATION RULES EXPERTLY CREATED PACKAGING SOLUTIONS A DESIGNATED APASS TEAM WITH CROSS- THAT MAXIMIZE THE UNBOXING EXPERIENCE FUNCTIONAL EXPERTISE Selling Through Amazon? Contact Us TOday! PACKAGING DESIGN PACKAGING SUPPLY PACKAGING TESTING • PROTOTYPING CREATION • CANADA & U.S DISTRIBUTION • WIDE VARIETY OF MATERIALS • SAMPLES CREATED WITH • JUST-IN-TIME INVENTORY AVAILABLE FOR TESTING TIER CERTIFICATION IN MIND REPLENISHMENT • ISTA-6 AMAZON TESTS • PACKAGING SOLUTIONS START HERE® • CONTACT OUR IN-HOUSE EXPERTS CROWNHILLPACKAGING.COM TO DEVELOP A CUSTOM, COST-EFFECTIVE [email protected] PACKAGING SOLUTION FOR YOUR PRODUCTS. TOLL-FREE (CAN): 888-571-1101 packaging solutions START HERE® Corrugated ProductS bubble cushion products SINGLE, DOUBLE & TRIPLE WALL CONTAINERS ROLLS, SHEETS & POUCHES PARTITIONS & PADS ADHESIVE, COHESIVE & ANTI-STATIC LAMINATED PRODUCTS SPECIALTY LAMINATION OPTIONS ASSEMBLED PACKS HONEYCOMB DIE CUTTING pallet stretch wrap HAND & MACHINE OPTIONS ASSEMBLED PACKS WIDE ASSORTMENT OF WIDTHS, GAUGES & COLOURS CUSTOM DESIGN STOCK PRODUCTS shipping supplies STEEL, POLYESTER & POLYPROPYLENE STRAPPING MOLDED PULP ANGLEBOARD TAPES & ADHESIVES CUSTOM DESIGN MAILER ENVELOPES STOCK PRODUCTS MAILING TUBES VOID FILL FOAM PRODUCTS moisture & corrosion protection ROLLS, SHEETS & POUCHES ADHESIVE, COHESIVE & ANTI-STATIC VCI PAPERS & FILMS SPECIALTY LAMINATION OPTIONS DESICCANTS & SILICA GELS EXTRUDED PROFILES polyplank foam CORRUGATED PLASTIC CUSTOM FABRICATION CUSTOM SIZES, SHAPES & DENSITIES PARTITIONS & SHEETS DIE CUTTING & ANTI-STATIC OPTIONS TOTES & BINS SPECIALTY LAMINATION OPTIONS foam-in-place first aid ST. JOHN AMBULANCE FIRST AID KITS IN-HOUSE MOLDING CAPABILITIES ST. -

A Flexible Packaging Path to a Circular Economy

A Flexible Packaging Path to a Circular Economy Flexible Packaging Sustainability Roadmap By PTIS, LLC & Priority Metrics Group, LLC Prepared for The Flexible Packaging Association 185 Admiral Cochrane Drive, Suite 105, Annapolis MD 21401 December 2020 1 © 2020 Flexible Packaging Association 2 About the Flexible Packaging Association The Flexible Packaging Association is the voice of the U.S. manufacturers of flexible packaging and their suppliers. The association’s mission is connecting, advancing, and leading the flexible packaging industry. Flexible packaging represents over $33 billion in annual sales in the U.S. and is the second largest and one of the fastest growing segments of the packaging industry. Flexible packaging is produced from paper, plastic, film, aluminum foil, or any combination of those materials, and includes bags, pouches, labels, liners, wraps, rollstock, and other flexible products. About PTIS PTIS, LLC is a leading business and technology management company focused on Creating Value Through Packaging© and helping clients throughout the packaging value chain develop long term packaging strategies and programs. PTIS, recognized for foresight, thought leadership, and the success of their 20 year Future of Packaging program, helps companies achieve and incorporate these elements into their innovation programs, e-commerce, holistic productivity, sustainability, holistic design, and consumer/retail insights related to packaging. To learn more about PTIS, visit their website www.ptisglobal.com About PMG PMG provides B2B market research, analysis, and consultation services designed to generate profitable growth for our clients. Our firm works with leading organizations in a variety of manufacturing and service industries. We are experts at gathering and processing market information, analyzing data, and translating information into actionable growth initiatives. -

The Unboxing Phenomenon Is Booming —But Will It Stick? Elaborate Mailed Kits Are Making Connections and Bringing Brands to Life

SPECIAL REPORT THE UNBOXING PHENOMENON IS BOOMING —BUT WILL IT STICK? ELABORATE MAILED KITS ARE MAKING CONNECTIONS AND BRINGING BRANDS TO LIFE Premiums and promotional items can be anything from an Savvy marketers are now getting in on the action and developing afterthought to a highly coveted item that anchors conversations at a elaborate mailers to more closely link up with these creators. launch, conference or trade show. But this year, as live events pivoted to Take Rimmel London. To promote its Lasting Matte product line, the in-home experiences, they’ve become just about the only touchpoints beauty brand developed an influencer kit where the package itself created for marketers looking to strengthen connections. the reveal. Opening like a set of swinging gates, the box slowly exposes Outfitted with everything from custom merchandise to digitally three trays at staggered heights that, when fully extended, artfully display enhanced happy hour packs, these elaborately produced kits are meant the products inside. to surprise recipients, engage their senses and lead them through a That element of theater is just one reason why unboxing engagements memorable brand experience. work. The ritual of opening these kits makes the occasion and the product But are these unboxing kits just a stop-gap solution, or are they feel special and creates that coveted “surprise and delight” response destined for a more permanent spot in the marketing toolkit? Let’s take that helps cement brand loyalty. a look. It’s no wonder that interest in such engagements spiked this past year as brands worked to stay connected with remote workers and former UNBOXING: TEMPORARY TREND OR HERE TO STAY? live audiences. -

A Chain of Changes: Crucial Information for Packagers | Packaging World

A Chain of Changes: Crucial Information for Packagers | Packaging World HOME | DESIGN | PROTECTIVE/TRANSPORT PACKAGING A Chain of Changes In this column, we will check in with several topics, and as it happens, the topics fow from one to the next like a chain of crucial information for packagers. Author — Eric Greenberg Mar 31s, 2021 1. An organization called the Toxics in Packaging Clearinghouse has been known since the 1990s as the source of an infuential Eric Greenberg, Attorney-at-Law, Packaging World Contributing Editor model sate law that put limits on four heavy metals in packaging (lead, cadmium, mercury, and hexavalent chromium). Though only adopted in 19 U.S. sates, the model law’s prohibition on intentional addition, and a total limit of 100 ppm of the four heavy metals, have become a worldwide fxture in product sewardship and guarantee documentation for packaging. Now the TPCH has updated its model legislation, mos notably by adding “the class of perfuoroalkyl and polyfuoroalkyl subsances (PFAS) and ortho-phthalates as regulated chemicals.” (For more on the changes, go to pwgo.to/6052 and pwgo.to/6053). Under the newly changed law, a package or packaging component would be prohibited if “PFAS has been intentionally introduced during manufacturing or disribution in any amount,” and “There shall be no detectable PFAS in any package or packaging component.” How exactly that sandard can be met is unclear (see below re baby food). https://www.packworld.com/design/protective-transport-packaging/article/21343056/a-chain-of-changes-crucial-information-for-packagers[4/1/2021 8:46:23 AM] A Chain of Changes: Crucial Information for Packagers | Packaging World The new model law also would prohibit sale or disribution of a package or of packaging components containing intentionally added phthalates, and the incidental levels of them couldn’t exceed 100 ppm by weight. -

The Effect of the Unboxing Experience on Positive Affect and Willingness to Share

Thinking inside the box: the effect of the unboxing experience on positive affect and willingness to share. Master’s thesis by Ceciel Berden Thinking inside the box: the effect of the unboxing experience on positive affect and willingness to share. Master thesis Ceciel Berden S2186373 April 22, 2020 University of Twente Faculty of Behavioural, Management and Social Sciences Master Communication Science Marketing, Communication and Design First supervisor: dr. T. J. L. van Rompay Second supervisor: R. S. Jacobs PhD Acknowledgements Before continuing with reading this Master’s thesis, I would like to take a moment to thank the people who helped me. First of all, I would like to thank my supervisors Thomas van Rompay and Ruud Jacobs for their guidance and critical feedback. Both helped me with their own expertise to make the best of my thesis. Furthermore, I would like to thank Jeroen Mulder. His knowledge of statistics was clarifying and I could come by with any question I had. Besides the aforementioned, I want to thank my friends Chris Boshuizen and Lina Heming for their emotional support and the many laughs during our time studying together. I am happy that we got to know each other during our pre-master and that we became friends for life. Lastly, my thanks go out to my parents for making this all possible and always believing in me. 3 Abstract Purpose – More beauty brands create unboxing experiences for their consumers. It would, for example, be able to elicit emotions of surprise and contribute to consumers’ willingness to share. However, scientific research on the emerging phenomenon of unboxing experiences is still lacking. -

August 8-12, 2021 Held in Conjunction with TAPPI/AICC Supercorrexpo® Orange County Convention Center, Orlando, FL

August 8-12, 2021 Held in conjunction with TAPPI/AICC SuperCorrExpo® Orange County Convention Center, Orlando, FL OPEN TO ALL FOLDING CARTON, RIGID BOX AND CORRUGATED CATEGORIES INCLUDE: MANUFACTURERS WORLDWIDE STRUCTURE PRINTING DEADLINE FOR ENTRY: COMBINED TECHNIQUES JUNE 11, 2021 DIGITAL E-COMMERCE STUDENT For complete details, please visit: SUPERCORREXPO.ORG BOX MANUFACTURING OLYMPICS ABOUT THE COMPETITION S For the first time in history, TAPPI’s CorrPak Competition and AICC’s Design Competition have joined Structure forces to become the 2021 Box Manufacturing Olympics (BMO). Debuting at SuperCorrExpo® 2021 at the Orange County Convention Center in Orlando, Florida, BMO is open to all TAPPI and AICC members from around the globe who produce corrugated, rigid box and folding cartons, as well as their suppliers. Packaging P schools and universities are also invited to participate in the competition and have their own categories Printing/Graphics and requirements. Judges will evaluate entries on a number of levels, including design, quality, graphic excellence, technical difficulty and innovative application, among others. Details on all 41 categories are ST included in this comprehensive brochure. All entries will be prominently displayed during SuperCorExpo and Student winners will be announced each day preceding the opening session, with the Best of the Industry winners being announced on the last day. Winners will be featured on the SuperCorrExpo, TAPPI and AICC websites, and will also be announced in various industry publications. Images shown are of past winners and should EX not be considered representative of the category that they are next to in this brochure. Experimental CORRUGATED CATEGORIES ▶ CATEGORY 1 Innovative Structural Design, Consumer & Industrial Focus Awards for the most innovative structural design in industrial or consumer product protection. -

Products Worth Protecting Deserve Pregis Complete Packaging Guide Contents Inflatable Packaging

Inside the Box Protection Mailing & Bagging Solutions Surface Protection Industry Solutions Products worth protecting deserve Pregis Complete Packaging Guide Contents Inflatable Packaging ..................................... 4 Paper Packaging ...........................................6 Foam-in-Place ................................................8 Flexible Packaging ......................................10 Shipping Mailers ..........................................14 Bubble ...........................................................15 Foam ..............................................................16 Fabricated Foam .........................................17 Temporary Protective Films ......................18 Specialty Products ......................................20 What Drives Us .............................................22 Contact us .....................................................24 Complete Portfolio of Solutions Inside the Box Protection Mailing & Bagging Solutions Surface Protection Industry Solutions In transit or on the production floor, we solve your toughest business challenges with our innovative packaging and protective solutions. We’ve got everything you need to create customers for life. Inflatable Packaging On Demand Systems Cushioning Wrappable HYBRID CUSHIONING QUILT High pressure cushioning for valuable or fragile products Low pressure solution provides light cushioning when wrapped or malleable void fill • Proprietary pattern of square pillows prevents “bottoming out” for ultimate • Low pressure cushioning -

Delivery & Takeout Solutions

Delivery & Takeout Solutions Unboxing a product should produce an unforgettable experience that customers will want to share on social media. Product pictured above: Expressions® Bases & Lids GROW with TO-GO! • Attract New Customers – More than 63% of families and 59% of Millennials agree delivery is more convenient and fits their lifestyle better than dining out. • Grow Incremental Sales – 60% of restaurant operators say that offering delivery has led to incremental sales. • Increase Customer Satisfaction – 46% of adults, including 61% of Millennials, say the availability of takeout or delivery options is important in choosing a restaurant. 1. Stephanie Resendes (2020). 50+ Restaurant Industry Statistics Restaurateurs Should Know in 2020. 2. Modern Restaurant Management (2019). 6 Food Delivery Packaging Trends PROTECTS PRESERVES Product above: Creative Carry-Outs Dinner Box Why should you look at tamper-evident solutions for Delivering a deconstructed sandwich in delivery? compartmented containers helps maintain • 28% of delivery drivers admit to taking food from an order4 food quality. • 21% of customers suspect a deliverer of taking food4 Put your customers' mind at ease by offering Make sure food stays in its lane: tamper-evident and tamper-resistant packaging. • Select containers that are leak resistant • 85% of customers would prefer their food was delivered in a tamper-evident, tamper-resistant container • Segregate components • Maintain food at the proper temperature U.S. Foods (2019). New Study Shows What before pickup Consumers -

Thinking Outside (And Inside!) the Box Board Converters Are ‘Wowing’ Their Customers with Flexo Printed Graphics on the Inside As Well As the Outside of the Packaging

INSIDE-OUTSIDE PRINT THINKING OUTSIDE (AND INSIDE!) THE BOX BOARD CONVERTERS ARE ‘WOWING’ THEIR CUSTOMERS WITH FLEXO PRINTED GRAPHICS ON THE INSIDE AS WELL AS THE OUTSIDE OF THE PACKAGING. BY JACKIE SCHULTZ he ability to flexo direct print on both sides of a corrugated sheet in one pass is T generating a new level of excitement well beyond the brown shipping container. “It’s cool and it’s sexy and it’s fun,” Rob Golove, General Manager and VP of Sales of Arma Container, says. “We live in a brown world. I always say, ‘Knowing someone in the corrugated business isn’t so great until you need to move.’ When you’re able to show somebody something that has a strong marketing application then you’ve got something.” Retailers, especially companies that sell products on-line, are looking for ways to differentiate and “wow” their customers. The box is no longer “just a box.” Consumers want an “unboxing” experience. “It’s certainly the way of the future,” Arma Container’s Arma Container has been producing inside/outside printed Rob Golove says. boxes since 2016 with its G-Grafix flexo folder-gluer. REPRINTED FROM JANUARY/FEBRUARY 2020 ISSUE OF CORRUGATED TODAY INSIDE-OUTSIDE PRINT The Haire Group has installed Apstar flexo folder-gluers and rotary diecutters with inside print units at plants around the U.S. Arma Container, a sheet plant in Deer Park, N.Y., has been printing on both sides of a sheet in one pass for several years now at the request of a customer that sells products on-line.